Texturing and cleaning method of silicon wafer and preparation method of crystalline silicon solar cell

A technology for making texture and silicon wafers, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problem of high unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The present invention also provides a method for preparing a crystalline silicon solar cell, which includes the steps of the above-mentioned texturing and cleaning method for silicon wafers, and after the texturing and cleaning, further includes sequentially depositing an amorphous silicon film and depositing a transparent conductive oxide Thin films and steps for making metal electrodes.

[0089] In some of the embodiments, the above-mentioned crystalline silicon solar cells are HJT cells. Specifically, its crystalline silicon solar cell includes the following steps:

[0090] Thin intrinsic amorphous silicon film (i-a-Si:H) and p-type amorphous silicon film (p-a-Si:H) are deposited on the front side of N-type monocrystalline silicon wafer (c-Si), and then deposited on the silicon wafer Thin intrinsic amorphous silicon film (i-a-Si:H) and n-type amorphous silicon film (n-a-Si:H) are deposited on the back of the wafer to form the back surface field; then transparent oxi...

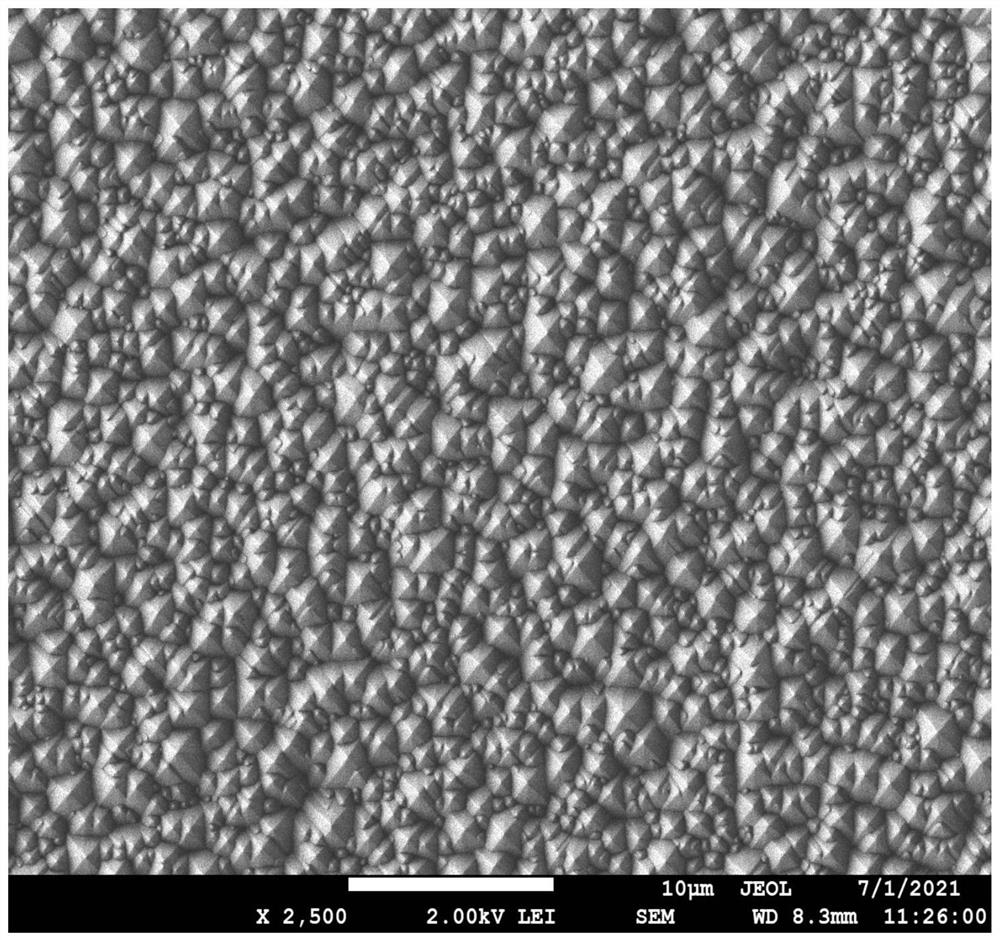

Embodiment 1

[0095] S1: Coarse throwing. The reagent used for rough throwing is KOH aqueous solution with a mass concentration of 5%, the temperature is set at 80°C, the time is 180s, and the circulation flow rate is kept at about 35L / min. The function is to remove the damaged layer on the surface of the silicon wafer. At this time, the etching depth of the single side of the silicon wafer is about 4 μm.

[0096] S2: pickling (ozone cleaning). The mass concentration of HCl in the pickling solution is 0.02%, the mass concentration of HF is 1%, ozone (O 3 ) concentration is set to 30ppm, the temperature is set to 25°C, the time is set to 240s, 35L / min.

[0097] S3: pre-cleaning (first alkaline washing). The first alkaline washing solution is KOH, H 2 o 2 aqueous solution, wherein the mass concentration of KOH is 1.1%, H 2 o 2 The mass concentration is 4.5%, the temperature is set at 65°C, the time is set at 240s, and the circulation flow is kept at about 40L / min. The function is to r...

Embodiment 2~4

[0106] The steps of Examples 2-4 are the same as those of Example 1, except that the concentrations of reagents used in each step and the temperature, time and flow rate of treatment are adjusted, as shown in Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com