Patents

Literature

59results about How to "Effective corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nanometer zirconia heat barrier coating

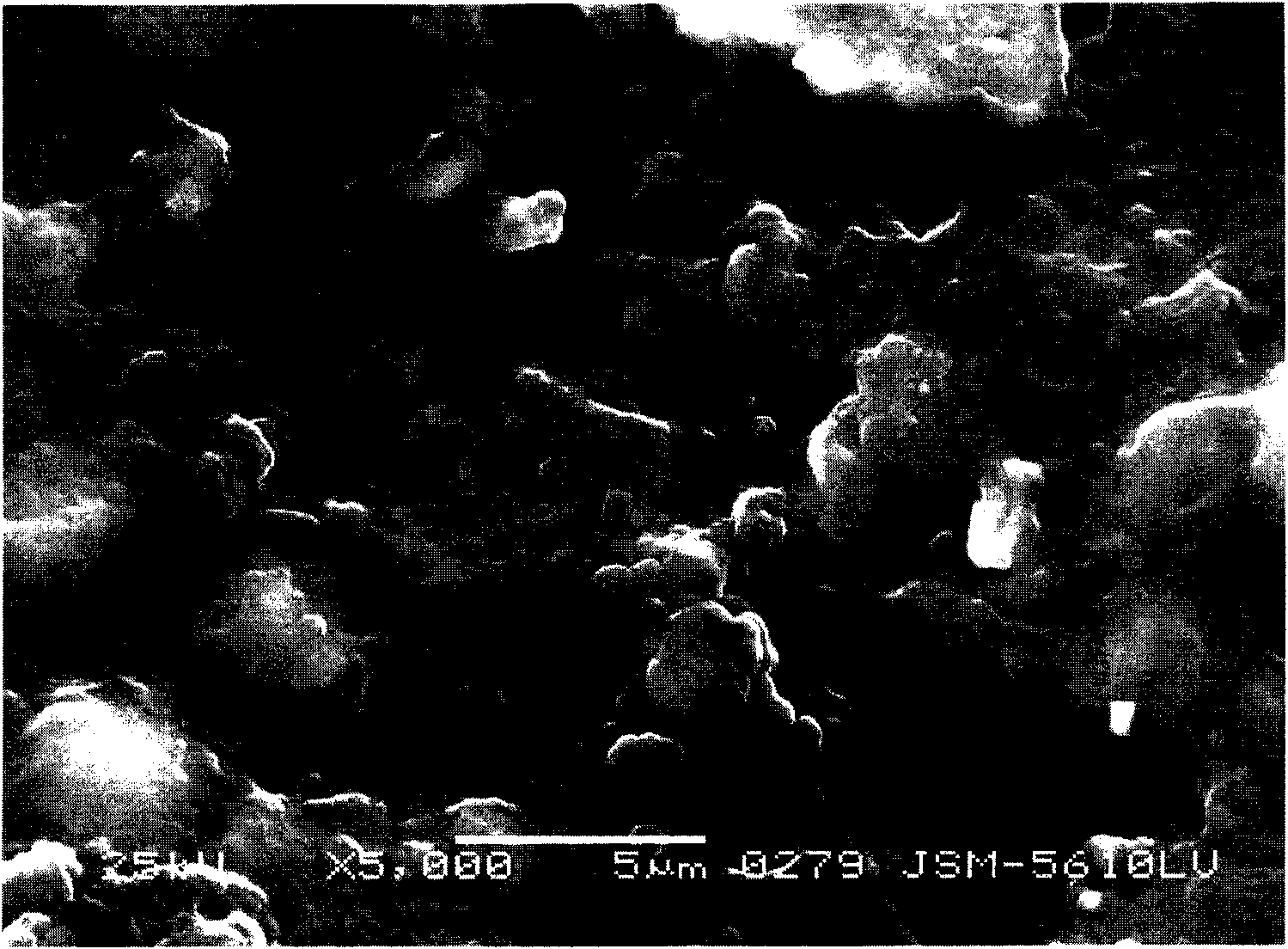

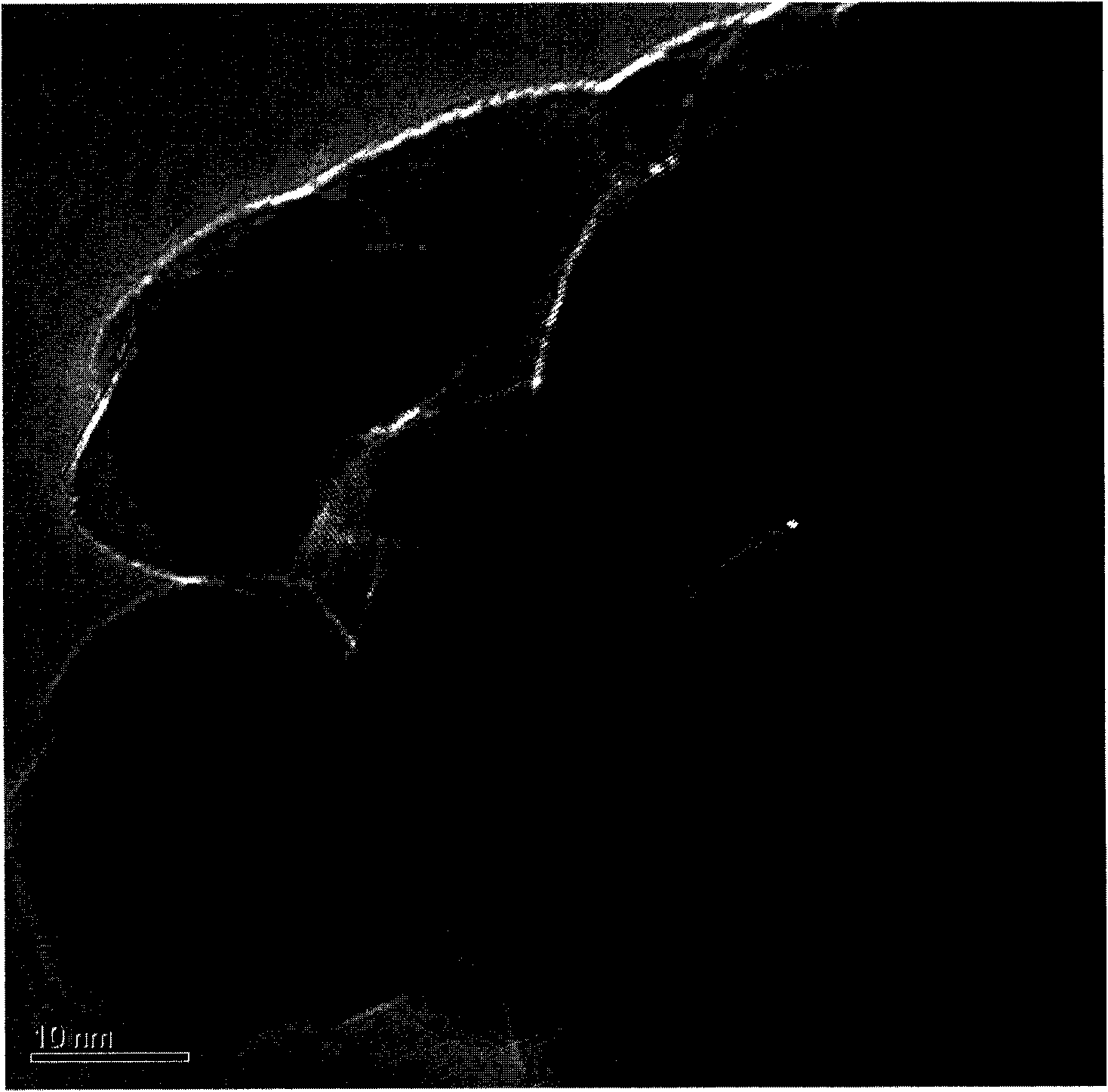

InactiveCN101660115AImprove applicabilityGood dispersionMolten spray coatingEfficient propulsion technologiesRare earthShock resistance

The invention relates to a preparation method of a nanometer zirconia heat barrier coating which is mixed with rare-earth oxide and used for liquid-phase plasma spraying. The method comprises that precursor sol is used as a spraying raw material, atomized into fine liquid drops under atomized gas pressure, sent into plasma flame flow and sprayed and deposited on a matrix to obtain the nanometer zirconia heat barrier coating. The precursor sol is hydroxid precursor sol. According to weight proportion, the raw material includes 63 to 73 percent of ZrOCl2.8H2O and 27 to 37 percent of crystalline-state stabilizer oxide which is rare earth oxide. The invention can overcome the problems of poor sol distribution, poor sol flowing performance, chlorid ion erosion, poor sol granule atomizing effect, uneven granule sizes, and the like in the the traditional liquid-phase plasma spraying process. In the invention, a composite coating is prepared, and has the advantages of high depositing efficiency, low cost, wide spraying material, strong adaptability of the liquid-phase precursor, low heat conductivity, good heat and shock resistance, and the like.

Owner:WUHAN UNIV OF TECH

Corrosion inhibitor composition applicable for aluminum and steel protection and procedure

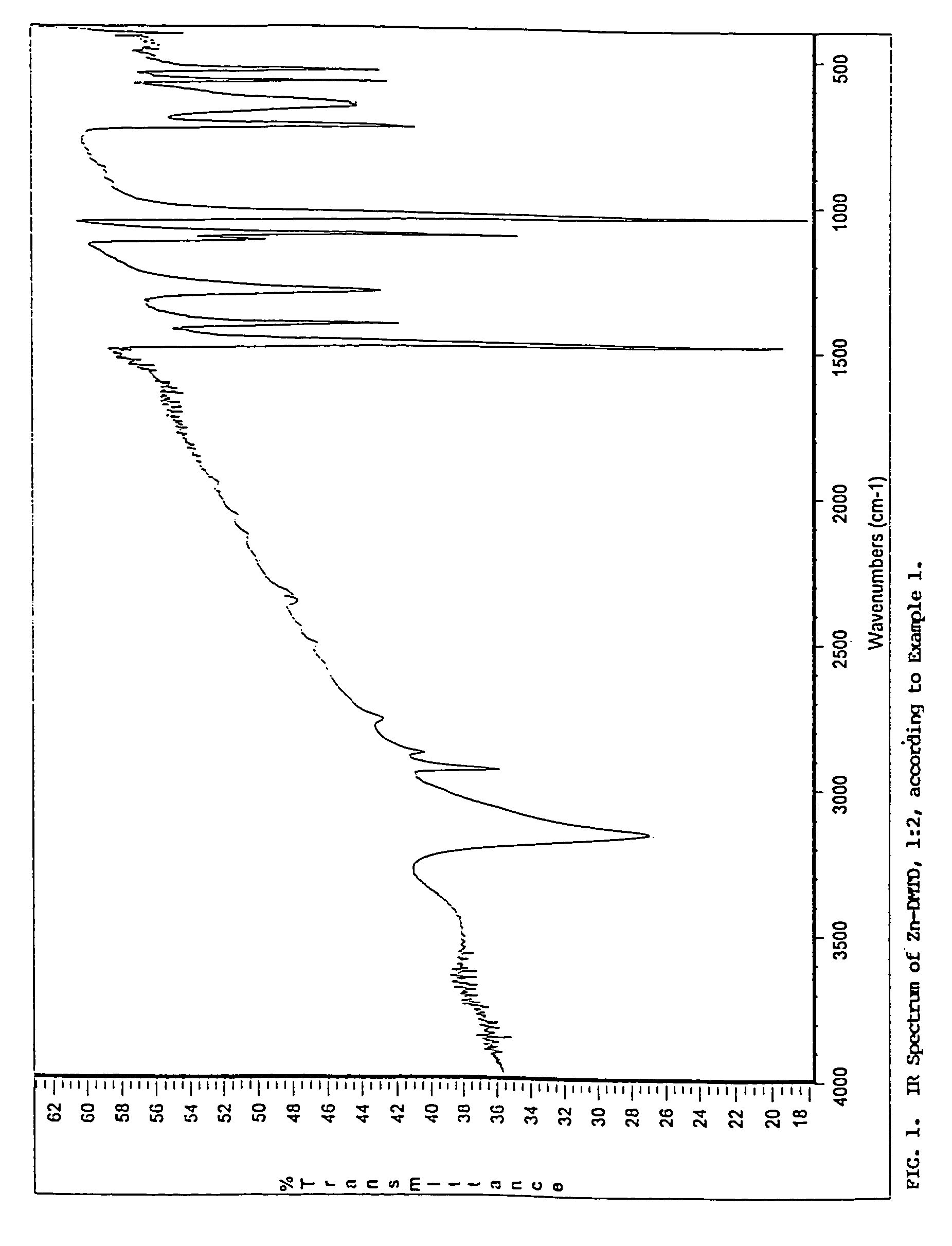

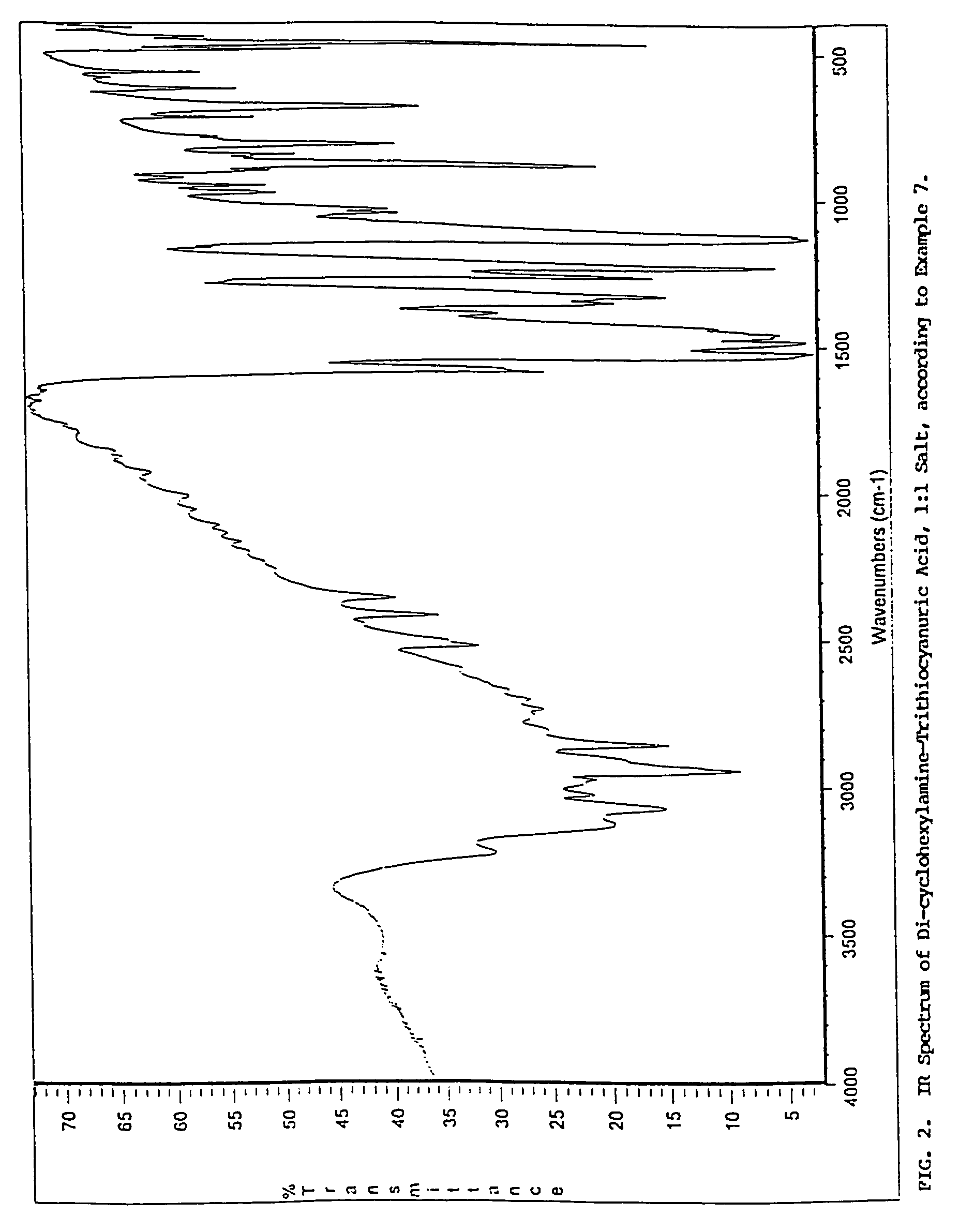

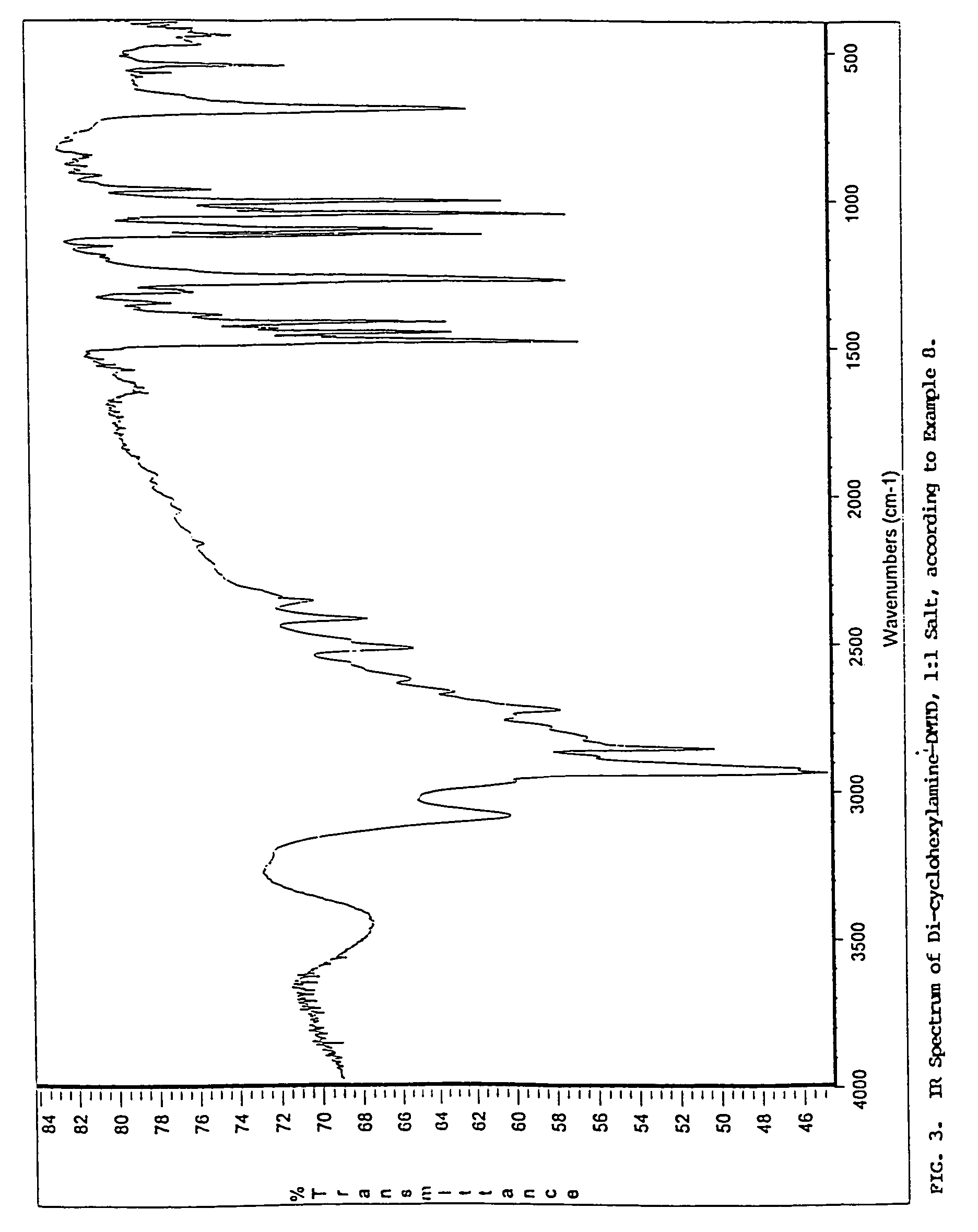

InactiveUS7662241B2High chemistryEffective corrosionOther chemical processesSolid state diffusion coatingMolybdatePhosphate

A corrosion-inhibiting composition for application to a metal substrate, such as aluminum or steel, and in connection with a paint, and the synthesis of the composition. The active inhibitor constituent of the composition can be selected from the group consisting of 2,5-dimercapto-1,3,4 thiadiazole (DMTD), 2,4-dimercapto-s-triazolo-[4,3-b]-1,3-4-thiadiazole, trithiocyanuric acid (TMT), and derivatives of DMTD and TMT, including various N— or S— and N, N—, S— and N—,S-substituted derivatives of DMTD, including salts of DMTD of the general formula: M(DMTD)n, where n=1,2 or 3, and M is a metal cation and preferably M=Zn(II), Bi(III), Co(II), Ni(II), Cd(II), Pb(II), Ag(I), Sb(III), Cu(II), Li(I), Ca(II), Sr(II), Mg(II), La(III), Ce(III), Pr(III), Al(III) or Zr(IV). DMTD, TMT, and their derivatives may also be combined with phosphates, molybdates, borates, silicates, tungstates, phosphotungstates, phosphomolybdates, cyanamides, carbonates, SiO2 and mixtures thereof.

Owner:LUMIMOVE

Method of fabricating a copper damascene structure

InactiveUS6660639B2Reducing copper polishing rateRetard the corrosion of said copper linesOther chemical processesSemiconductor/solid-state device manufacturingSlurryCopper

The present invention provides a method of removing copper overlaying a tantalum-based barrier layer during the fabrication of a copper damascene structure having a plurality of copper lines. The method includes providing a chemical-mechanical polishing slurry and polishing the copper layer using the slurry until the tantalum-based barrier layer is exposed. The slurry includes an oxidizing agent that releases free radicals and a non-chelating free radical quencher that retards the corrosion of said copper lines during chemical mechanical polishing. Preferred non-chelating free radical quenchers are ascorbic acid, thiamine, 2-propanol, and alkyl glycols. The present invention also provides copper damascene structures formed according to the method.

Owner:FERRO CORP

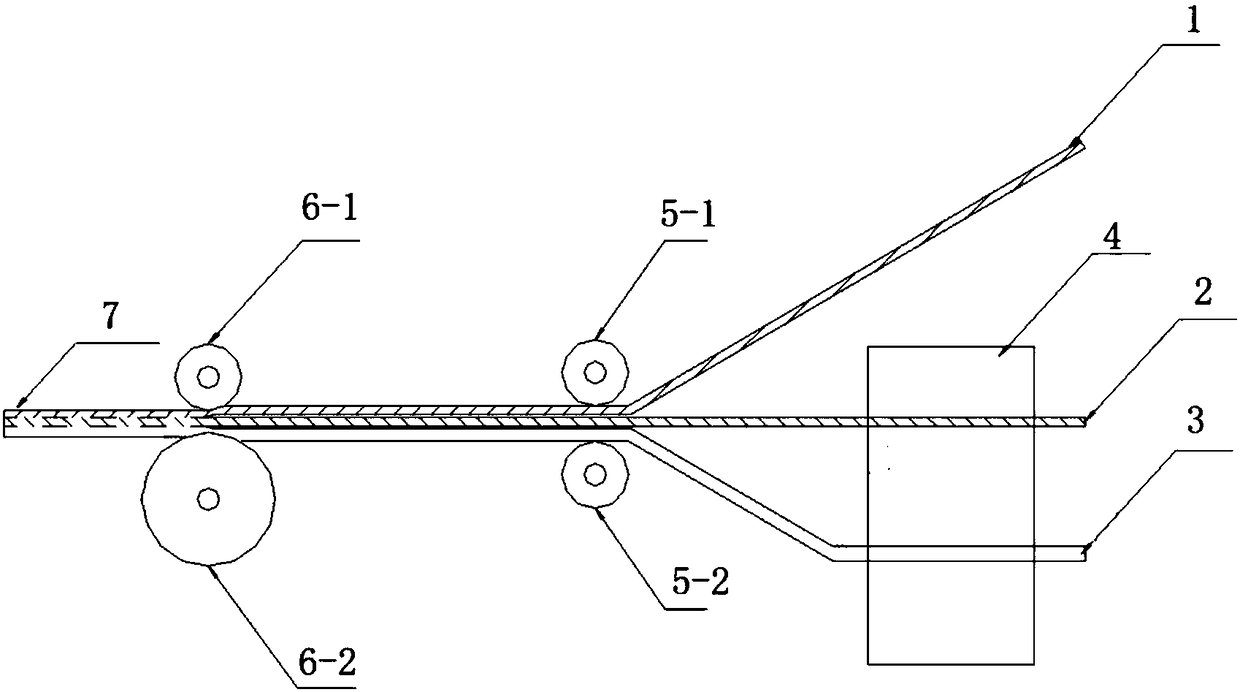

Rotary kiln flue gas treating device capable of automatically controlling blowing rate of draught fan

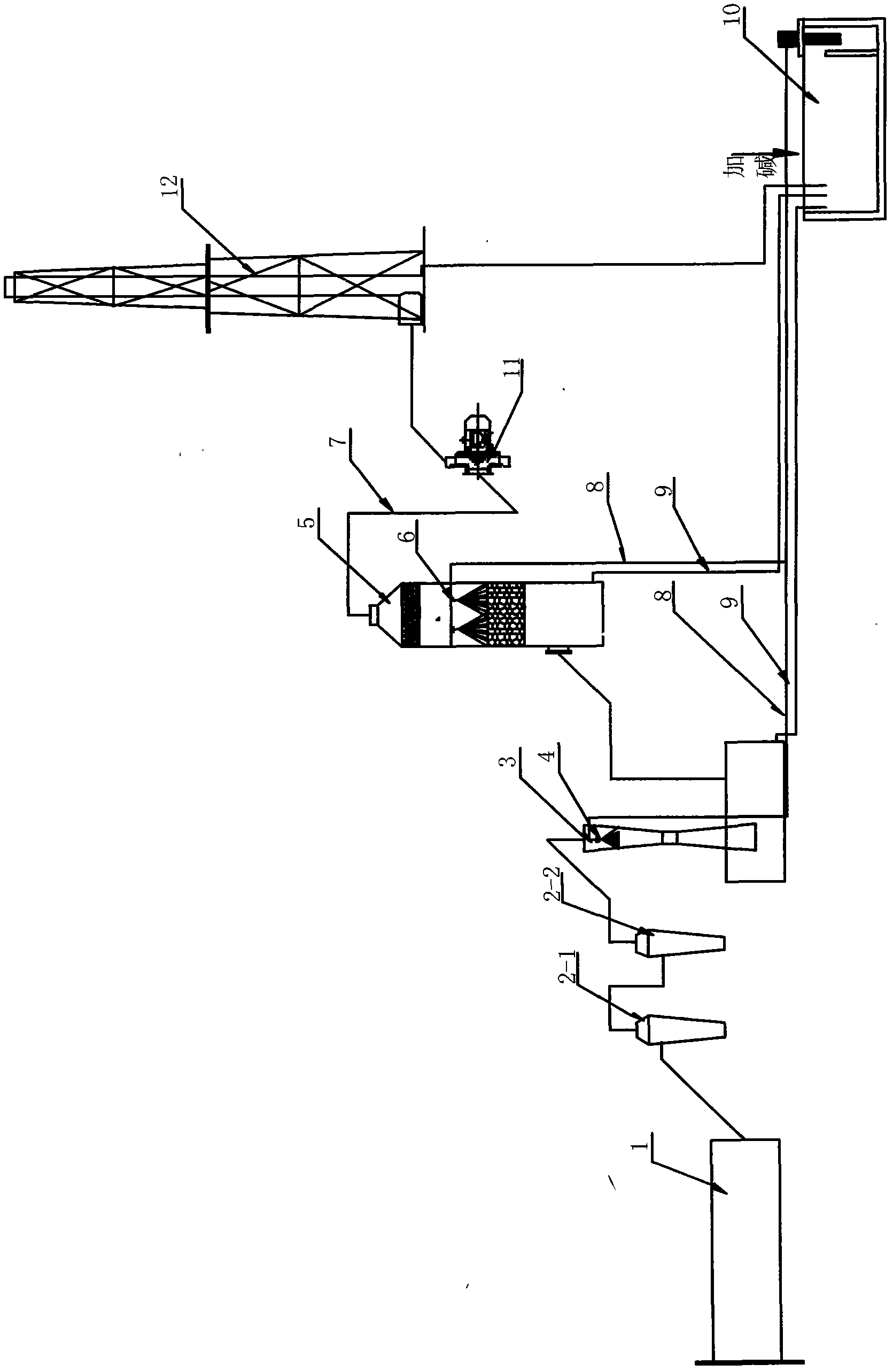

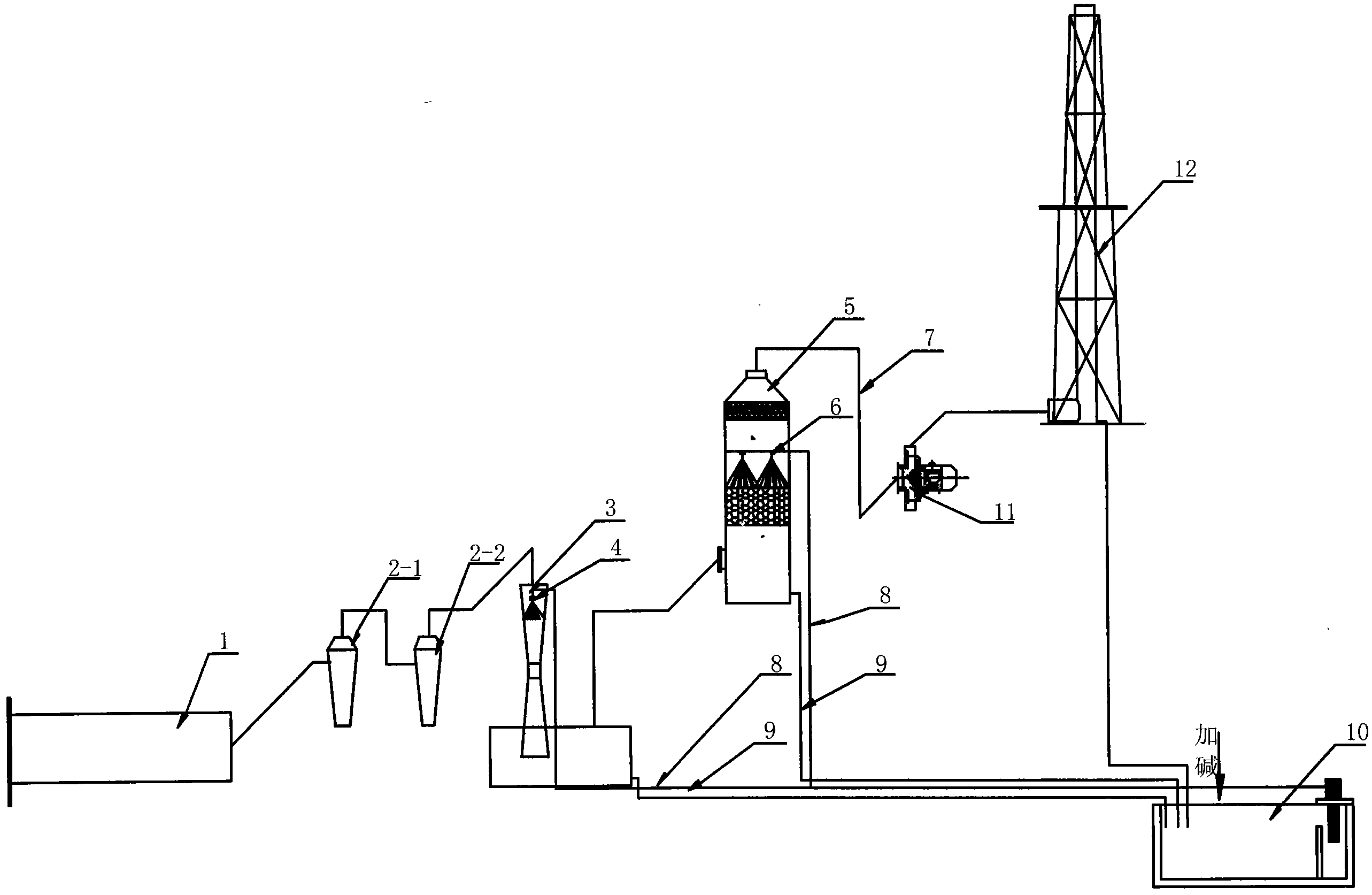

InactiveCN101972578AEffective corrosionExtended service lifeCombination devicesIncreasing energy efficiencyAutomatic controlSprayer

The invention discloses a rotary kiln flue gas treating device capable of automatically controlling the blowing rate of a draught fan, which relates to flue gas treating equipment for a rotary kiln used in titanium dioxide production. A main structure is that: a primary cyclone dust collector is connected with the rotary kiln and a secondary cyclone dust collector; the secondary cyclone dust collector is connected with a Venturi dust collector; the Venturi duct collector is connected with an acid mist washing tower; the acid mist washing tower is connected with a chimney through an exhaust pipe; an induced draught fan is arranged on the exhaust pipe and provided with a frequency converter; a sprayer and a washing sprayer on the Venturi dust collector and the acid mist washing tower are connected with water supply pipes respectively; the water supply pipes are connected with a water supply pump of a cooling and settling pond; water ponds at the bottoms of the Venturi dust collector and the acid mist washing tower are connected with water return pipes; and the water return pipes are connected with the cooling and settling pond. The rotary kiln flue gas treating device capable of automatically controlling the blowing rate of the draught fan captures and cools about 600 DEG C high temperature flue gas and fine dust which are generated in a metatitanic acid calcining process by the rotary kiln, and finally realizes the clean emission standard of tail gas and the recycling of captured dry ash.

Owner:XICHANG NEW VANADIUM & TITANIUM

Method of fabricating a copper damascene structure

InactiveUS20030098434A1Reducing copper polishing rateRetard the corrosion of said copper linesOther chemical processesSemiconductor/solid-state device manufacturingPersulfateSlurry

The present invention provides a chemical-mechanical polishing slurry for use in removing copper overlaying a tantalum-based barrier layer during the fabrication of a copper damascene structure, and a method of retarding the corrosion of copper lines during the chemical-mechanical polishing of a copper damascene structure using the slurry. The slurry according to the invention includes an oxidizing agent that releases free radicals and a non-chelating free radical quencher that is effective to retard the corrosion of the copper lines during chemical-mechanical polishing. Preferred oxidizing agents that release free radicals used in the slurry according to the invention include peroxides, peroxydiphosphates, and persulfates. Preferred non-chelating free radical quenchers used in the slurry according to the invention include ascorbic acid, thiamine, 2-propanol, and alkyl glycols, with ascorbic acid being most preferred.

Owner:FERRO CORP

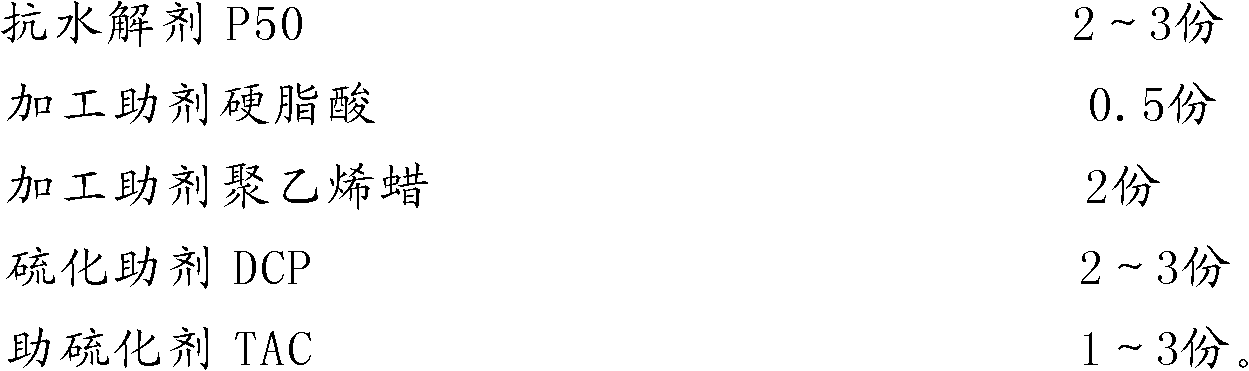

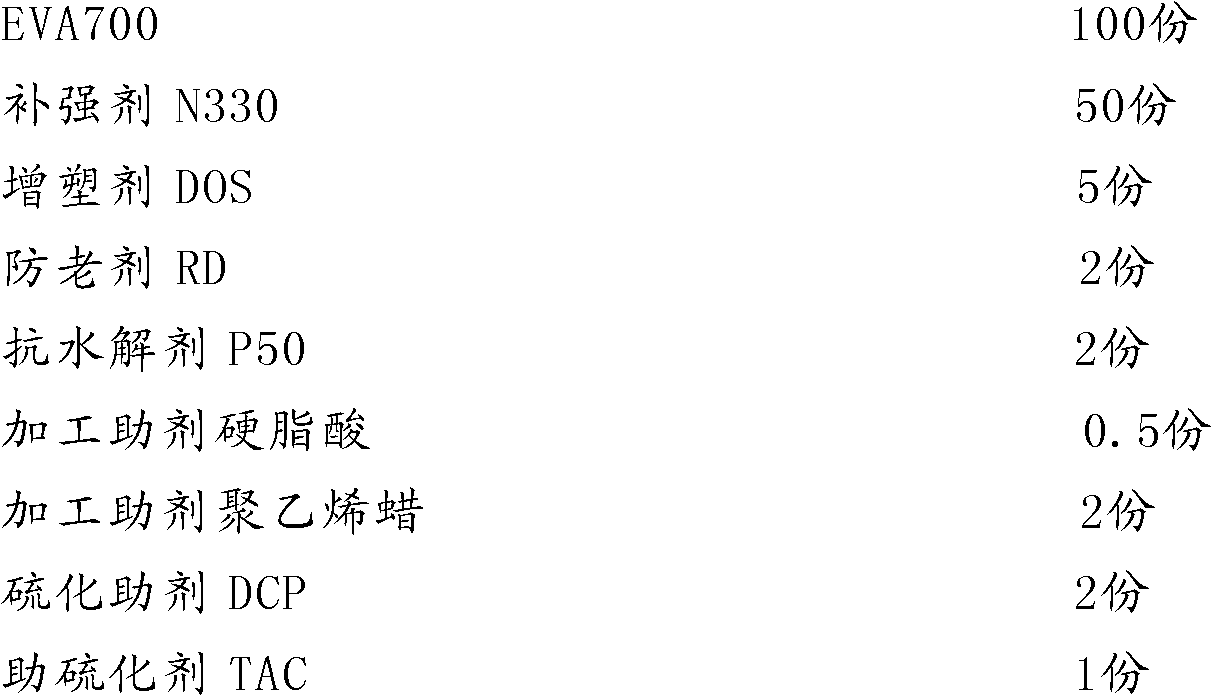

EVM rubber composition used as fuel hose coating

InactiveCN102532680AEffective corrosionProtection and safe transportationFlexible pipesProcedure AgentsPlasticizer

The invention relates to an EVM rubber composition used as a fuel hose coating. The composition comprises the following components in parts by weight: 100 parts of EVA, 50 to 60 parts of reinforcer N330, 5 to 10 parts of plasticizer DOS, 2 parts of anti-aging agent RD, 2 to 3 parts of anti-hydrolysis agent P50, 0.5 parts of processing aid stearic acid, 2 parts of processing aid polyethylene wax, 2 to 3 parts of vulcanizing aid DCP, and 1 to 3 parts of vulcanizing aid TAC. Since EVM (ethylene vinyl-acetate copolymer) is used as the major material, on the one hand, the EVM rubber composition as the fuel hose coating is resistant to fuel corrosion and more favorable for safety transportation of fuels, and on the other hand, the cost is lower than that of AEM and about a half that of AEM provided by the DuPont company, so that the cost is saved.

Owner:TIANJIN PENGYI GRP CO LTD

Method for rapidly corroding and patterning indium tin oxide surface by using electrochemical technology

InactiveCN102691093AEasy to operateAccelerated corrosionPhotomechanical apparatusChronoamperometryIndium tin oxide

The invention relates to a method for rapidly corroding and patterning an indium tin oxide (ITO) surface by using an electrochemical technology, belonging to the fields of electrochemistry and micro-nanotechnologies. Aiming at the problem of the traditional ITO-corroding method, the method for rapidly corroding and patterning the indium tin oxide surface by using the electrochemical technology, provided by the invention, comprises the steps as follows: (1) washing the ITO surface; (2) pressing a used photoresist into a protective film on an ITO substrate by using a plastic-envelop machine, directly placing a mask of a used pattern, performing ultraviolet exposure and developing, and forming and washing to form a needed pattern; (3) corroding exposed ITO part of the photoresist on the ITO surface with diluted hydrochloric acid as a corrosive liquid by using cyclic voltammetry or chronoamperometry and the electrochemical technology; and (4) washing an electrochemically corroded ITO glass sheet by using an alkali solution, removing a protective photoresist film; and drying by using N2 to obtain a patterned ITO surface. The method for rapidly corroding and patterning the indium tin oxide surface by using the electrochemical technology has the advantages of simplicity in operation, high speed, good corrosive effect, clearness of borders, low cost and the like.

Owner:HARBIN INST OF TECH

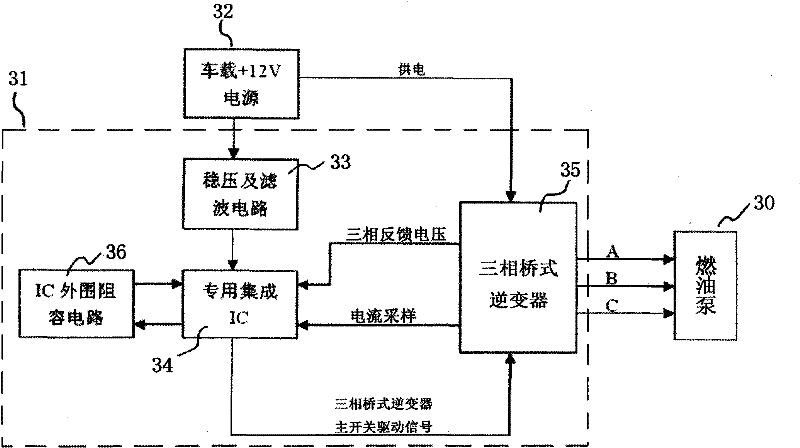

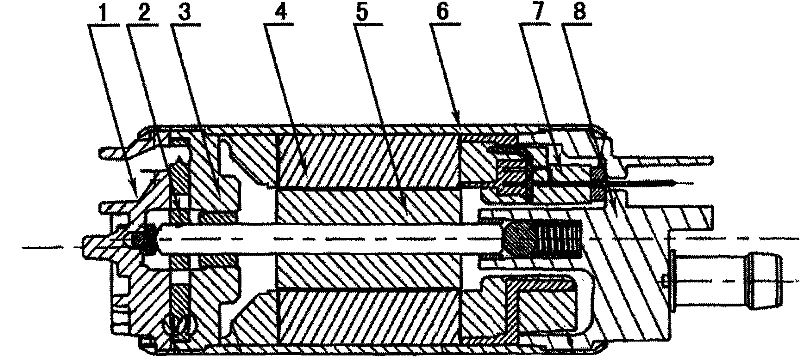

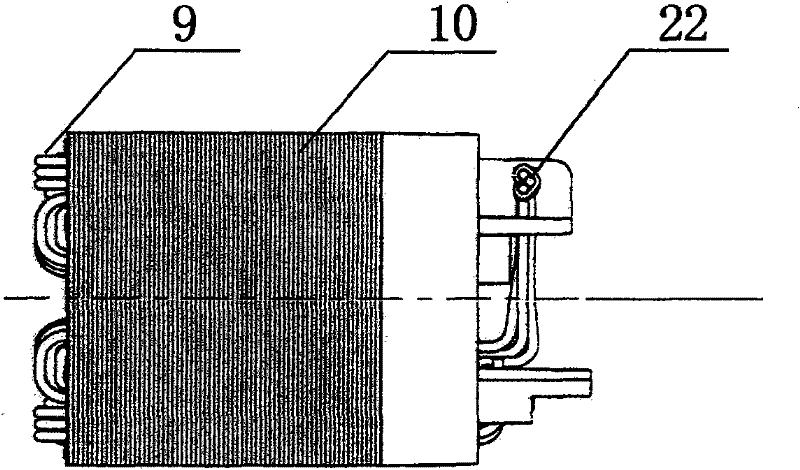

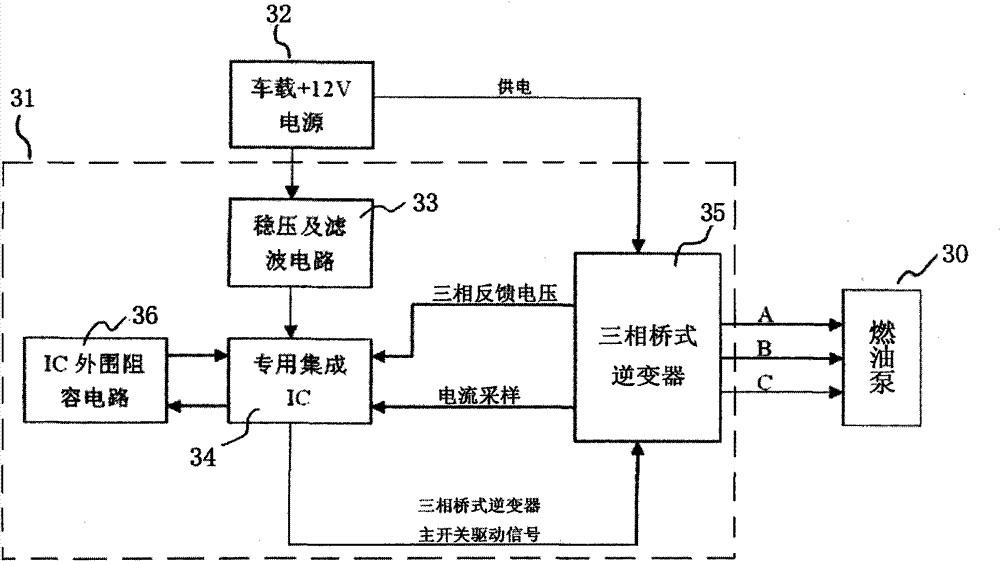

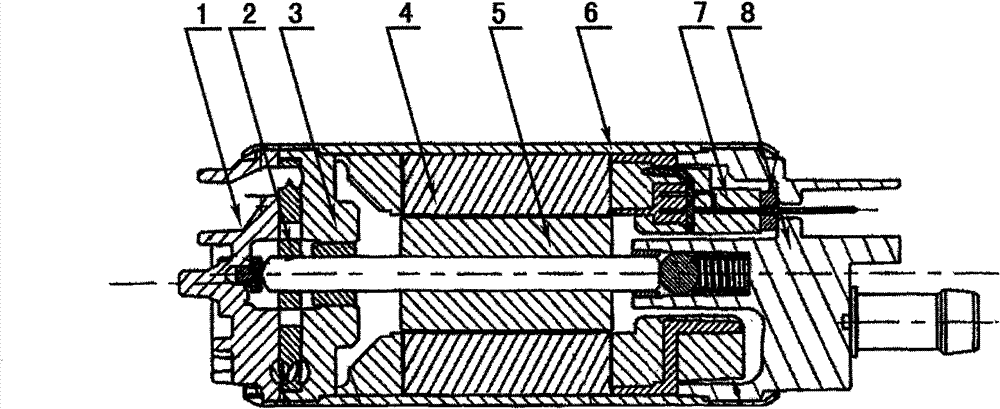

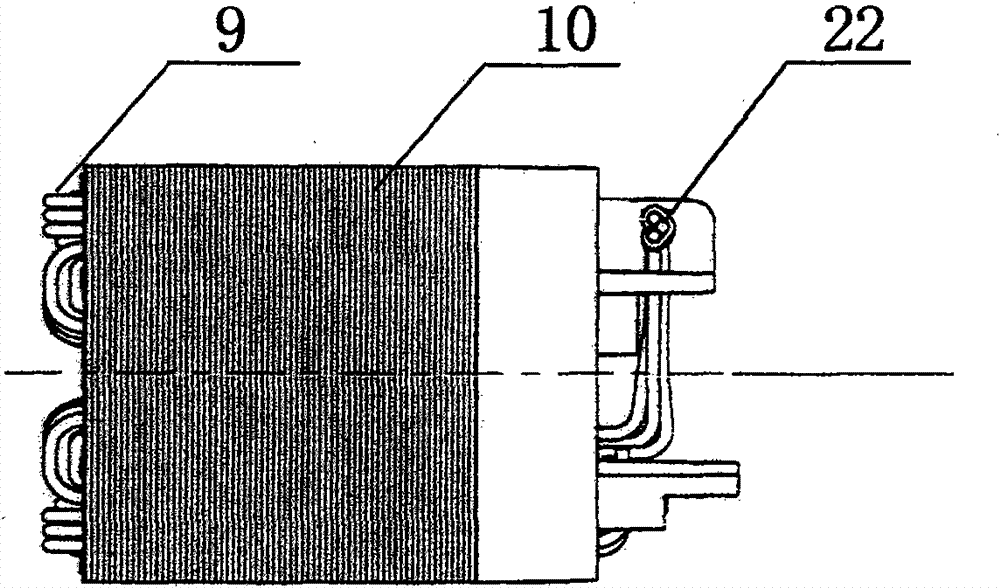

Novel brushless motor fuel pump

InactiveCN102207050AEffective corrosionEfficient conductionMachines/enginesLiquid fuel feedersCapacitanceBrushless motors

The invention relates to a novel brushless motor fuel pump. In the technical scheme, a brushless motor controller is connected outside the fuel pump, namely one end of an electronic plug-in part is connected with a fuel pump motor stator, and the other end of the electronic plug-in part is connected with the brushless motor controller; a vehicle-mounted power supply is connected outside and an integrated circuit is connected inside a voltage-stabilizing and filtering circuit in the brushless motor controller; the integrated circuit is respectively connected with a peripheral resistance-capacitance circuit and a three-phase bridge inverter; and a starting circuit and three-phase feedback voltage in the integrated circuit are connected with a phase locked logic phase change circuit respectively. The defects that a position sensor has low sealing property, ages quickly, is corroded, and the like are overcome. By a counter potential reversing technology, the pump can effectively resist fuel corrosion and fuel electric conduction, can be suitable for various liquid fuels such as gasoline, methanol, ethanol and the like, has high reliability, small volume, long service life and low price, is convenient to install, reduces a motor gap, and improves motor output and motor efficiency, and the volume of a pump body is reduced.

Owner:周铁

Pigment grade corrosion inhibitor host-guest compositions and procedure

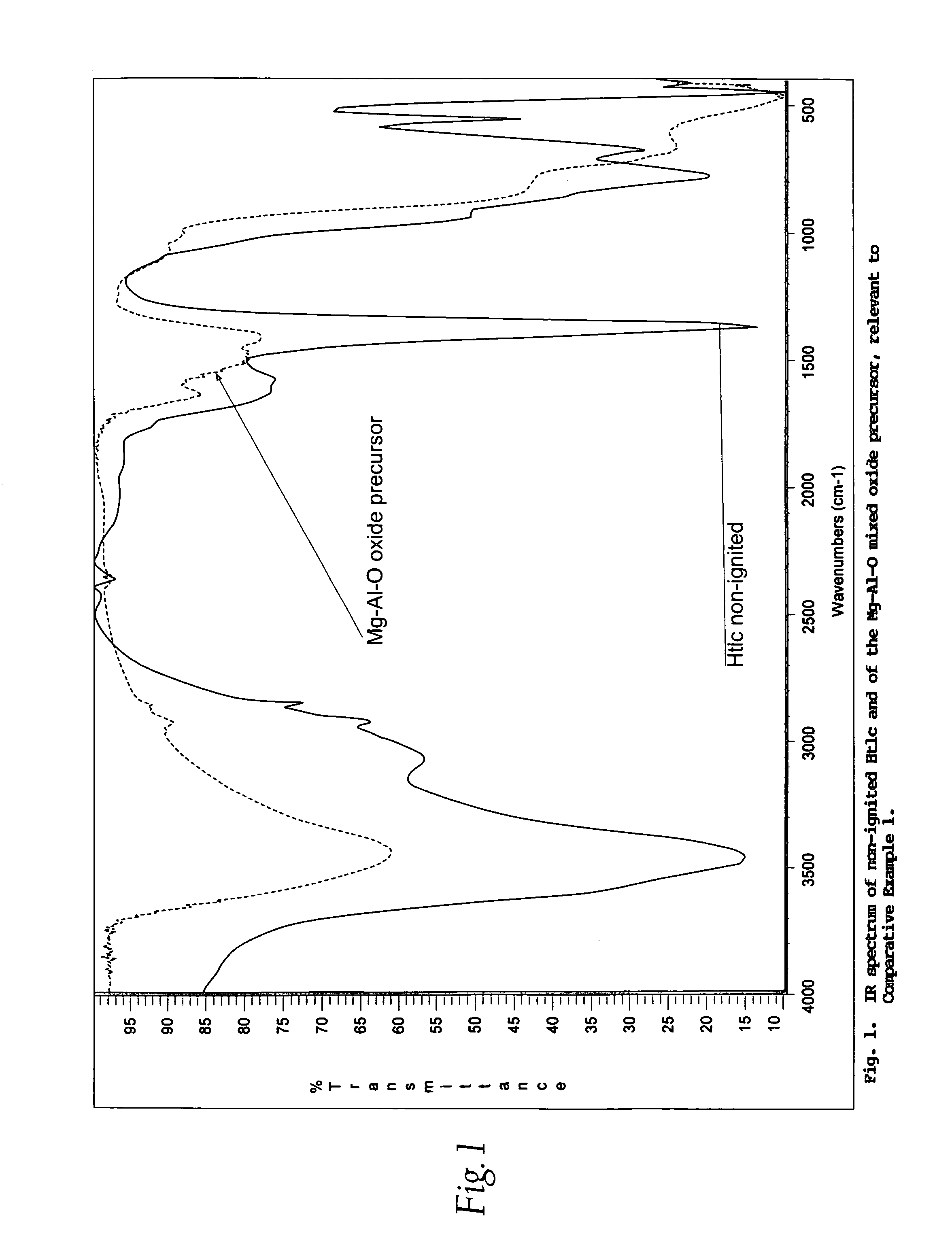

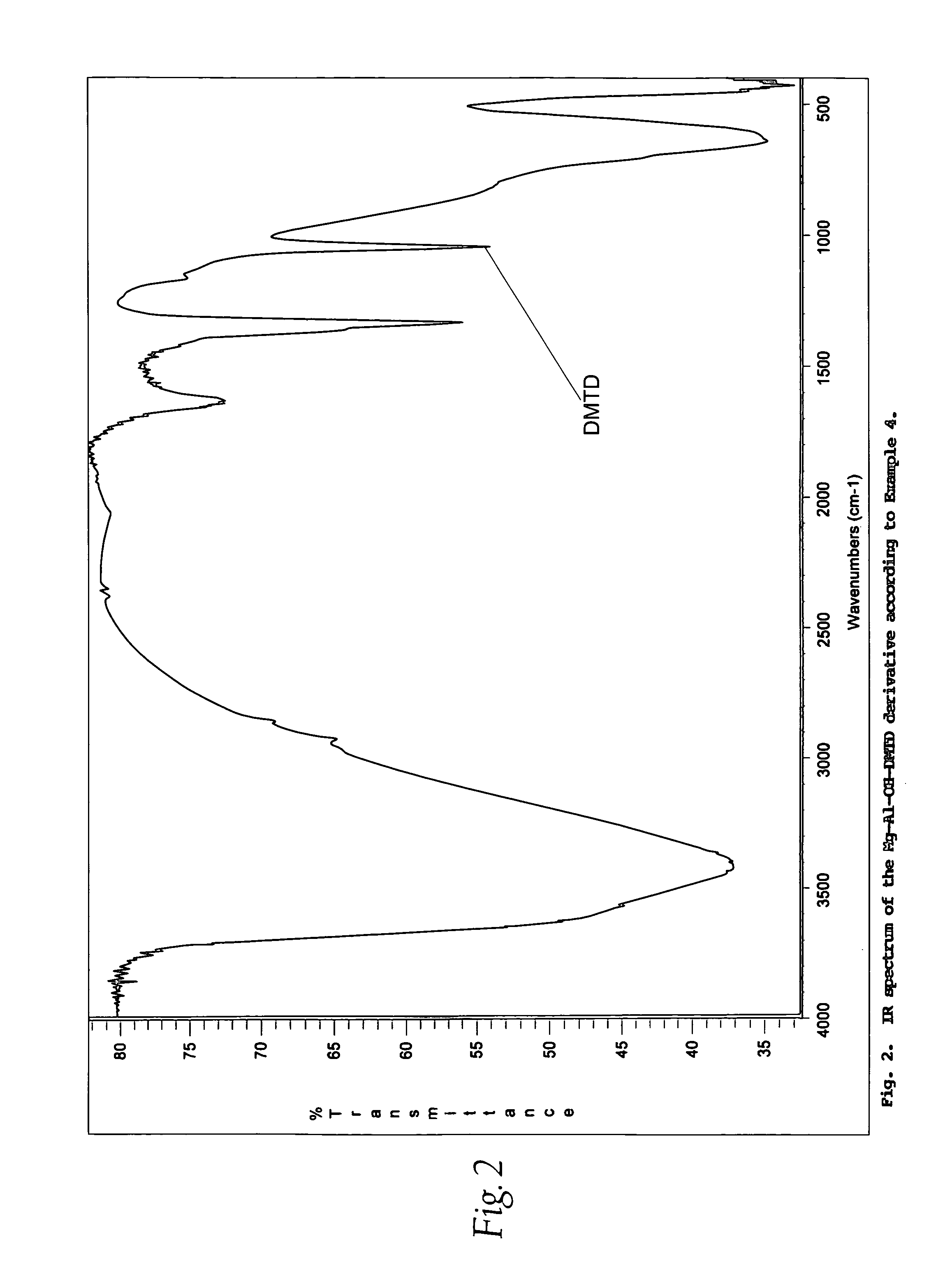

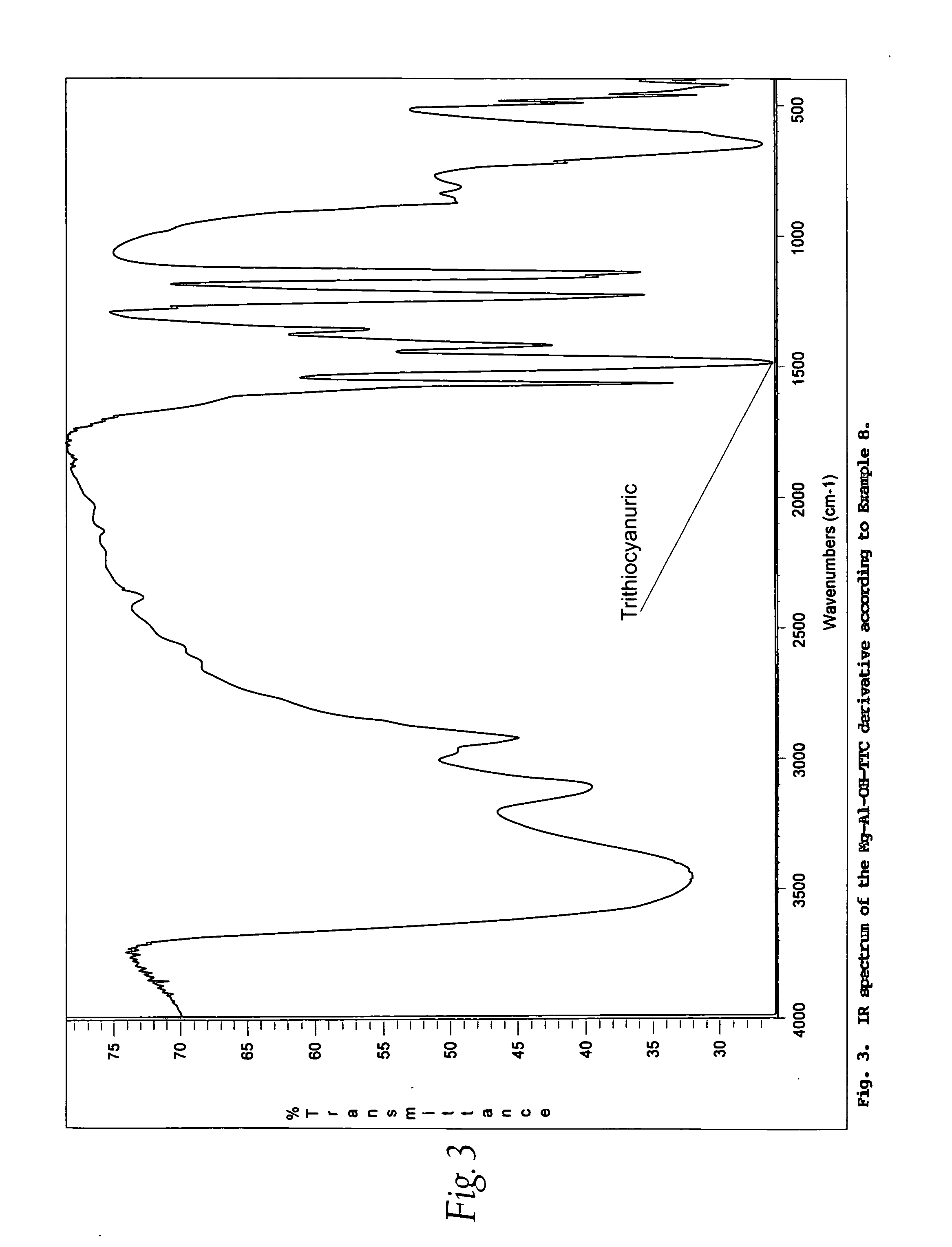

InactiveUS20080258114A1Maximize loadingEffective corrosionPigmenting treatmentOther chemical processesO-Phosphoric AcidThio-

A pigment grade corrosion inhibitor and a method of applying the inhibitor is disclosed. The inhibitor is comprised of a host species comprised of an inorganic compound having a layered structure and a guest species comprised an anionic species of a weak acid. The host species is preferably a double hydroxide having a structure of: [M(II)1-x M(III)x (OH−)2] [An−x / n·y H2O], where M(II) is a divalent metal cationic species, M(III) is a trivalent metal cationic species, and An− is an anionic species, preferably with the species present in a range of: 0.2≦M(III) / (M(II)+M(III))≦0.4. The guest species include: various phosphoric acids and derivatives thereof; boric acid; cyanamidic acid; nitrous acid; derivatives of thio- and dithiocarbonic acid; thio-organic compounds functionalized with at least one —SH group of acidic character, including: 2,5-dimercapto-1,3,4-thiadiazole (DMTD), 2,4-dimercapto-s-triazolo-[4,3-b]-1,3-4 thiadiazole, trithiocyanuric acid (TMT), and dithiocyanuric acid.

Owner:LUMIMOVE

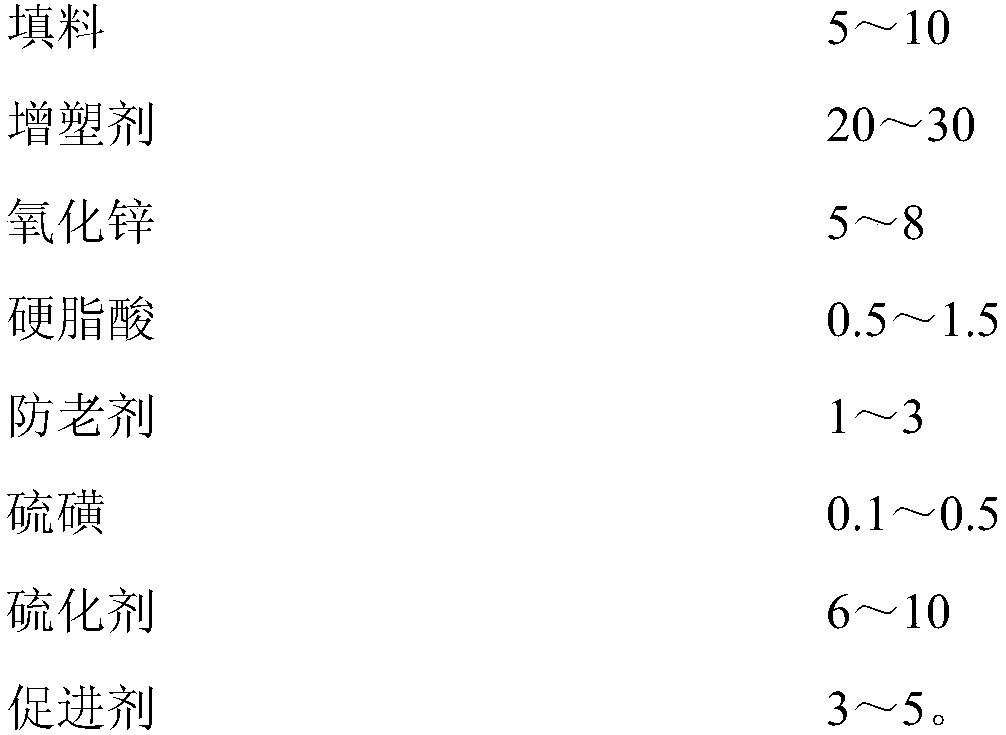

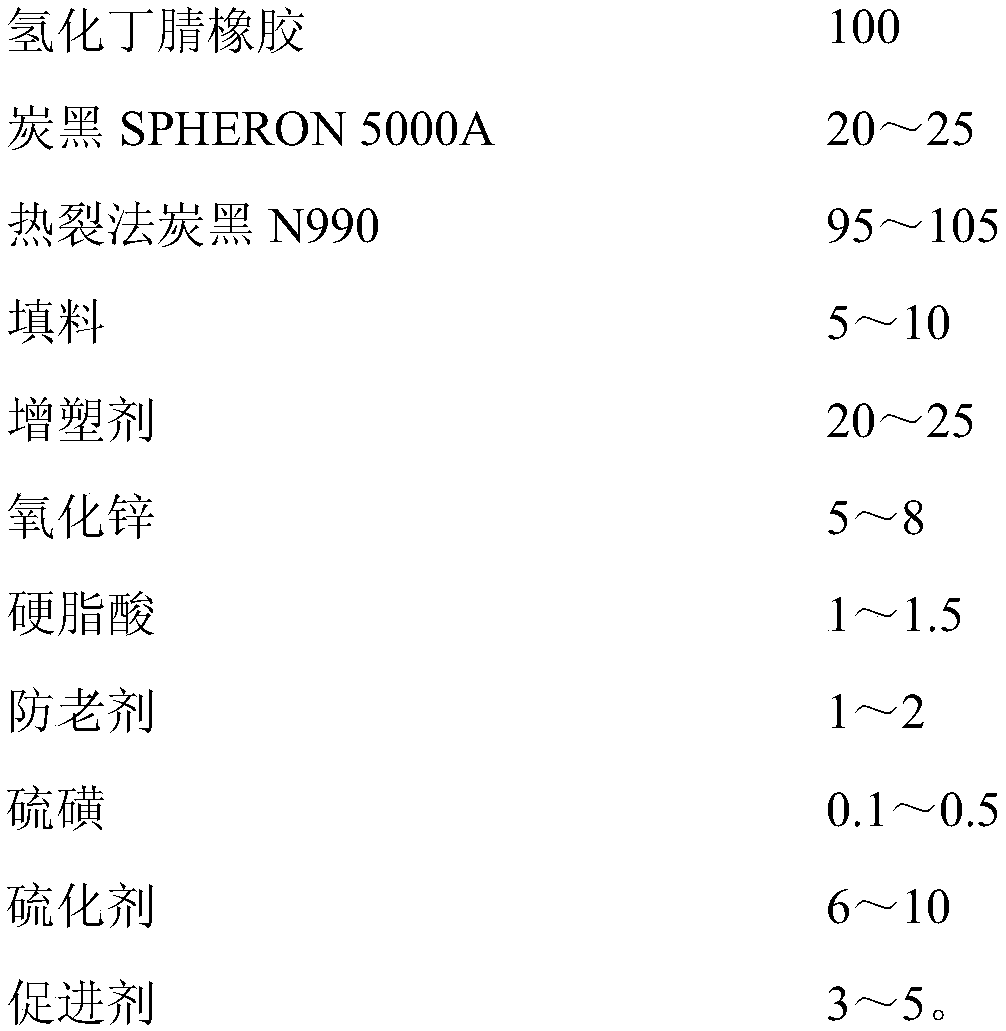

High-tearing strength, biodiesel-resistant hydrogenated acrylonitrile butadiene rubber composition for automobile hoses

The invention discloses a high-tearing strength, biodiesel-resistant hydrogenated acrylonitrile butadiene rubber composition for automobile hoses, which is prepared from the following components in parts by weight: 100 parts of hydrogenated acrylonitrile butadiene rubber, 15 to 25 parts of highly clean carbon black, 90 to 120 parts of thermal decomposition process carbon black, 5 to 10 parts of filler, 20 to 30 parts of plasticizer, 5 to 8 parts of zinc oxide, 0.5 to 1.5 parts of stearic acid, 1 to 3 parts of anti-aging agent, 0.1 to 0.5 part of sulfur, 6 to 10 parts of vulcanizing agent and 3to 5 parts of accelerant. Since the rubber composition disclosed by the invention adopts hydrogenated acrylonitrile butadiene as a main material, on one hand, biodiesel corrosion can be effectively resisted, which is more favorable for the protection of safe fuel transportation, and on the other hand, the operating requirements of a high temperature-resistant, low-permeability fuel system can bemet.

Owner:NANJING ORIENTLEADER TECH CO LTD

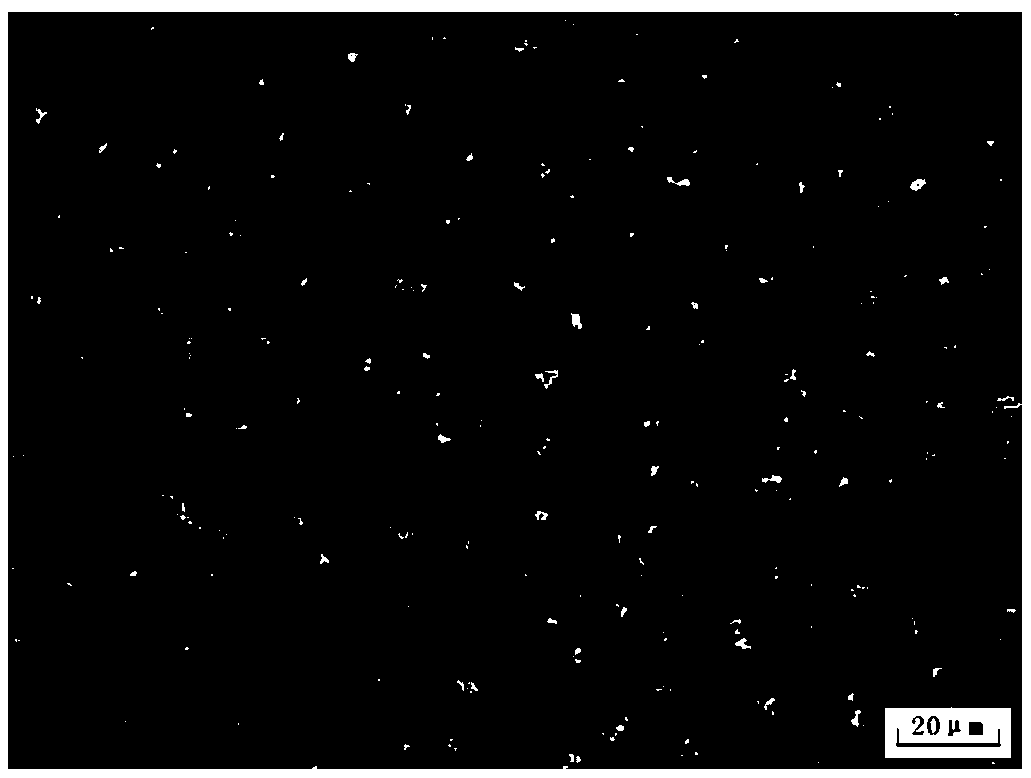

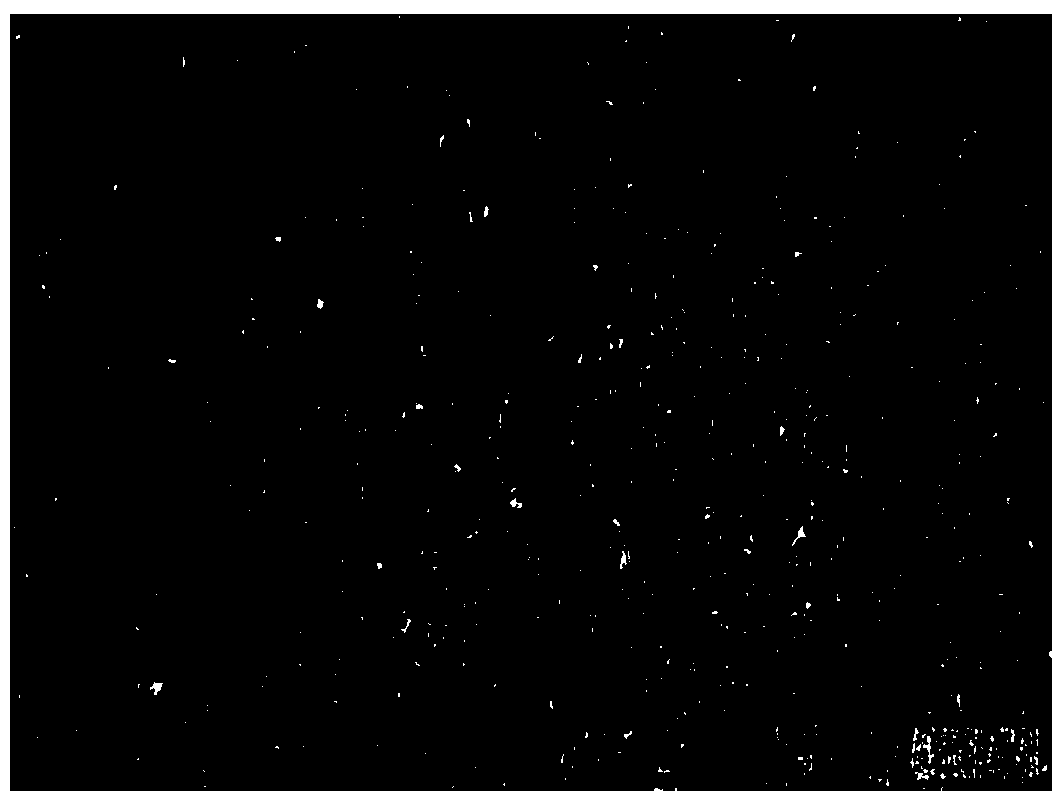

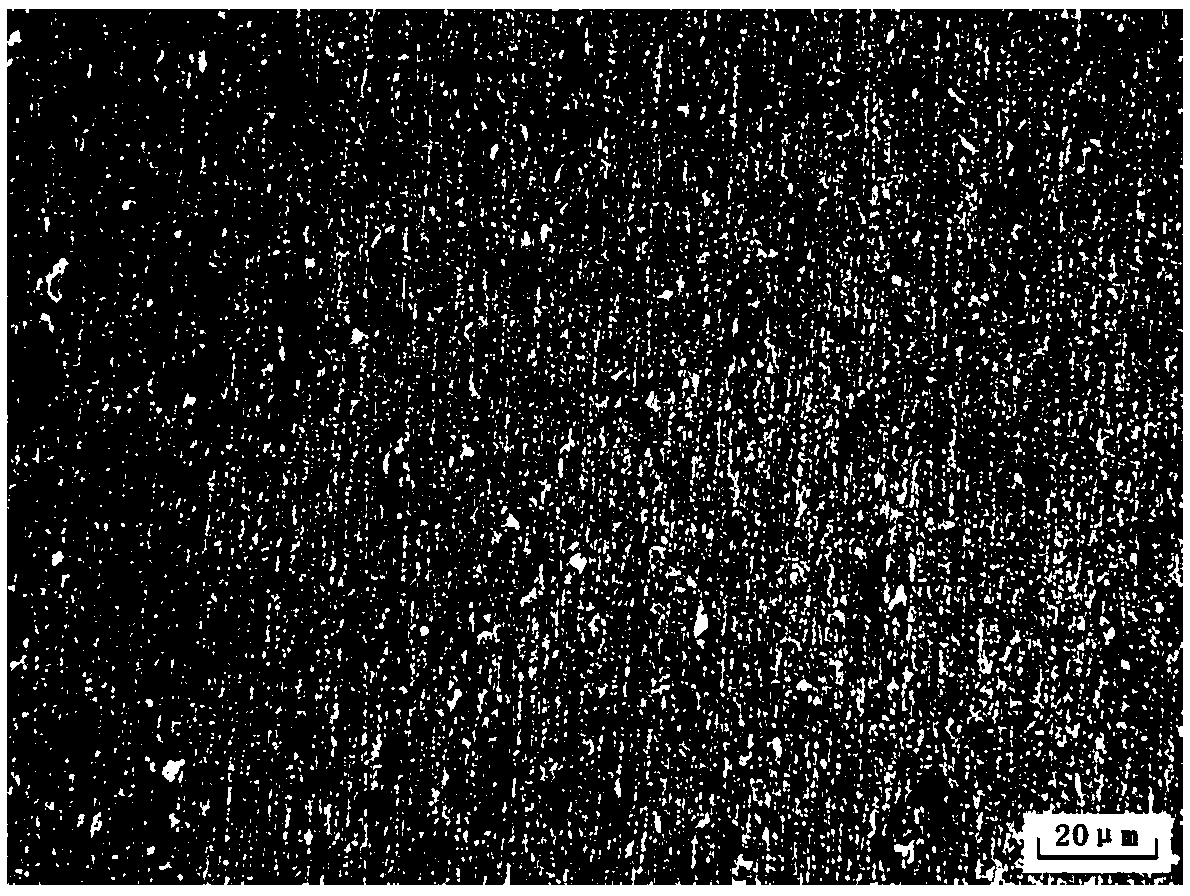

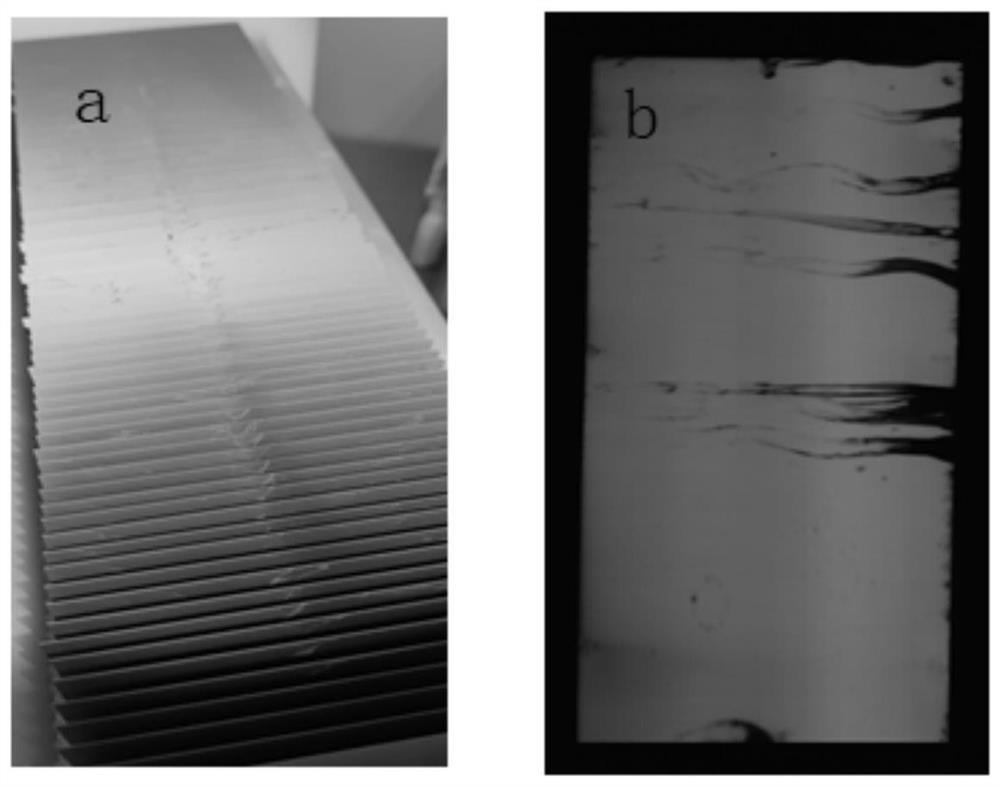

Method for detecting distribution and content of residual austenite in low alloy structure steel

ActiveCN109142010AThe overall image is beautifulGood for metallographic observationPreparing sample for investigationMaterial analysis by optical meansAlloySolvent

The invention discloses a method for detecting distribution and the content of residual austenite in low alloy structure steel. Water is used as cooling liquid, metallographic waterproof abrasive paper is used for rough grinding and fine grinding of a test surface of a sample, the sample subjected to fine grinding is polished, sodium metabisulfite, picric acid, sodium hydroxide, distilled water, hydrochloric acid and absolute ethyl alcohol are mixed, stirred and heated to prepare a corrosion reagent, the polished sample is subjected to electrolytic polishing treatment, the sample subjected toelectrolytic polishing treatment is placed into prepared corrosion solvents to remove interference phases, and distribution and the content of the residual austenite of the sample are detected by metallographic observation and representation. The method is simple in operation and short in polishing corrosion time. After the low alloy structure steel is corroded, a residual austenite structure in the low alloy structure steel can be clearly displayed. Characteristic parameters such as the content, the size, the shape and distribution of the residual austenite can be rapidly, accurately and quantitatively analyzed by metallographic software.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

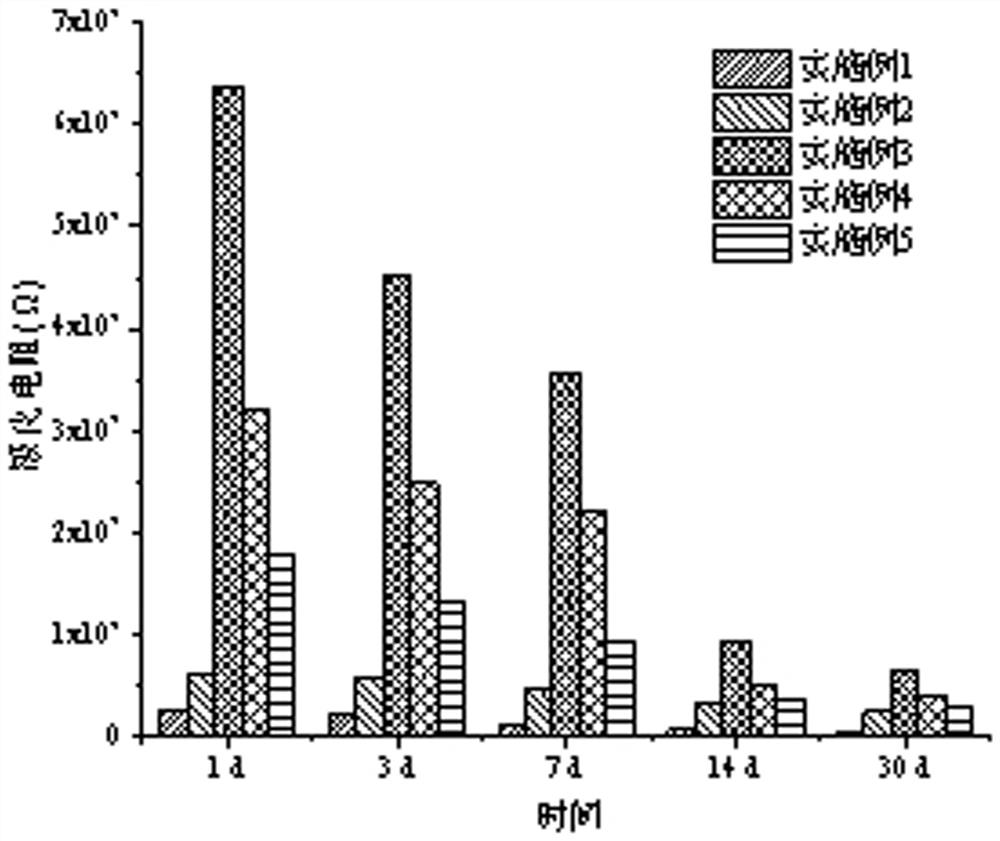

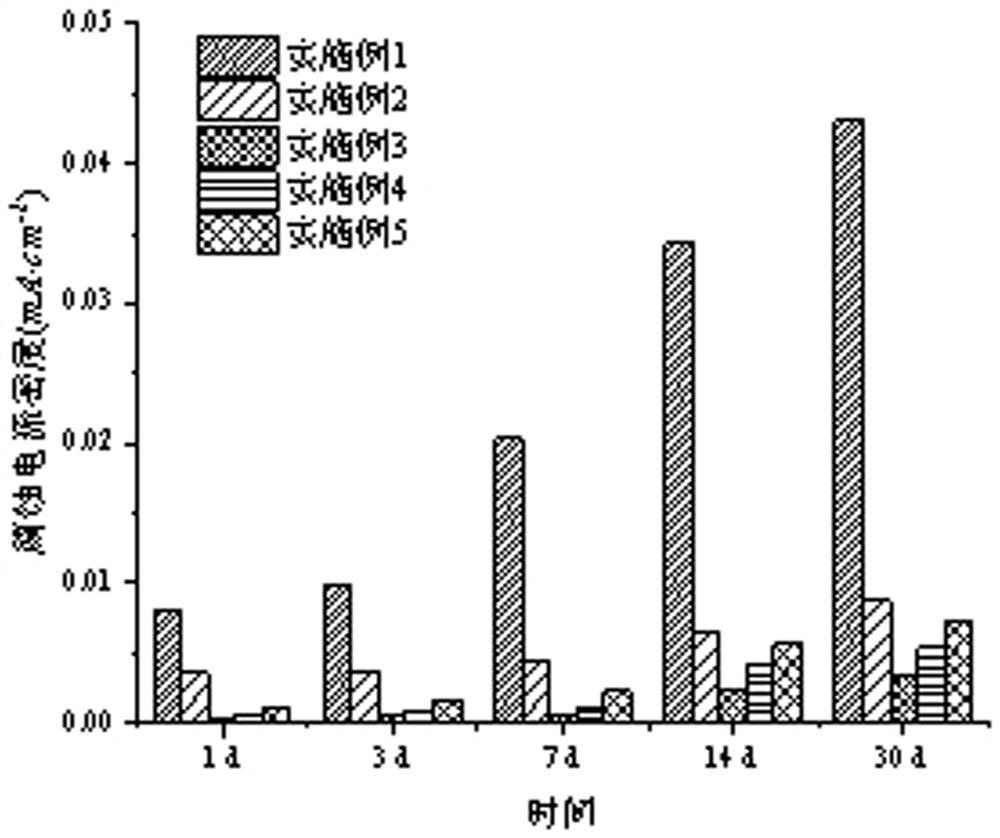

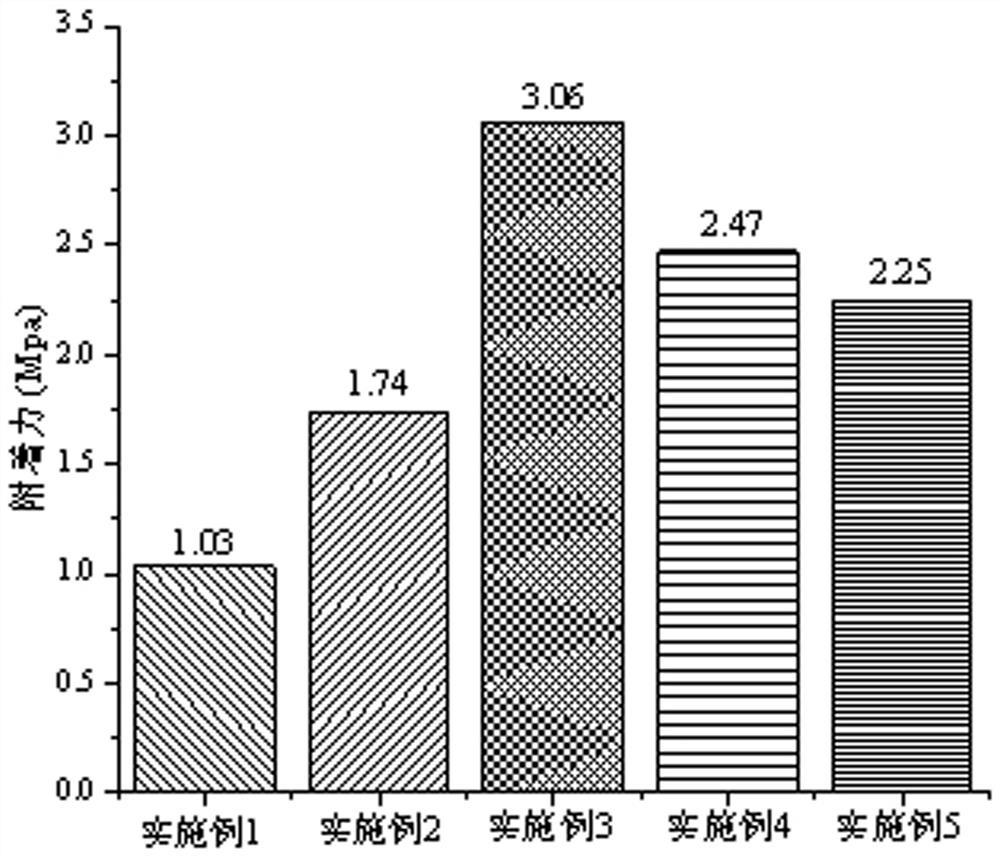

Rusty protective coating with rust conversion function and preparation method

The invention relates to a rusty protective coating with a rust conversion function and a preparation method. The rusty protective coating comprises 10-40 parts of a rust conversion agent, 60-90 partsof an acidic resin emulsion, an antifoaming agent accounting for 0.1-0.5% of the total mass of the acidic resin emulsion and the rust conversion agent, a thickening agent accounting for 0.1-0.5% of the total mass of the acidic resin emulsion and the rust conversion agent, and a wetting agent accounting for 0.1-0.5% of the total mass of the acidic resin emulsion and the rust conversion agent. Therusted protective coating with the rust conversion function is uniformly brushed on the surface of a rusted reinforcing steel bar, a rust layer can be converted and dissolved to generate a polymer protective film under the condition of normal temperature, the utilization rate of the reinforcing steel bar is increased by effectively converting the rust layer, the bonding and anchoring performance of the coating and concrete is excellent when a reinforced concrete structure is poured again, and an anti-rust action is achieved without affecting the performance of the concrete. The rusty protective coating has the characteristics of environmental protection, low cost, strong adhesive force, high corrosion resistance and the like.

Owner:YANTAI UNIV

Large-scale cultivation method of pumpkin seedlings

InactiveCN107172909AReduce penetration rateEffective corrosionBiocideDead animal preservationPumpkin seedPest control

The invention relates to a large-scale cultivation method of pumpkin seedlings. The method includes the steps of firstly, preprocessing seeds; secondly, processing before sowing; thirdly, performing spaced sowing, and performing daily weeding and pest control. Experiments show that the method can effectively avoid diseased and weak seedlings, the cultured seedlings can be sold, and the method is of great significance to the large-scale cultivation of the pumpkin seedlings.

Owner:安徽祥飞枞阳媒鸭养殖有限公司

Use of amino carboxylate for enhancing metal protection in alkaline detergents

ActiveUS9267096B2Prevention/reduction of corrosionParticulate matter in the residual wash water is also reduced.Inorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCarboxylic saltNuclear chemistry

The invention includes ware detergent compositions which prevent buildup of precipitates and also surprisingly provides significant metal protection of items exposed to alkaline detergent composition. According to the invention alkaline ware detergents may include an effective amount of amino carboxylate. Surprisingly, detergents which included amino carboxylate also provided significant metal protection against corrosion, even when traditional corrosion inhibiting components are reduced.

Owner:ECOLAB USA INC

Multifunctional water-treating composition and method of water-treating using the same

InactiveCN1473137ALong-term sustained bactericidal effectSustained bactericidal effectBiocideSpecific water treatment objectivesZinc saltsCarboxylate

In order to provide a water-treating compositon which has a superior stability during storage or the use and simultaneously prevents the corrosion, the scale formation and the growth of microorganism in a colling water, the present invention provides a multifunctional water-treating composition comprising at least one component selected from a group consisting of a mixture including azole compound and carboxylate, orthophosphate salt and zinc salt; a microorganism growth inhibitor; a scale formation inhibitor; an organic phosphonate; and nitrate.

Owner:TSK WATER CO LTD

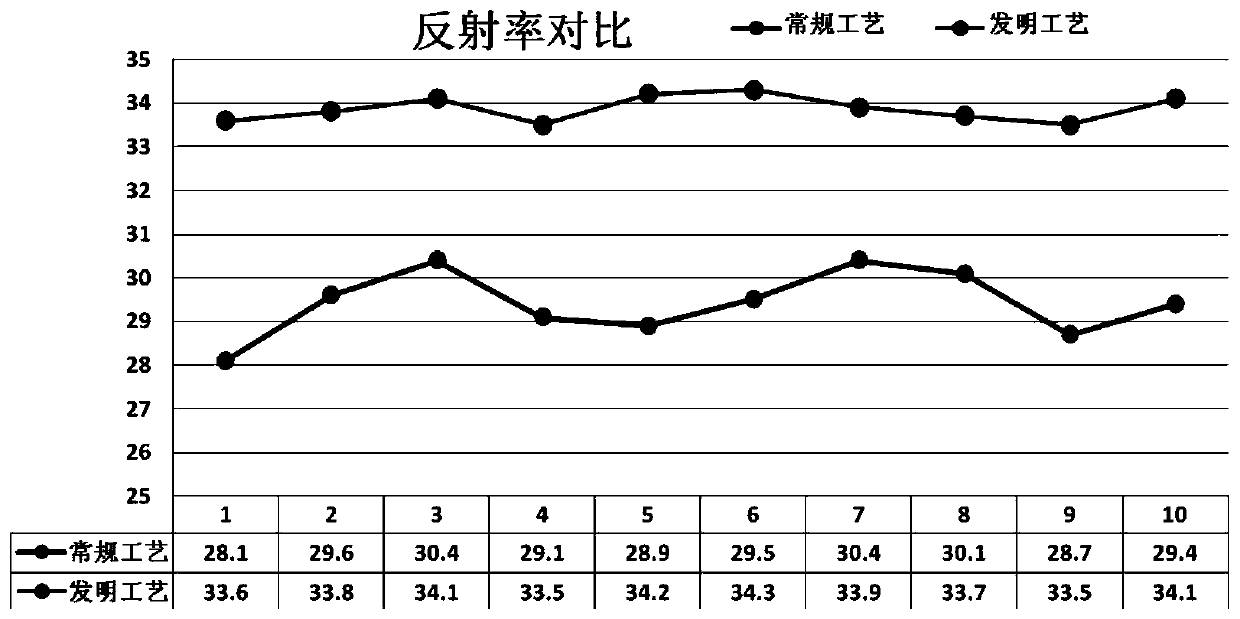

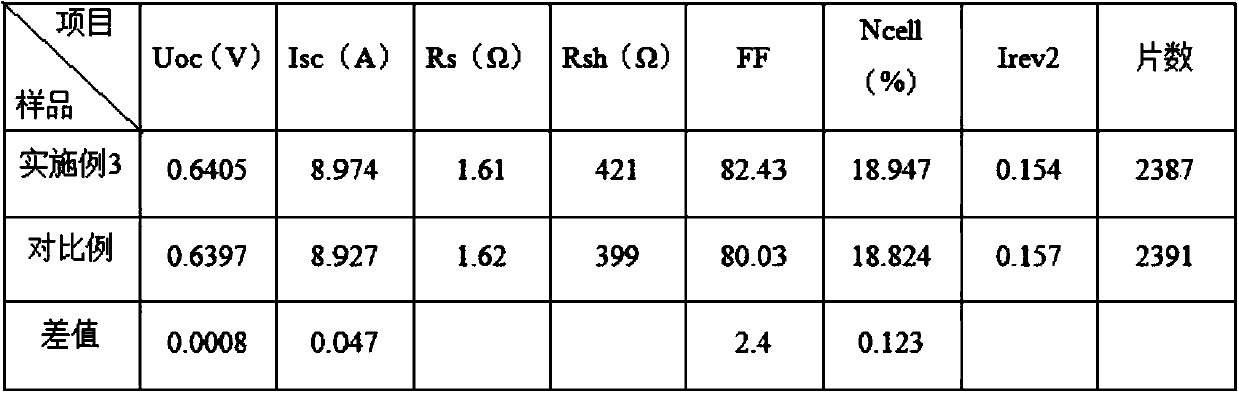

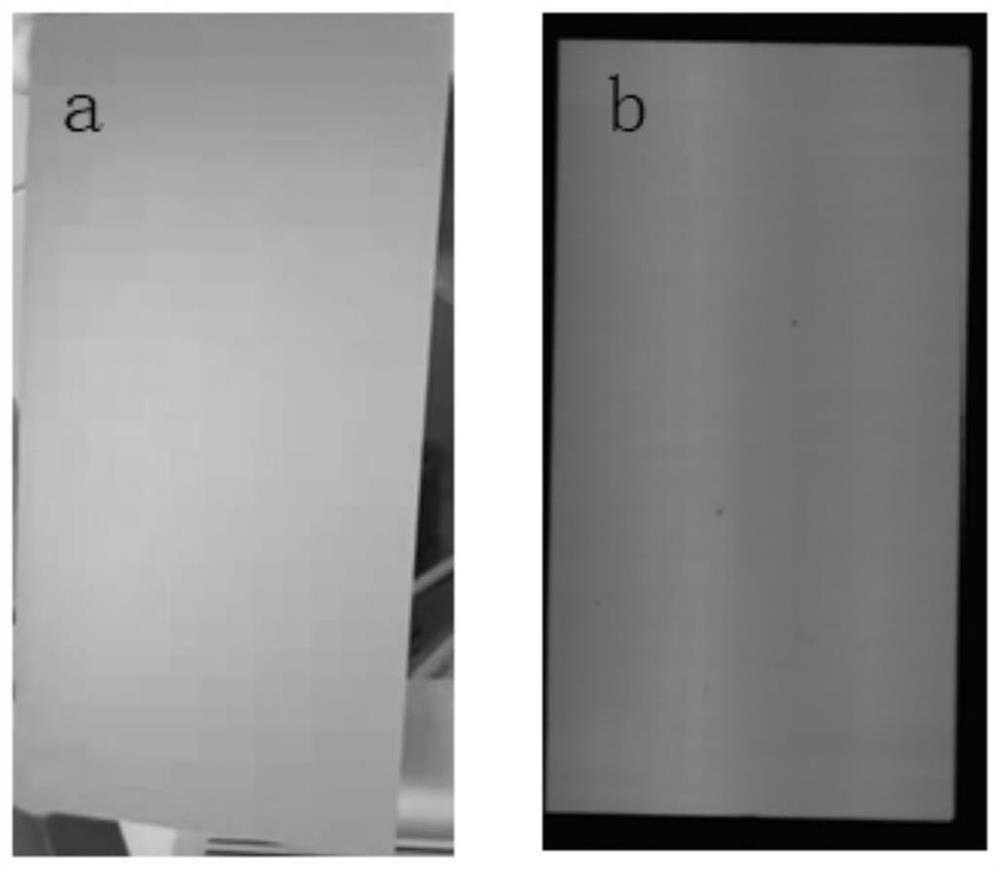

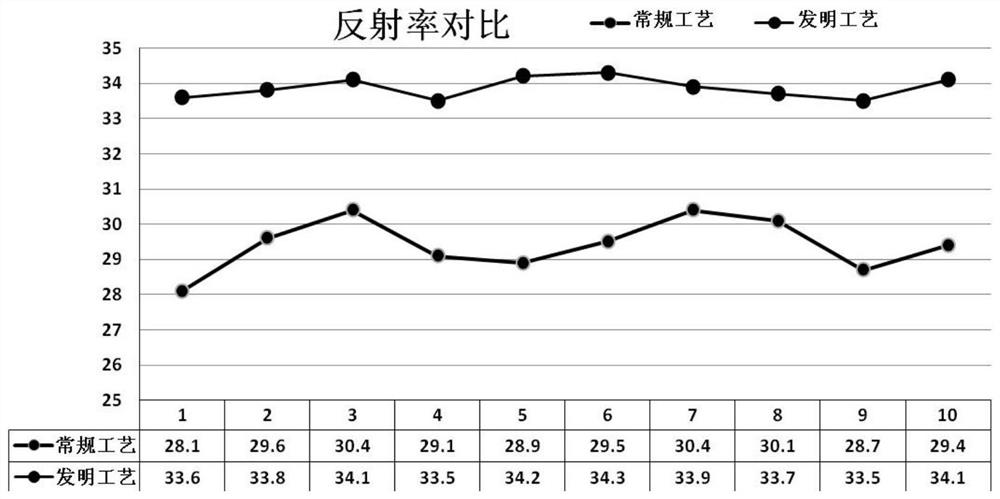

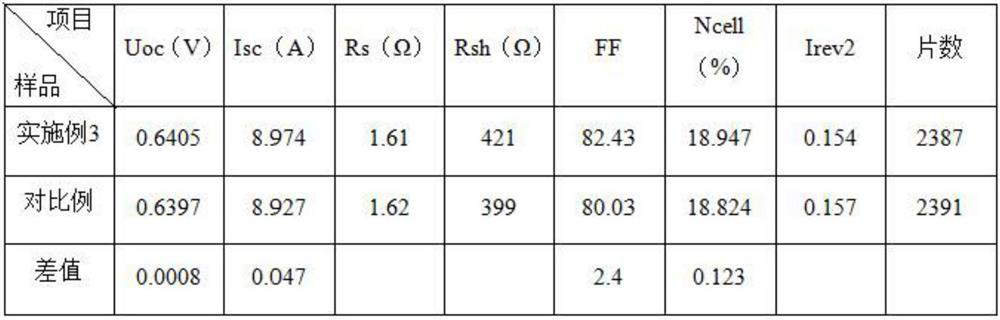

Back polishing process of solar cell sheet

ActiveCN109830564AImprove protectionNot corrodedFinal product manufacturePhotovoltaic energy generationScreen printingElectron hole

The invention discloses a back polishing process of a solar cell sheet. The back polishing process comprises the following steps of: preprocessing an unpolished silicon wafer; polishing the back sideof the silicon wafer; performing screen printing and drying. A silicon nitride film is grown by PECVD in the back polishing process to achieve good protection for a non-polished surface. The silicon wafer is successively polished by an alkali solution and an acid solution, which greatly improves the polishing quality of the silicon wafer. Thus, a good immersion polishing effect is achieved and theprobability of damaging the silicon wafer is reduced. An etching solution can corrode the textured surface on the back side of the cell and form a flat mirror structure to achieve a uniform polishingeffect and improve the reflectance and absorption rate of the silicon wafer. The silicon wafer of the back-polished silicon cell has a flat and bright back surface. The photons incident into the backsurface of the silicon wafer can be reflected only in one direction, thereby increasing the energy of the reflected light, exciting more electron-hole pairs, increasing the current of the cell sheet,and improve the efficiency of the cell sheet.

Owner:中建材浚鑫(桐城)科技有限公司

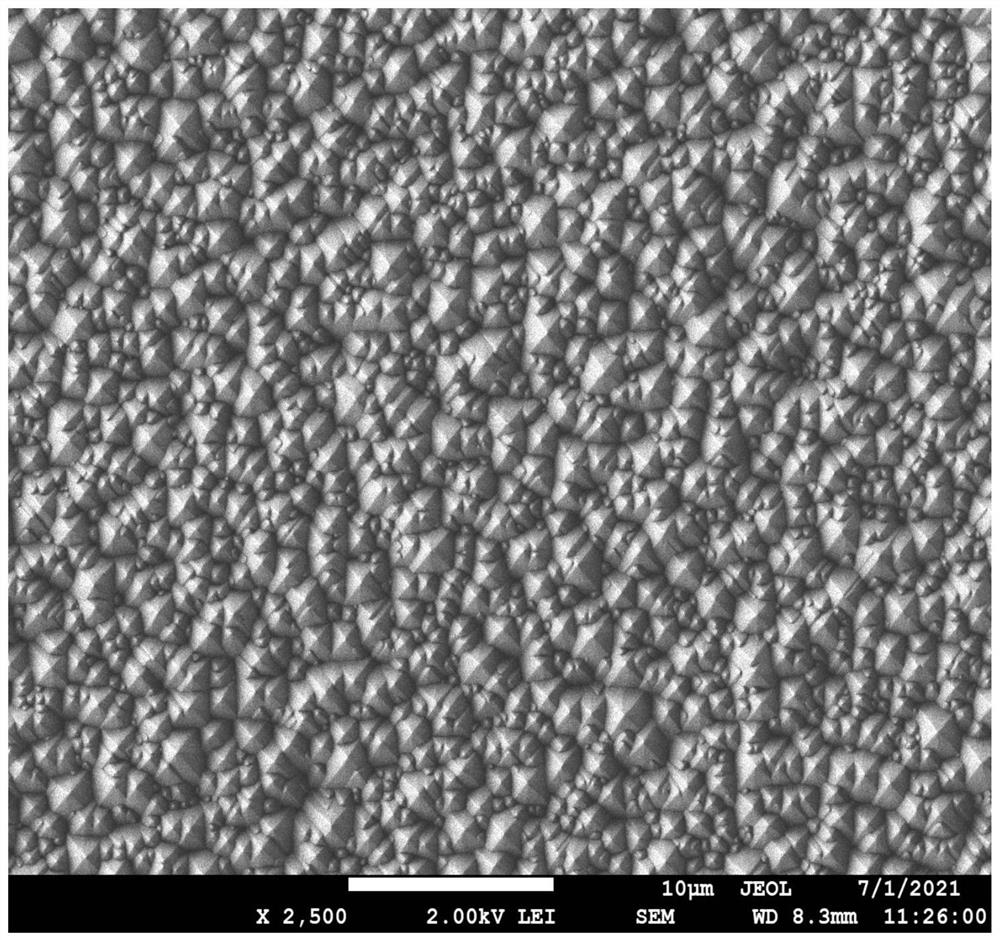

Texturing and cleaning method of silicon wafer and preparation method of crystalline silicon solar cell

PendingCN114256382AReduce consumptionEffective corrosionFinal product manufactureSemiconductor/solid-state device manufacturingSilicon solar cellCleaning methods

The invention relates to a silicon wafer texturing and cleaning method and a preparation method of a crystalline silicon solar cell. The silicon wafer texturing and cleaning method comprises the following steps: sequentially carrying out rough polishing treatment, acid washing treatment, first alkali washing treatment, texturing treatment, second alkali washing treatment, smoothing treatment, passivating treatment and drying treatment on a silicon wafer; a pickling solution used in the pickling treatment contains ozone, HCl and HF; a first alkali wash solution used in the first alkali wash treatment contains soluble alkali metal hydroxide salt and H2O2. The acid washing treatment and the first alkali washing treatment which are sequentially carried out are added between the rough polishing treatment and the texturing treatment; the combination of hydrogen peroxide and hydrochloric acid can greatly improve the cleaning effect, so that a post-cleaning step between subsequent smooth treatment and passivation treatment can be omitted, the consumption of hydrogen peroxide and hydrochloric acid is greatly reduced, the production cost is saved, and meanwhile, the efficiency of the technological process has no obvious difference.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

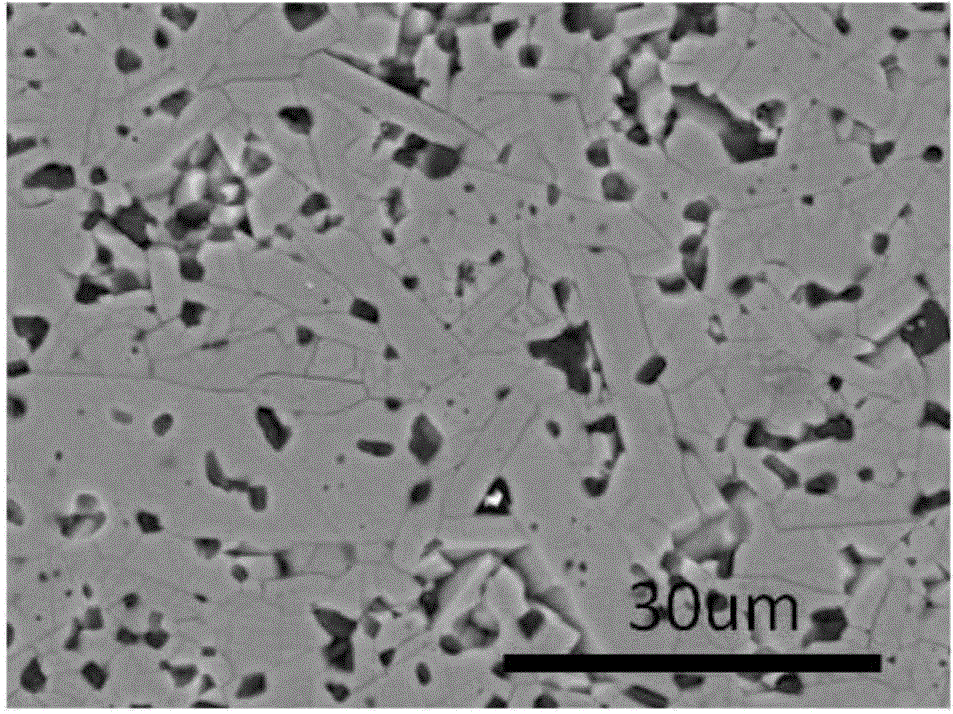

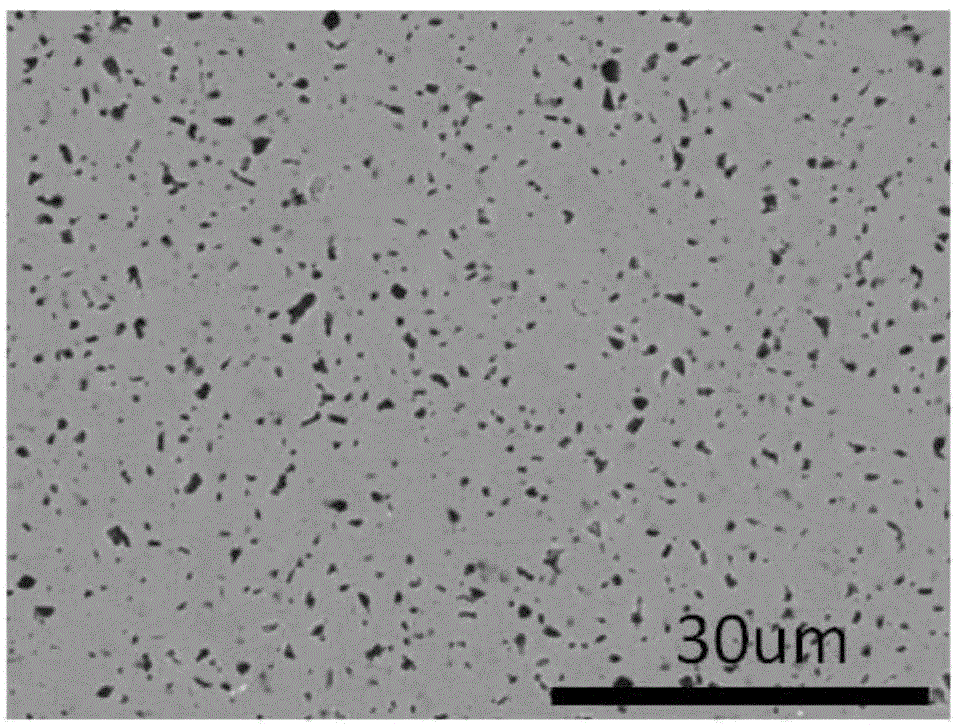

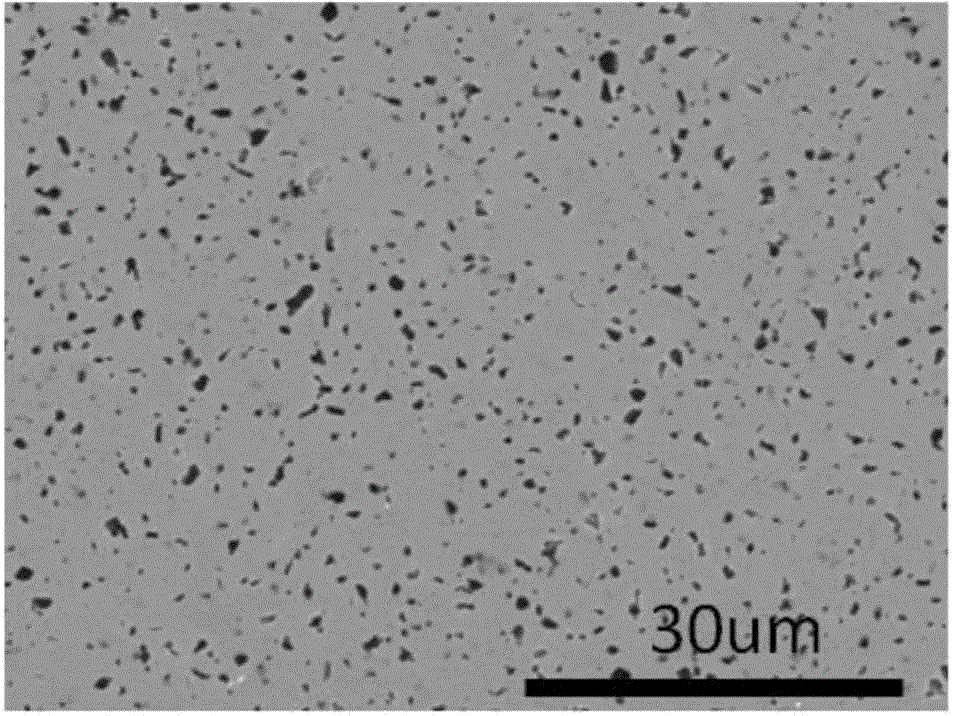

Method for corroding silicon carbide ceramics

The invention relates to a method for corroding silicon carbide ceramics, comprising: firstly adding concentrated hydrofluoric acid into a reaction vessel, then slowly adding concentrated nitric acid, stirring evenly, sealing and standing for 10-30 minutes to obtain an etching solution; The samples were immersed in the obtained etching solution and etched at 150-200°C for 12-24 hours. The method corrodes the solid-phase sintered silicon carbide ceramics at low temperature, so that the grain contrast after corrosion is obvious, and the grain boundary is cleaned, and at the same time, thermal defects introduced by high-temperature corrosion and defects introduced by high-energy etching are avoided.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method of preventing hydrogen fluoride corrosion for glass in aluminum electrolysis industry

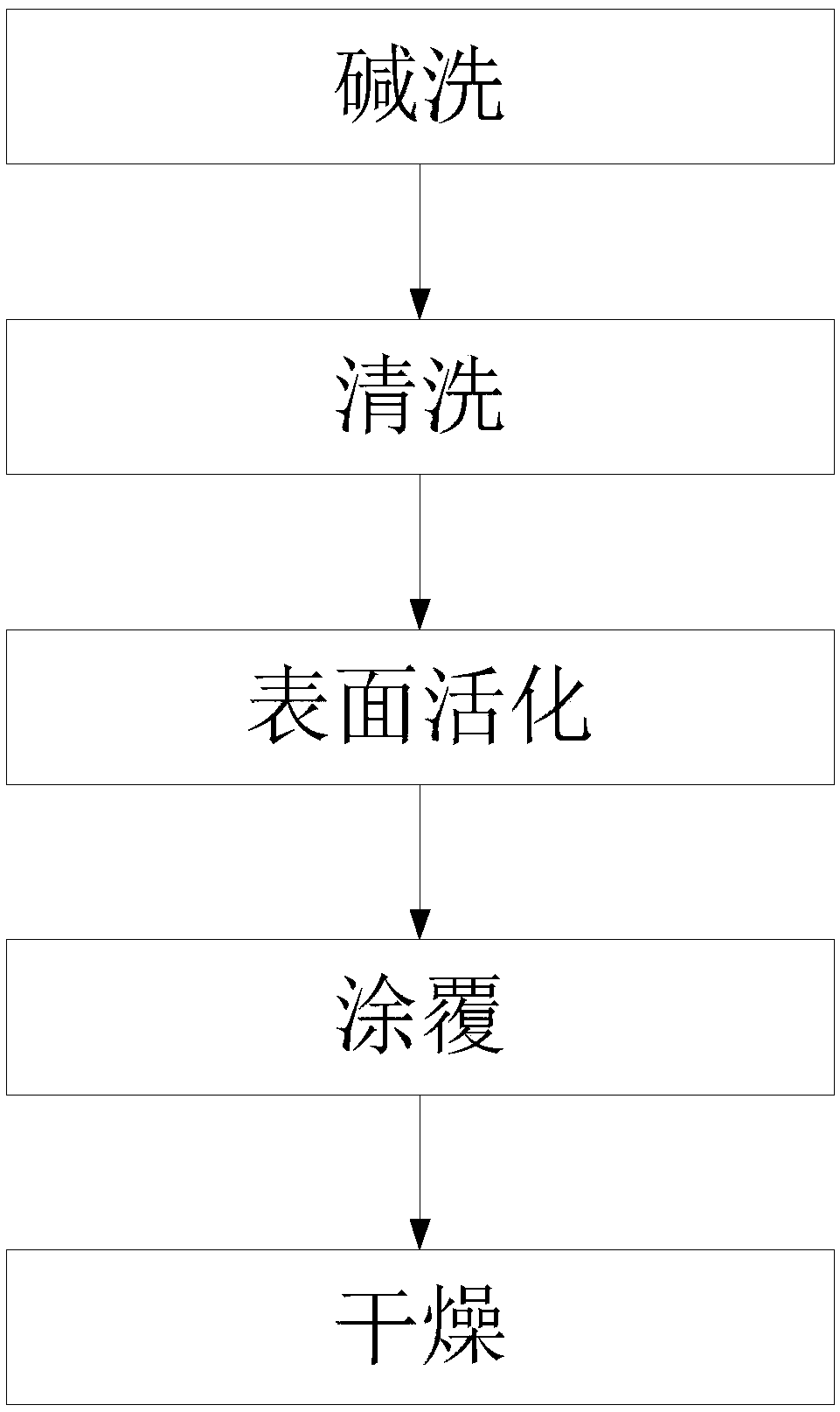

ActiveCN108970944ANo reduction in physical and chemical propertiesDoes not reduce light transmittanceLiquid surface applicatorsCoatingsHydrogen fluorideOptical transmittance

The invention discloses a method of preventing hydrogen fluoride corrosion in aluminum electrolysis industry and belongs to the field of glass corrosion prevention. The method includes the sequentialsteps of alkali washing of glass, cleaning, surface activation, coating, and drying. The method allows a coating and glass to be combined better; mechanical properties of the glass coating can be improved; whole mechanical and chemical properties and light transmittance of glass are not lowered. In addition, the method helps effectively prevent hydrogen fluoride corrosion and improve tolerance ofglass to acids and bases, attraction of dust to glass surface is greatly reduced, and light transmittance of the glass is greatly improved. The method allows coating precision to be improved on the whole, adaptability of machine batch treatment is improved, and it is guaranteed that anticorrosion performance of glass meets the standard at the premise of improved efficiency; as the whole coating step is applicable to automation on equipment, the method has better control convenience than the prior art.

Owner:CHONGQING UNIV

Engineering plastic formula

The invention relates to an engineering plastic formula, wherein the engineering plastic is prepared from the following raw materials by weight: 50-60 parts of a synthetic resin, 30-40 parts of an epoxy resin, 20-30 parts of a filler, 5-10 parts of a plasticizer, 2-5 parts of a lubricant, 5-10 parts of a curing agent, and 5-10 parts of reinforcing fiber. According to the present invention, the main component of the plastic formula is polyethylene; and the plastic produced according to the formula has advantages of no toxicity, strong chemical stability, high-temperature resistance and no environment pollution, can effectively resist acid corrosion and alkali corrosion, and is the environment-friendly plastic.

Owner:丹阳市景顺塑料制品有限公司

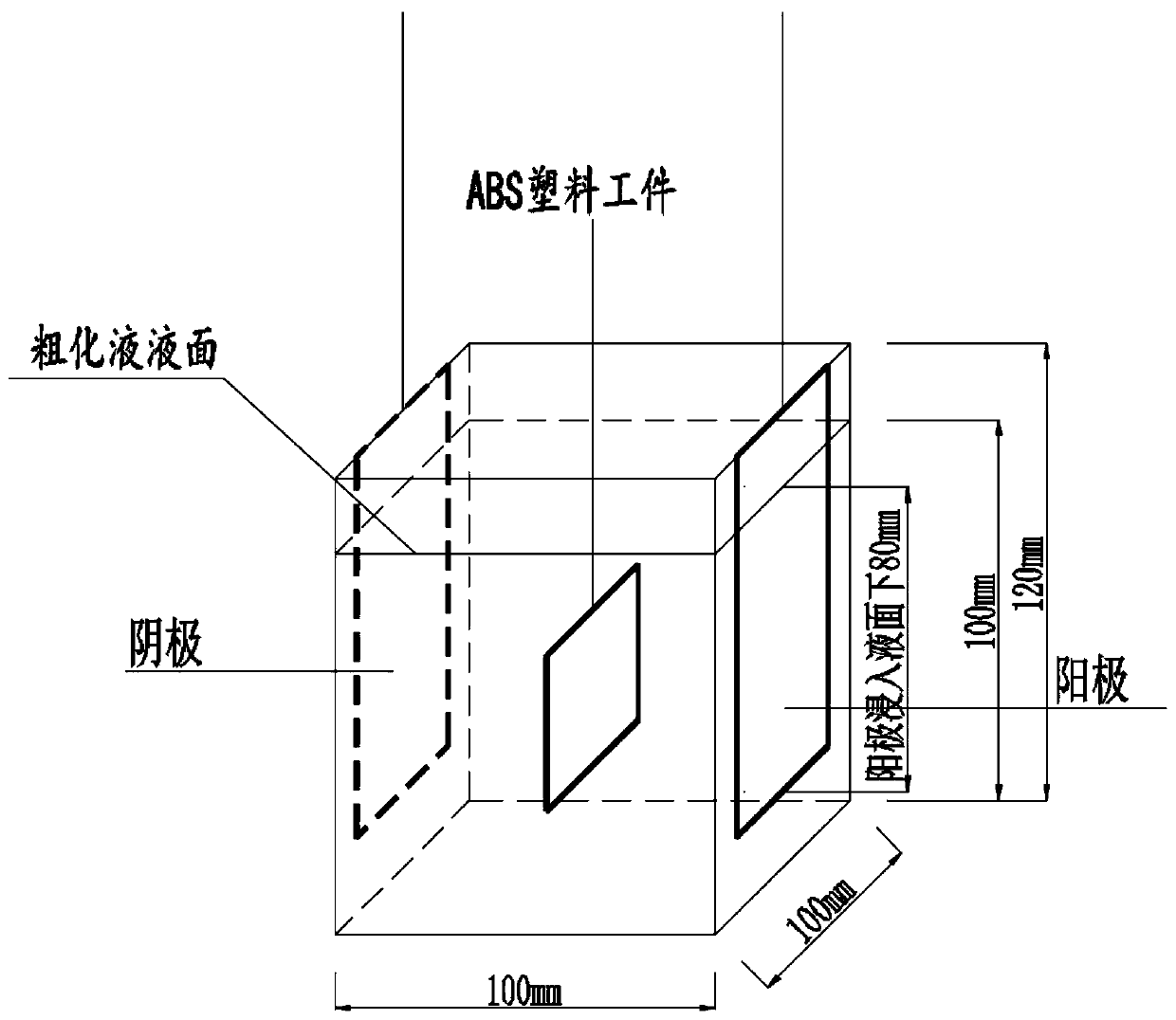

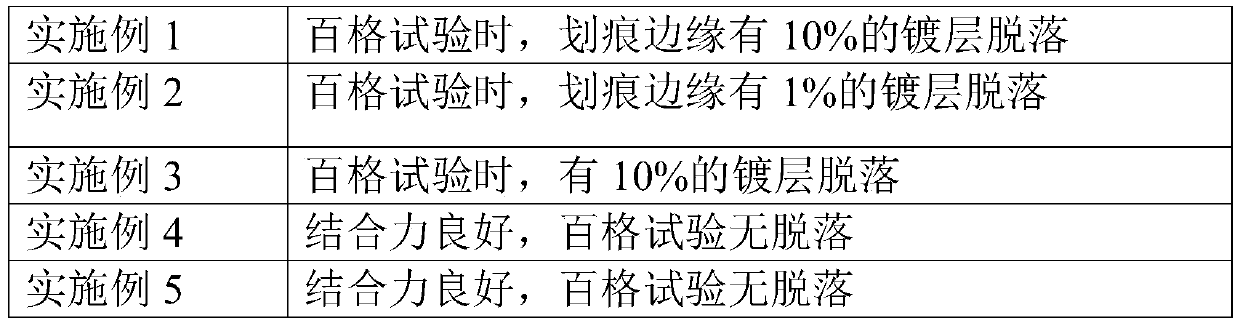

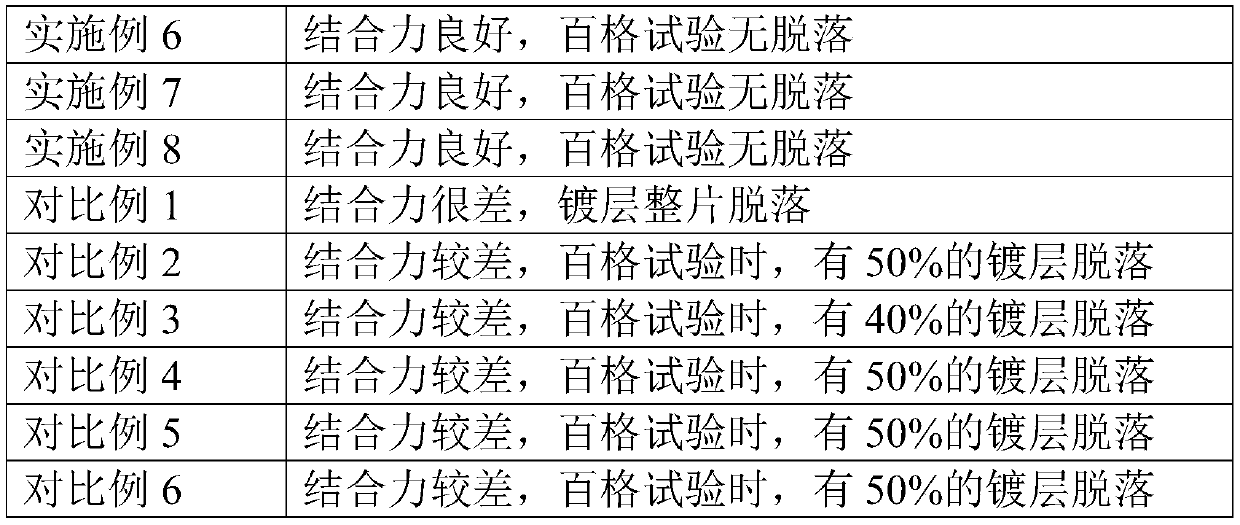

Chromium-free manganese-free coarsening liquid for ABS plastic and application method thereof

ActiveCN111519225ASatisfy coarsening requirementsImprove adhesionPhysical chemistryCatalytic decomposition

The invention relates to chromium-free manganese-free coarsening liquid for ABS plastic and an application method thereof. With water as a solvent, the chromium-free manganese-free coarsening liquid is mainly prepared from following raw materials with the concentrations through mixing: 1 g / L-30 g / L of ferrous sulfate heptahydrate and 10 mL / L-100 mL / L of hydrogen peroxide. The pH of the chromium-free manganese-free coarsening liquid is 1-7. According to the chromium-free manganese-free coarsening liquid for ABS plastic, no chromic anhydride and no manganese at any valence state are added to thecoarsening liquid. In an acid system, the chromium-free manganese-free coarsening liquid achieves the higher oxidizing ability under the catalytic decomposition effect of H2O2 of Fe2+ so as to conduct effective corrosion on the ABS plastic to complete coarsening. Thus, the bonding force between a follow-up plating layer and a base material is good, and the requirements for electroplating production are met.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

Pressure-resistant plastic formula

InactiveCN108003418AGood chemical stabilityNo pollution in the processTemperature resistanceChemical stability

The invention relates to a pressure-resistant plastic formula, wherein the pressure-resistant plastic is prepared from the following raw materials by weight: 50-60 parts of a synthetic resin, 20-30 parts of a filler, 5-10 parts of a plasticizer, 5-10 parts of silicon-aluminum carbon black, 5-10 parts of a curing agent, and 2-5 parts of an enhancer. According to the present invention, the main component of the plastic formula is polyethylene; the plastic produced according to the formula has advantages of no toxicity, strong chemical stability, high-temperature resistance and no environment pollution, can effectively resist acid corrosion and alkali corrosion, and is the environment-friendly plastic; and by adding the silicon-aluminum carbon black, the pressure resistance of the plastic isincreased.

Owner:丹阳市景顺塑料制品有限公司

Novel brushless motor fuel pump

InactiveCN102207050BEffective corrosionEfficient conductionMachines/enginesLiquid fuel feedersBrushless motorsCapacitance

Owner:周铁

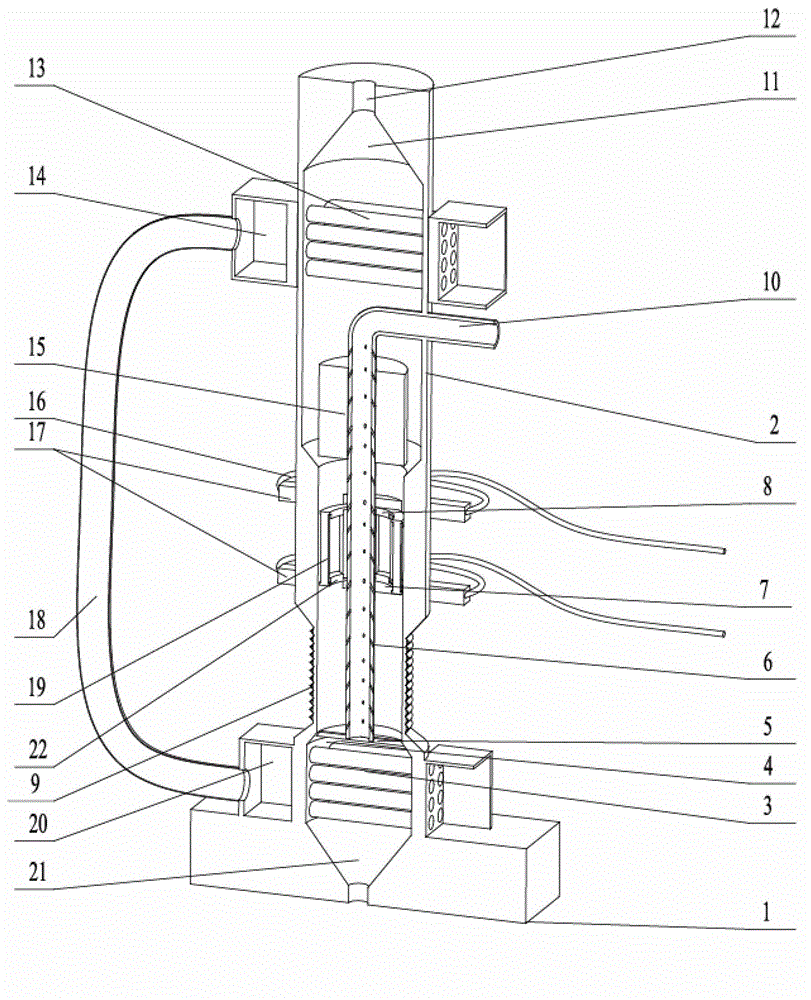

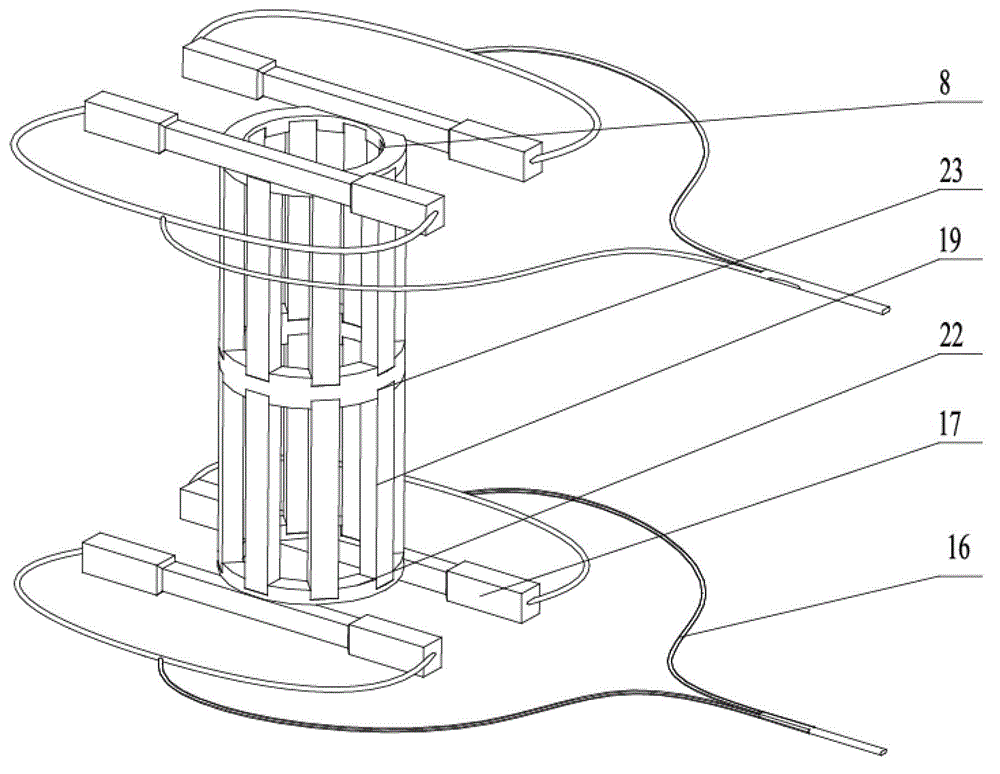

Novel carbon calcining furnace

ActiveCN102980393AEffective corrosionEffectively prevent corrosionFurnace typesLower gradeLow graded

The invention discloses a novel carbon calcining furnace, which comprises a furnace body (2), and is characterized in that: a heating bin (7) is arranged in the furnace body (2), and adopts a carbon liner; an upper heating connecting ring (8) and a lower heating connecting ring (22) are arranged in the heating bin (7); a heating body (19) is arranged between the upper heating connecting ring (8) and the lower heating connecting ring (22); and the upper heating connecting ring (8) and the lower heating connecting ring (22) are respectively connected with a graphite cross beam (17). According to the calcining furnace, the furnace body adopts the carbon liner, so that the corrosion of fluorine can be effectively prevented, and the furnace body is high temperature resistant; and the furnace body is used for preheating materials to be heat through a preheating bin, so that the heat energy is saved. The calcining furnace can be used for calcining, electrolytic aluminium wastes, low-grade inferior graphite, coal, petroleum coke and other carbon materials at high temperature, for desulfurizating and devolatilizing, so that the quality of the carbon materials is improved.

Owner:周俊和 +1

Low-temperature-resistant plastic formula

The invention relates to a low-temperature-resistant plastic formula, wherein the low-temperature-resistant plastic is prepared from the following raw materials by weight: 50-60 parts of a synthetic resin, 40-50 parts of polyvinyl chloride, 20-30 parts of a filler, 5-10 parts of a plasticizer, 2-5 parts of a cross-linking agent, 5-10 parts of a curing agent, and 2-5 parts of a reinforcing agent. According to the present invention, the main component of the plastic formula is polyethylene; and the plastic produced according to the formula has advantages of no toxicity, strong chemical stability, low-temperature resistance and no environment pollution, can effectively resist acid corrosion and alkali corrosion, and is the environment-friendly plastic.

Owner:丹阳市景顺塑料制品有限公司

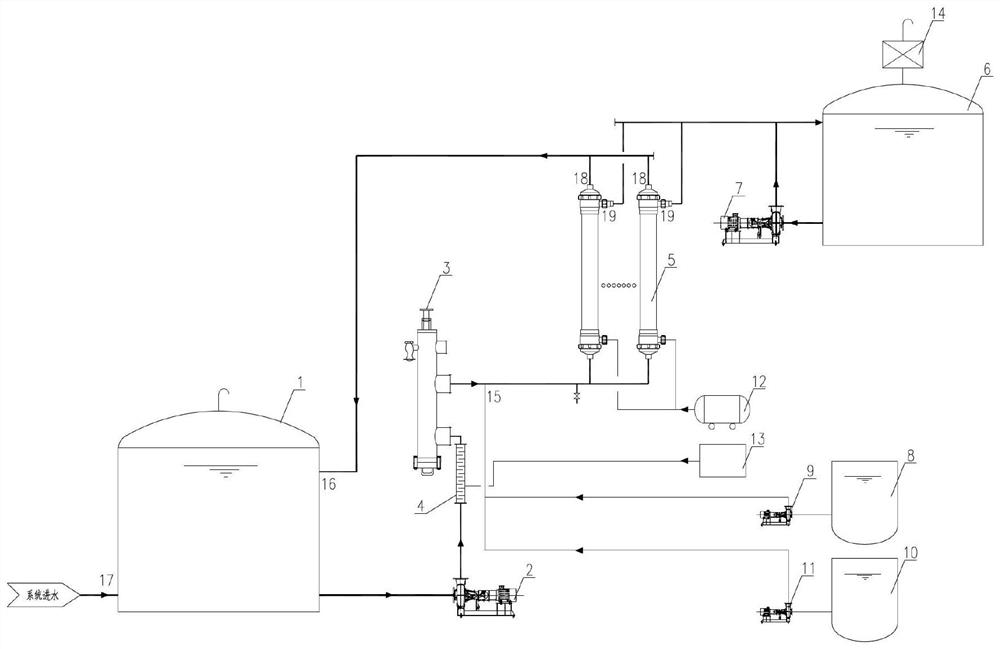

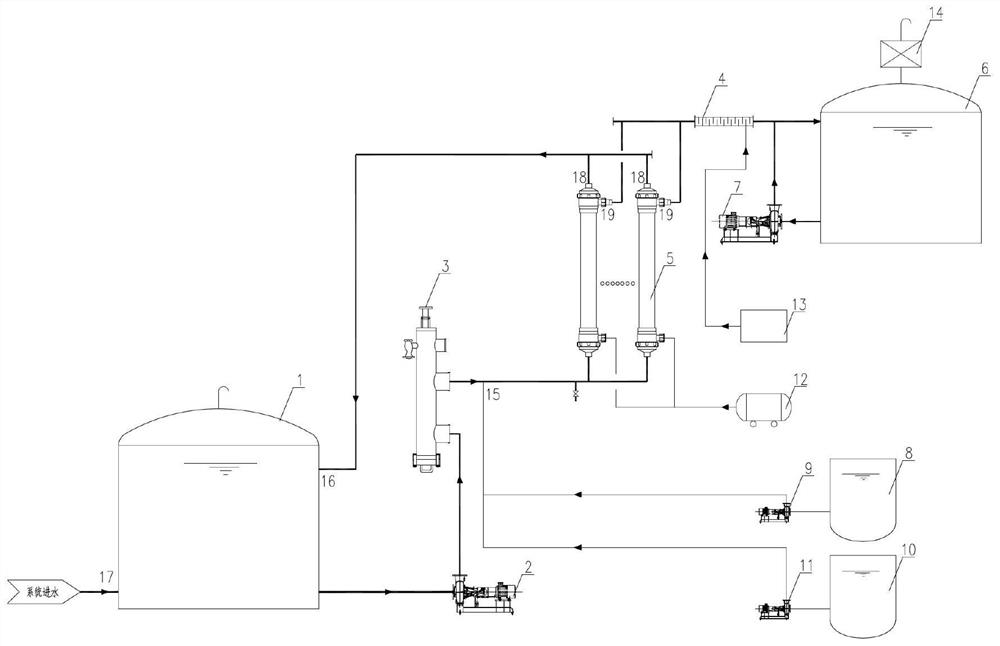

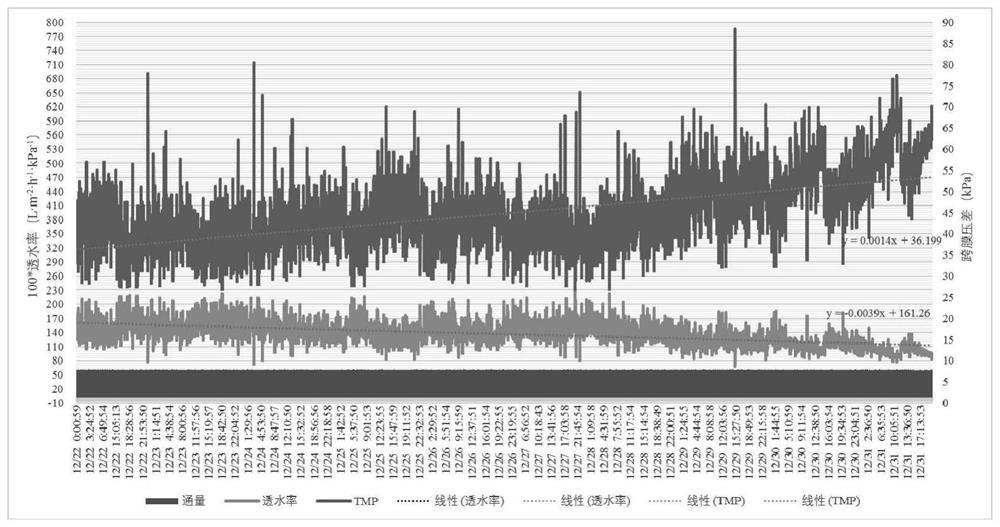

Cleaning system and method for ultrafiltration membrane

PendingCN114849487AReduce irreversible damageLess irreversible damageUltrafiltrationTreatment involving filtrationRinse waterAir compressor

The invention belongs to the technical field of ultrafiltration membrane cleaning, and discloses an ultrafiltration membrane cleaning system and method. The system comprises a raw water tank, an ultrafiltration water inlet pump, a self-cleaning filter, ultrafiltration equipment, a water producing tank, a tail gas destroying device, a backwashing water pump, an air compressor subsystem, an ozone generator subsystem and an optional dosing cleaning subsystem. By using the novel ultrafiltration membrane system in cooperation with the ozone pre-oxidation method, the service life of the ultrafiltration membrane can be prolonged, the cleaning effect is improved, and the influence on the online rate of membrane operation is reduced.

Owner:北京北排膜科技有限公司

A back polishing process for solar cells

ActiveCN109830564BImprove protectionNot corrodedFinal product manufacturePhotovoltaic energy generationScreen printingPhysical chemistry

Owner:中建材浚鑫(桐城)科技有限公司

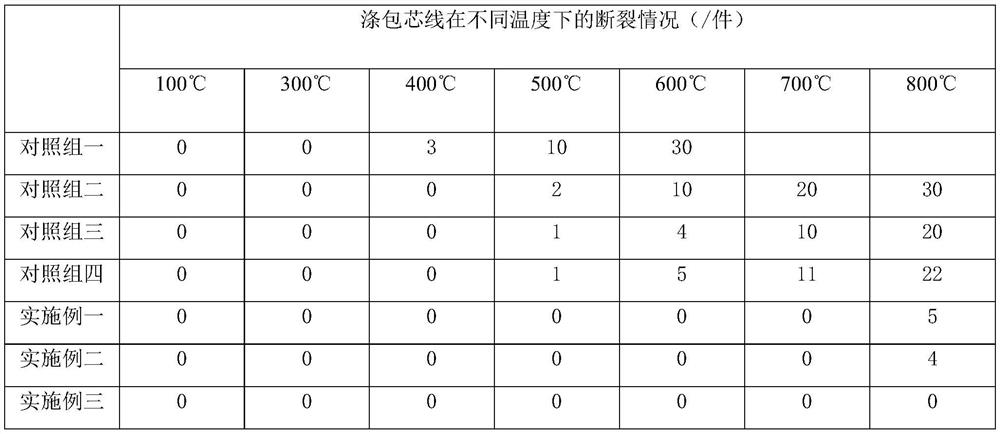

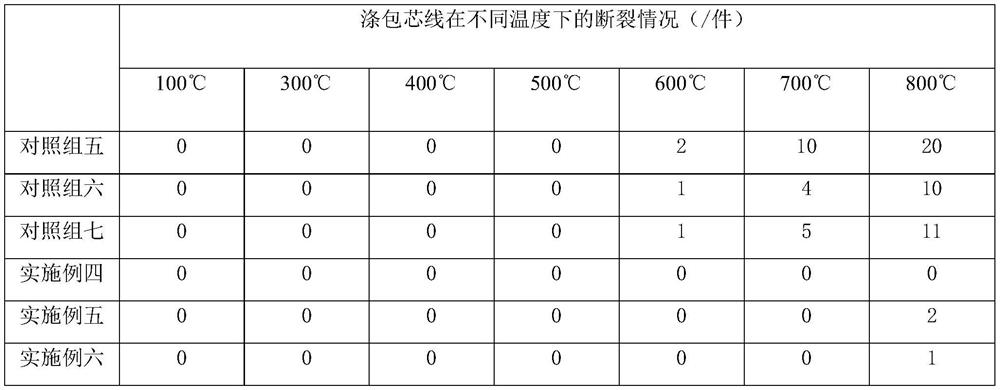

High-elastic wear-resistant antibacterial regenerated polyester core-spun yarn and production process thereof

The invention discloses a high-elastic wear-resistant antibacterial regenerated polyester core-spun yarn and a production process thereof, and particularly relates to the technical field of polyestercore-spun yarns. The core-spun yarn comprises a polyester core-spun yarn A and a polyester core-spun yarn B. The polyester core-spun yarn A comprises boron fibers, carbon fibers and basalt fibers; andthe polyester core-spun yarns B take polyimide filaments as core yarns and take polyester staple fibers as covering yarns. The boron fibers, the carbon fibers and the basalt fibers are used in cooperation, so that the heat resistance and the flame retardance of the polyester core-spun yarn can be effectively enhanced, heat insulation and flame retardance treatment can be effectively conducted atthe sewing position of a garment fabric, and the safety performance is improved. A carbon fiber yarn made of the polyester core-spun yarn A material and polyester staple fibers in the polyester core-spun yarn B are matched to be used as covered yarns, and a composite bulked yarn made of the polyester core-spun yarn A material and polyimide filaments in the polyester core-spun yarn B are matched tobe used as core yarns, so that the heat-resistant strength and the flame retardant property of the polyester core-spun yarn can be further improved, and the safety performance is improved.

Owner:江阴远闻纺织有限公司

Corrosion-resistant composite board and processing method thereof

ActiveCN108608694ARolling realizationReduce usageLaminationLamination apparatusTitaniumComposite plate

The invention provides a corrosion-resistant composite board and a processing method thereof. By utilizing original warm-rolling and asymmetrical rolling methods, composite boards for flue can be continuously produced. The composite board comprises a titanium layer, an aluminum layer and a steel layer overlapped and compounded in sequence, wherein the thickness of the aluminum layer is 0.5-1mm, the total thickness of the aluminum layer and the titanium layer is 1-2mm, and the thickness of the steel layer is 3-40mm. By utilizing the board, an effect of reaching corrosion-resistant life of 10 years or longer of the flue can be achieved, the service life is greatly prolonged, and the composite board has extremely high popularization value.

Owner:MAANSHAN JILI MACHINERY EQUIP

Functional silver flake and preparation method thereof

The invention discloses a preparation method of functional silver flakes, which includes the following steps of (A), preparing microcrystalline micro-silver powder containing silver oxide by means of primary reduction; (B), grinding silver flakes with a ball mill and then filtering the same to obtain silver slurry containing ball-milled dispersant; (C), treating the silver powder by etching and secondary reduction to obtain stereoscopic cross-linked structural silver flakes with 3-12% micro-silver powder, wherein a reducing agent A is an alcohol weak reductant while a reducing agent B is a strong reductant. The preparation method is simple in process, easy to realize mass production and applicable to large-scale production in the industry. The functional silver flakes prepared by the method have stereoscopic cross-linked reticular space structures, small in grain size and low in apparent density. Besides, since the functional silver flakes contain 3-10% of monocrystal or flocculent silver powder, point-surface contact among the silver powder and filling capability of the silver powder are improved, and conductivity is high.

Owner:广东羚光新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com