Rusty protective coating with rust conversion function and preparation method

A protective coating and rust conversion technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of complex preparation process and field engineering application limitations, and achieve the effect of simple preparation method, excellent anchoring performance and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

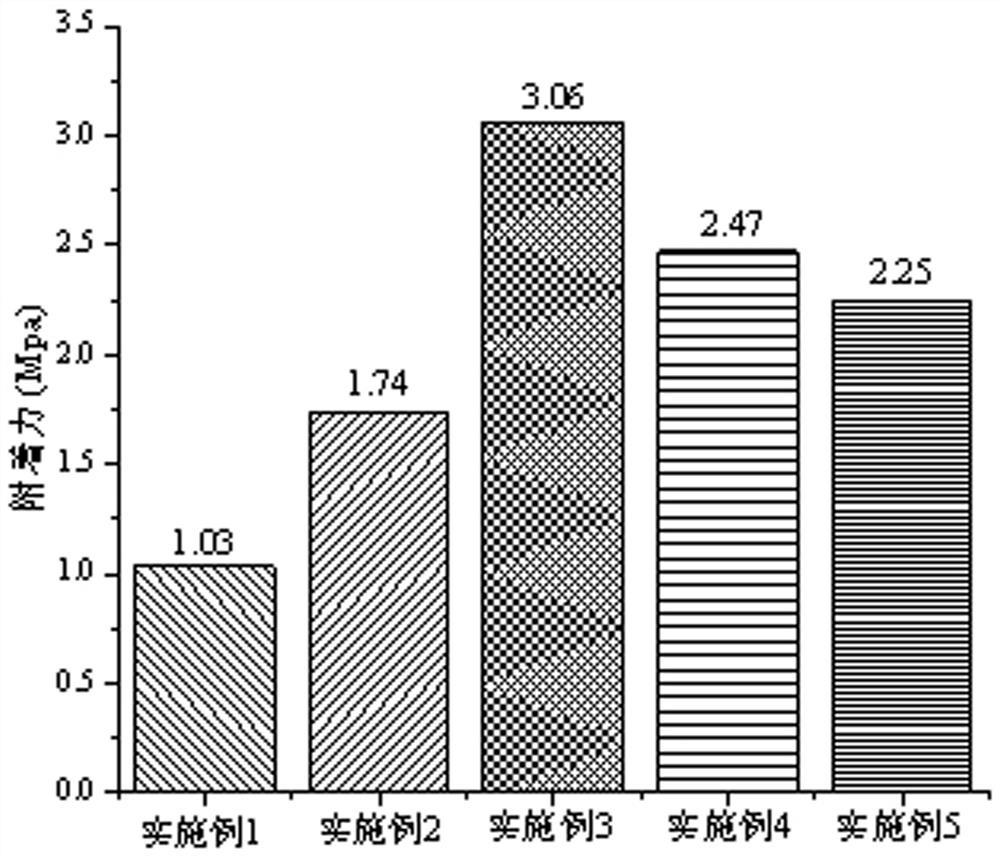

Embodiment 1

[0031] Dosing according to the following weight: acidic resin emulsion with a solid content of 60%, defoamer with a mass of 1‰ of the acidic resin emulsion, wetting agent with a mass of 1‰ of the acidic resin emulsion, and thickener with a mass of 1‰ of the acidic resin emulsion.

[0032] When preparing the rust protective coating, proceed as follows:

[0033] 1) Weigh according to the parts by weight of each component;

[0034] 2) Add coating additives such as defoamer, wetting agent and thickener to the acidic resin emulsion in turn. That is, the rust-carrying protective paint is obtained.

Embodiment 2

[0036] Solid content is 90 parts of the acidic resin emulsion of 60%, 10 parts of rust conversion agent; The defoamer of acidic resin emulsion and rust conversion agent gross mass 1‰, the wetting agent of acidic resin emulsion and rust conversion agent gross mass 1‰ and A thickener with a total mass of 1‰ of acidic resin emulsion and rust converting agent.

[0037] Wherein the rust converting agent is prepared from raw materials in the following mass ratios: according to the mass parts, by 1 part of phosphoric acid, 1 part of tannic acid, 5 parts of citric acid, 5 parts of benzoic acid, 5 parts of n-octanoic acid, 5 parts of ethanol, 5 parts of Parts of sodium secondary alkyl sulfonate, 5 parts of alcohol amine compounds and 10 parts of deionized water.

[0038] Wherein, the mass concentration of phosphoric acid is 25%, the mass concentration of tannic acid is 55%, the mass concentration of citric acid is 50%, the mass concentration of benzoic acid is 45%, and the mass concent...

Embodiment 3

[0045] Solid content is 80 parts of the acidic resin emulsion of 60%, 20 parts of rust conversion agent; The defoamer of acidic resin emulsion and rust conversion agent gross mass 1‰, the wetting agent of acidic resin emulsion and rust conversion agent gross mass 1‰ and A thickener with a total mass of 1‰ of acidic resin emulsion and rust converting agent.

[0046] The rust converting agent is prepared from raw materials in the following proportions: 5 parts of phosphoric acid, 5 parts of tannic acid, 10 parts of citric acid, 10 parts of benzoic acid, 15 parts of n-octanoic acid, 10 parts of ethanol, 10 parts of secondary alkylsulfonate Sodium acid sodium, 15 parts of alcohol amine compounds and 20 parts of deionized water.

[0047] Wherein, the mass concentration of phosphoric acid is 30%, the mass concentration of tannic acid is 50%, the mass concentration of citric acid is 40%, the mass concentration of benzoic acid is 50%, and the mass concentration of n-octanoic acid is 60%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com