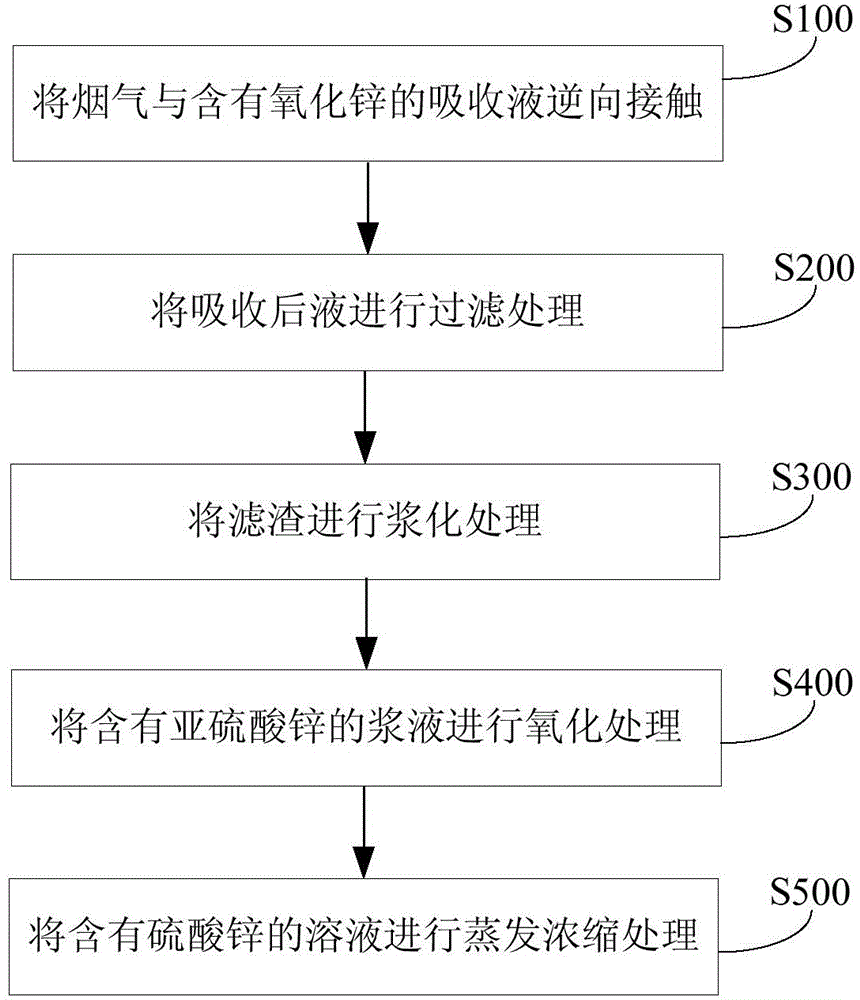

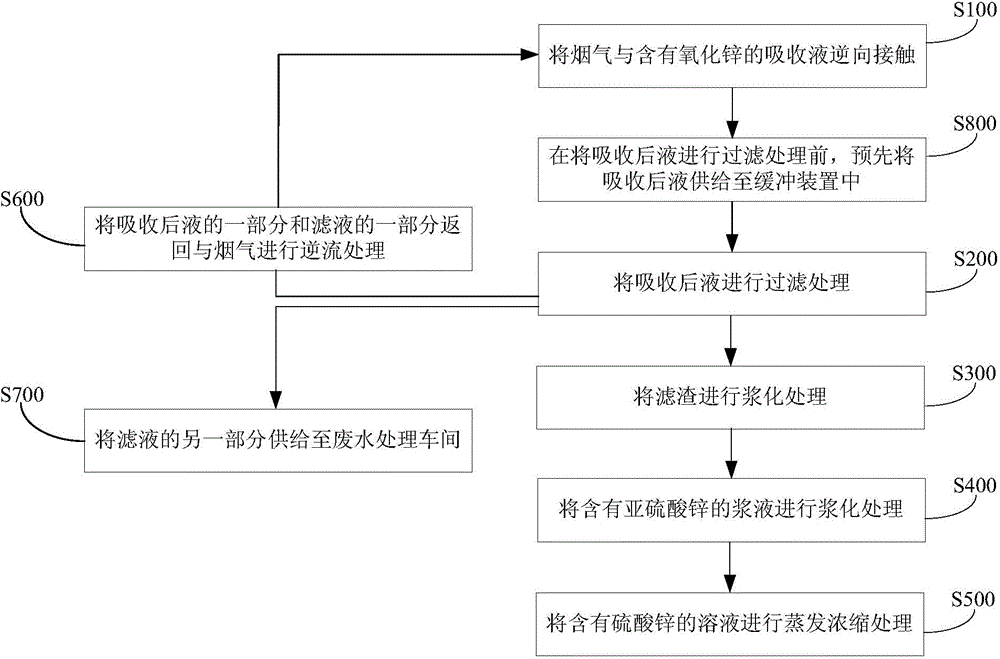

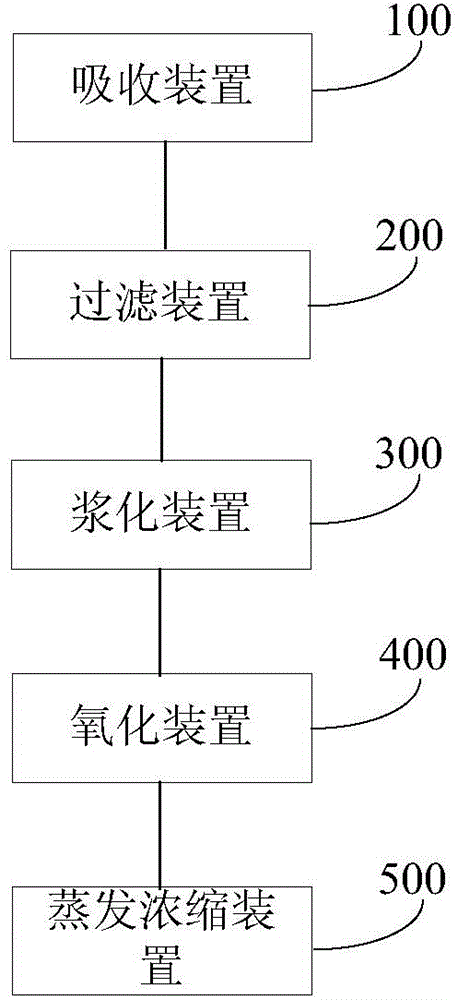

Flue gas treatment method and system

A flue gas and zinc sulfite technology, which is applied in the chemical industry, can solve the problems of inability to carry out normal absorption reaction, poor process economy, and high processing cost, and achieve the effect of realizing effective utilization, realizing resources, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The flue gas is the flue gas of the smelting furnace. The flue gas first enters the high-efficiency purification reaction tower. The flue gas is in reverse contact with the absorption liquid containing zinc oxide from the top of the reaction tower in the reverse nozzle from top to bottom. After exposure, SO in flue gas 2 , HCl, HBr react with the absorption solution containing zinc oxide to obtain purified flue gas and ZnSO 3 , ZnCl 2 and ZnBr 2 At the same time, the temperature of the purified flue gas is reduced to 65-85°C, and the purified flue gas is sent to the chimney for discharge through the exhaust fan. The absorbed liquid is stored in the liquid storage tank at the bottom of the tower, and most of it is sent to the reverse nozzle by circulating pumps. The circulating spray and the flue gas continue to be in reverse contact, and a small part is pumped to the buffer device, and the buffer device delivery pump sends the absorbed liquid to the vacuum belt filter...

Embodiment 2

[0102] The flue gas is the mixed flue gas from the fuming furnace and the reformer, and the SO in the mixed flue gas 2 The concentration is relatively high. First, the flue gas is passed into the first-level high-efficiency purification reaction tower. The flue gas is in countercurrent contact with the bottom-up absorption liquid containing zinc oxide from the top of the reaction tower in the reverse nozzle, and the gas-liquid is fully After contact, the absorbed liquid containing zinc sulfite, zinc chloride and zinc bromide and primary flue gas are obtained, while the temperature of the primary flue gas is reduced to 50-85°C, and then the obtained primary flue gas is passed into the secondary The first-stage high-efficiency purification reaction tower further absorbs SO in the first-stage flue gas 2 , and then remove the acid mist, gaseous arsenic and its compounds in the flue gas through the electric demister, and then obtain the absorbed liquid containing zinc sulfite, zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com