Chromium-free manganese-free coarsening liquid for ABS plastic and application method thereof

A technology of ABS plastic and roughening liquid, applied in the field of roughening liquid, can solve the problems of unstable bonding force, easy pitting of the coating, uneven processing results of roughening liquid, etc., so as to improve stability and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

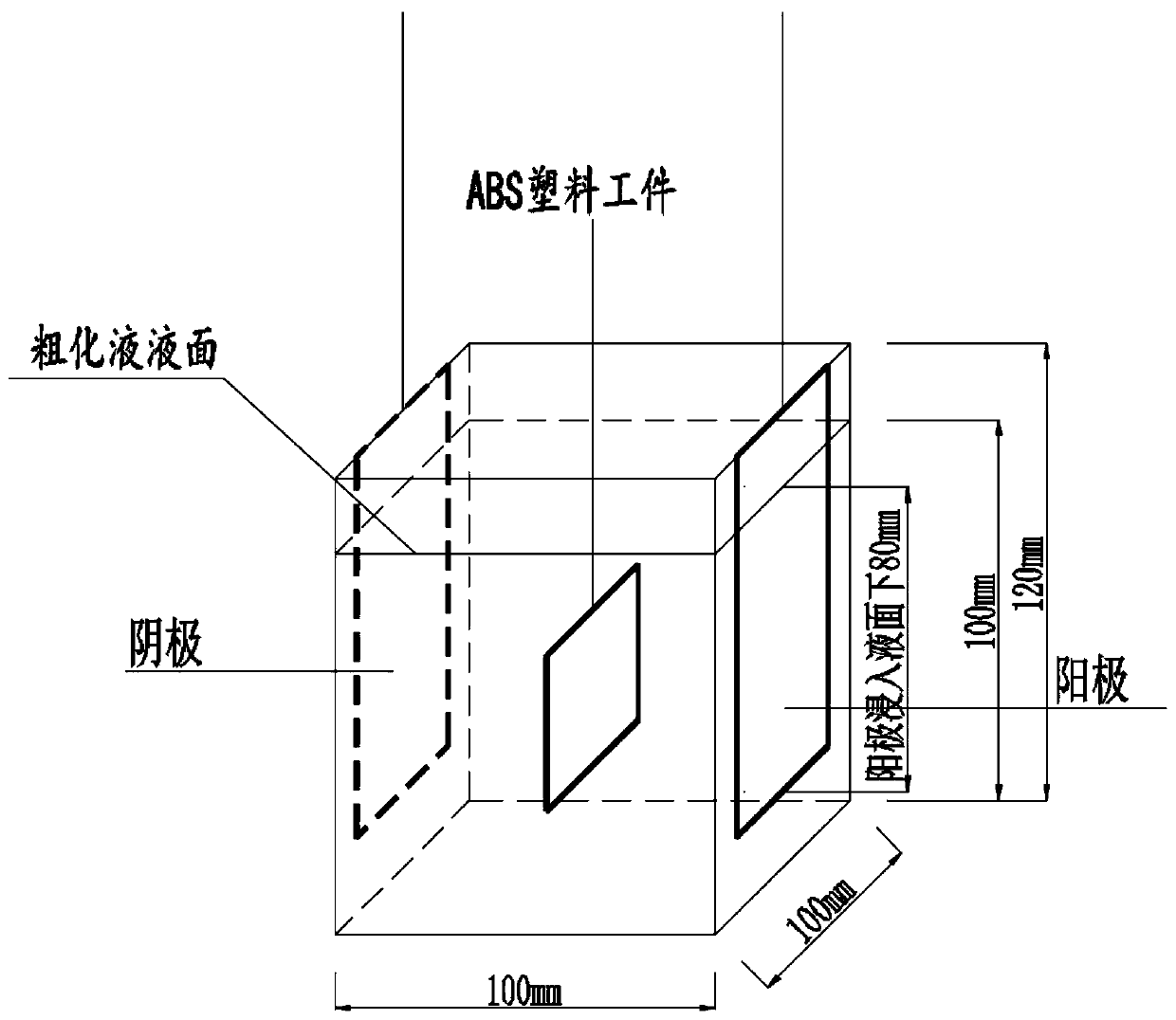

Image

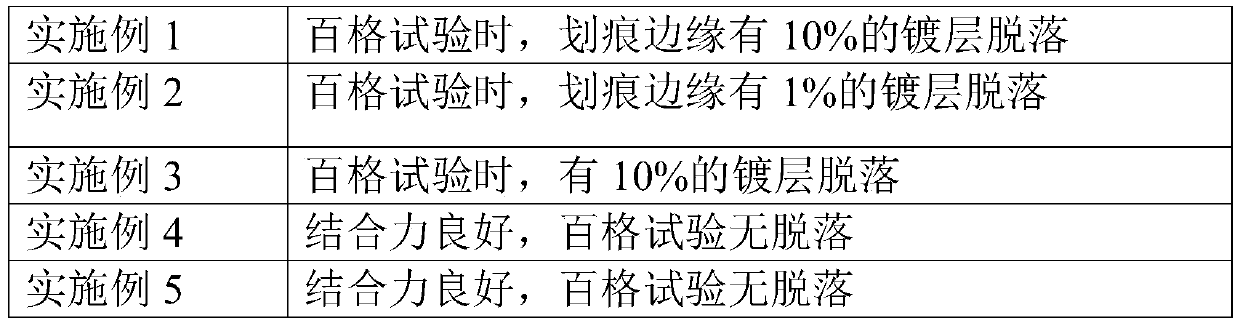

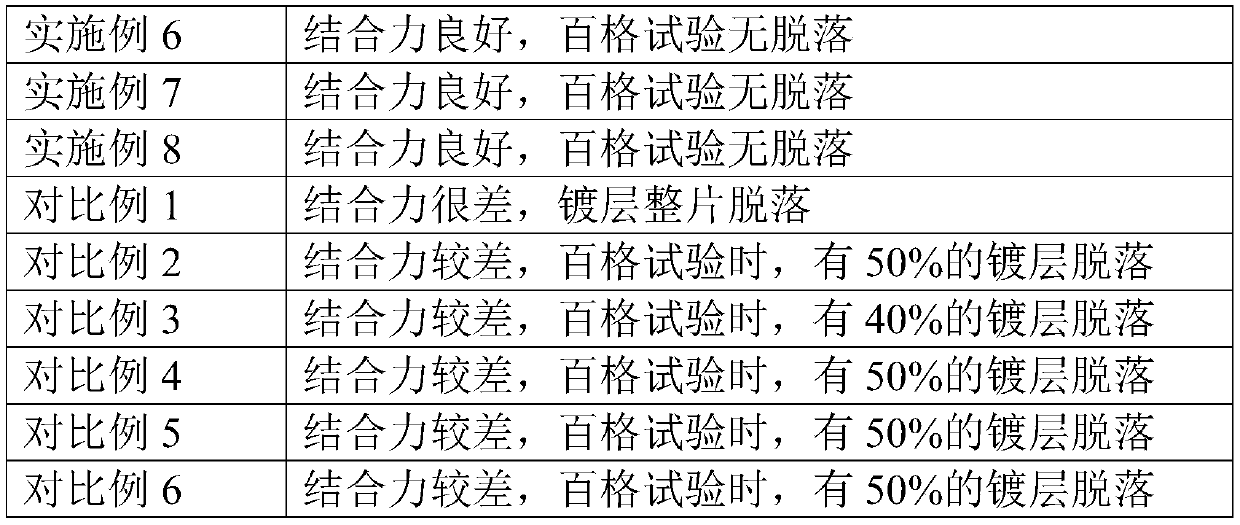

Examples

Embodiment 1

[0085] This embodiment provides a chrome-free and manganese-free roughening solution for ABS plastics and a preparation method thereof. The preparation method of the chromium-free and manganese-free roughening solution is as follows:

[0086] Add 8 g of ferrous sulfate heptahydrate, 32 mL of 30% hydrogen peroxide and 0.3 mL of 98% sulfuric acid to 1 L of water to obtain a chromium-free and manganese-free roughening solution with a pH of 3.0.

Embodiment 2

[0088] This embodiment provides a chrome-free and manganese-free roughening solution for ABS plastics and a preparation method thereof. The preparation method of the chromium-free and manganese-free roughening solution is as follows:

[0089]Add 12g of ferrous sulfate heptahydrate, 42mL of 30% hydrogen peroxide and 0.3mL of 98% sulfuric acid to 1L of water to obtain a chrome-free and manganese-free roughening solution with a pH of 3.0.

Embodiment 3

[0091] This embodiment provides a chrome-free and manganese-free roughening solution for ABS plastics and a preparation method thereof. The preparation method of the chromium-free and manganese-free roughening solution is as follows:

[0092] Add 6 g of ferrous sulfate heptahydrate, 28 mL of 30% hydrogen peroxide, 0.3 mL of 98% sulfuric acid, 0.5 g of potassium persulfate, 0 g of citric acid monohydrate, 1.8 g of EDTA, and 0.4 g of oxalic acid pentahydrate in 1 L of water iron, 0.02g of cerium sulfate octahydrate and 0.2g of copper sulfate pentahydrate to obtain a chromium-free and manganese-free roughening solution with a pH value of 3.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com