Weaving machine, yarn feeder and method for inserting a weft yarn

a weft yarn and feeder technology, applied in the field of weaving machines, can solve the problems of insufficient work of the known yarn feeder, insufficient work of the passive balloon breaker, etc., and achieve the effects of low disturbance quota, high weaving speed, and considerable weaving width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

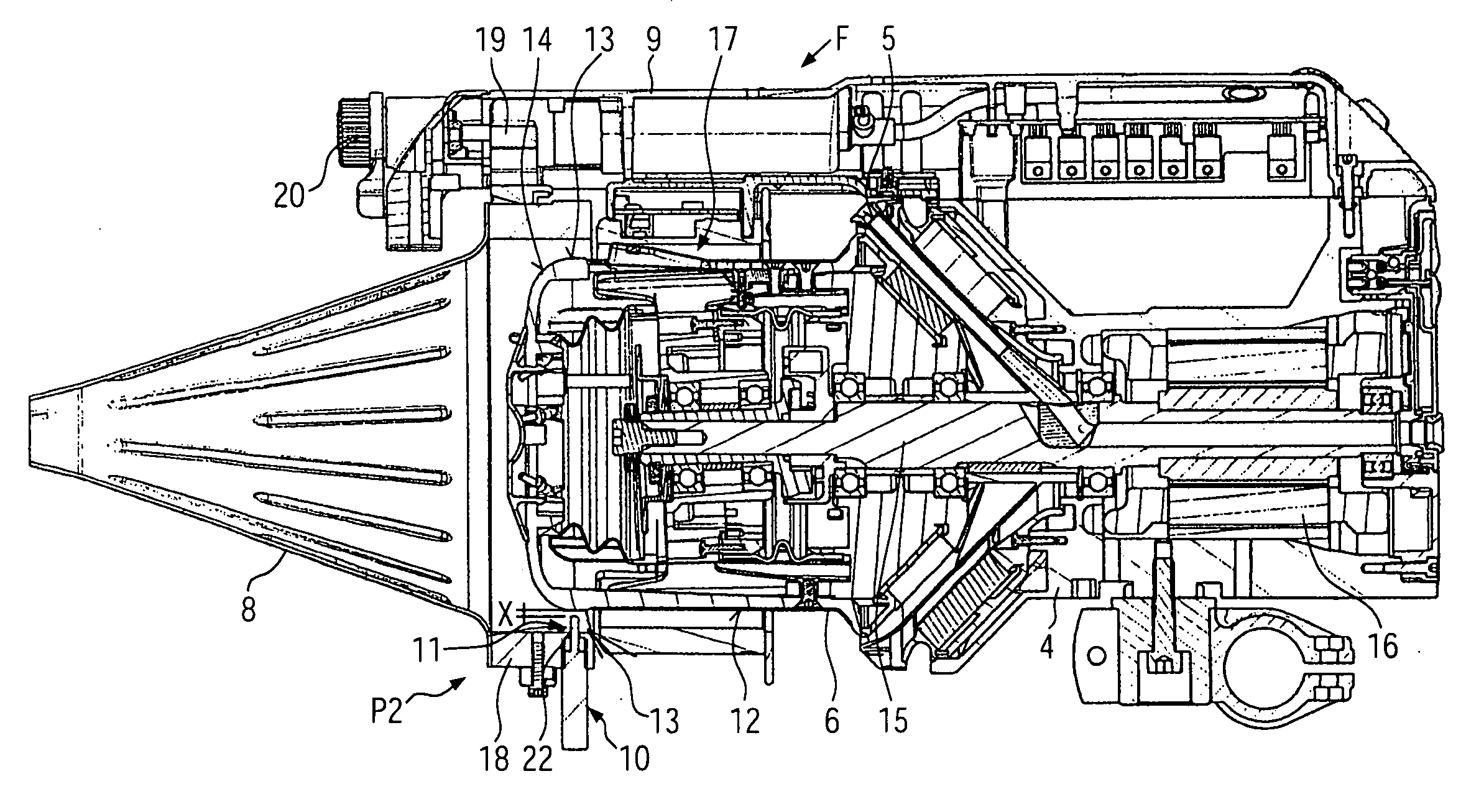

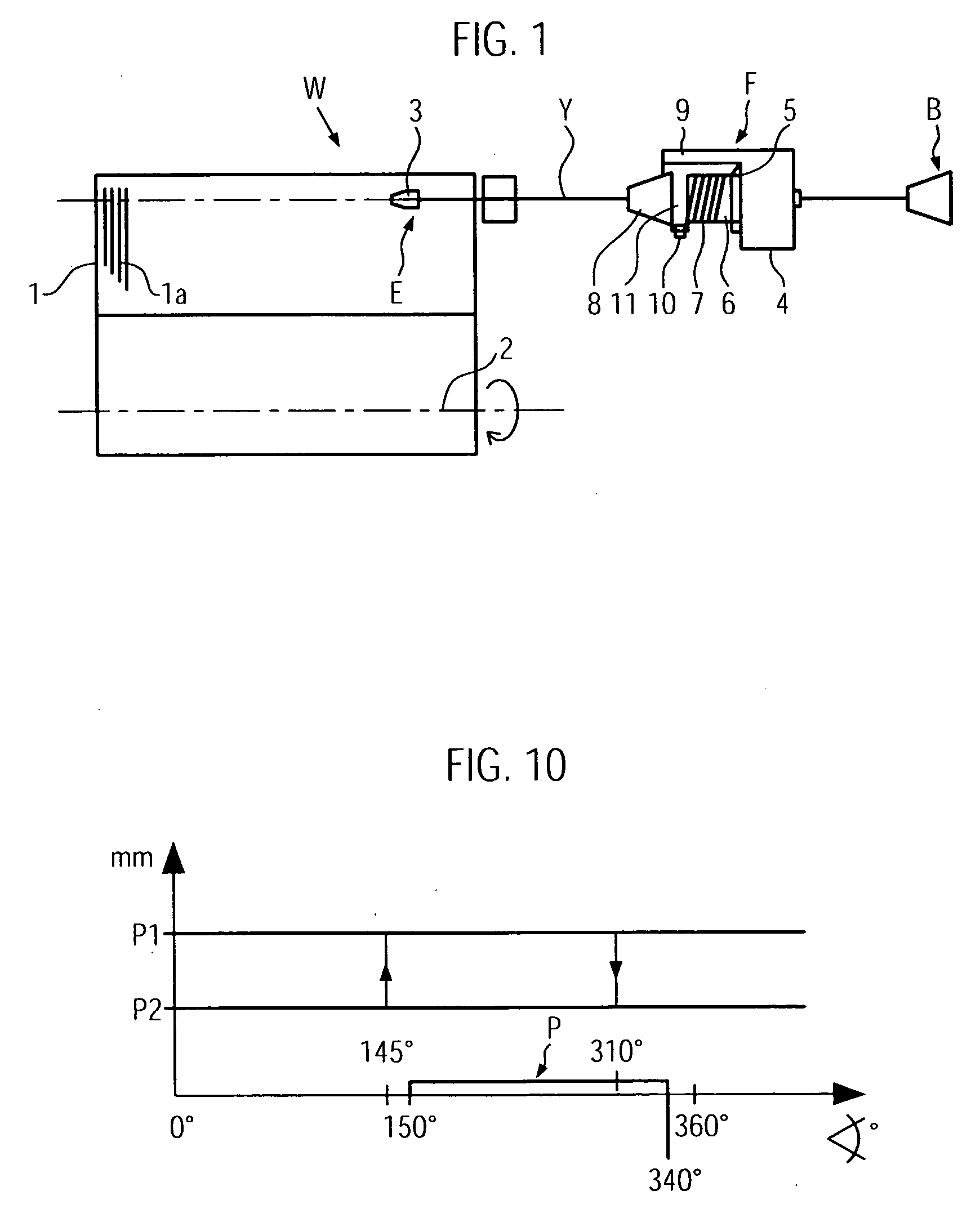

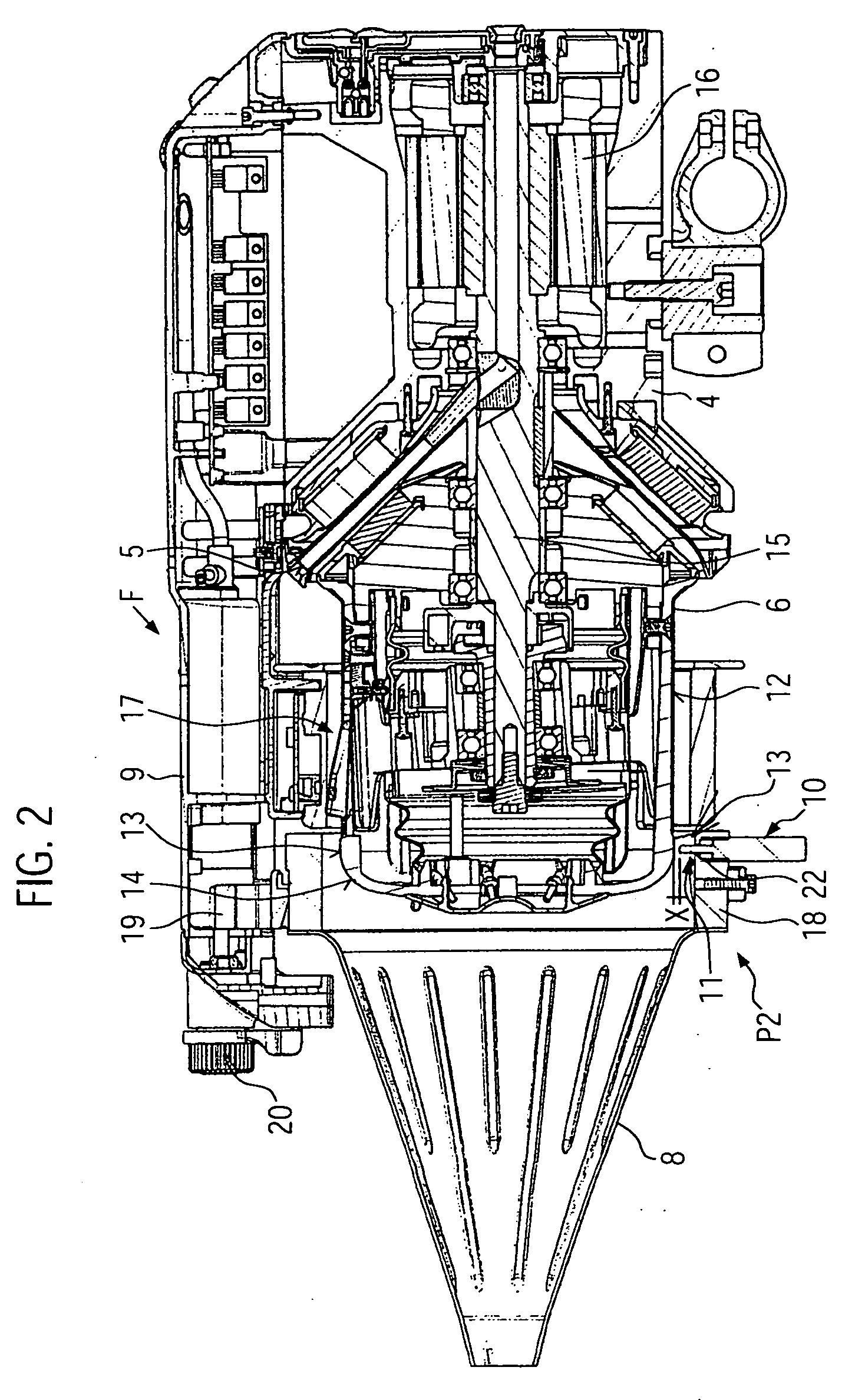

[0034]A weaving machine W, schematically shown in FIG. 1, comprises a weaving shed 1 having a reed la driven by a main shaft 2 of the weaving machine. One of a plurality of projectiles 3 serves as an insertion element E for inserting a weft yarn Y into the weaving shed 1. The weft yarn Y is intermediately stored in a yarn store 7 on a stationary storage body 6 of a weft yarn feeder F which takes off the weft yarn Y from a storage bobbin B. The weft yarn feeder F has a housing 4 and a winding-on-element 5 which can be driven for rotation by a motor 16 in relation to the stationary storage body 6 which might have substantially the form of a drum. A housing bracket 9 supports a hollow passive balloon breaker 8 (e.g. a balloon breaker cone) aligned with the storage body 6 such that the withdrawn weft yarn Y has to pass through the passive balloon breaker 8. Furthermore, several yarn control elements 11 are provided which can be actively driven by either a common or by separate drives 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com