Novel carbon calcining furnace

A calcining furnace and carbon technology, applied in the field of new carbon calcining furnaces, can solve the problems of long heating time, complex process, and many equipment, and achieve the effect of improving true density, fast heating and small carbon powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

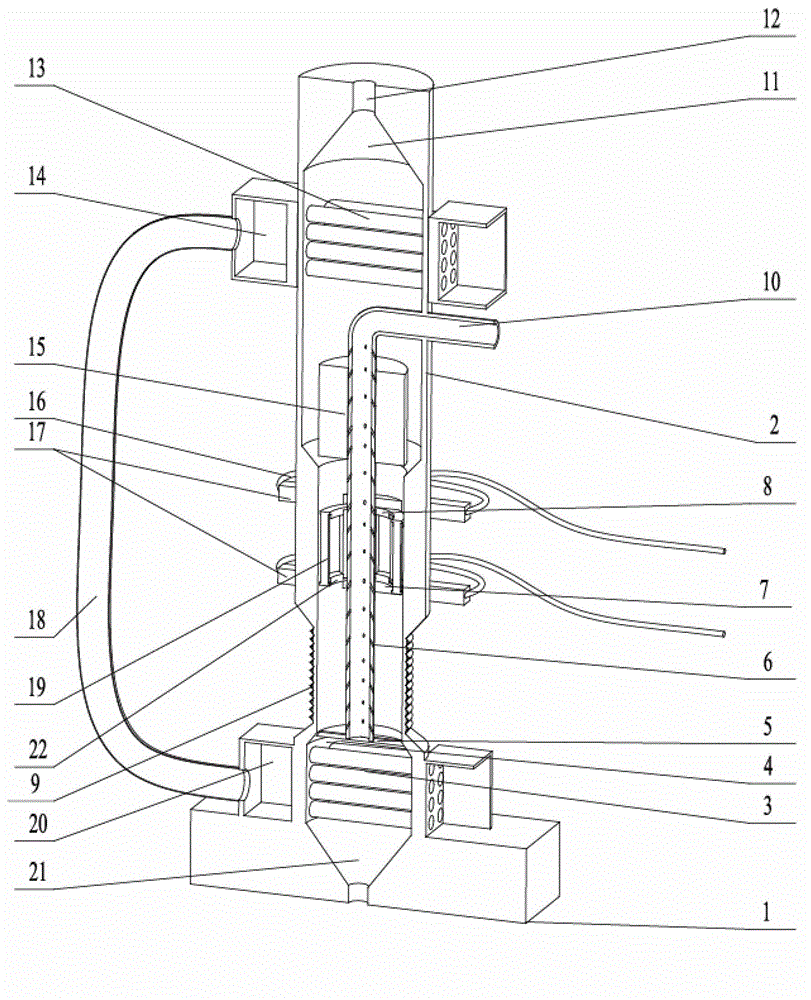

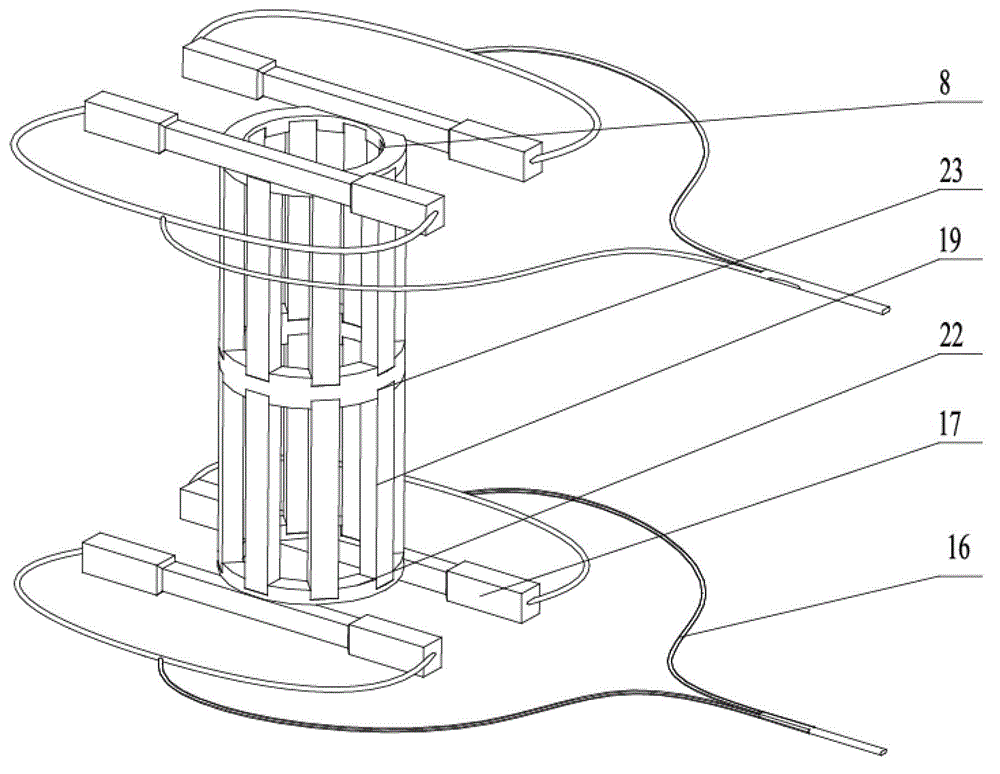

[0022] Embodiment 1 of the present invention. New carbon calciner, such as figure 1 As shown, the furnace body 2 is made, and the heating chamber 7 is made in the furnace body 2. The heating chamber 7 is lined with carbon. The upper heating connecting ring 8 and the lower heating connecting ring 22 are arranged in the heating chamber 7. The upper heating connecting ring 8 and the lower heating connecting ring 22 are connected to the heating body 19, and the upper heating connecting ring 8 and the lower heating connecting ring 22 are respectively connected to the graphite beam 17. The upper and lower graphite beams 17 are respectively connected with cables as positive and negative poles.

[0023] A feed inlet 12, a preheating bin 11, a heating bin 7, a rapid cooling bin 4, and a discharge port 21 are sequentially arranged in the furnace body 2 from top to bottom. The preheating bin 11 and the rapid cooling bin 4 can utilize the residual heat of the calcined material to prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com