Rotary kiln flue gas treating device capable of automatically controlling blowing rate of draught fan

A technology for flue gas treatment and fan air volume is applied in the field of flue gas treatment equipment to achieve the effects of improving yield, reducing dust loss and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

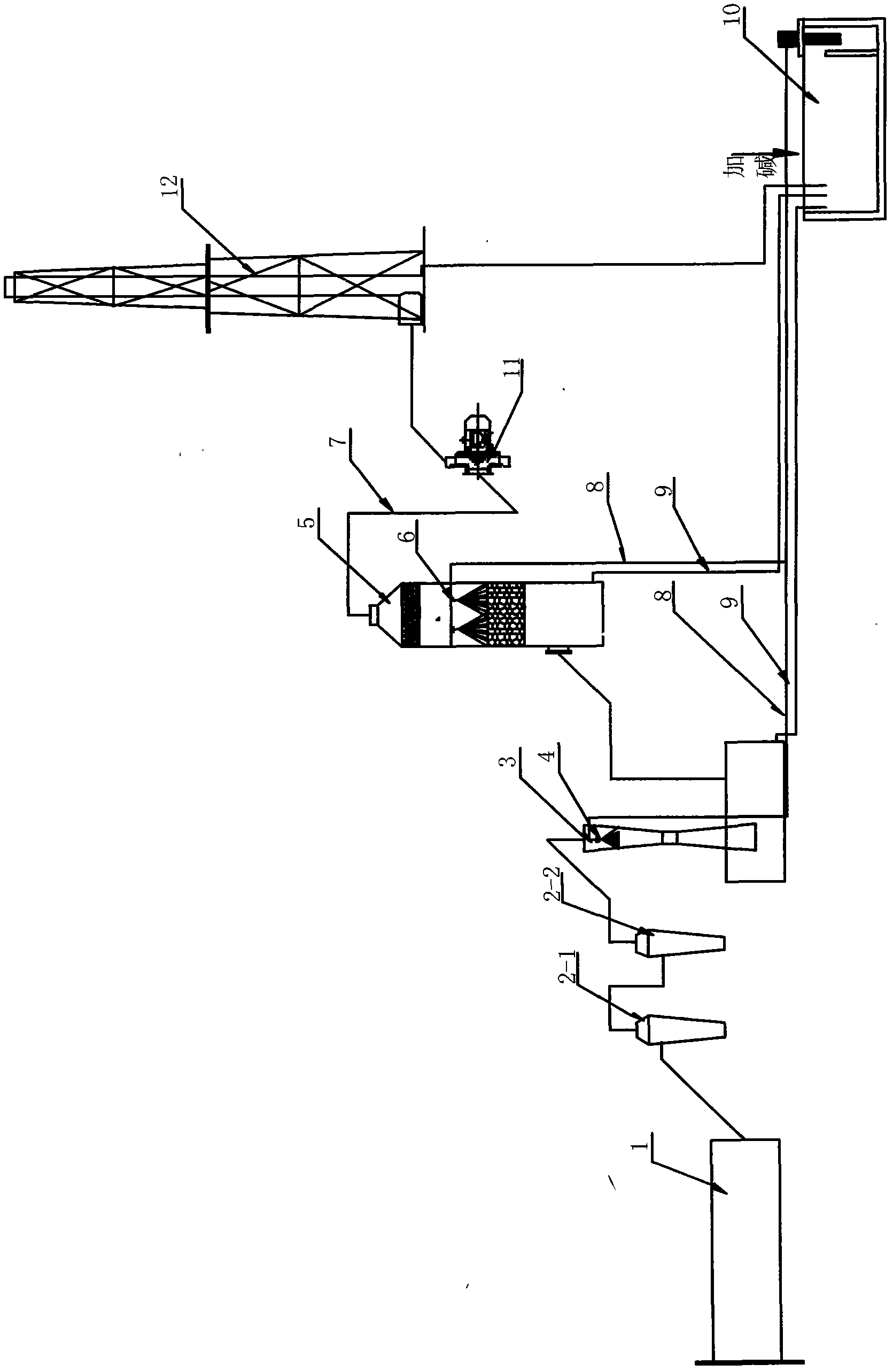

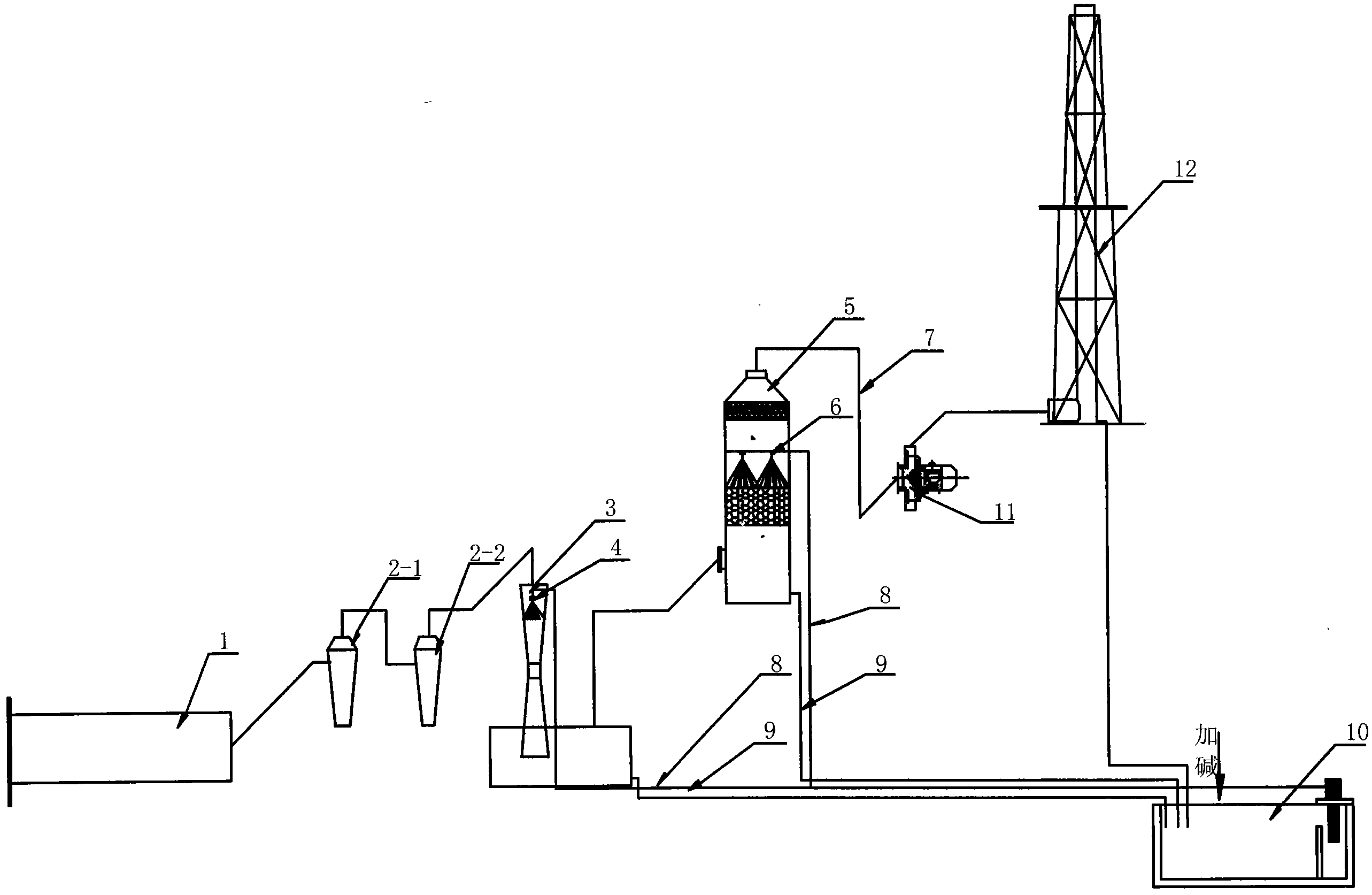

[0014] refer to figure 1 , a rotary kiln flue gas treatment device that automatically controls the air volume of the fan, including a primary cyclone dust collector 2-1, a secondary cyclone dust collector 2-2, a venturi tube dust collector 3, an acid mist scrubber 5, a cooling sedimentation tank 10, The induced draft fan 11; the air inlet of the primary cyclone dust collector 2-1 is connected to the rotary kiln 1 through pipelines, the air outlet of the primary cyclone dust collector 2-1 is connected to the air inlet of the secondary cyclone dust collector 2-2, and the secondary cyclone dust collector The air outlet of device 2-2 is connected to the air inlet of Venturi dust collector 3, the air outlet of Venturi dust collector 3 is connected to the air inlet of acid mist scrubber 5, and the air outlet of acid mist scrubber 5 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com