Method for detecting distribution and content of residual austenite in low alloy structure steel

A technology for retained austenite and structural steel, applied in the field of detection of residual austenite distribution and content in low-alloy structural steel, can solve the problems of long test period, complicated process, complicated sample preparation process, etc., and achieve short polishing and corrosion time , simple operation, beautiful image effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

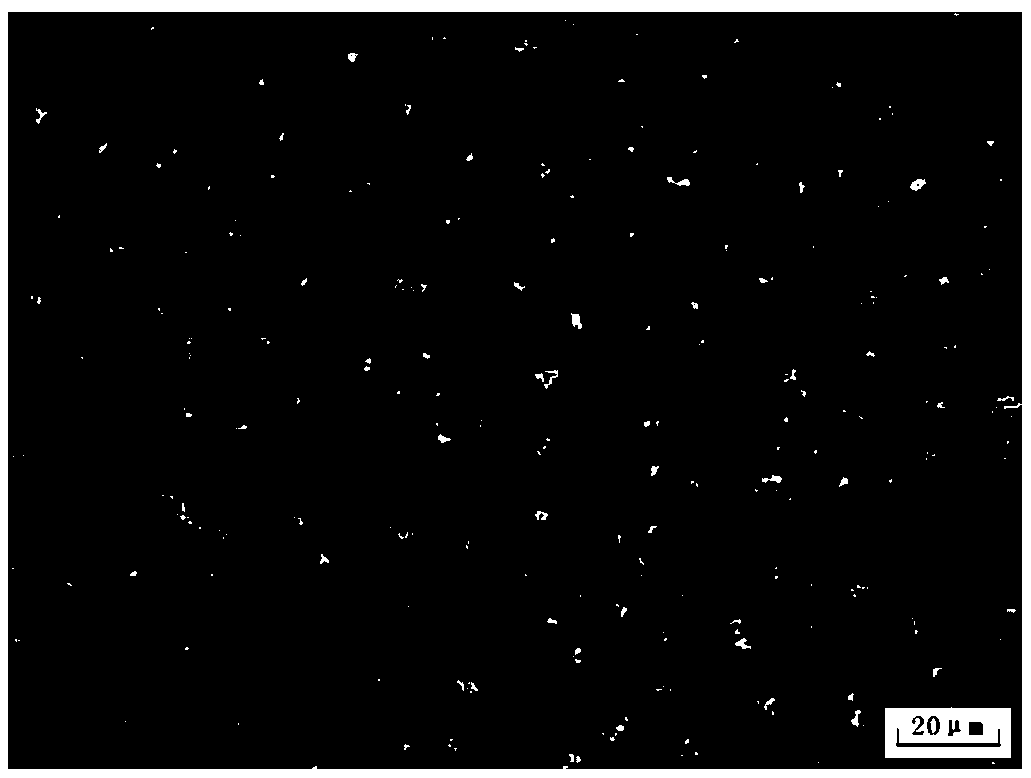

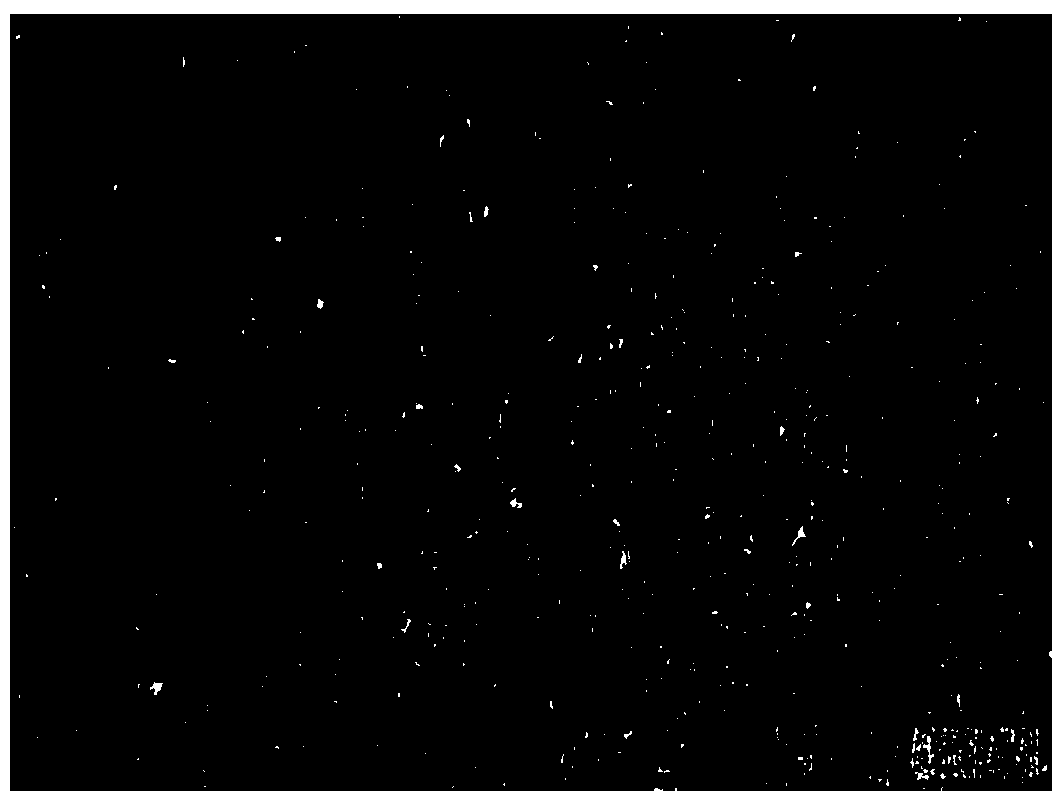

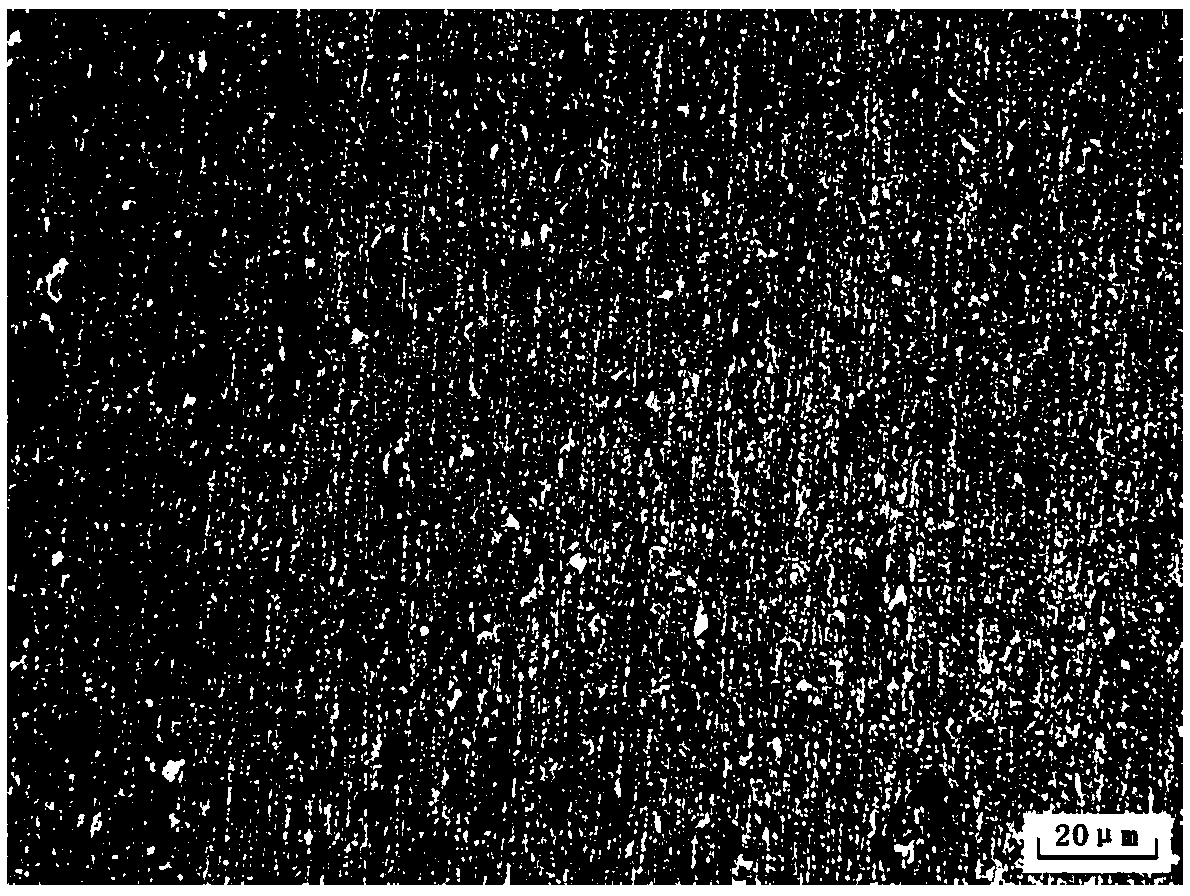

[0033] The present invention provides a method for detecting the distribution and content of retained austenite in low-alloy structural steels, and is able to quickly and clearly display the low-alloy structure in view of the complicated operation of the existing method and the inability to accurately reflect the content and distribution of retained austenite The retained austenite structure in structural steel can be quantitatively analyzed accurately.

[0034] The present invention is a method for detecting the distribution and content of retained austenite in low alloy structural steel, including the following steps:

[0035] S1, sample preparation

[0036] Use metallographic water sandpaper for rough grinding and fine grinding on the test surface of the sample. After replacing the fine sandpaper, the grinding direction should be 90° with the direction of the upper track until the upper track wear marks are worn away; the above process needs to keep a constant flow of water As a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com