A modular skid-mounted system and method for treating oily sludge with low-temperature ion method

A skid-mounted, sludge-based technology, applied in chemical instruments and methods, sludge treatment, special treatment targets, etc., can solve the problems of inability to meet industrialized treatment requirements, single types of thermal chemical agents, different treatment temperatures, etc., and achieve high The effects of automatic treatment of oily sludge, low labor intensity, and low production and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

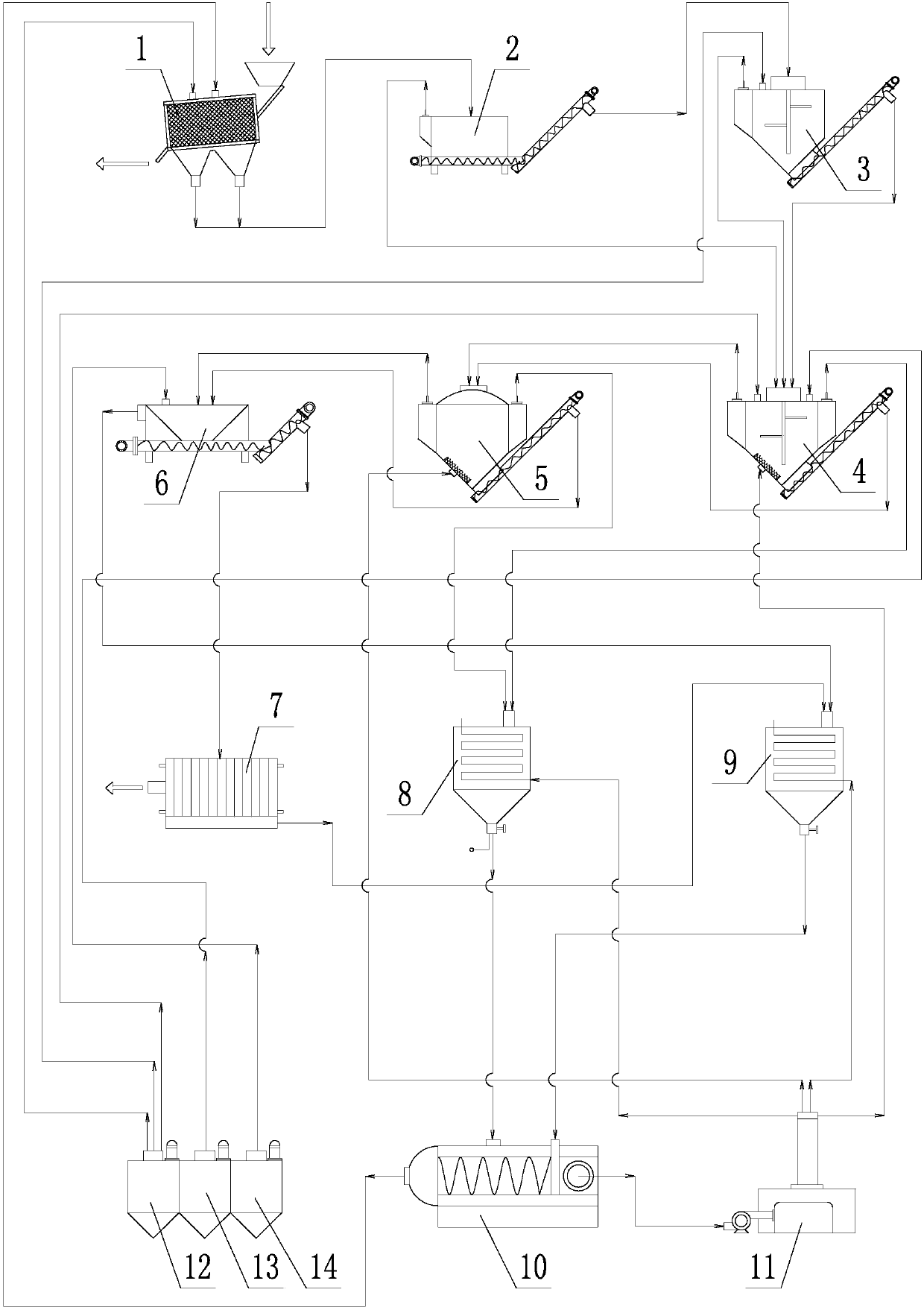

Image

Examples

Embodiment 1

[0101] Example 1: Treat oily sludge 10×10 per year 4 t for example.

[0102] In this embodiment, the grapple machine is equipped with a crawler-type long-arm grapple machine model KT320, and the hook of the grapple machine can be specially made according to the type of oily sludge. The length of the steel teeth on the hook can range from 50mm to 500mm, the number of steel teeth is between 2 and 10; in this embodiment, the length of the steel teeth of the grapple hook is 350mm, and the number of steel teeth is 5; for the remaining sludge at the bottom of the sludge storage pit Slurry, since it can no longer be transported by the grab machine, it needs to be pumped. Specifically, a submerged slurry pump can be used. In this embodiment, the power of the pump is 11kw, and the flow rate of the pump is 55m 3 / h, the head of the pump is 30m; with the cooperation of the grapple machine and the submerged slurry pump, the oily sludge transfer capacity can reach 45 tons / hour.

[0103] ...

Embodiment 2

[0118] Example 2: Treat oily sludge 2×10 per year 4 t for example.

[0119] In this embodiment, the grapple machine is equipped with a crawler-type long-arm grapple machine whose model is KT320. The length of the steel teeth of the grapple machine hook is 350 mm, and the number of steel teeth is 5; Sludge slurry is pumped by submerged slurry pump, the power of the pump is 3kw, and the flow rate of the pump is 3m 3 / h, the head of the pump is 30m; the hook machine cooperates with the submerged slurry pump, and the oily sludge transfer capacity is 5 tons / hour.

[0120] In this embodiment, the mesh diameter of the trommel 1 is 30 mm, and the processing capacity of the trommel 1 is 5 tons / hour.

[0121] In this embodiment, the oily sludge is not mixed with a large amount of inclusions such as plastic cloth, stones, ironware and wood, so the plastic cleaning and granulating machine is not used.

[0122] In this embodiment, the tank body diameter of the mud material storage tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com