A back polishing process for solar cells

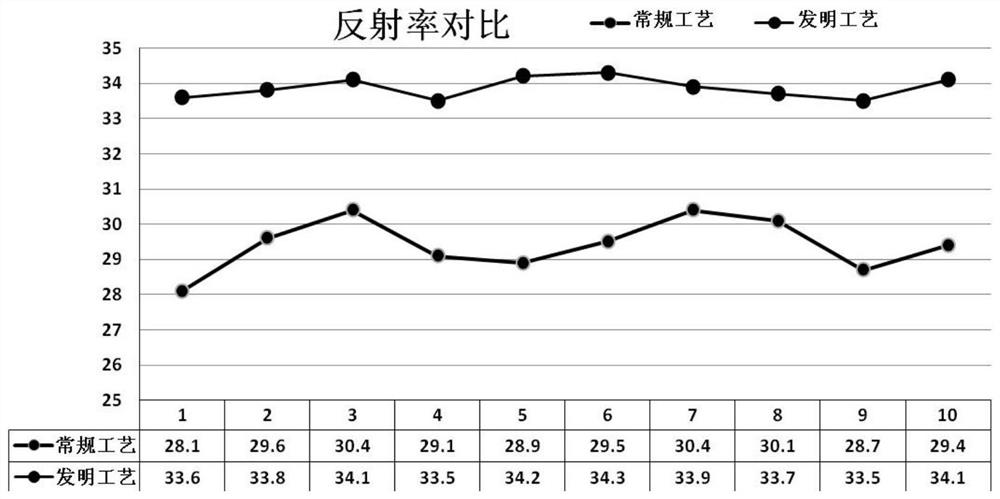

A solar cell, back polishing technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of no light, short process time, long soaking time, etc., to reduce the probability of damage and improve the polishing quality , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of back polishing process of solar cells, this back polishing process comprises the following steps:

[0034] (1) Place the silicon wafer in a sodium hydroxide solution with a mass fraction of 10% for pre-cleaning for 1 min. The temperature of the sodium hydroxide solution is controlled at 60° C., and then washed with deionized water, and then the silicon wafer is placed at 65° C. Texturing in the texturing solution for 10 minutes, the texturing solution is formed by mixing a nitric acid solution with a mass percentage of 60% and a hydrofluoric acid solution with a mass fraction of 40% in a volume ratio of 3:1, forming The wormhole-like suede structure is washed with deionized water and dried, and the phosphorus is diffused on the front of the silicon wafer. The diffusion resistance is 60Ω to obtain a PN junction. The silicon glass is cleaned and dried, and finally a layer of silicon nitride anti-reflection film is deposited on the front of the silicon wafer by P...

Embodiment 2

[0038] A kind of back polishing process of solar cells, this back polishing process comprises the following steps:

[0039] (1) Place the silicon chip in a sodium hydroxide solution with a mass fraction of 12% for pre-cleaning for 1.2 min. The temperature of the sodium hydroxide solution is controlled at 65° C., and then washed with deionized water, and then the silicon chip is placed at 70 Texture in the texturing solution at ℃ for 15 minutes. The texturing solution is made by mixing nitric acid solution with a mass percentage of 65% and a hydrofluoric acid solution with a mass fraction of 42% in a volume ratio of 3:1. Form a wormhole-like suede structure, wash and dry with deionized water, carry out phosphorus diffusion on the front of the silicon wafer, the diffusion resistance is 65Ω, and obtain a PN junction, and use a hydrofluoric acid solution with a volume fraction of 11% to dissolve the phosphorus on the surface of the silicon wafer. The phosphosilicate glass is clean...

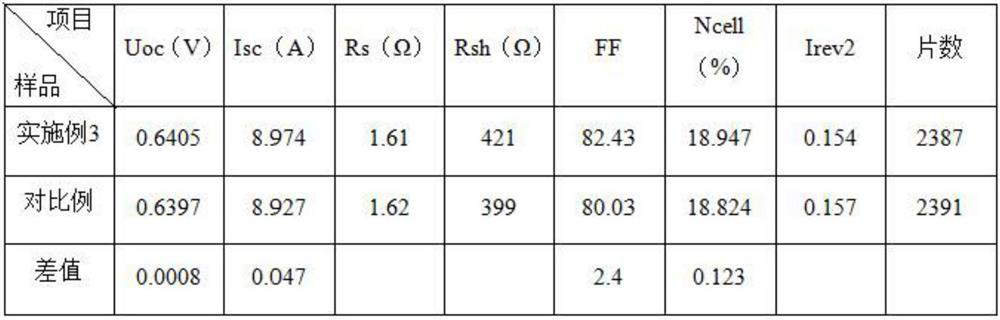

Embodiment 3

[0043] A kind of back polishing process of solar cells, this back polishing process comprises the following steps:

[0044] (1) Place the silicon chip in a sodium hydroxide solution with a mass fraction of 15% for pre-cleaning for 1.5 min. The temperature of the sodium hydroxide solution is controlled at 70° C., and then washed with deionized water, and then the silicon chip is placed at 75 17min in the texturing solution at ℃, the texturing solution is made by mixing 70% nitric acid solution and 45% hydrofluoric acid solution in a volume ratio of 4:1, and the front and back of the silicon wafer Form a wormhole-like suede structure, wash and dry with deionized water, carry out phosphorus diffusion on the front side of the silicon wafer, the diffusion resistance is 70Ω, and obtain a PN junction, and use a hydrofluoric acid solution with a volume fraction of 12%. The phosphosilicate glass is cleaned and dried, and finally a layer of silicon nitride anti-reflection film is deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com