EVM rubber composition used as fuel hose coating

A technology of rubber composition and fuel hose, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of breakage, high working pressure, and the advantages of AEM materials are no longer obvious, and achieve cost saving and low cost Effect

Inactive Publication Date: 2012-07-04

TIANJIN PENGYI GRP CO LTD

View PDF1 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, during the use of the outer layer of fuel, AEM will inevitably come into contact with a small amount of fuel or fuel vapor, which will cause corrosion of the protective layer of the fuel pipe. With continuous improvement, the advantages of AEM materials with poor fuel resistance are no longer obvious, and are gradually being replaced by materials with lower prices and better fuel resistance.

The working pressure of the fuel pipe supplying fuel is relatively high, and a large torque clamp assembly or crimping joint is required during assembly. However, AEM vulcanizate has no rigidity, and it is easy to cause damage under excessive pressure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

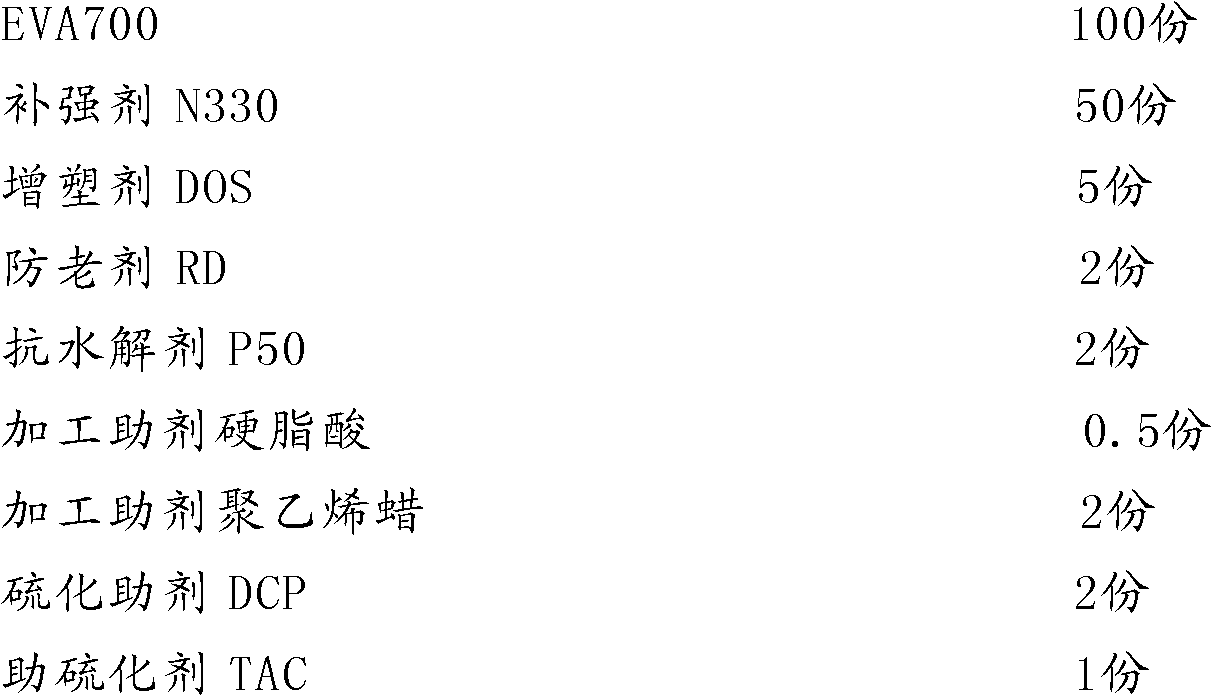

Embodiment 1

[0013]

[0014] Vulcanization curve and performance test, see the table below:

[0015]

[0016]

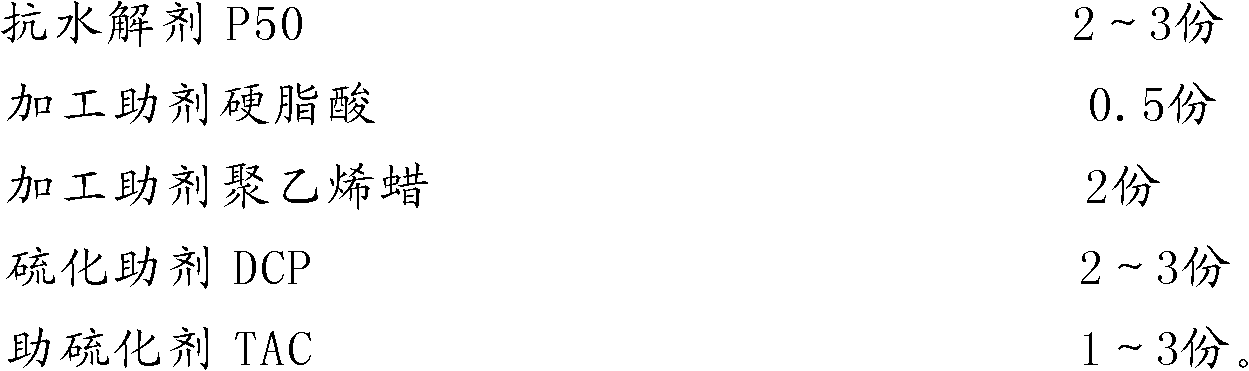

Embodiment 2

[0018]

[0019] Vulcanization curve and performance test, see the table below:

[0020]

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an EVM rubber composition used as a fuel hose coating. The composition comprises the following components in parts by weight: 100 parts of EVA, 50 to 60 parts of reinforcer N330, 5 to 10 parts of plasticizer DOS, 2 parts of anti-aging agent RD, 2 to 3 parts of anti-hydrolysis agent P50, 0.5 parts of processing aid stearic acid, 2 parts of processing aid polyethylene wax, 2 to 3 parts of vulcanizing aid DCP, and 1 to 3 parts of vulcanizing aid TAC. Since EVM (ethylene vinyl-acetate copolymer) is used as the major material, on the one hand, the EVM rubber composition as the fuel hose coating is resistant to fuel corrosion and more favorable for safety transportation of fuels, and on the other hand, the cost is lower than that of AEM and about a half that of AEM provided by the DuPont company, so that the cost is saved.

Description

technical field [0001] The invention relates to the technical field of automobile rubber hoses, in particular to an EVM rubber composition for the outer layer of a fuel hose with the characteristics of heat resistance, fuel resistance and flame retardancy. Background technique [0002] Automotive fuel hoses include fuel delivery pipes and fuel pipes that supply fuel to the engine. They are relatively important safety parts and have many performance requirements for their materials. The inner layer glue should choose materials with good resistance to fuel medium and heat resistance, and the outer layer glue should choose materials with good heat resistance, ozone resistance, environmental impact resistance and good adhesion with the inner layer glue. [0003] The traditional fuel hose uses a three-layer structure of inner rubber / middle layer / outer rubber. The inner layer is NBR (nitrile rubber); the middle layer is a reinforcement layer; the outer layer is CR (chloroprene rub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L31/04C08K13/02C08K5/09F16L11/08

Inventor 张洪起陈亮

Owner TIANJIN PENGYI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com