Patents

Literature

113results about How to "Achieve desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

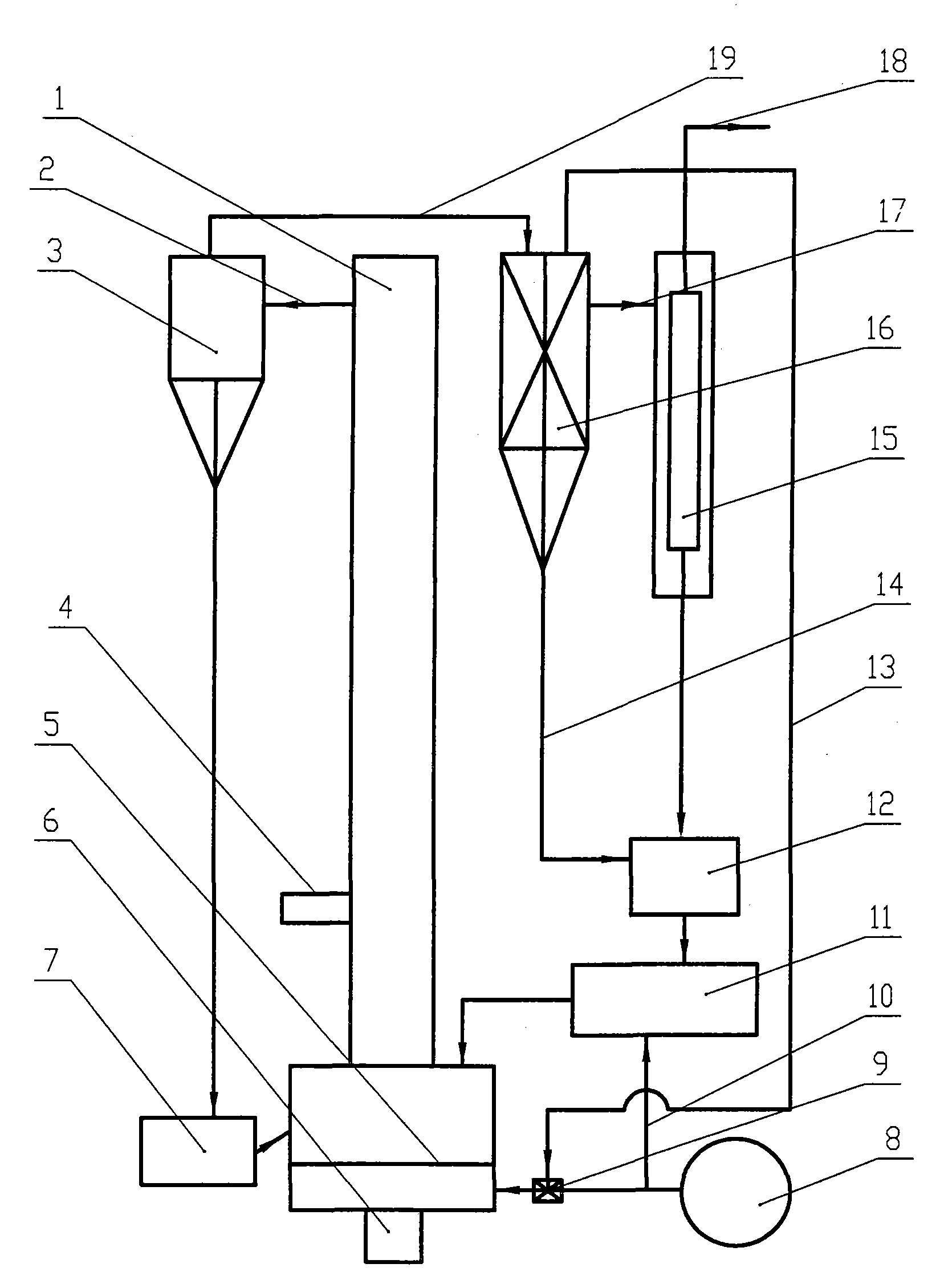

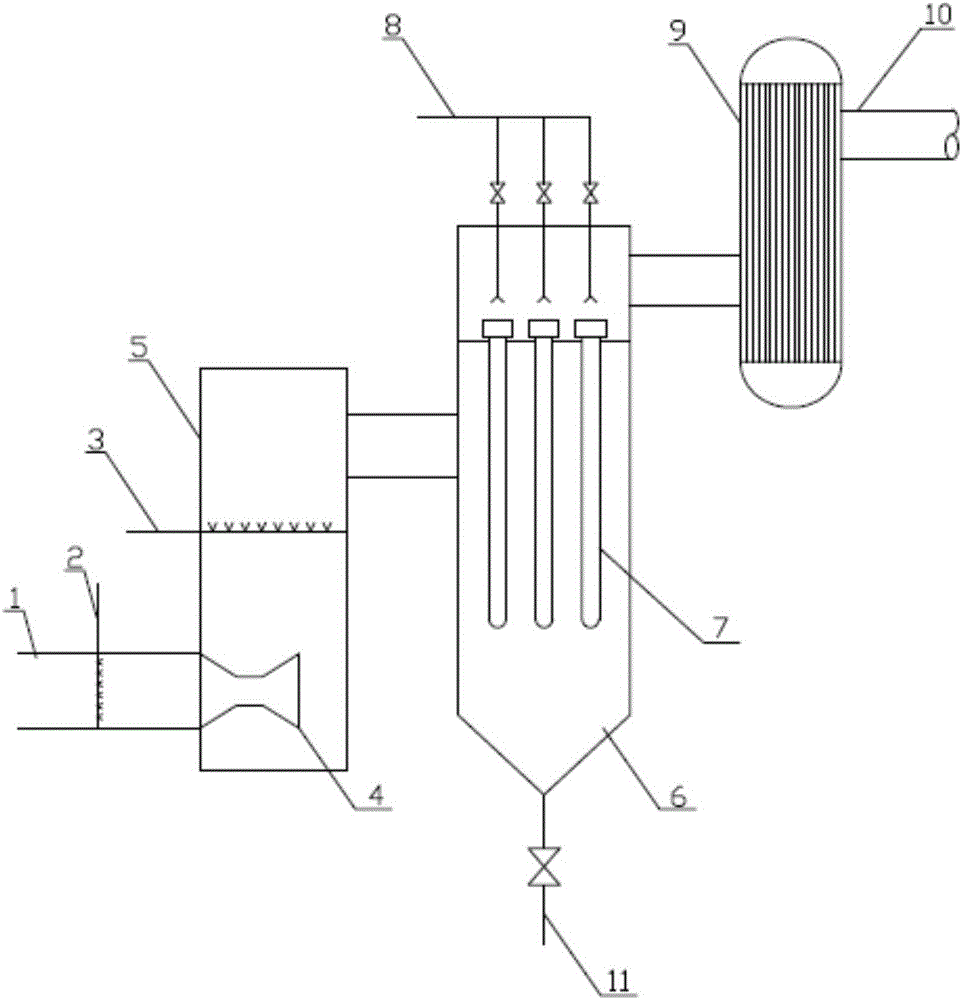

Method for producing coal gas by staged gasification of pulverized coal

InactiveCN102277200AAchieve desulfurizationAdaptableGranular/pulverulent flues gasificationCycloneSuperheated steam

The invention relates to a method for producing coal gas by staged gasification of pulverized coal. The steps are as follows: the pulverized coal fed into the furnace is mixed with rapidly fluidized high-temperature particles and gasification gas in a fluidized bed, and the pulverized coal of small and medium particles flows upwards. Pyrolysis at a high temperature of 900-1000°C, enter the cyclone separator through the gas-solid mixing pipeline for separation, the medium particles return to the lower part of the main body of the circulating fluidized bed through the first-stage feeder, and the gas carries small particles out of the upper port of the cyclone separator, and passes through the high temperature The gas pipeline enters the superheated steam heat exchanger for heat exchange and separation, and then enters the circulation separator, and the gas is discharged from the gas outlet for users. The invention has the characteristics of integrated circulating fluidized bed and entrained flow bed, high gasification intensity, flexible adjustment of production load, stable and reliable operation, high operation rate, reduced gas production cost, and no phenolic water pollution.

Owner:舒克孝

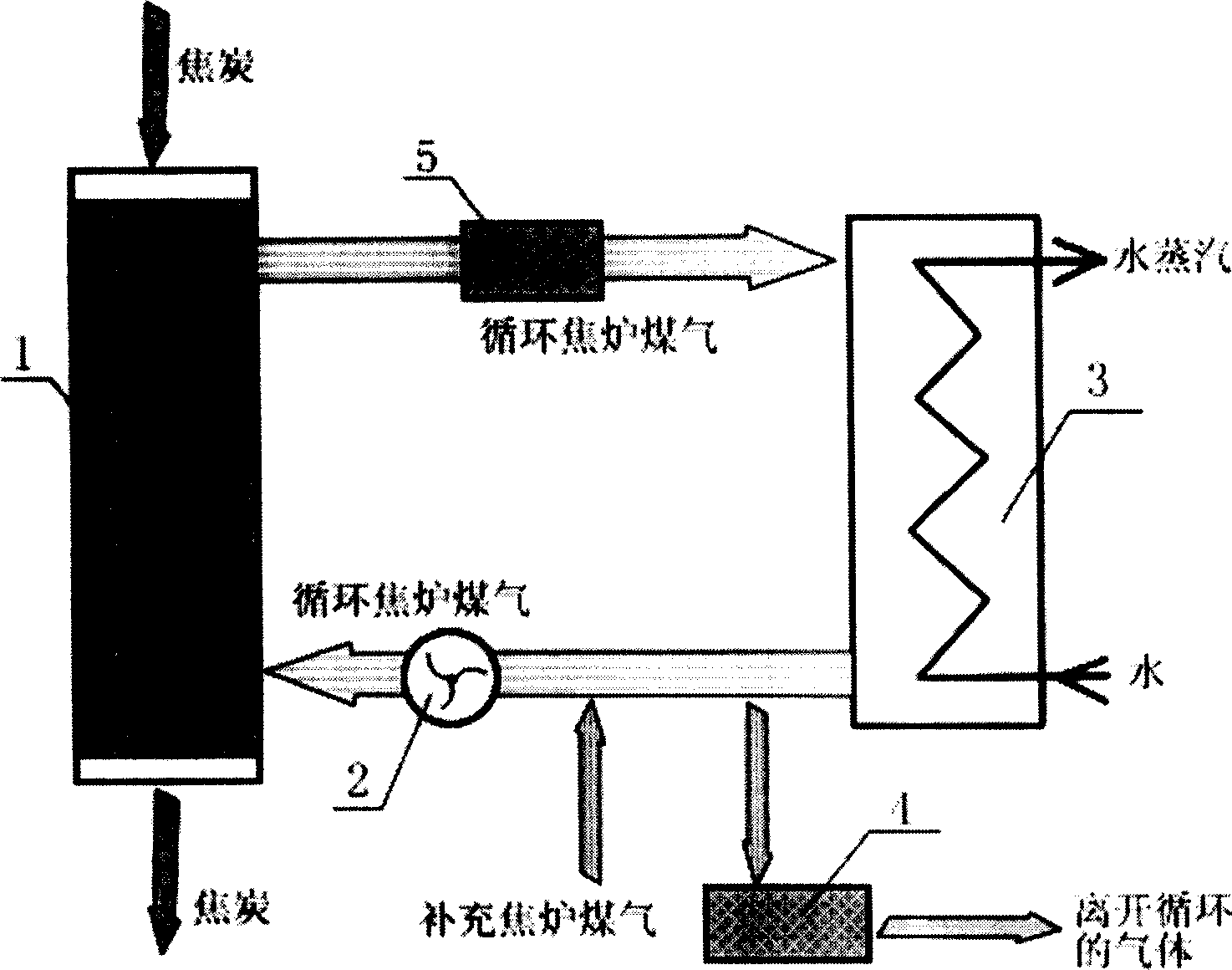

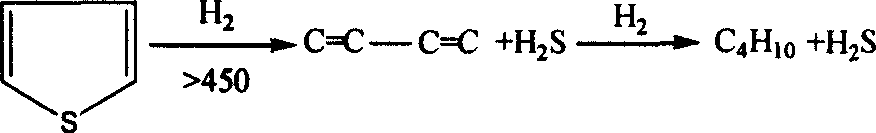

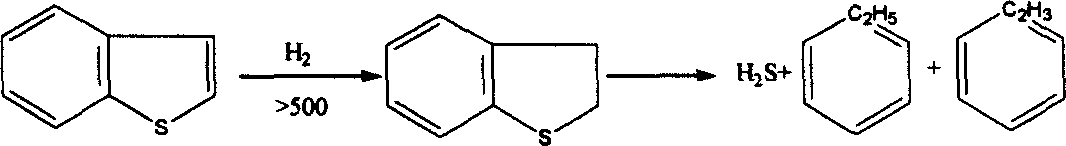

Process for dry coke quenching and coke desulfurating by coke oven gas

A process for using coke oven gas to extinguish coke and desulfurize coke features that the coke oven gas is circulated in the coke extingushing furnace, the heat-absorbing cracking reaction of methane in gas and the high heat transfer efficiency of gas can effectively extinguish to coke, and the H2 in gas can react on the sulfide and organosulfur in coke to generate H2S, so desulfurizing coke.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

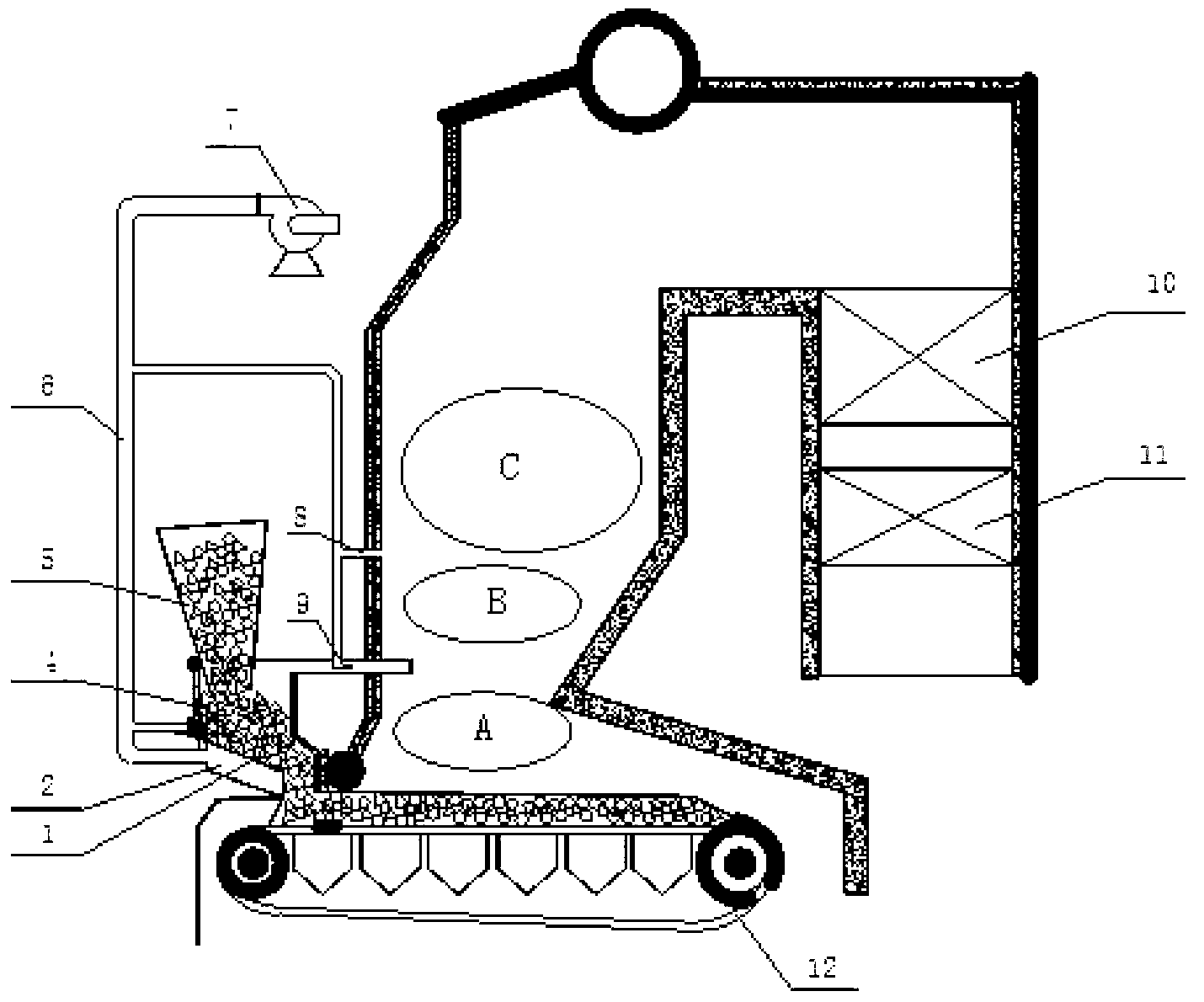

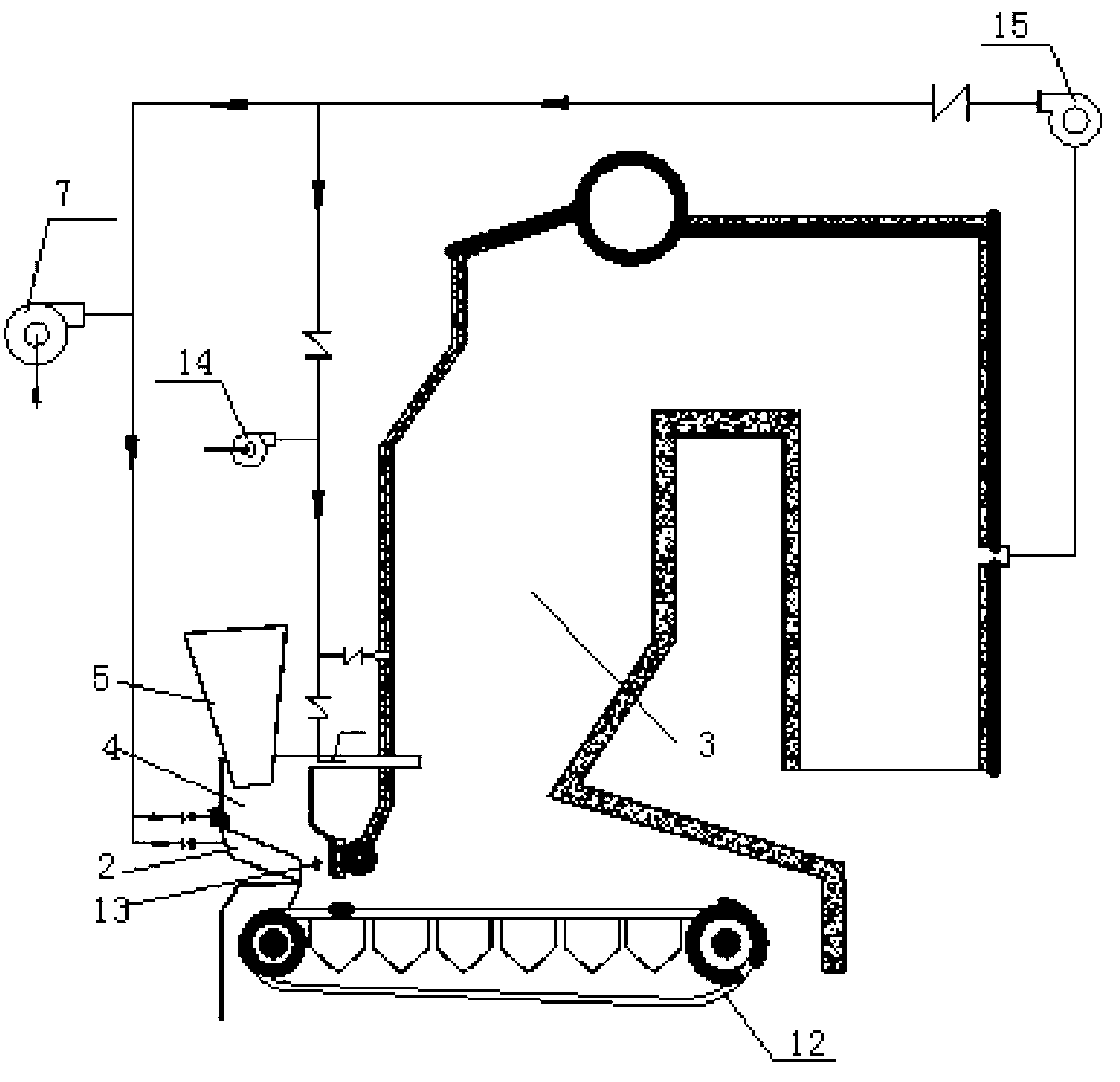

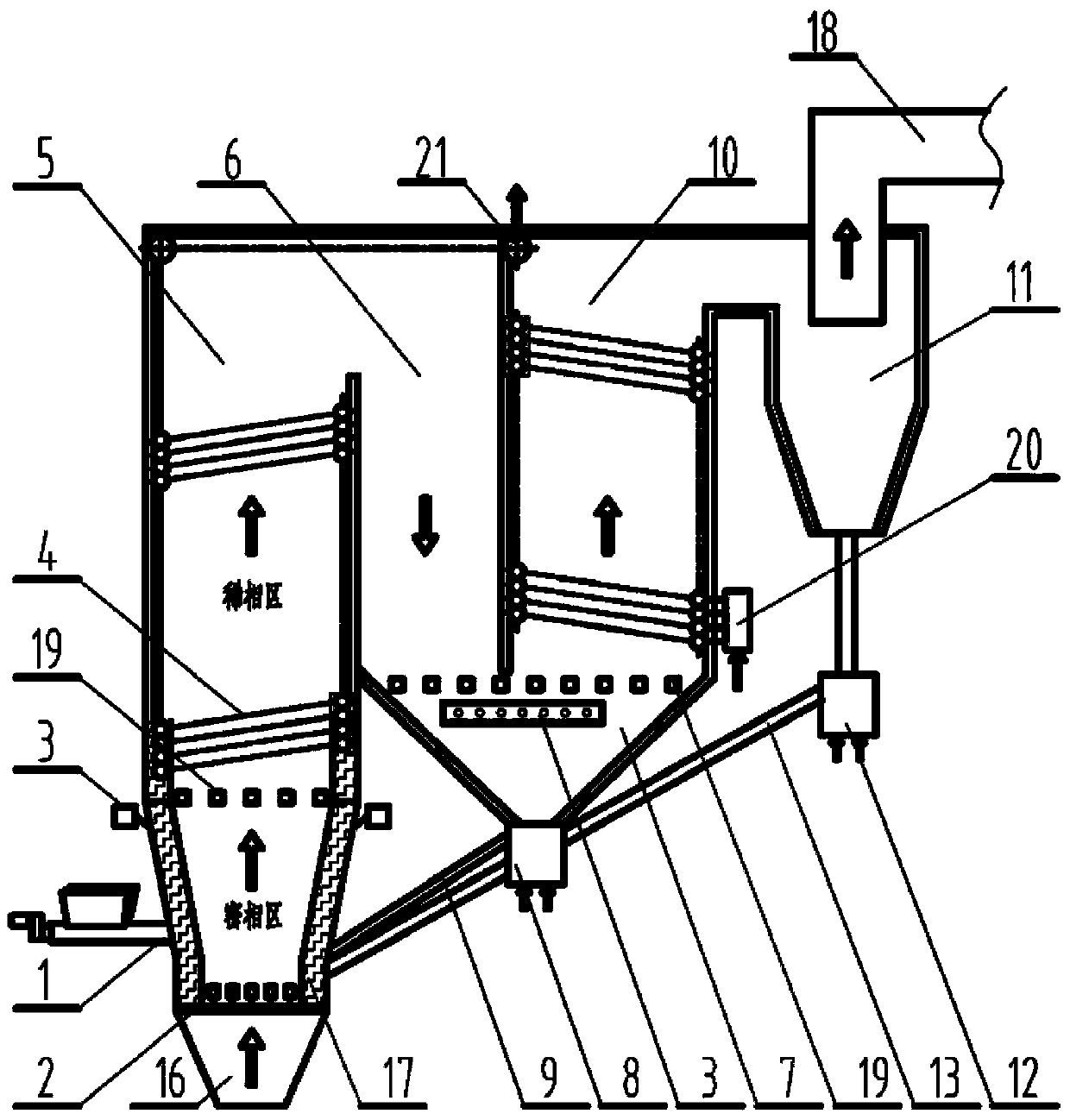

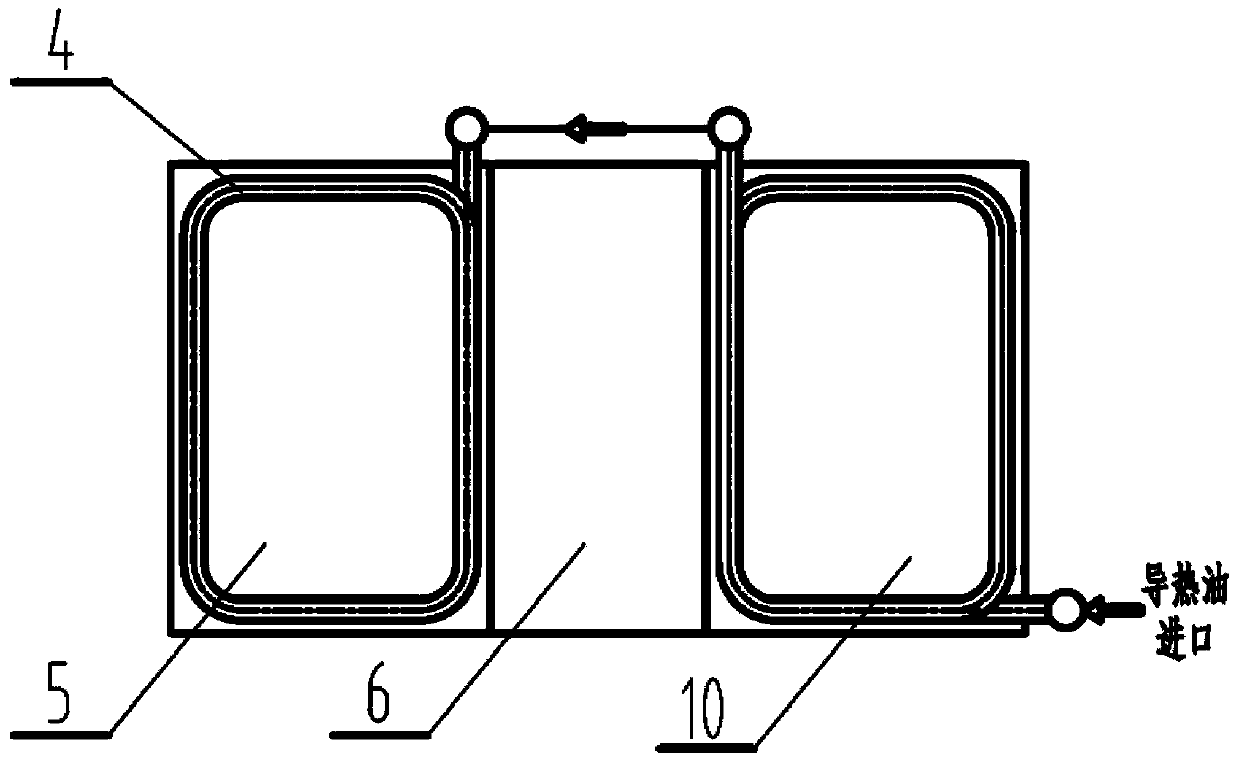

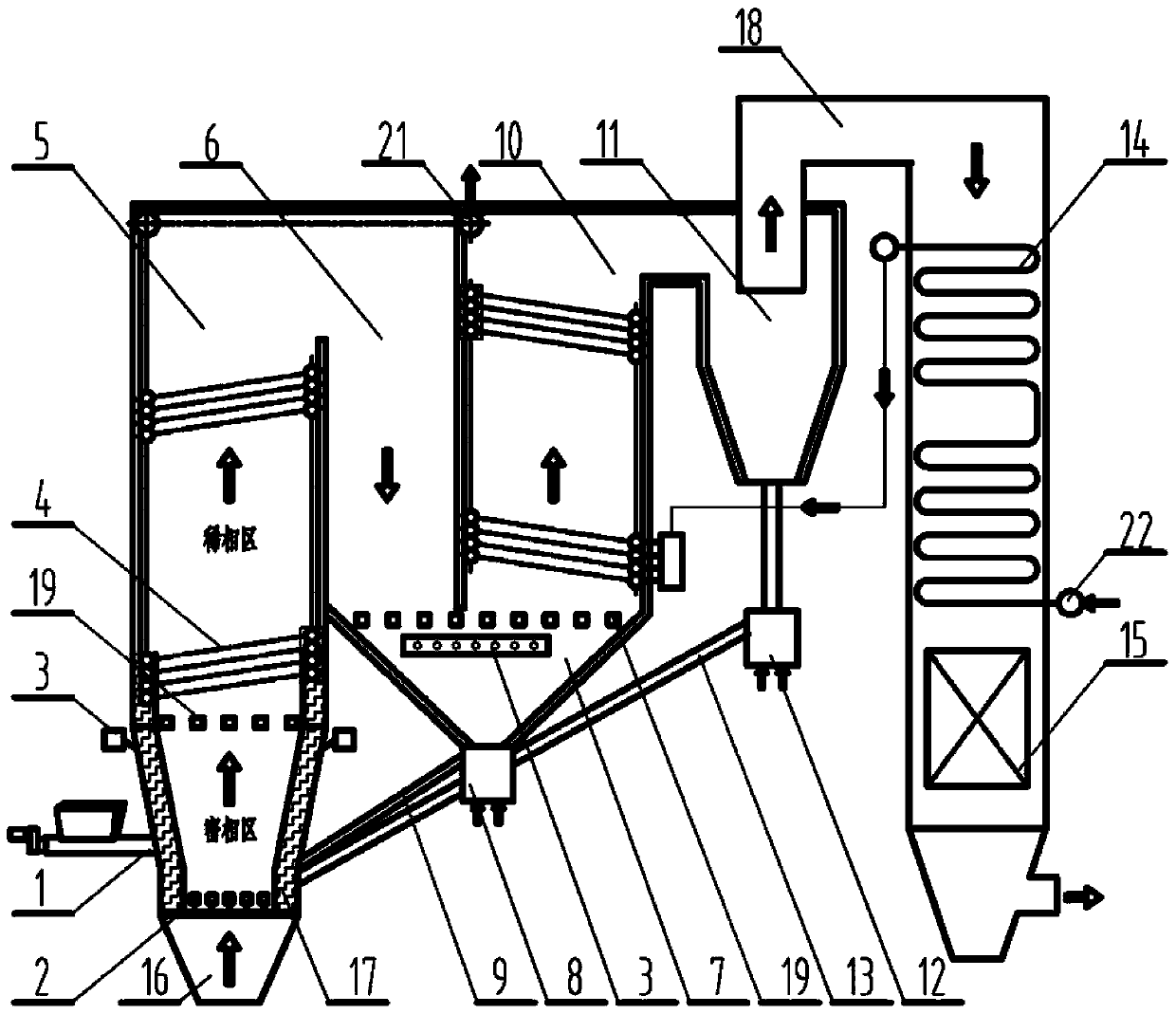

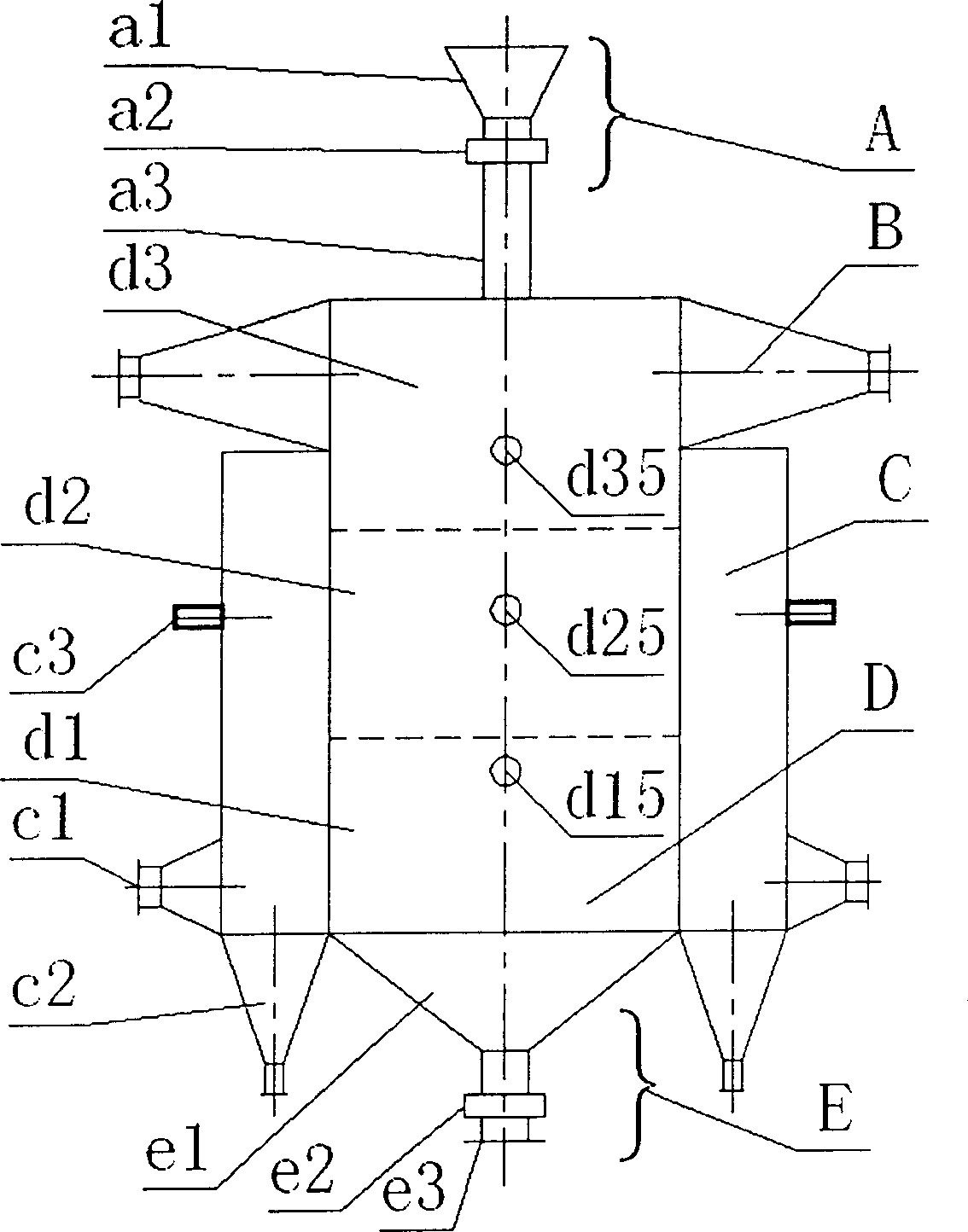

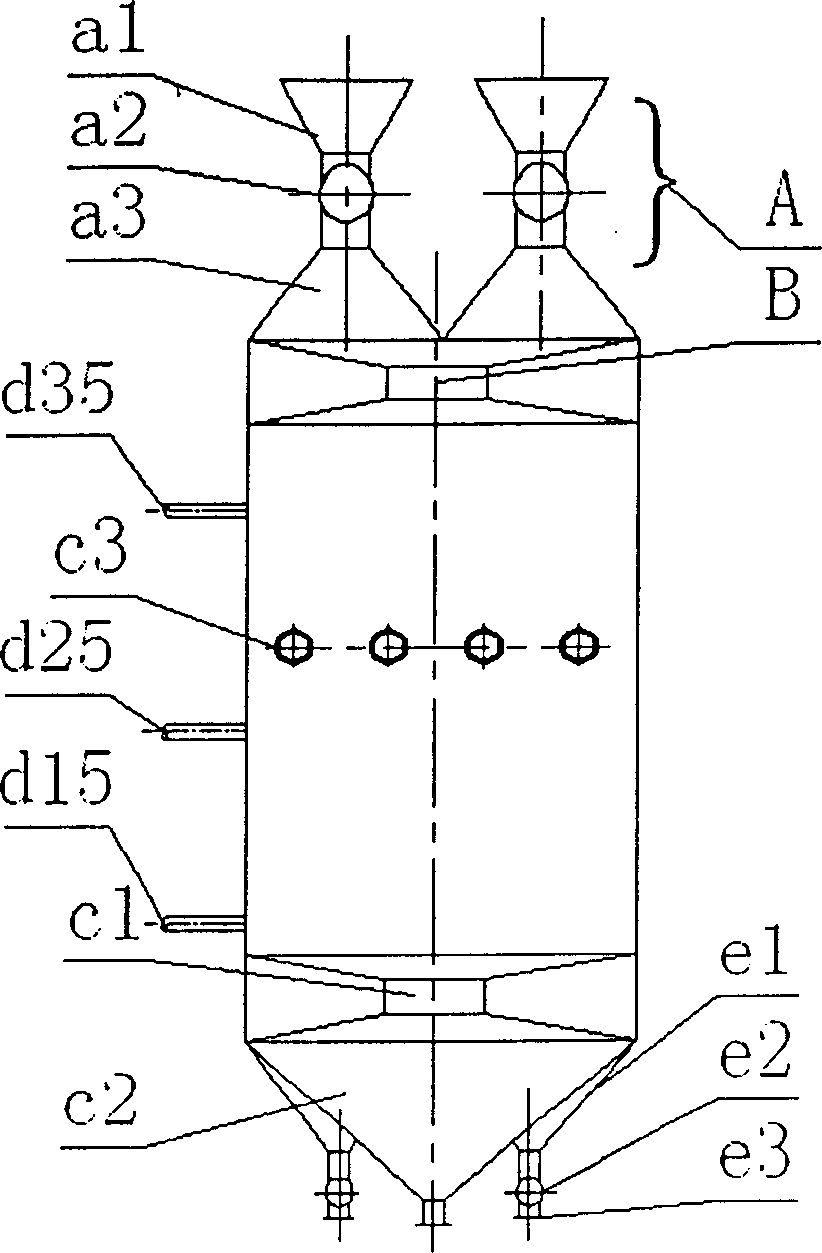

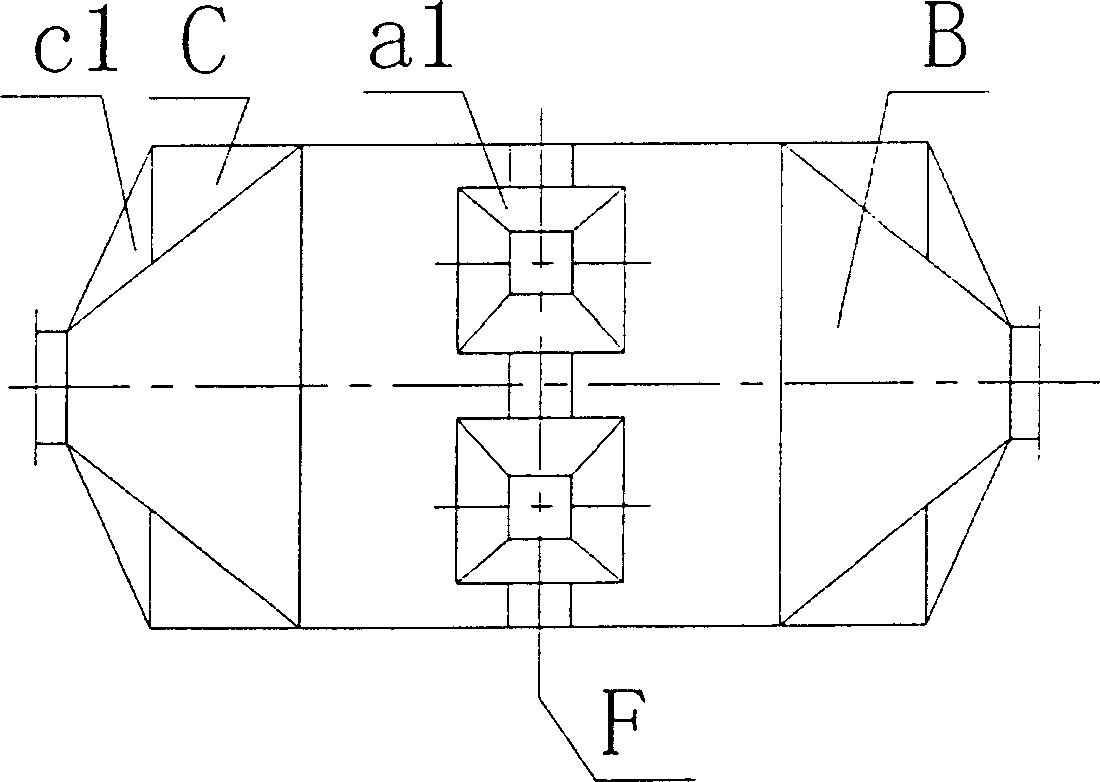

Heat-conduction oil furnace of horizontal circulating fluidized bed

ActiveCN103423869AWide fuel adaptabilityHigh temperature flue gas process is longFluidized bed combustionStorage heatersCirculating fluidized bed boilerCombustion chamber

The invention discloses a heat-conduction oil furnace of a horizontal circulating fluidized bed, and relaters to combustion equipment of the circulating fluidized bed for inferior coal, solid wastes, urban and industrial sludge and biomass fuels, in particular to a heat-conduction oil heating device. The heat-conduction oil furnace is mainly composed of a feeding device, a main combustion chamber, an auxiliary combustion chamber, an after-combustion chamber and a cyclone separator, wherein heat-conduction oil coils are arranged in the main combustion chamber and the after-combustion chamber, an economizer and an air pre-heater can be arranged behind the cyclone separator, and a waste heat boiler can also be arranged behind the cyclone separator. The heat-conduction oil heating device adopts a horizontal circulating fluidized bed technology, changes the traditional structural style adopting a chain grate furnace to heat, changes the single-stage and vertical circulating structure of the traditional fluidized bed boiler, effectively reduces the height of the boiler, and reduces the requirement on the construction height of plants. Through reasonable structural layout, the problem that the circulating fluidized bed boiler is easily abraded is effectively solved, and the heat-conduction oil heating device has wide adaptability to fuels, has high combustion efficiency, and has lower pollutant discharging quantity.

Owner:BEIJING NOWVA ENERGY TECH CO LTD

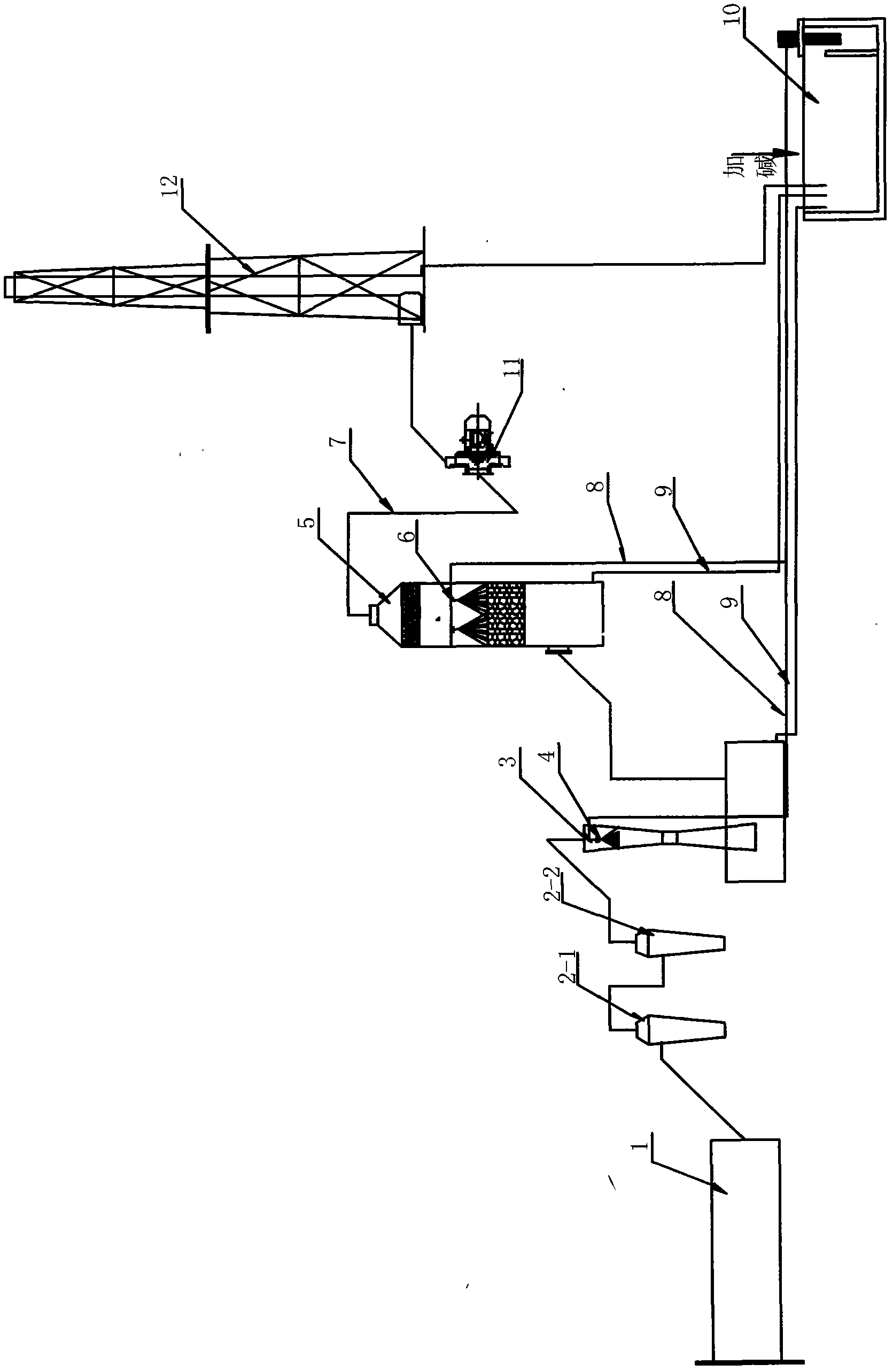

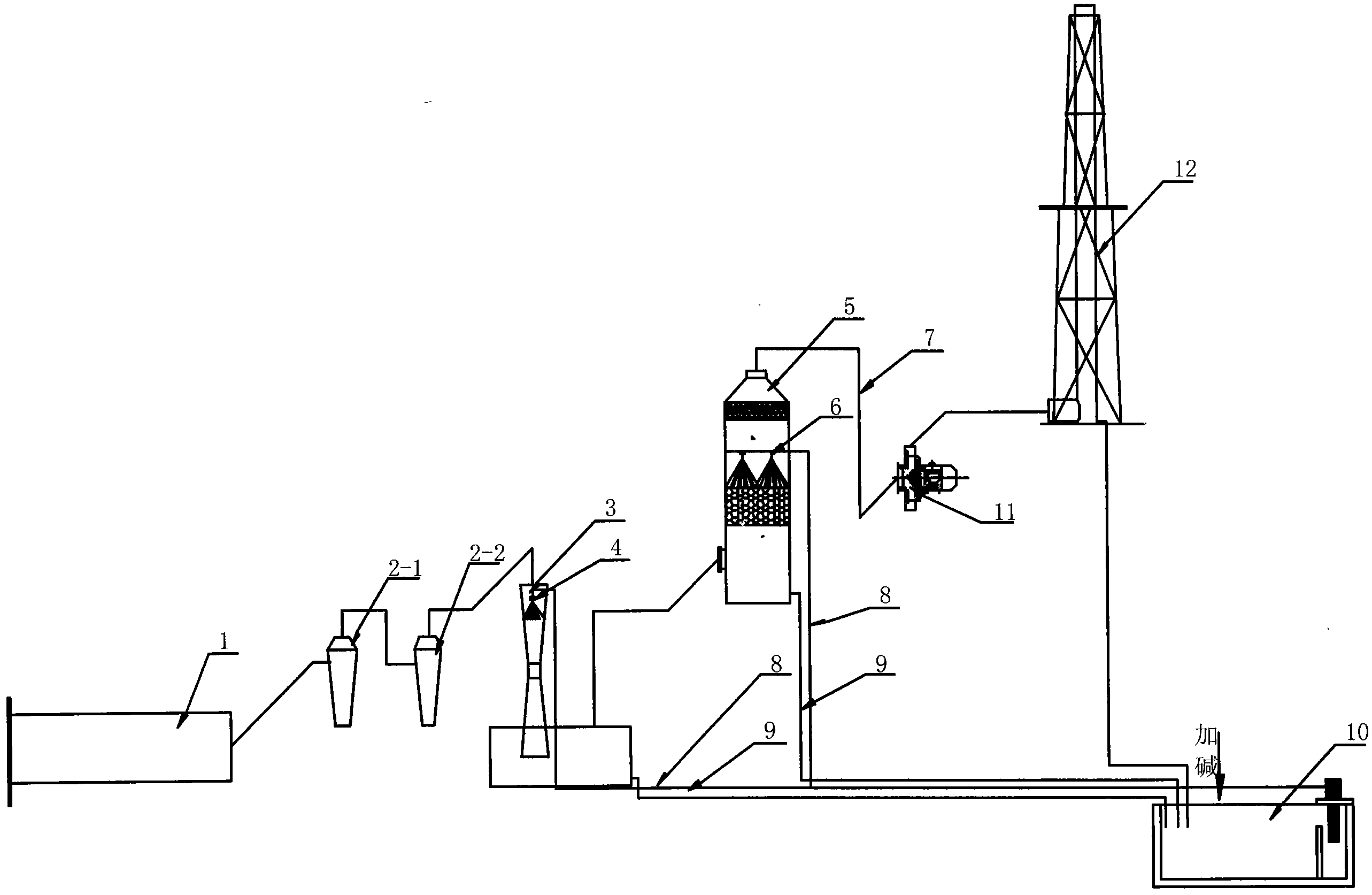

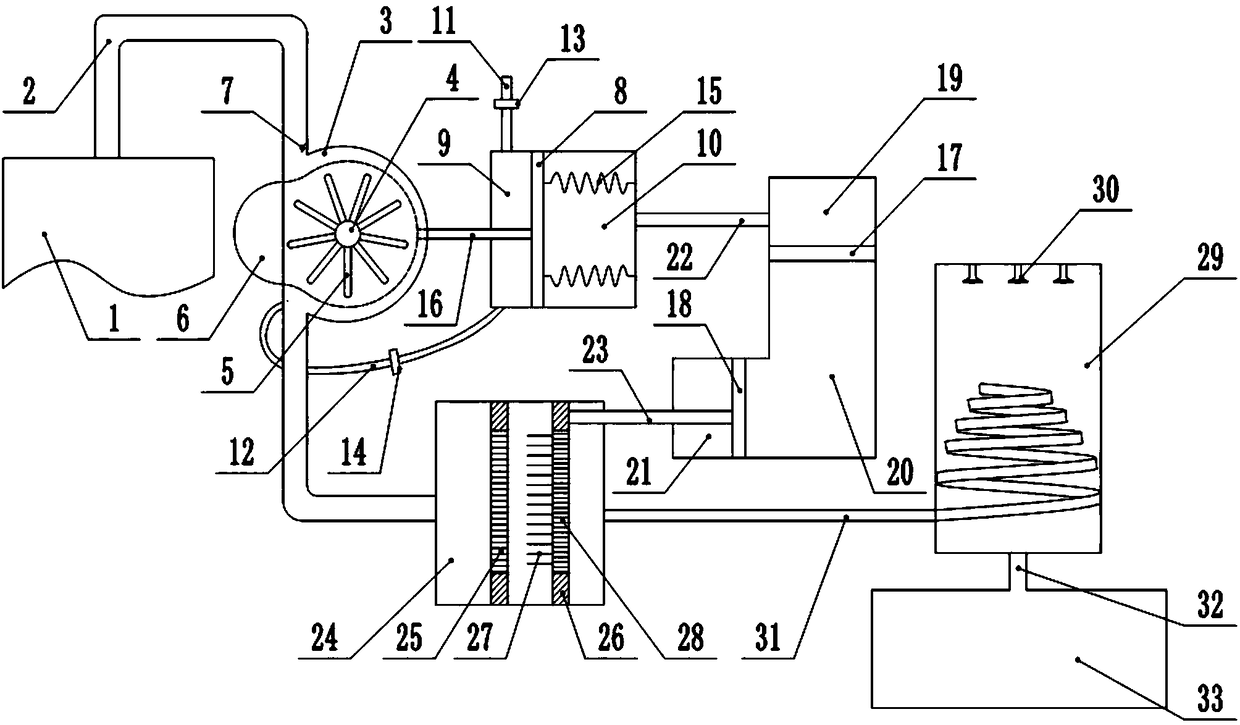

Rotary kiln flue gas treating device capable of automatically controlling blowing rate of draught fan

InactiveCN101972578AEffective corrosionExtended service lifeCombination devicesIncreasing energy efficiencyAutomatic controlSprayer

The invention discloses a rotary kiln flue gas treating device capable of automatically controlling the blowing rate of a draught fan, which relates to flue gas treating equipment for a rotary kiln used in titanium dioxide production. A main structure is that: a primary cyclone dust collector is connected with the rotary kiln and a secondary cyclone dust collector; the secondary cyclone dust collector is connected with a Venturi dust collector; the Venturi duct collector is connected with an acid mist washing tower; the acid mist washing tower is connected with a chimney through an exhaust pipe; an induced draught fan is arranged on the exhaust pipe and provided with a frequency converter; a sprayer and a washing sprayer on the Venturi dust collector and the acid mist washing tower are connected with water supply pipes respectively; the water supply pipes are connected with a water supply pump of a cooling and settling pond; water ponds at the bottoms of the Venturi dust collector and the acid mist washing tower are connected with water return pipes; and the water return pipes are connected with the cooling and settling pond. The rotary kiln flue gas treating device capable of automatically controlling the blowing rate of the draught fan captures and cools about 600 DEG C high temperature flue gas and fine dust which are generated in a metatitanic acid calcining process by the rotary kiln, and finally realizes the clean emission standard of tail gas and the recycling of captured dry ash.

Owner:XICHANG NEW VANADIUM & TITANIUM

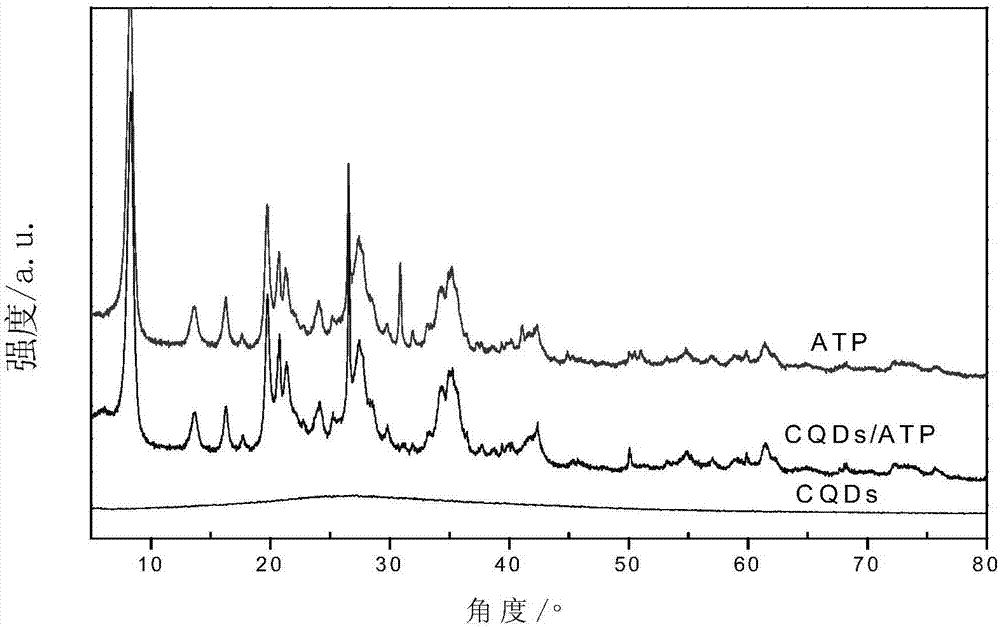

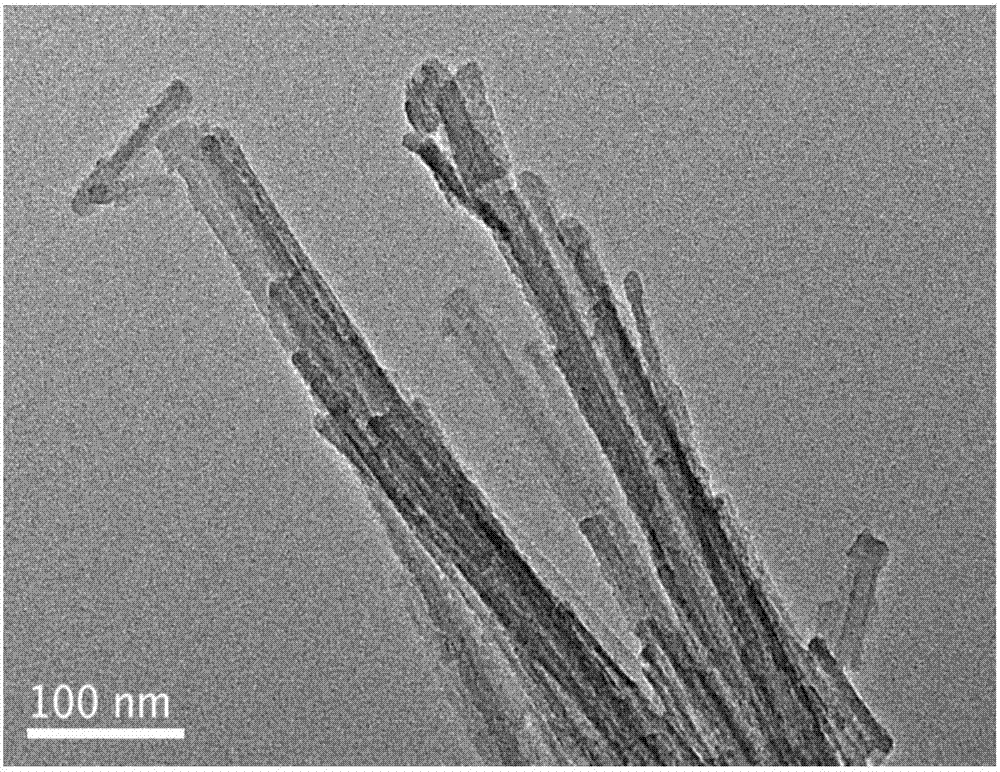

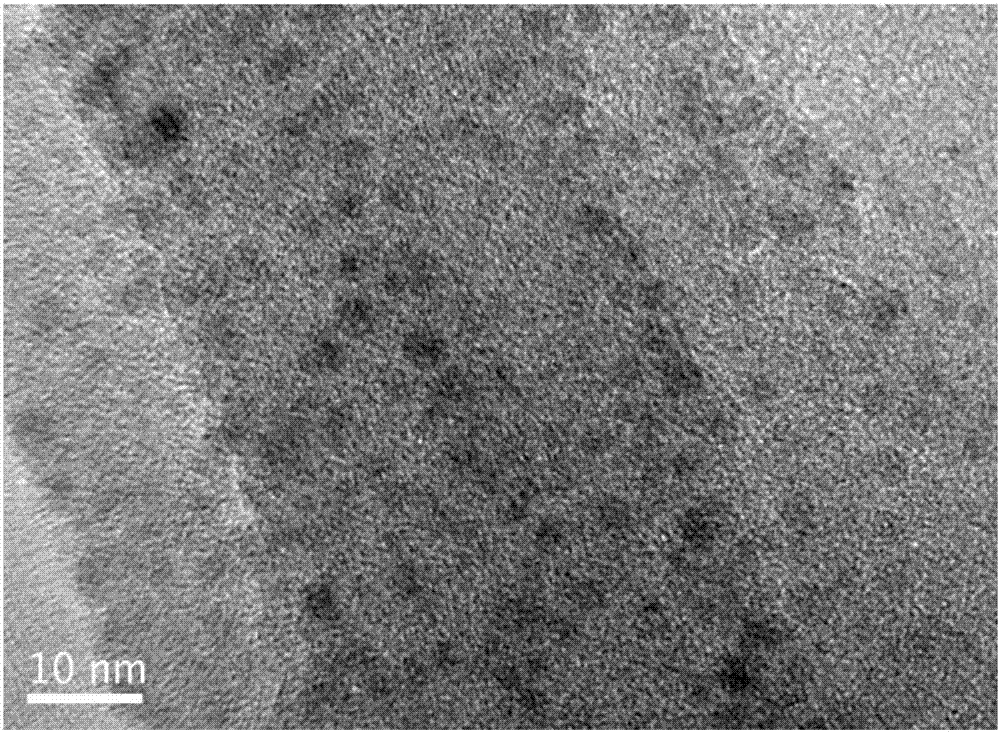

Carbon quantum dot/attapulgite nanocomposite as well as preparation method and application thereof

ActiveCN106944029AEffective particle size controlSmall particle sizePhysical/chemical process catalystsRefining with oxygen compoundsNanocompositeCitric acid

The invention belongs to the field of new chemical materials and in particular relates to a carbon quantum dot / attapulgite nanocomposite as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing citric acid, hydrogen peroxide and attapulgite, carrying out hydrothermal reaction, and then centrifuging, washing and drying, so that the carbon quantum dot / attapulgite nanocomposite is obtained, and then the nanocomposite is used for photocatalytic desulphurization.

Owner:CHANGZHOU UNIV

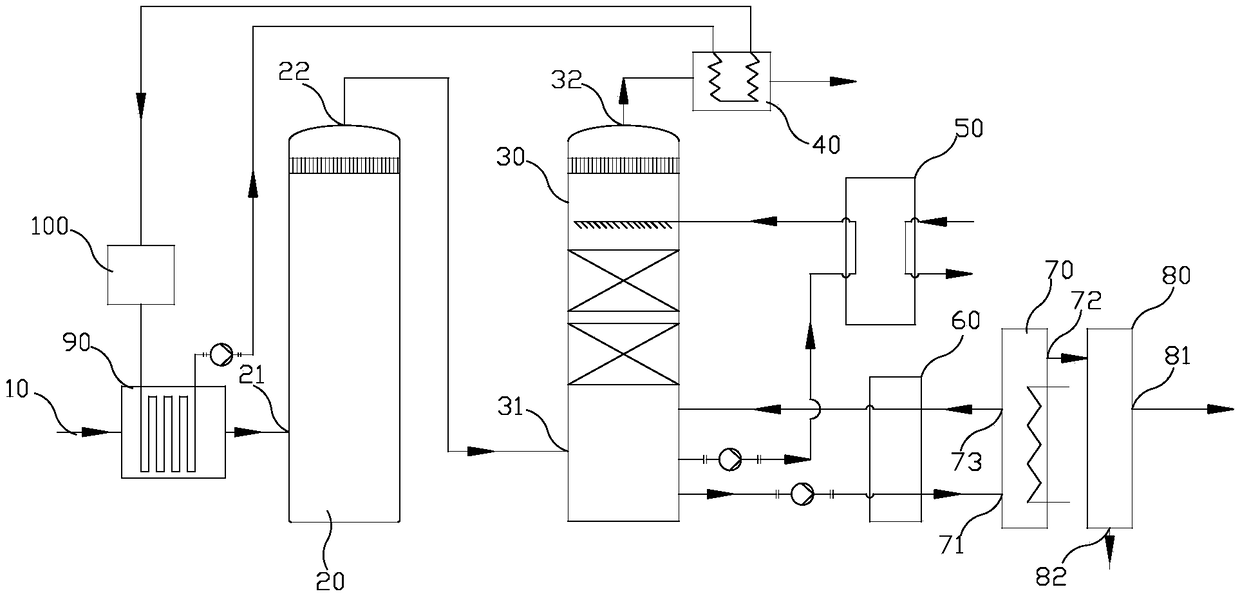

Desulphurization, denitration and dust removal integrated treatment process of exhaust gas

InactiveCN105664717AAchieve desulfurizationAchieve dust removalGas treatmentDispersed particle filtrationOperational costsFlue gas

The invention relates to a desulphurization, denitration and dust removal integrated treatment process of exhaust gas. The treatment process comprises the following steps: introducing the flue gas into an integrated catalytic agent ceramic filter drum device at an appropriate temperature section, wherein the integrated catalytic agent ceramic filter drum device is provided with a back flushing ash removal device; injecting a desulphurization agent and a denitration agent before the exhaust gas enters the integrated catalytic agent ceramic filter drum device; arranging a flue gas mixing device in front of the integrated catalytic agent ceramic filter drum device; and introducing the treated flue gas reaching the standard into an energy recycling system to recycle the heat by virtue of a pressurizing fan, and finally discharging the flue gas into a chimney, wherein the appropriate temperature section is 280 to 420 DEG C. The process has the advantages of stable and reliable system, small maintenance workload, long product service life, low device operation cost and small device occupation area; and the flue gas flowing into a waste heat boiler is clean gas, so that the heat exchanging efficiency of the energy recycling device is greatly improved, the service life of the energy recycling device is greatly prolonged, and the economic benefit is vast.

Owner:NANJING CEEP TECH

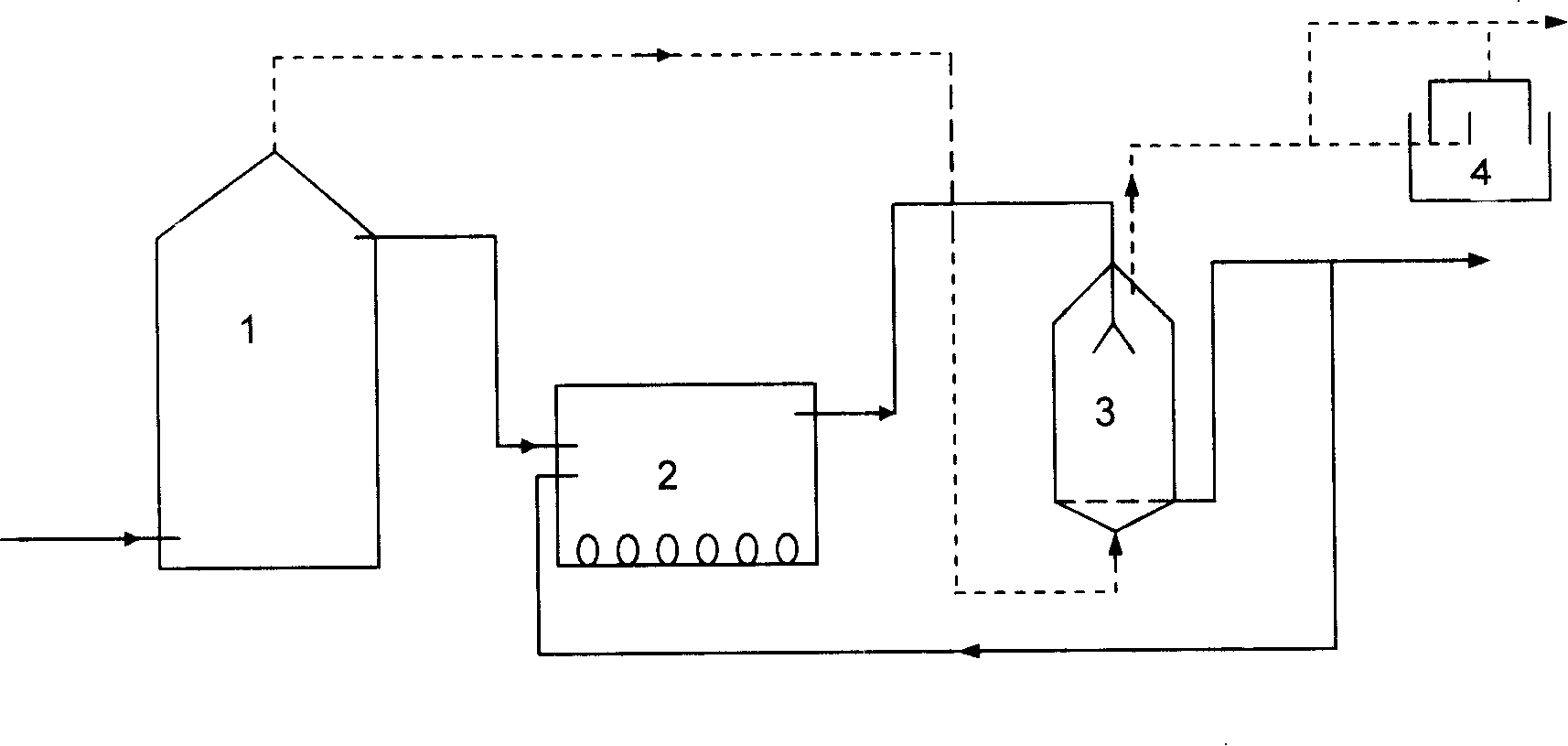

Waste water denitrogenation and marsh gas desulfurization coupling technique

InactiveCN101234831ARealize denitrificationAchieve desulfurizationWater contaminantsTreatment with aerobic and anaerobic processesNitrogen gasDigestion

The invention relates to a technology for coupling wastewater denitrification and biogas desulphurization, which is characterized in that: wastewater or pretreated wastewater flow into an anaerobic digestion unit; organic matter in the wastewater is transformed to biogas, and organic sulfur and sulfate are transformed to hydrogen sulfide, and organic nitrogen is transformed to ammoniacal nitrogen by the anaerobic digestion unit. The effluent of the precipitated anaerobic digestion unit flows into a digestion liquid aerobic processing unit; residual organic matter is degraded and the ammoniacal nitrogen is transformed to nitrate nitrogen or nitrite nitrogen by the digestion liquid aerobic processing unit. A denitrification and desulphurization unit adopts a tower reactor; the effluent of the precipitated aerobic processing unit flows into the reactor from the top of the tower reactor and the biogas generated by the anaerobic digestion unit flows into the reactor from the bottom of the tower reactor. The nitrate nitrogen or the nitrite nitrogen is transformed to nitrogen and the hydrogen sulfide is transformed to elemental sulfur or the sulfate by the tower reactor. The technology for coupling wastewater denitrification and biogas desulphurization has the advantages that: the nitrogen in the wastewater and the sulfur in the biogas are removed at the same time; no extra carbon source is needed in the denitrification of the anaerobic digestion liquid; no other catalyst and oxidizer are needed in the biogas desulfurization; little biological mud is generated and the operation cost is low.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Glass fiber coated filter material with catalytic function and preparation method thereof

InactiveCN109603306AAvoid deactivationTo achieve the purpose of comprehensive prevention and controlDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsGlass fiberReactive site

The invention discloses a glass fiber coated filter material with a catalytic function and a preparation method thereof. The glass fiber coated filter material consists of a glass fiber filter material base material, a glass fiber protective film, a catalyst nano-particle layer and an expanded microporous polytetrafluoroethylene filter film. During application in filtering, dust is firstly blockedby the expanded microporous polytetrafluoroethylene filter film of the glass fiber coated filter material with the catalytic function, so that the active sites on catalyst nano-particles are prevented from being covered with the dust and thus losing activity, the catalytic function of the catalyst is efficient and can last for a long time, and residual harmful gas is decomposed by the catalyst nano-particle layer to achieve the purpose of comprehensive prevention and control of the dust and harmful gas. The integration of dust removal, desulfurization, denitration, dioxin removal, mercury removal and the like is achieved, and the filter material is particularly suitable for industrial production.

Owner:太湖金锦鸿过滤材料有限公司

Coupling multistage device with active carbon purifying waste gas

InactiveCN1820819ATake advantage ofCompact structureDispersed particle separationActivated carbonMaterial distribution

The present invention provides coupling multistage apparatus with active carbon to purify waste gas, and the apparatus is used in desulfurizing, denitrating, dedusting, eliminating heavy metal and eliminating organic compound of waste gas. It consists of pre-purifying room, movable adsorption bed, purified gas outlet, material feeding mechanism, and discharging mechanism. Each of the material feeding mechanism and the discharging mechanism consists of material bin, material guide pipe and gas trap valve. The movable adsorption bed consists of one or several adsorption sections superposed sequentially, the material feeding mechanism is set on the top, the discharging mechanism is set in the bottom, and the pre-purifying room and the purified gas outlet are set in the side. The apparatus has compact structure, simple material distribution, complete functions, less resistance, high purifying effect, fully use of active carbon, long service life and low running cost.

Owner:史鱼海

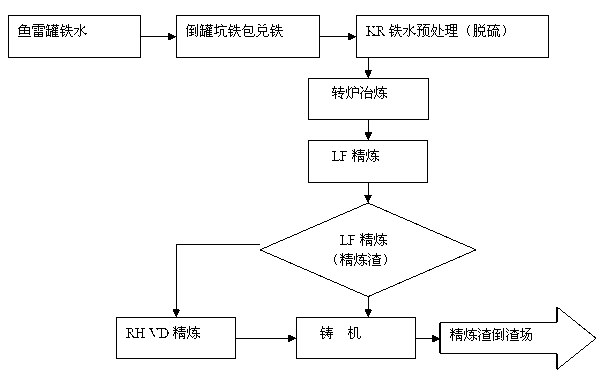

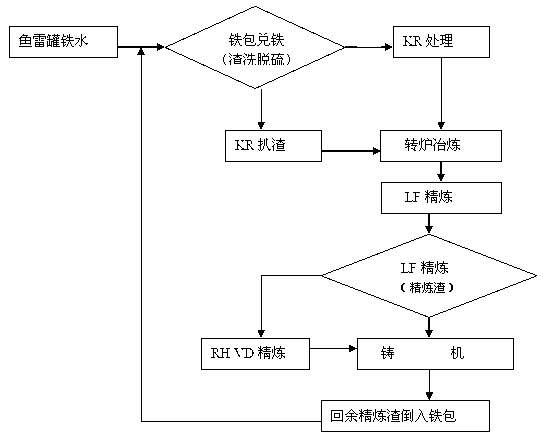

Recycling method for pulling ladles into refining slag

InactiveCN103320576AEfficient recyclingAchieve desulfurizationProcess efficiency improvementSlagSmelting

The invention belongs to the technical field of smelting and specifically relates to a recycling method for putting ladles into refining slag. The recycling method for putting ladles into refining slag comprises following steps: melted iron in a torpedo ladle-adding iron into a iron ladle-pretreatment of KR melted iron / KR slagging off-smelting in a converter-LF refining-letting refining slag enter a chamber machine-recycling and putting the surplus refining slag into the iron ladle-adding iron into the iron ladle and repeating above processes. The method has beneficial effects that the refining slag is effectively recycled and relevant characteristics thereof are fully used for the second time, melted iron desulphurization is realized and KR desulphurization cost is effectively reduced; surplus molten steel in the refining slag during pouring is completely recycled, reducing the consumption of steel and iron materials; the refining slag has a certain temperature and floats on a slag iron interface in order to realize good isolation; the process flow is simplified. The desulphurization can be completed through the KR slagging-off treatment during the melted iron desulphurization in the refining slag, buying time for production and organization in the converter.

Owner:JIGANG GRP

Heavy-rail steel sulfur content controlling method

ActiveCN102443670AAchieve desulfurizationControl desulfurizationManufacturing convertersSulfideSulfur content

The invention provides a heavy-rail steel sulfur content controlling method. According to the invention, sulfur weight during a converter tapping process is controlled, LF furnace and VD furnace slagging manners are improved, and casting parameters of a casting machine are adjusted. With the measures, desulphurization speed in the processes are effectively controlled, such that heavy-rail steel sulfur weight is stably controlled in a range of 0.08-0.20%. Compared to existing technologies, with the method provided by the invention, large-amplitude desulphurization of the LF furnace and the VD furnace can be realized, and desulphurization during the processes can be effectively controlled. With traditional technologies, included sulfide caused by large-amplitude desulphurization can hardly be sufficiently discharged. With the method provided by the invention, the problem is solved, such that a defect of over-standard heavy-rail steel sulfide is avoided. With the method, a sulfur weight of a tundish finished product is improved from 0.0052% to 0.0124%. The proportion of S>0.008% is improved from 42.6% to 99.1%, such that the quality qualification rate of heavy-rail steel is substantially improved.

Owner:ANGANG STEEL CO LTD

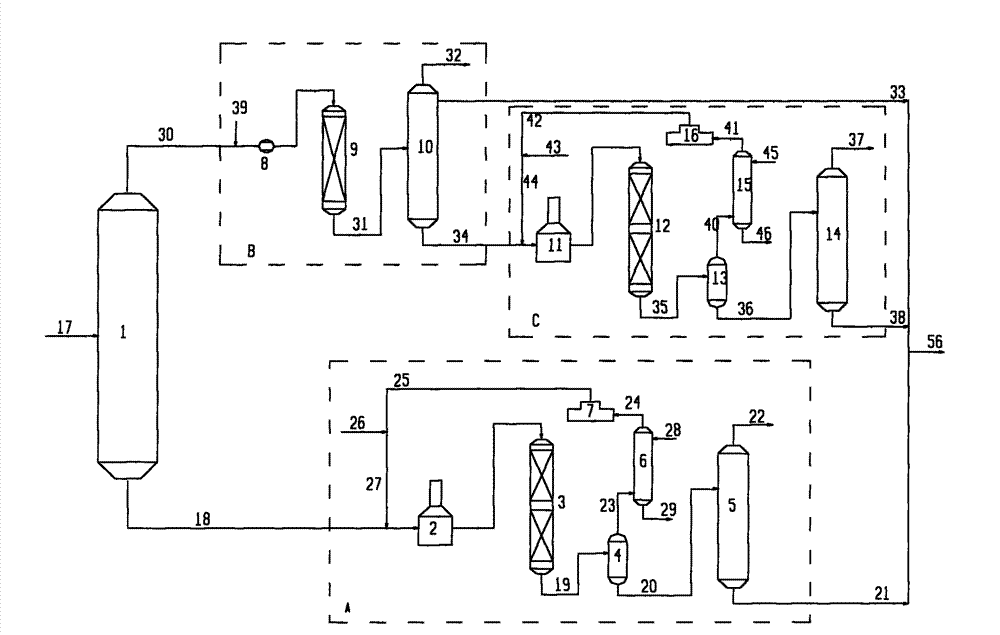

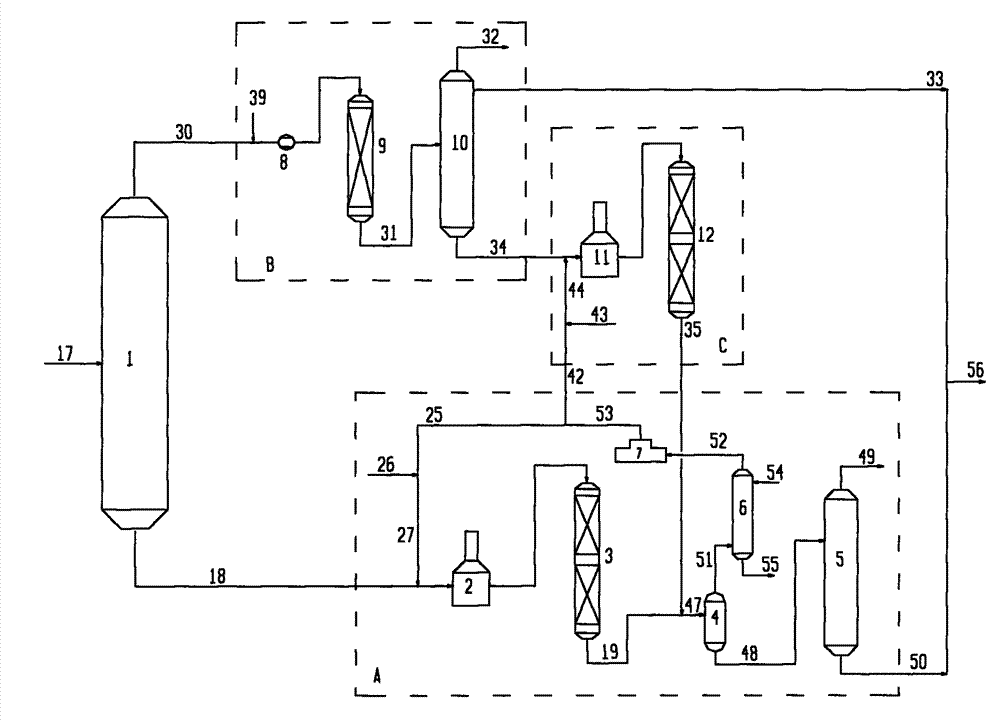

Hydrogenation method for deeply desulfurizing gasoline

ActiveCN103087771AHigh desulfurization depthReduce lossesTreatment with hydrotreatment processesHydrogenation reactionBoiling point

The invention provides a hydrogenation method for deeply desulfurizing gasoline. The hydrogenation method comprises the steps that catalytically cracked gasoline is fractionated into light fractions and heavy fractions; the heavy fractions and hydrogen are mixed and enter into a first hydrogenation reaction zone to react to obtain low-sulfur heavy fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; the light fractions and hydrogen are mixed and enter into a second hydrogenation reaction zone, diene is subjected to hydrogenation saturation to obtain mono-olefin low-boiling sulfides and the mono-olefin low-boiling sulfides are converted to high-boiling sulfides; the hydrogenated light fraction oil enters a light-medium fraction fractionating tower and is divided into light fractions and medium fractions and low-sulfur light fraction oil is obtained; the medium and light fractions and hydrogen are mixed and enter into a third hydrogenation reaction zone to react to obtain low-sulfur medium fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; and the heavy fraction oil, the light fraction oil and the medium fraction oil are mixed to obtain the low-sulfur gasoline product. Aiming to produce the gasoline with sulfur content not more than 10mu g / g, the method provided by the invention has the characteristics of high desulfurization depth, long device running period and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

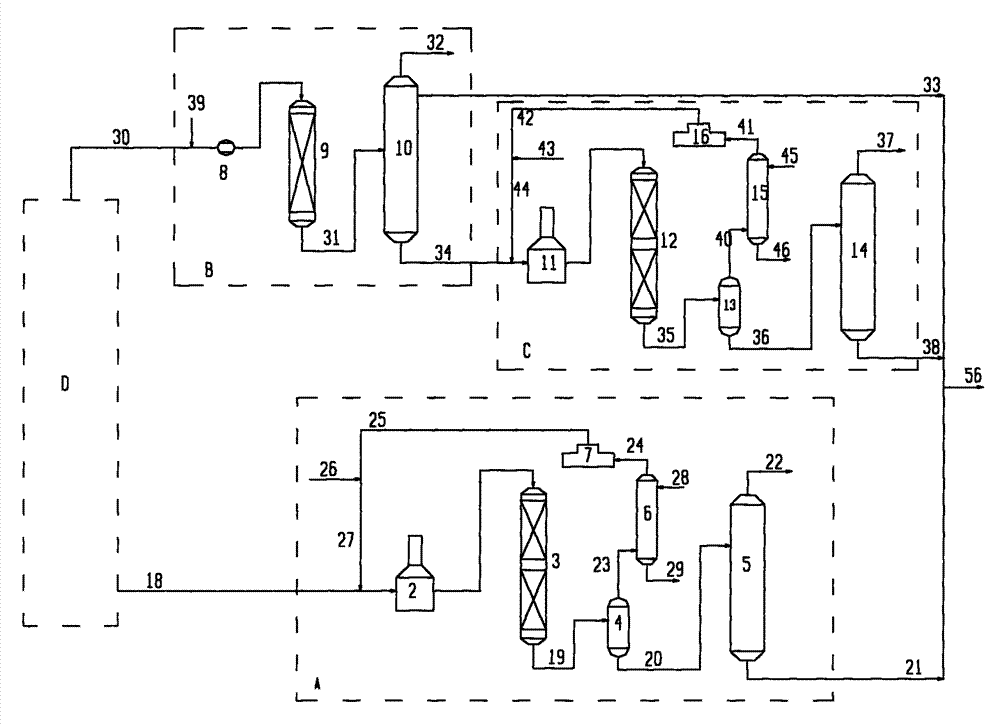

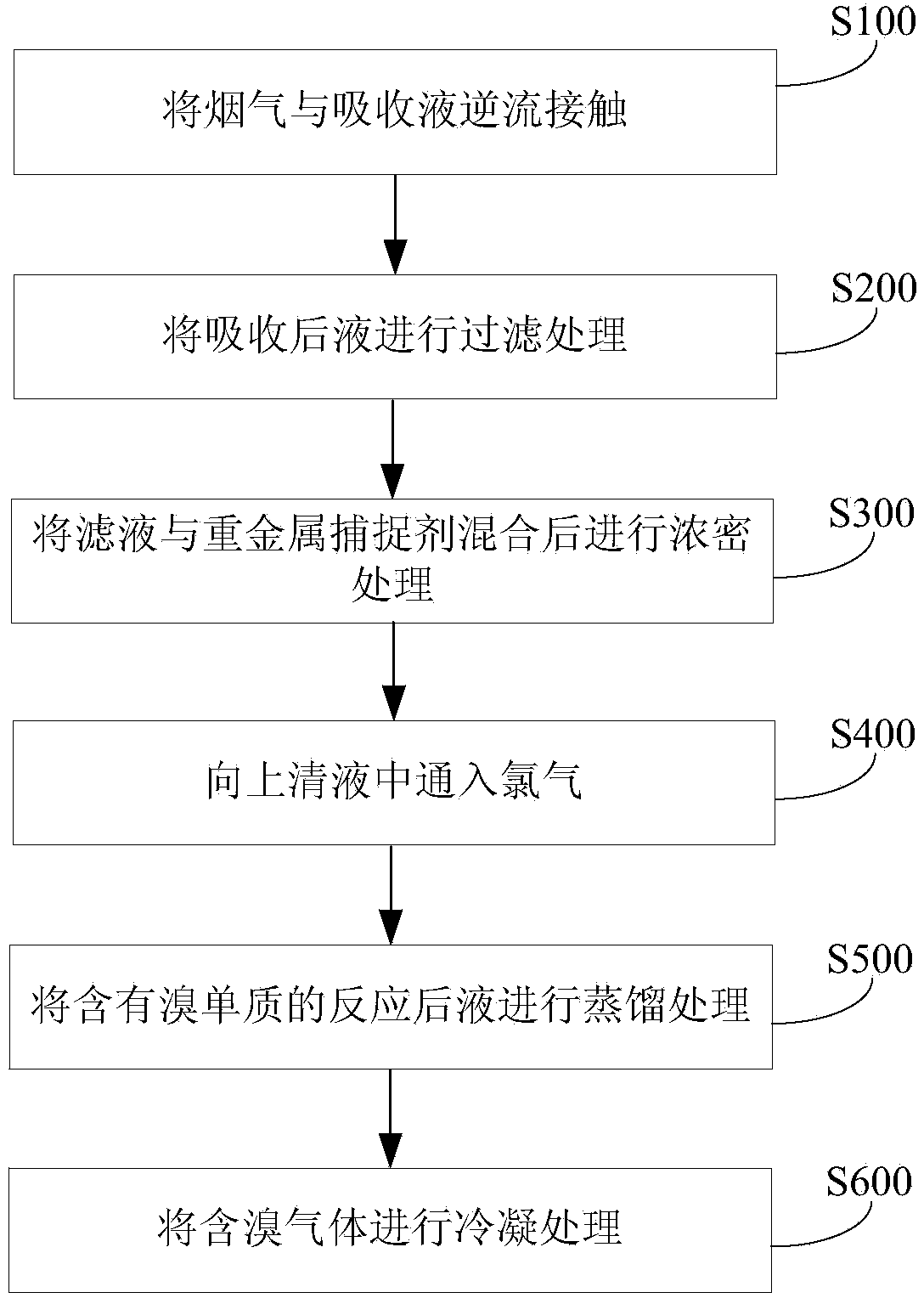

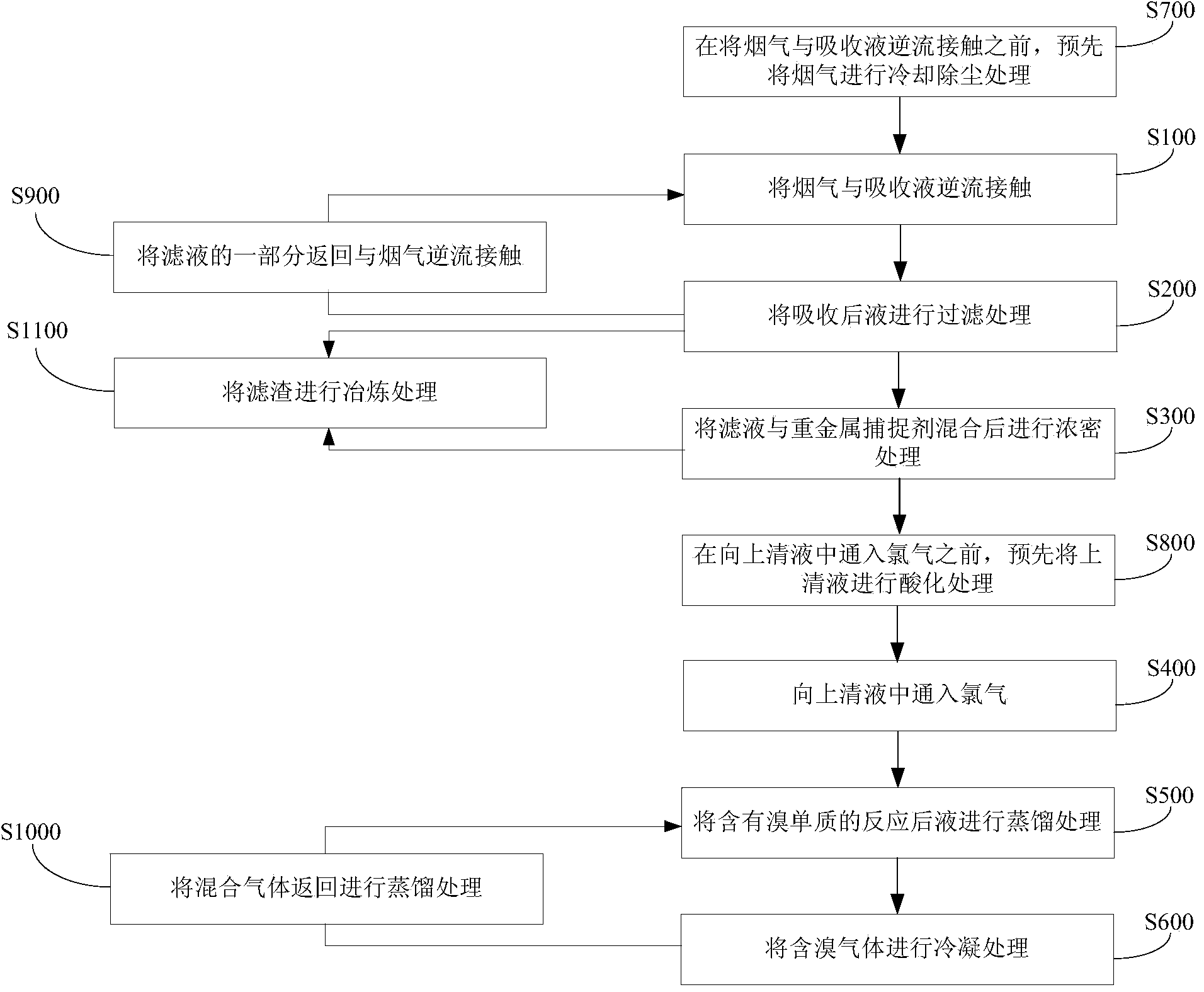

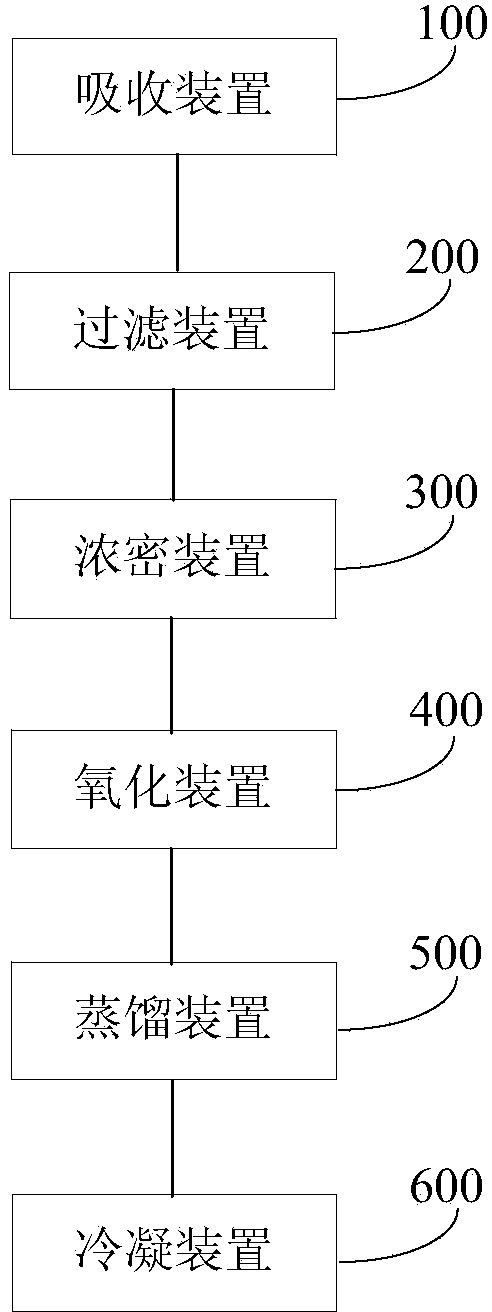

Method and system for treating electronic scrap smoke

ActiveCN104383801AAchieve desulfurizationAchieve dehalogenationDispersed particle separationBromine/hydrogen-bromideBrominePhysical chemistry

The invention discloses a method and a system for treating electronic scrap smoke. The method comprises the following steps: (1) performing countercurrent contact between smoke and absorption liquid so as to obtain purified smoke and absorbed liquid; (2) filtering the absorbed liquid so as to obtain filtrate and filter residue; (3) mixing the filtrate with a heavy metal capture agent, and performing concentration treatment so as to obtain supernatant and filter residues containing heavy metals; (4) introducing chlorine into the supernatant, oxidizing bromide ions in the supernatant into molecular bromine, so as to obtain a reaction solution containing the molecular bromine; (5) distilling the reaction solution containing the molecular bromine so as to obtain bromine-containing gas; and (6) condensing the bromine-containing gas so as to obtain a bromine product and mixed gas. According to the method, the electronic scrap smoke can be effectively purified, the purified smoke can meet the national environmental protection standard, the bromine element can be efficiently recovered, the bromine extraction rate is over 90 percent, and the purity of the bromine product is over 99 percent.

Owner:CHINA NERIN ENG

Desulfurizing method of ladle refining furnace and desulfurizing method used for slab-grade steel

InactiveCN102051444AAchieve desulfurizationImprove desulfurization efficiencyProcess efficiency improvementSlagMolten steel

The invention provides a desulfurizing method of a ladle refining furnace and a desulfurizing method used for slab-grade steel, wherein the desulfurizing method of a ladle refining furnace comprises the steps of adding 3 to 10 kg / t lime or high-alkalinity top slag of steel into the molten steel in the ladle refining furnace, adding 0.5 to 1.0 kg / t aluminum of steel into the molten steel, and blowing argon gas from the bottom to carry out forced agitation with the flow of the argon gas not lower than 450 NL / min; and at the time of three minutes before the refining ends, reducing the flow of the argon gas blown at the bottom to the flow not higher than 200NL / min, and softly blowing the argon gas for more than 5 minutes after the refining and the alloying end. The desulfurizing method used for the slab-grade steel comprises the steps of adding 5.0 to 12.0 kg / t mixed slag of steel into the ladle at the tapping of the converter, and after tapping, adding a slag regulating agent of steel, which is not higher than 20 kg / t into the slag surface of the molten steel; and then carrying out the desulfurizing method of the ladle refining furnace. The method based on the refining technology of the ladle refining furnace or the steel-making technology with the combination of the converter smelting and the refining of the ladle refining furnace of the invention realizes the desulfurization of the molten steel and has high desulfurizing efficiency.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

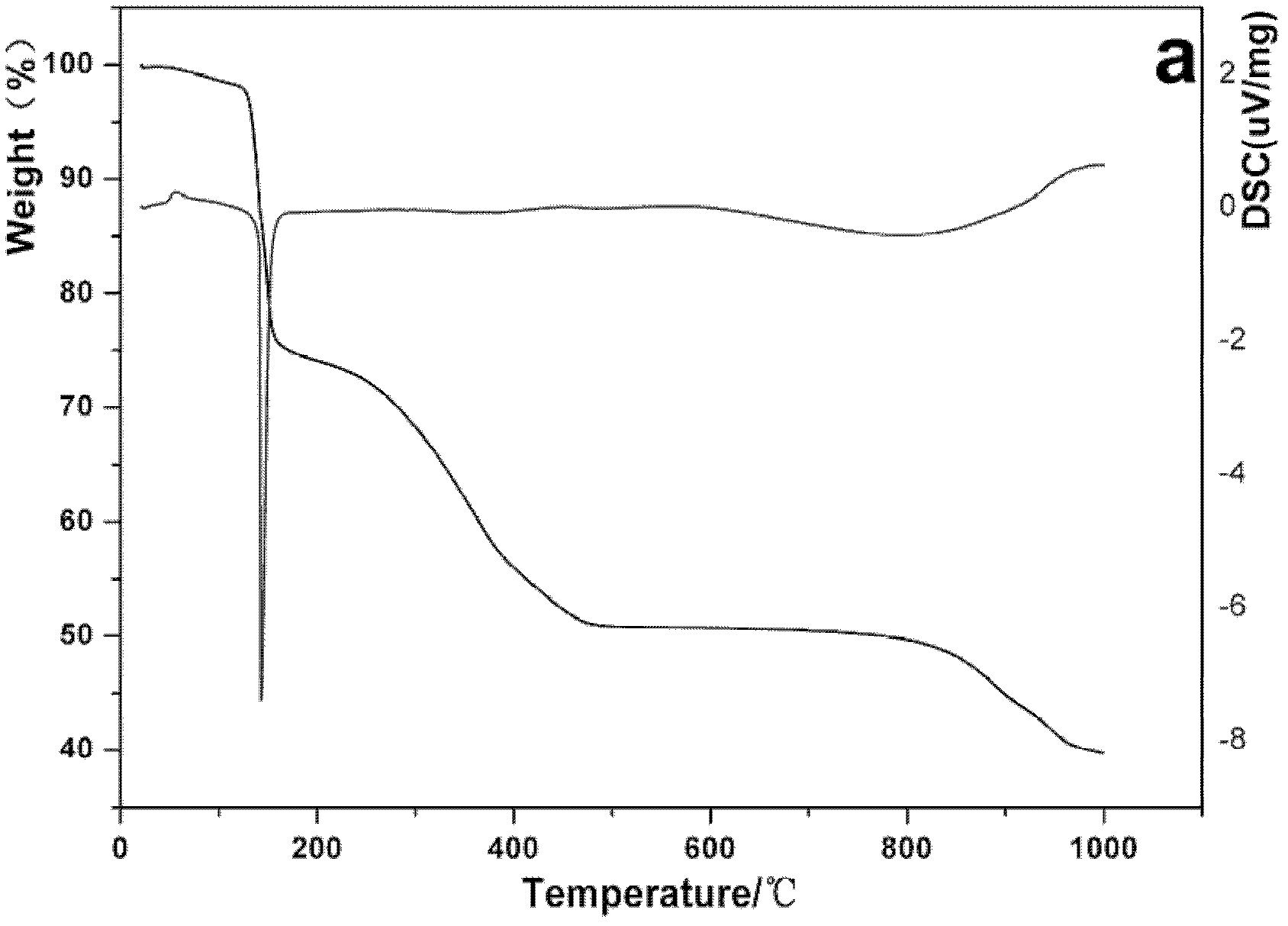

Method for preparing reclaimed rubber powder from waste tire rubber powder

The invention discloses a method for preparing reclaimed rubber powder from waste tire rubber powder and belongs to the technical field of polymer material recovery. The method includes the steps thatthe waste tire rubber powder is first subjected to acid leaching, alkali leaching, washing, impurity removal and drying to obtain pretreated waste tire rubber powder, an inorganic salt is heated andmolten to obtain molten salt, the molten salt is used as an electrolyte, the pretreated waste tire rubber powder is added for constant-temperature electrolysis, cooling and smashing are conducted to obtain electrolytic scrap, the electrolytic scrap is mixed with water and filtered to obtain porous electrolytic scrap, then the porous electrolytic scrap and a microbial bacteria liquid are mixed andfermented to obtain a fermented material, and the fermented material is soaked in water and frozen and crushed to obtain the reclaimed rubber powder. The reclaimed rubber powder according to the technical scheme has the advantages of excellent mechanical properties and processing properties.

Owner:山东润通橡胶有限公司

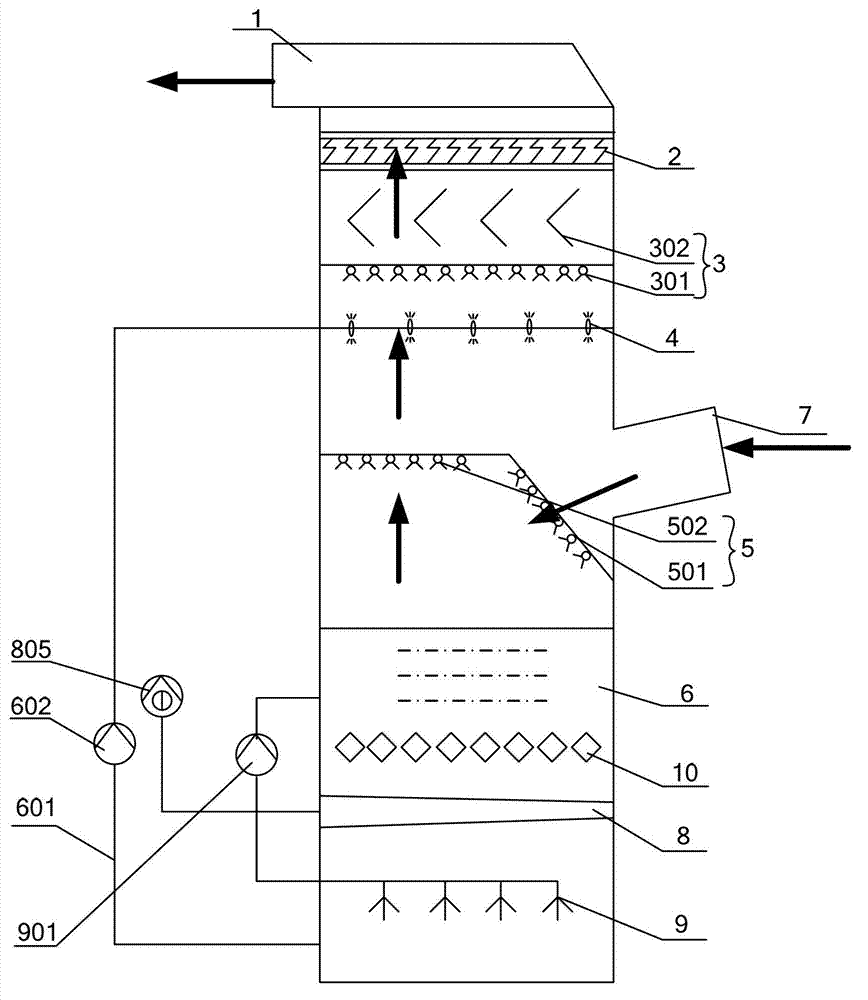

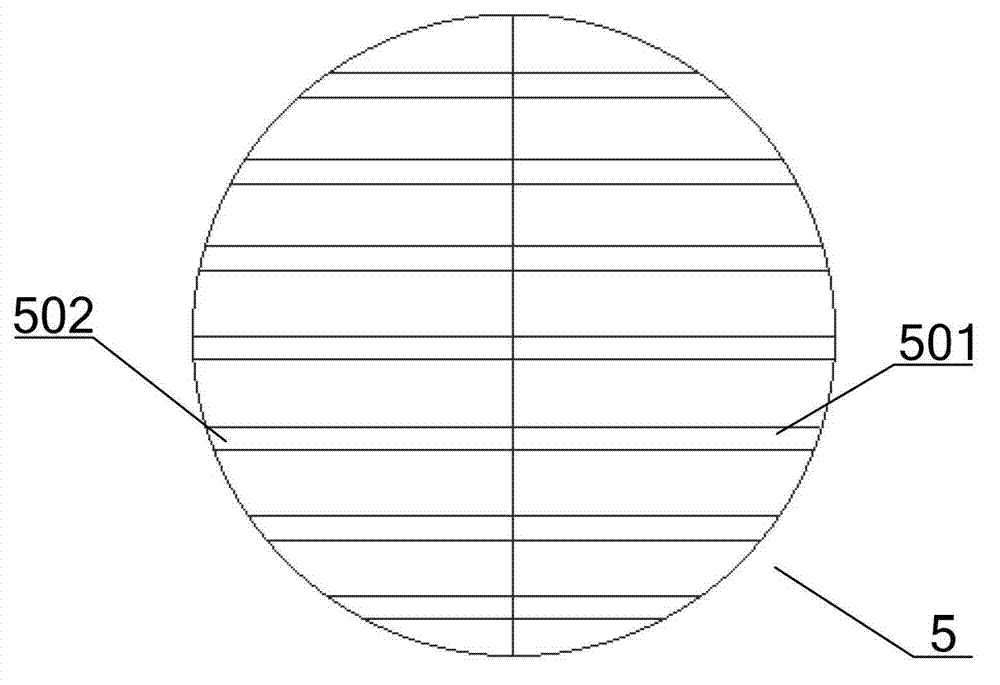

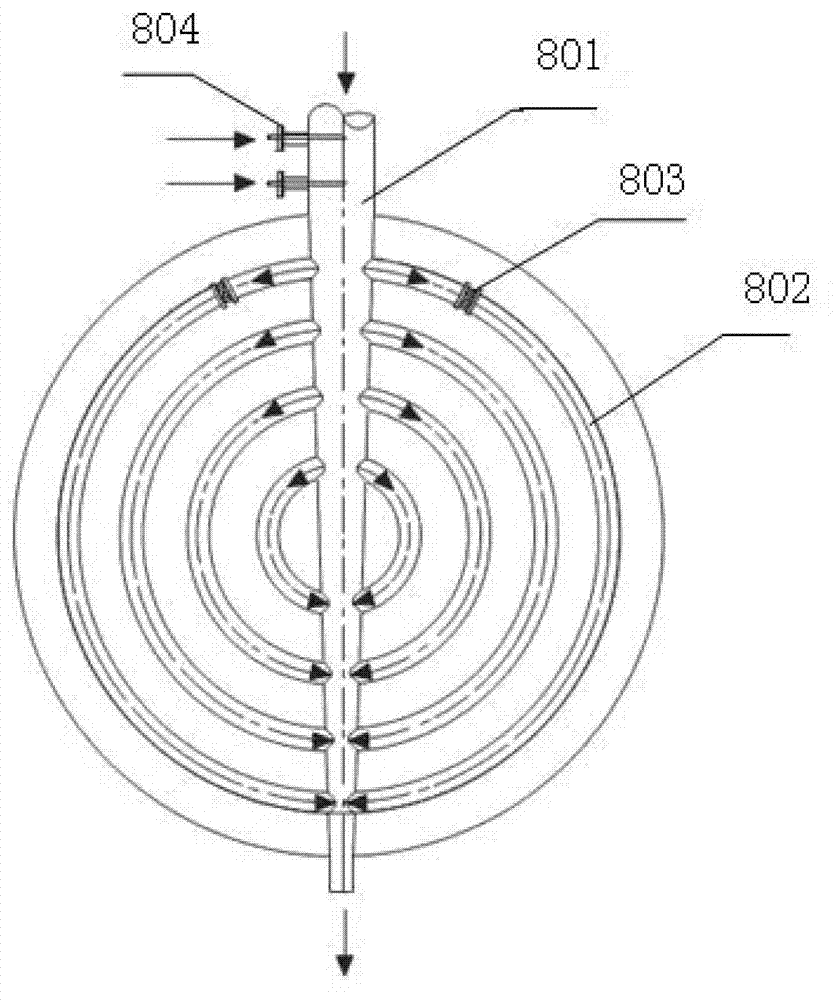

Removal tower and method for collaboratively desulfurizing and removing PM2.5 (Particulate Matter 2.5) in smoke

ActiveCN103041690AImprove purification efficiencyAchieve desulfurizationCombination devicesParticulatesInlet channel

The invention discloses a removal tower and a removal method for collaboratively desulfurizing and removing PM2.5 (Particulate Matter 2.5) in smoke. The removal tower is internally provided with a smoke outlet channel, a defogging device, a phase change condensing area, a slurry spraying layer, a first smoke humidifying device and a slurry tank which are arranged from top to bottom in sequence; the slurry tank is communicated to the slurry spraying layer through a slurry pipeline and a circulating pump; a smoke inlet channel is arranged between the slurry spraying layer and a first smoke humidifying device; an oxide-isolation device, an oxide air distributing device and a stirrer are arranged in the slurry tank from top to bottom in sequence; and the phase change condensing area comprises a second smoke humidifying device and a plurality of bent baffle plates. The removal tower is provided with a structure for desulfurizing and also has a structure for removing the PM2.5, and the two structures are distributed in the same removal tower; and the steam phase technology is carried out, so that the purposes of desulfurizing and removing the PM2.5 can be realized at the same time, and the purifying efficiency of the smoke can be improved; and furthermore, the whole removal tower is simple in structure, the floor space is saved, and the operation cost is reduced.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

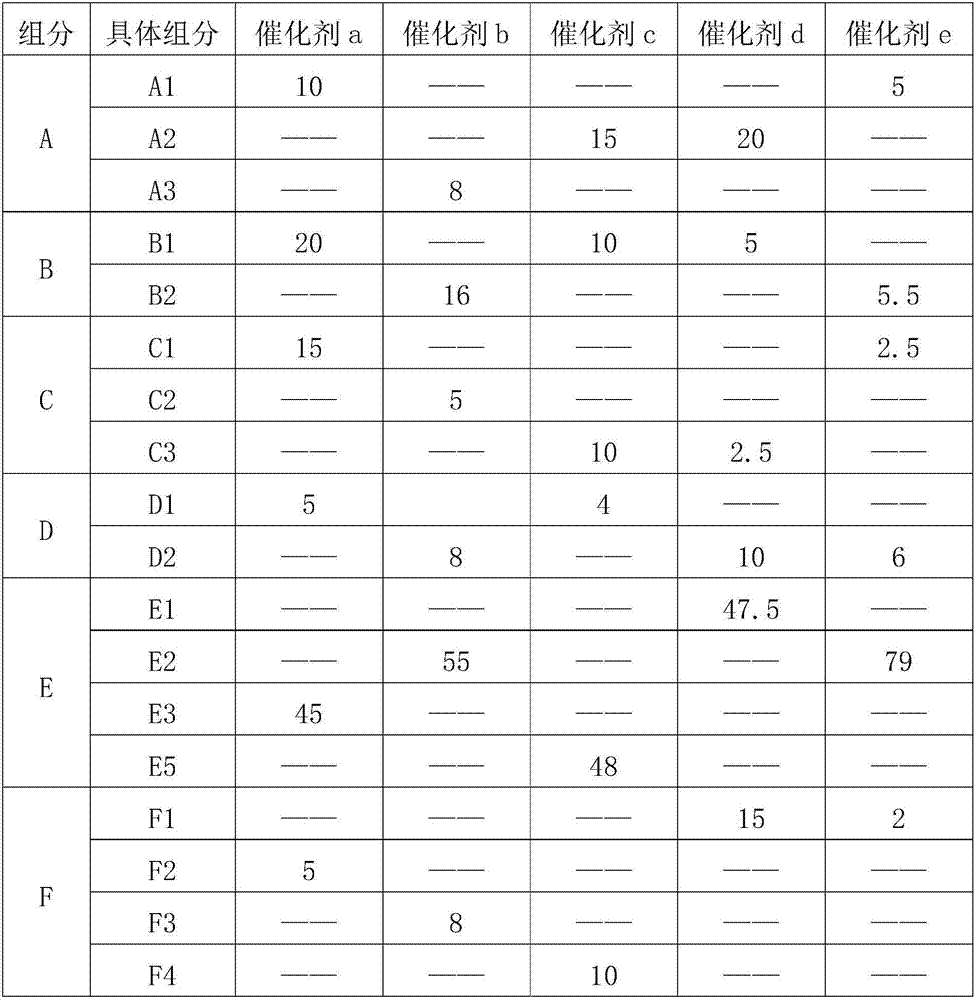

Catalyst for preparing gasoline blending component through alcohol-naphtha coupling, preparation method and application thereof

ActiveCN107952476AHigh yieldBoost octaneMolecular sieve catalystsCatalyst activation/preparationRare-earth elementRhenium

The invention relates to the technical field of catalysts for preparing gasoline, in particular to a catalyst for preparing a gasoline blending component through alcohol-naphtha coupling, a preparation method and application thereof. The catalyst comprises a metal modified molecular sieve, a rare earth element modified molecular sieve, one or multiple active components like platinum, palladium, tin and rhenium loaded on a carrier and two or three active components like nickel, molybdenum and tungsten. The catalyst has functions of isomerization, naphthene dehydrogenation, cracking, alkylation,aromatization and desulfurization and can effectively increase gasoline yield and octane value of gasoline and lower sulfur content.

Owner:SINOPEC ENG GRP CO LTD

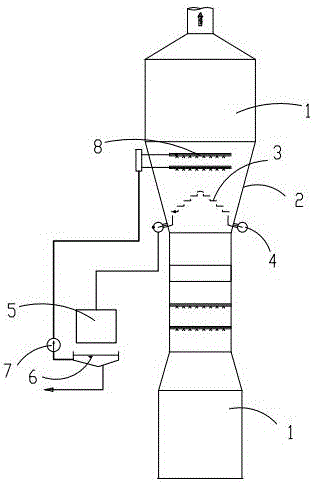

Process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in in-furnace calcium-spraying circulating fluidized bed

The invention discloses a process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in an in-furnace calcium-spraying circulating fluidized bed. The process comprises the following steps: gradually expanding a conical circulating fluidized bed of a hearth, carrying out partial air combustion on the deoiled asphalt on the lower part of the circulating fluidized bed, releasing heat for water vapor gasification on most of deoiled asphalt material; spraying a limestone desulfurization agent into a furnace, and carrying out desulfurization in a circulating fluidized bed furnace; feeding a synthesis gas generated by the circulating fluidized bed into a moving bed reactor; carrying out CO2 in-situ adsorption-enhanced water-gas shift reaction to prepare hydrogen; setting a water-gas shift moving bed reactor and a regenerator through the adsorption-enhanced water-gas shift reaction, so that successive and simultaneous movement, reaction and regeneration of an NiO / Al2O3 catalyst and an CaO adsorbent of adsorbing CO2 are carried out. By virtue of coupling of successive catalytic water-gas shifting and CO2 in-situ adsorption separation processes and enhanced water-gas shifting for heat and mass transfer, a high-purity hydrogen product can be continuously prepared by the synthesis gas from the circulating fluidized bed at 450-600 DEG C.

Owner:DALIAN UNIV OF TECH

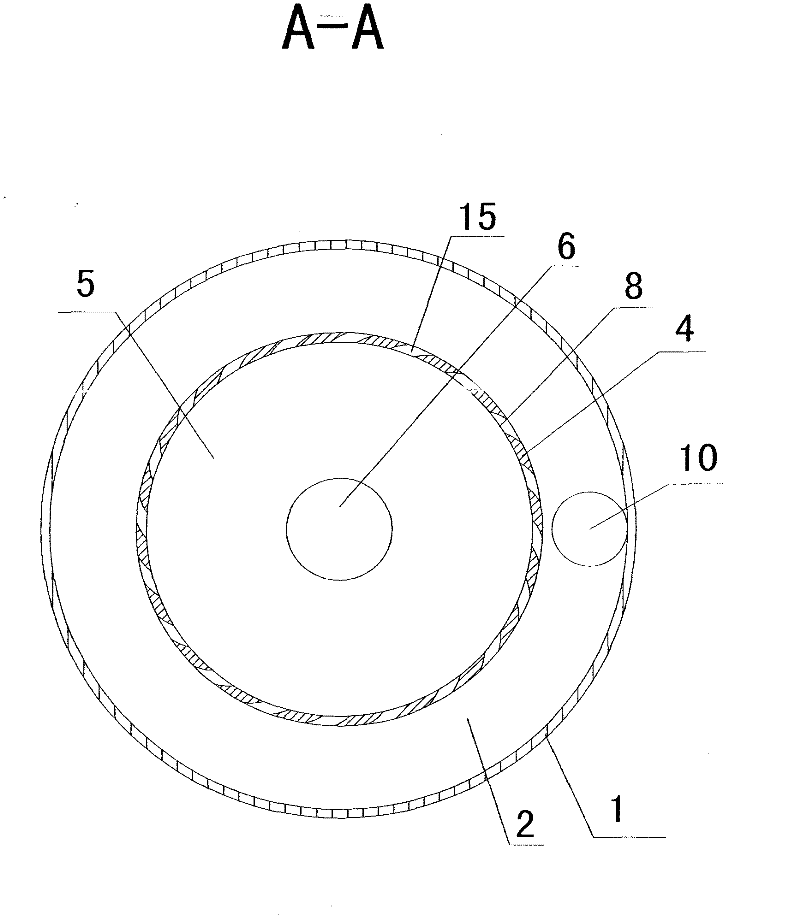

Separator

A separator comprises a casing; at least one casing cavity is arranged in the casing; a driving device is mounted on the casing; a vortex separating cylinder is arranged in the casing cavity; the driving device is connected with the vortex separating cylinder; a vortex separating chamber is arranged in the vortex separating cylinder; a fluid inlet is formed at one end of the vortex separating chamber; a plurality of vortex separating chamber outlets are formed on the periphery of the vortex separating chamber; a casing cavity inlet corresponds to the fluid inlet; and the casing cavity is provided with at least two casing cavity outlets. The separator can achieve the separation of fluid from vortex through adopting a brand-new separating principle and a brand-new separating method, making the best of the circular motion and the fluid motion, and utilizing vortex with the rotating speed progressively increased from the center to the periphery. The separator can be widely used in the fields such as sewage disposal, dust removal, dust absorption, garbage disposal, powder concentrating, mineral separation, seawater desalination, ocean chemical engineering, oxygen production, hydrogen production, nano material manufacturing, harmful gas resolving treatment, refrigeration, reactors, oil refining, metallurgy and the like, can provide clean energy, solves the energy problem and the environment pollution problem, and can thoroughly create an environment of blue sky, white cloud and clear water.

Owner:陈久斌

Flue gas desulfurization and dust-whitening integrated device

PendingCN106621724ASmall footprintLower overall investmentCombination devicesVapor condensationWater pipeElectrostatic precipitator

The invention provides a flue gas desulfurization and dust-whitening integrated device, comprising a desulfurizing tower, a whitening device communicated with a flue gas outlet of the desulfurizing tower, and a wet electrostatic precipitator which is arranged on the top of the whitening device and is communicated with the whitening device, wherein the whitening device comprises a device shell fixedly arranged above the desulfurizing tower, a water collector arranged in the device shell, and a spray device arranged above the water collector; a water collecting hole is formed in the device shell, and is communicated with a water collecting pipe; the water collecting pipe is communicated with a water cooling tower by a water collecting pipeline; the water cooling tower is communicated with a sedimentation tank; the upper part of the sedimentation tank is connected with a spray pipeline by a spray pump; the spray pipeline is communicated with the spray device; the bottom of the sedimentation tank is connected with a desulfurization pulping system by a sewage pump. After the device is used, the aim of whitening flue gas is achieved; spray water can be separately recycled, and water removed from the flue gas can be also recycled so as to be used for the desulfurization pulping system, so that the aim of saving water is achieved.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for removing slag before solvent extraction in process of producing industrial-grade phosphoric acid by wet-process phosphoric acid

The invention discloses a method for removing the slag before solvent extraction in the process of producing industrial-grade phosphoric acid by wet-process phosphoric acid. The method comprises the following steps of: procedures of solid-liquid separation and fine filtration, i.e., continuously conveying concentrated phosphoric acid slurry, which needs to be pretreated by desulfurization, defluorination and decolorization before extraction and purification of the phosphoric acid by an organic solvent and has 8-10% solid content, to a centrifugal machine, carrying out solid-liquid separation at a rotating speed of 1800-2500r / min, controlling the solid content in clear solution to be in 1%, and conveying solid slag into the next procedure for retreatment; and conveying the clear solution into fine filtration equipment for fine filtration, enabling the solid content in the clear solution to be less than 0.2%, and conveying refined acid to the organic extraction and purification procedures. The method adopts the two procedures of solid-liquid separation and fine filtration to enable the solid content in the treated acid slurry to be reduced below 0.2%, and be conductive to the obtainment of high-quality and high-added-value phosphoric acid products. The method has the advantages that the process is simple, the working is stable and reliable, solid slag in acid liquor can be effectively treated, simultaneously the purposes of desulfurization, defluorination and decolorization can be achieved, and the favorable conditions are created for extracting and purifying the phosphoric acid by the organic solvent.

Owner:KUNMING CHUAN JINNUO CHEM IND

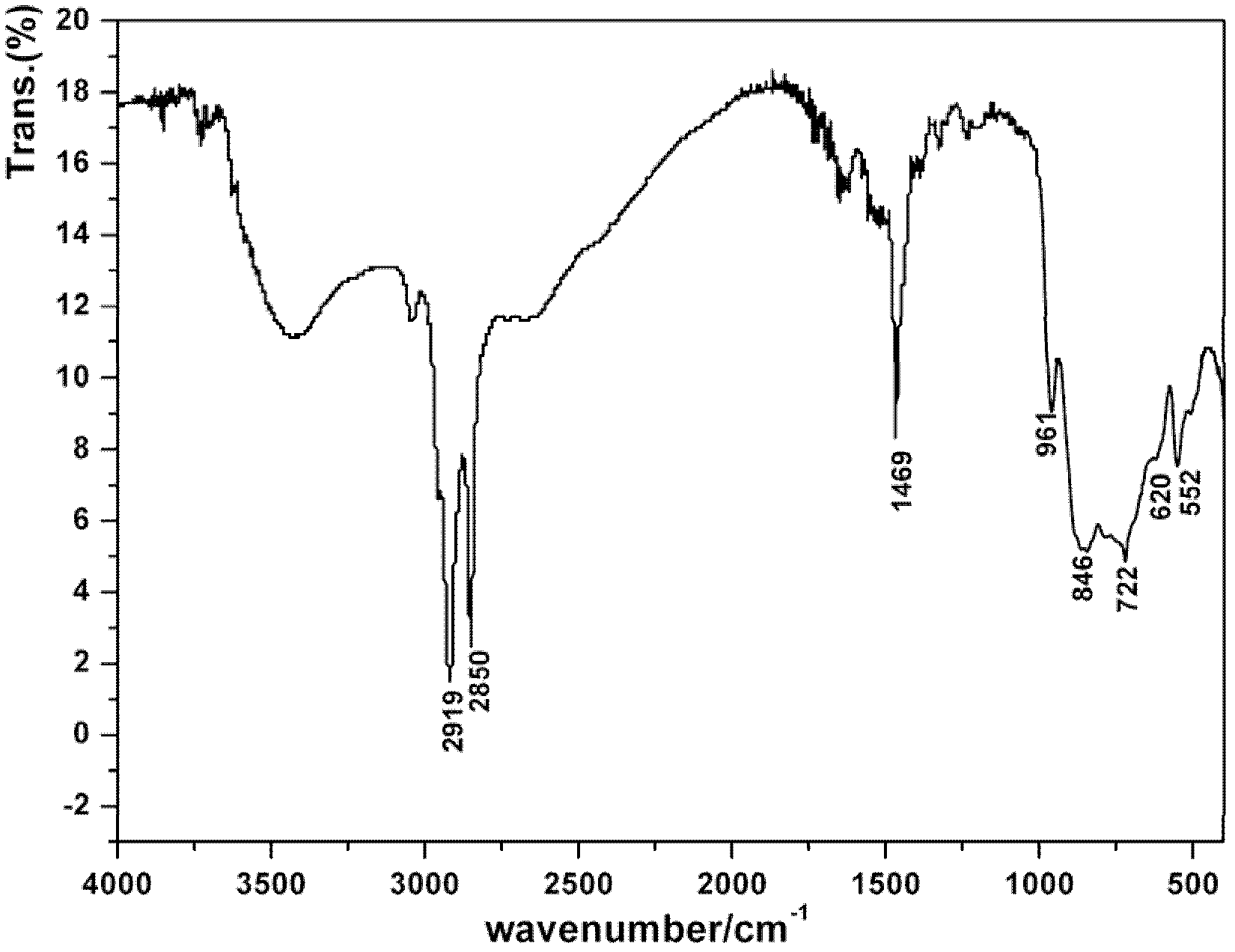

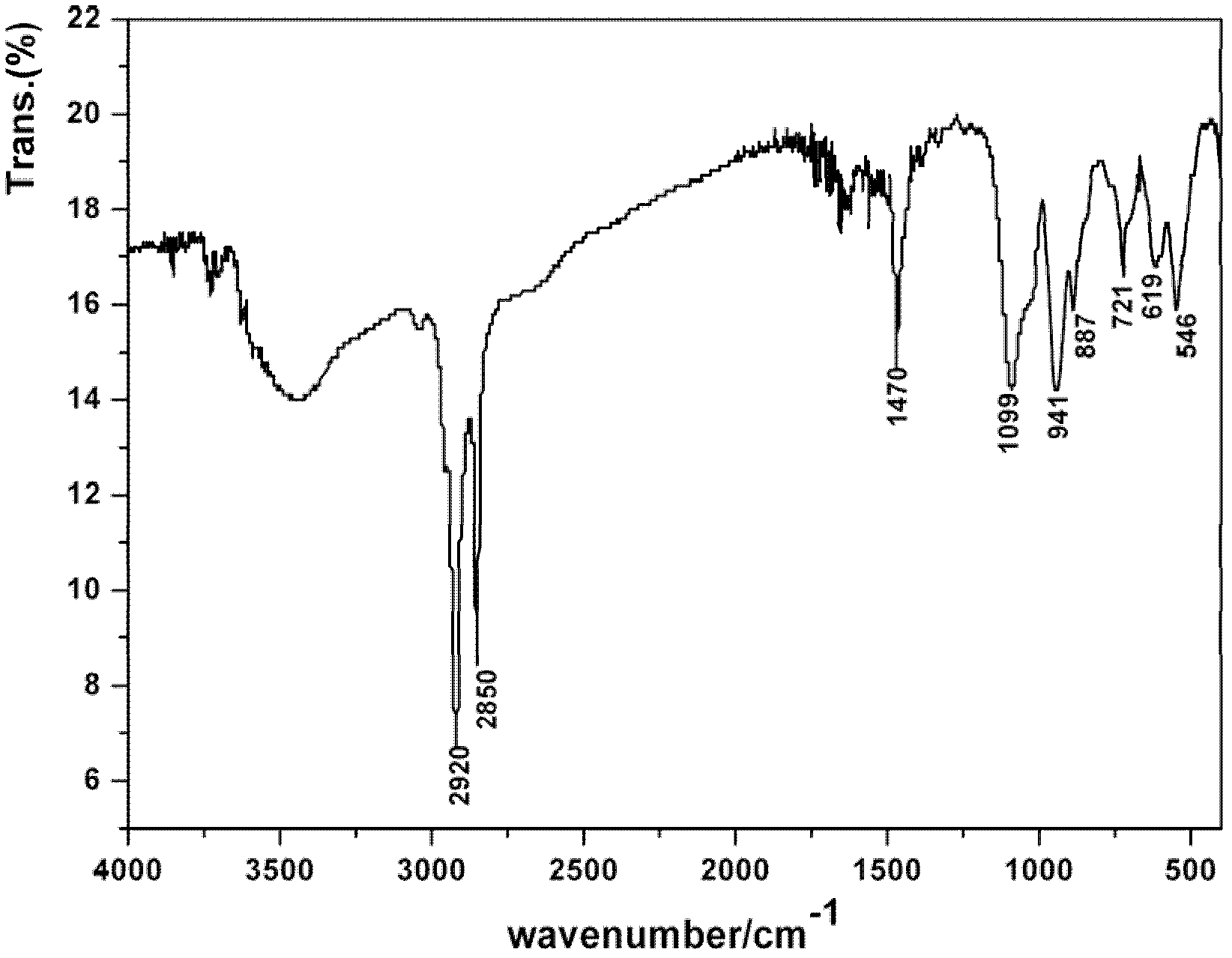

Desulfurization application method of super-deep oxidative desulfurization catalyst

InactiveCN102430428AEfficient oxidation capacityReduce desulfurization costOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPhosphoniumTransition metal atoms

The invention relates to a super-deep oxidative desulfurization catalyst and desulfurization application thereof. The super-deep oxidative desulfurization catalyst is an amphiphilic catalyst and has an expression of Qp[HqSexMyOz], wherein in the expression, p is an integer greater than or equal to 1, q is an integer greater than or equal to 0 and less than 2x and x is an integer greater than or equal to 1; y is greater than or equal to 2x and is less than or equal to 16x; z is greater than or equal to 3(x+y) and is less than or equal to 4x+5y; p is equal to 2x-q; Q represents surfactant cation which can be quaternary ammonium salt cation, alkyl pyridine salt cation, phosphonium cation, sulfonium cation and the like, generally quaternary ammonium salt cation with at least one alkyl chain of which the number of carbon atoms is not less than 4 is chosen; Se represents selenium atom which can be in the valence state of tetravalence or sexavalence; Se in a contrast catalyst can also be P, AS, S or Si of the highest valence, be blank, and the like, M represents transition mental atom which can be W, Mo, Ti, V, Mn, Ru, Cr, Fe, Co and the like, and generally can be W or Mo; and O represent oxygen atom. The catalyst in the invention can also be used for preparing an ultra-low-sulfur oil product with sulfur content of less than 5 ppm; implement conditions are mild; and the utilization rate of an oxidant is high.

Owner:NANJING UNIV

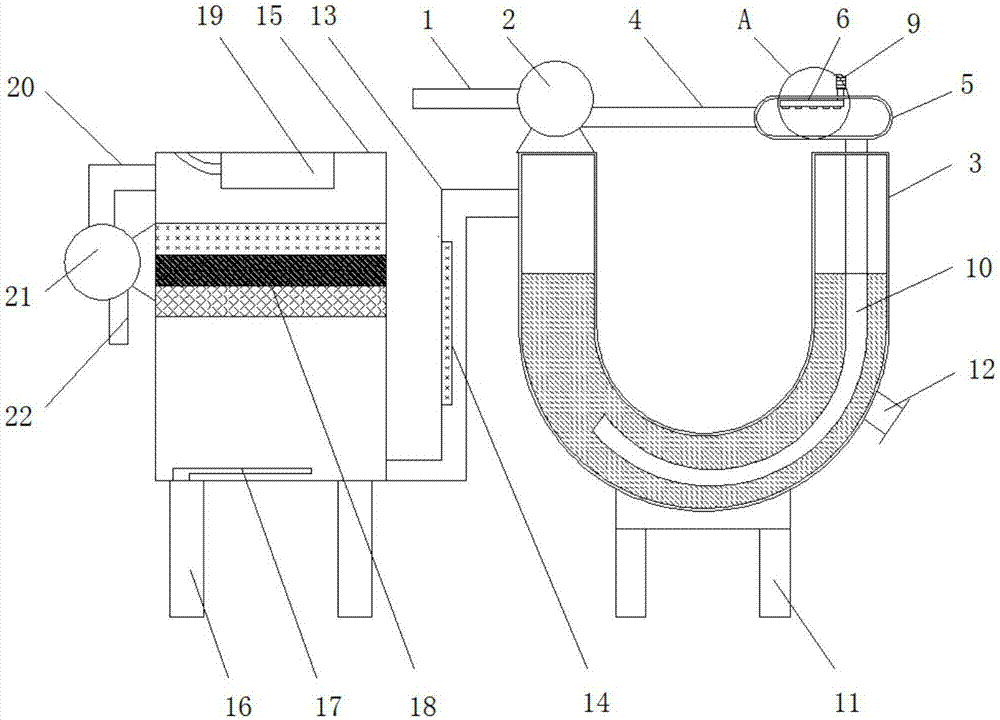

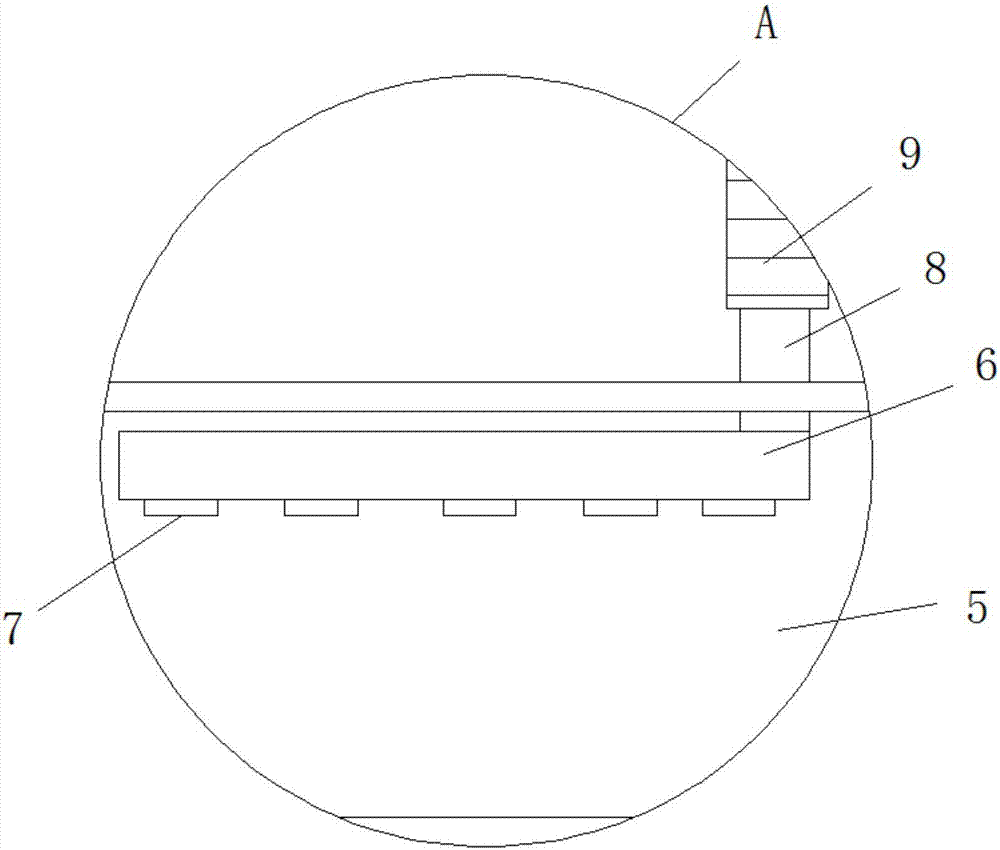

Waste gas treatment device having deodorization function

InactiveCN107497269AWith deodorizing functionAchieve desulfurizationCombination devicesOzone generatorSpray nozzle

The invention relates to the technical field of waste gas treatment, and discloses a waste gas treatment device having a deodorization function. The waste gas treatment device comprises a gas inlet pipe, wherein one end of the gas inlet pipe is fixedly connected with one side of a first gas extraction pump; the bottom part of the first gas extraction pump is fixedly connected to the top part of a U-shaped box; the other side of the first gas extraction pump is fixedly connected with one end of a first connection pipe; the other end of the first connection pipe is fixedly connected with one side of a spraying box; a spray pipe is arranged inside the spray box; the bottom part of the spray pipe is fixedly connected with the top parts of spray nozzles. According to the waste gas treatment device having the deodorization function disclosed by the invention, the spraying box fixedly connected to one end of the first connection pipe and the U-shaped box spliced in the bottom part of an elbow pipe are matched with a filter layer fixedly connected with an inner wall of a filter box and an ozone generator fixedly connected with the top part of the inner wall of the filter box, so that sulfide in waste gas is absorbed, odour in the waste gas is removed, and desulfurization and deodorization effects can be achieved.

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

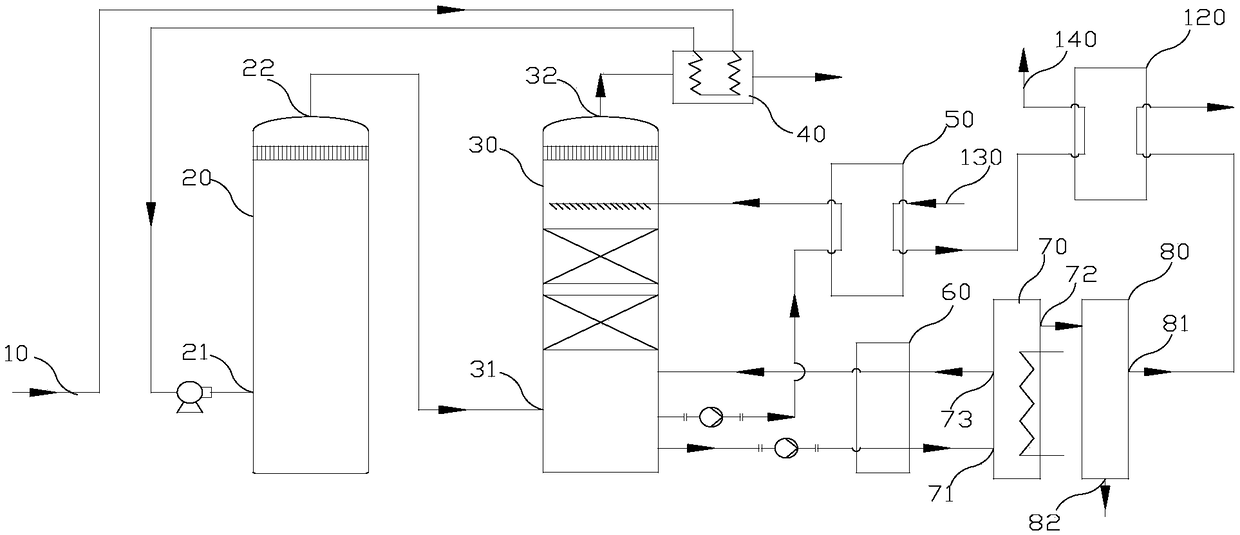

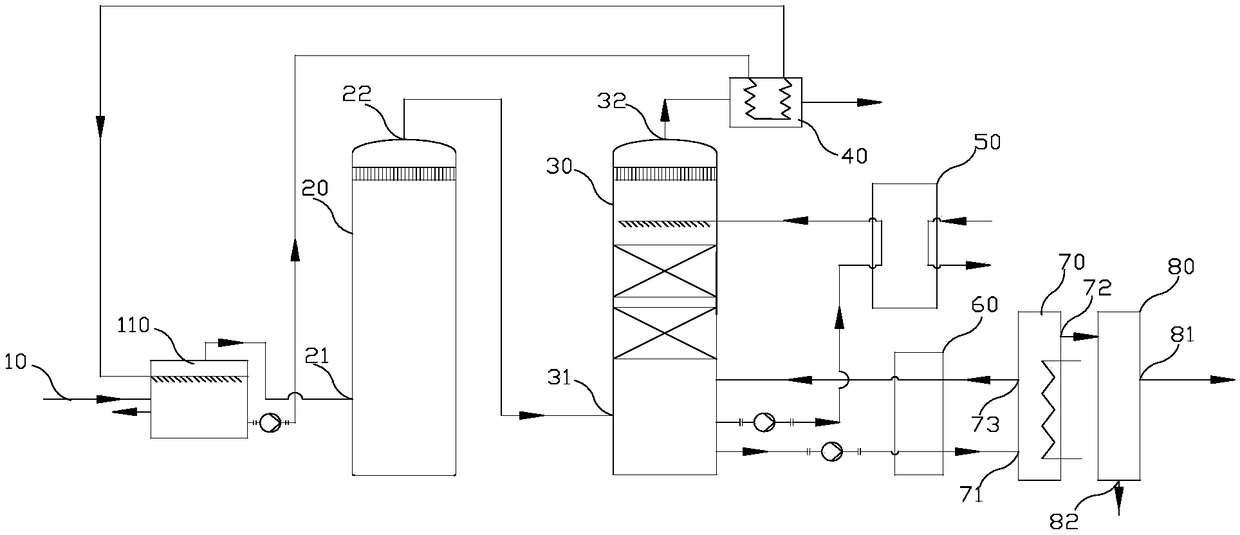

Integrated system for industrial flue gas desulfurization and dewhitening and method thereof

PendingCN109248552AAdjust usageAdvanced technologyGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses an integrated system for industrial flue gas desulfurization and dewhitening and a method thereof. The integrated system comprises a desulfurization tower, a de-whitening unitand a flue gas heat exchanger; the desulfurization tower is provided with a first flue gas inlet and a first flue gas outlet, and the de-whitening unit is provided with a second flue gas inlet and a second flue gas outlet; the flue gas heat exchanger is configured for dividing-wall transmission of the heat of the industrial flue gas in an industrial flue gas conveying pipeline to the second flue gas outlet to discharged the dried gas, and then the industrial flue gas is send to the first flue gas inlet; the first flue gas outlet is in communication with the second flue gas inlet; the de-whitening unit is provided with a first circulation loop and a second circulation loop; a regeneration device is arranged at the first circulation loop; and a self-circulating heat exchanger is arranged onthe second circulation loop; wherein the type of self-circulating heat exchanger is a dividing wall heat exchanger and is used for cooling the absorbing liquid flowing therethrough. The integrated system and the method thereof have low heat energy consumption, and can reduce the dew point of the gas at the outlet.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

Sintering furnace waste gas treatment device

ActiveCN108592643AAchieve desulfurizationAvoid pollutionHuman health protectionDispersed particle filtrationCombustionCylinder block

The invention relates to the technical field of waste gas treatment equipment, and particularly discloses a sintering furnace waste gas treatment device. The sintering furnace waste gas treatment device comprises a furnace body, a first cylinder body, a filtering chamber and a spraying chamber; a smoke exhaust pipe is connected to the top of the furnace body and provided with a buffering cavity, arotation shaft is rotatably connected to the side wall of the buffering cavity, a cam and a plurality of blades are coaxially and fixedly connected to the rotation shaft, the blades are located in the buffering cavity, and a jetting nozzle used for jetting flames is installed on the inner wall of the buffering cavity; a first piston is slidably connected to the interior of the first cylinder body, a first piston rod is fixedly connected to the first piston and abuts against the cam, and a gas outlet pipe is arranged between the first cylinder body and the buffering cavity in a communicating mode; and the smoke exhaust pipe is connected to the filtering chamber, and an exhaust pipe is arranged between the filtering chamber and the spraying chamber in a communicating mode. According to thesintering furnace waste gas treatment device, waste gas can be fully combusted in the buffering cavity, smoke dust is removed after the waste gas obtained after combustion is filtered through the filtering chamber, the waste gas obtained after the smoke dust is removed is subjected to spraying desulfurization through the spraying chamber, and then the finally-exhausted waste gas does not contain the smoke dust and sulphur and can not pollute the environment.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

Method for recycling metal lead from lead-containing material such as lead sulfate slag

ActiveCN110923468AEfficientWith energy savingPhotography auxillary processesProcess efficiency improvementMethane sulfonic acidSlag

The invention provides a method for recycling metal lead from a lead-containing material such as lead sulfate slag. The problems that when metal lead is recycled from a lead-containing material such as lead sulfate slag in the prior art, energy consumption is high, cost is high, pollution is severe, the application range is limited, potential safety hazards exist, and metal cannot be sufficientlyutilized are solved. According to the method, the lead in the lead-containing material such as the lead sulfate slag is recycled in the following steps of (1) a chlorination leaching process; (2) a sodium carbonate conversion process; (3) a methane sulfonic acid leaching process; (4) an electrodeposition process; and (5) a melting-casting process

Owner:赵坤

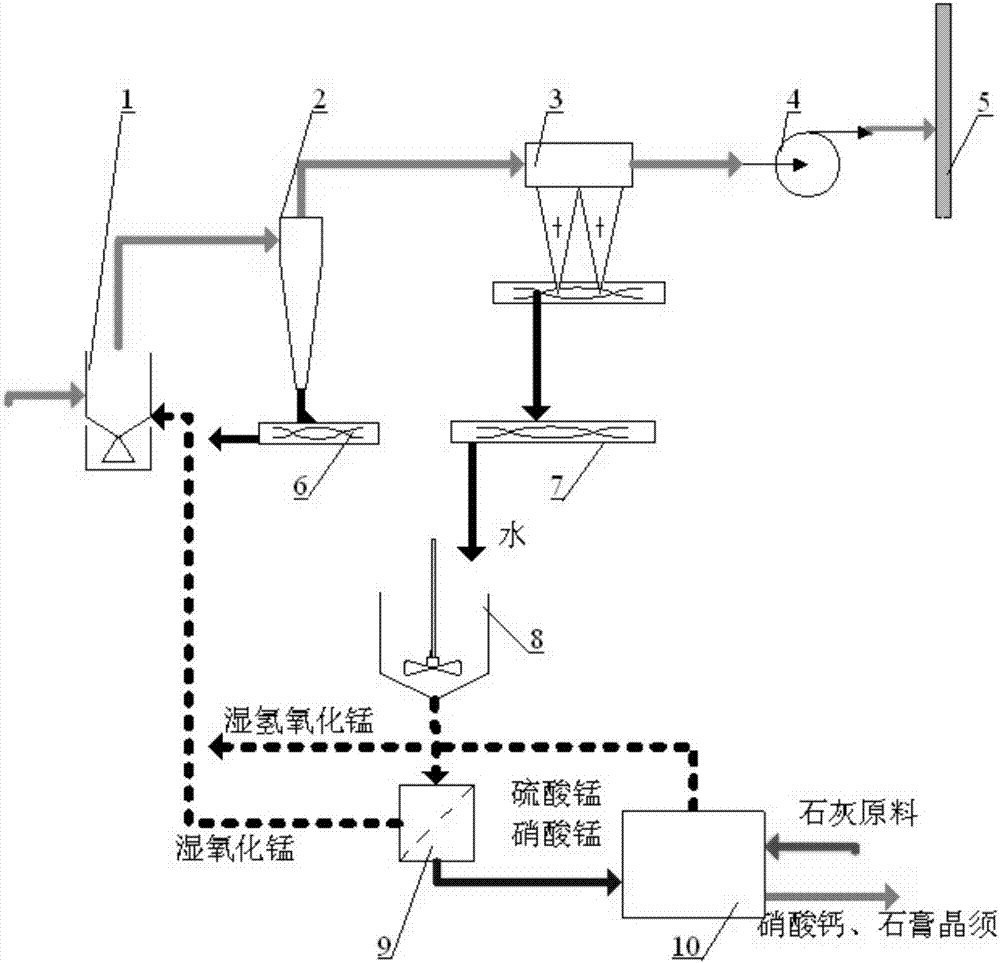

Dry-type deep flue gas desulfurization and denitration integrated method taking manganese hydroxide as circulating work medium

ActiveCN106861410AAchieve desulfurizationRealize the denitrification taskCombination devicesGas treatmentChemical productsManganese oxide

The invention discloses a dry-type deep flue gas desulfurization and denitration integrated method taking manganese hydroxide as a circulating work medium. The method comprises the steps of replenishing a reactor, containing the manganese hydroxide, with flue gas; enabling the manganese hydroxide to react with oxygen in the flue gas at the temperature within a temperature range of 160-50 DEG C so as to generate manganese oxide MnOx (x is more than 1 and less than or equal to 2); meanwhile, enabling the manganese hydroxide to absorb SO2 and NOx in the flue gas and immediately react with the SO2 and the NOx to generate manganese sulfate and manganese nitrate; enabling an alkaline substance to react with the manganese sulfate and the manganese nitrate which are dissolved in water so as to prepare manganese hydroxide again for circulating desulfurization and denitration, wherein the by-products such as sulfate and nitrate produced in the regeneration reaction are useful chemical products. The method can be used for completely removing the SO2 in the flue gas only by using alkaline raw materials such as lime having wide sources and low price, and has the NOx removal rate of 90% or above; the by-products of the method are sulfate and nitrate products which are marketable, so that economic benefit is obtained; furthermore, a recycling and economic dry-type desulfurization and denitration process route is added for the clean utilization of fossil fuel and the atmospheric environment protection.

Owner:QINGDAO UNIV OF SCI & TECH

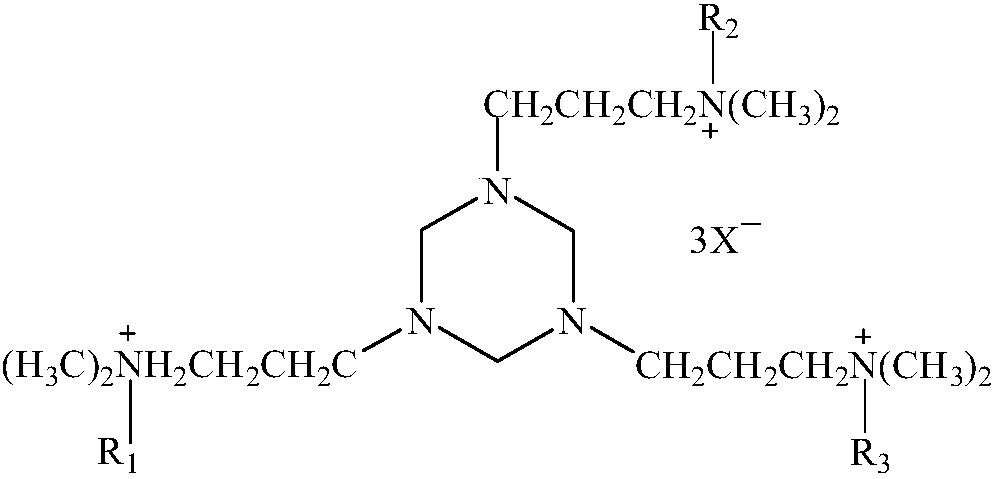

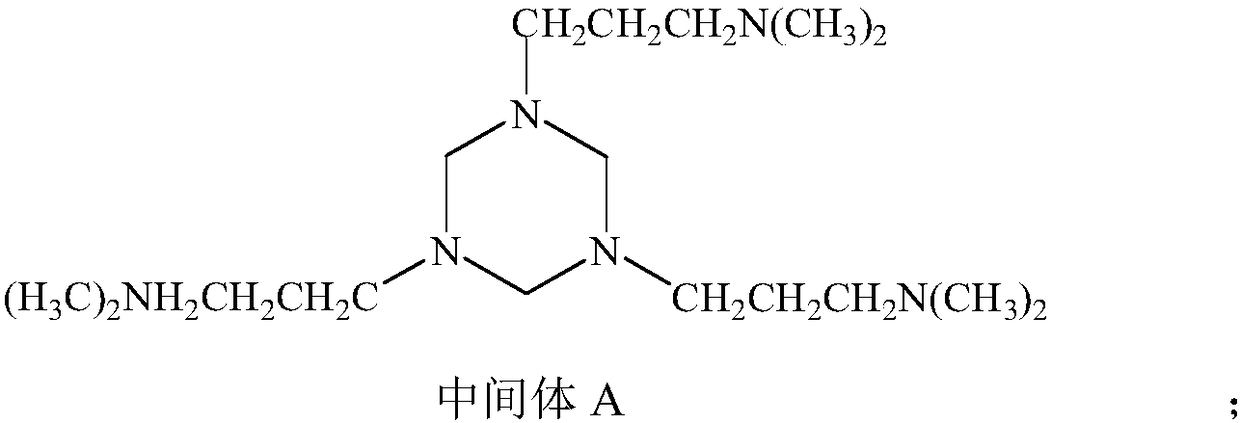

Trimeric quaternary ammonium salt type oil field sterilizing desulfurizer and preparation method thereof

InactiveCN109231291AImprove the bactericidal effectHarm reductionWaste water treatment from quariesBiocideChemical reactionDisinfectant

The invention belongs to the technical field of wet hydrogen sulfide removal during oil and gas field exploitation and gathering processes, and particularly relates to a trimeric quaternary ammonium salt type oil field sterilizing desulfurizer and a preparation method thereof. The trimeric quaternary ammonium salt type oil field sterilizing desulfurizer comprises the following components in percentage by weight: 20-50% of a trimeric quaternary ammonium salt compound, 10-30% of an organic aldehyde compound, 5-20% of a pour point depressant and the balance of water, wherein the sum percentage ofthe components is 100%. Combined with the characteristics of oil field sewage, the trimeric quaternary ammonium salt type oil field sterilizing desulfurizer not only improves the bactericidal effecton SRB bacteria, but also directly chemically reacts with secondary hydrogen sulfide, reduces the harm of the SRB bacteria to metal equipment, pipelines and stratums, and also solves the compatibilityproblem between an on-site disinfectant and the desulfurizer during on-site use.

Owner:陕西日新石油化工有限公司

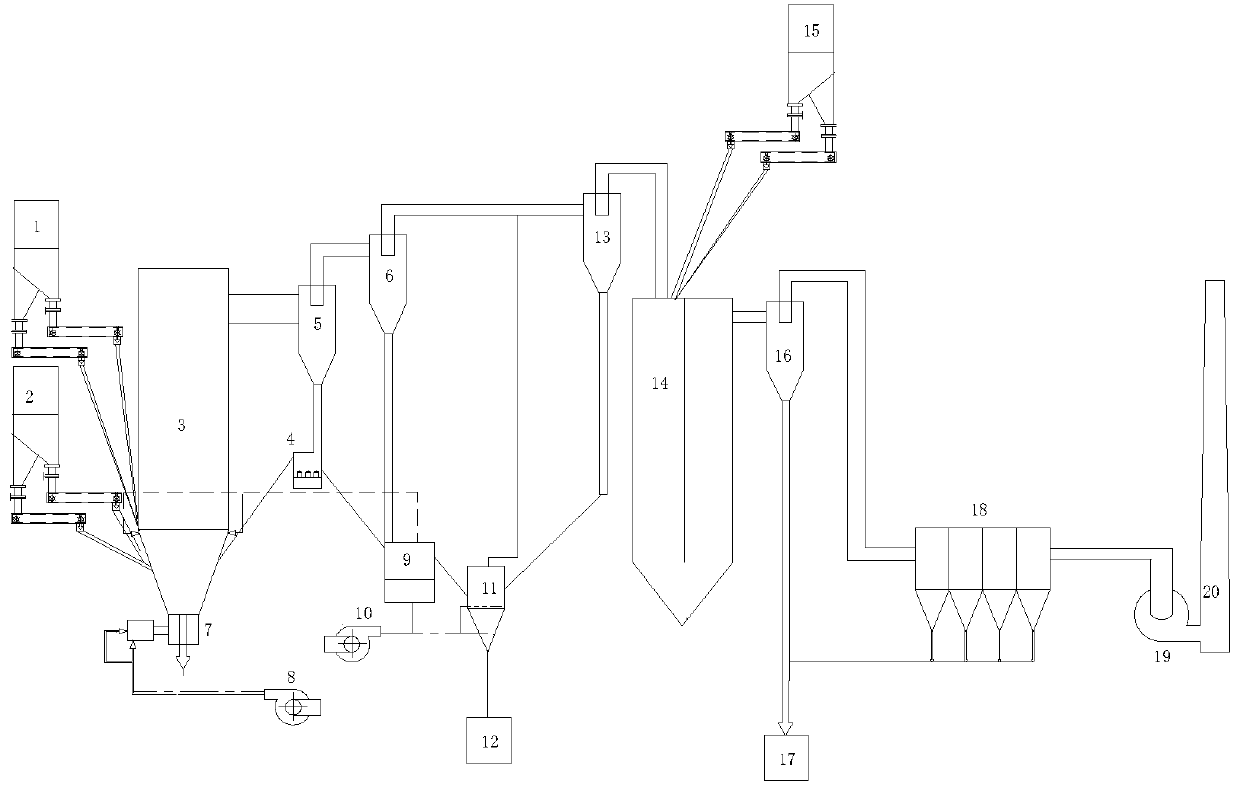

Phosphogypsum circulating fluidized bed reduction roasting comprehensive utilization process and device thereof

The invention discloses a phosphogypsum circulating fluidized bed reduction roasting comprehensive utilization process and a device thereof. The device comprises a circulating fluidized bed reactor body provided with a slag discharging opening. An air inlet is formed in the bottom of the circulating fluidized bed reactor. A coal feeding hole, a phosphogypsum / mineral mixture inlet, a circulating material inlet and a secondary air inlet are respectively formed in the lower part of a dense-phase zone; a flue gas outlet is formed in the top of the circulating fluidized bed reactor; a primary cyclone separator is connected with a circulating material inlet and a first-stage fluidized bed cooling device; a flue gas outlet of the primary cyclone separator is connected with a secondary cyclone separator; the lower portion of a second-stage separator is connected with the first-stage fluidized bed cooling device; a flue gas outlet of the secondary cyclone separator is connected with a third-stage cyclone separator; the lower portion of the third-stage cyclone separator is connected with a second-stage fluidized bed cooling device; and meanwhile the first-stage fluidized bed cooling device is connected with the second-stage fluidized bed cooling device. The invention aims to realize activation of a phosphogypsum / tailing mixture under a reduction roasting condition at a temperature of about 850 DEG C by blending phosphogypsum / tailing mixed raw material components. Therefore, the efficient roasting technology and the device are the key to efficient and clean utilization of the phosphogypsum / tailings mixed raw materials. On the other hand, semi-hydrated gypsum is a good building material and has a good application market at present. Therefore, the application value of the phosphogypsum can also be improved by making the existing water-containing gypsum into the semi-hydrated gypsum through processes such as drying and the like.

Owner:车建青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com