Patents

Literature

55results about How to "Increase true density" patented technology

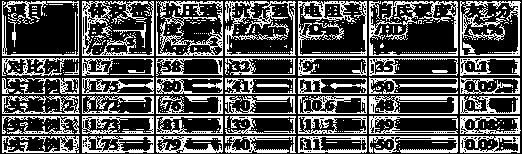

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

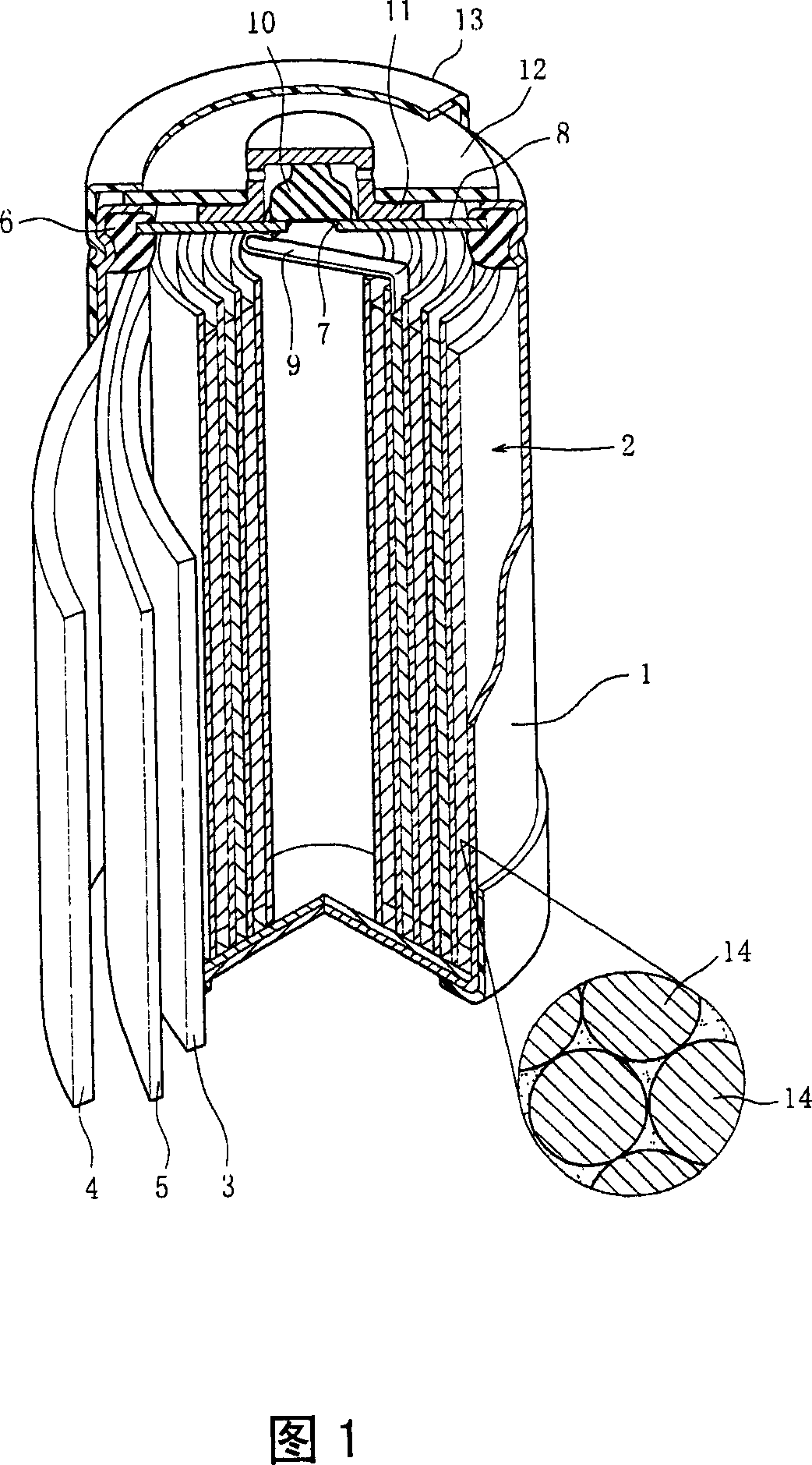

Non-aqueous electrolyte secondary battery and method of manufacturing the same

InactiveUS20110200879A1Stable structureIncrease true densityFinal product manufactureCobalt compoundsIon exchangeCobalt

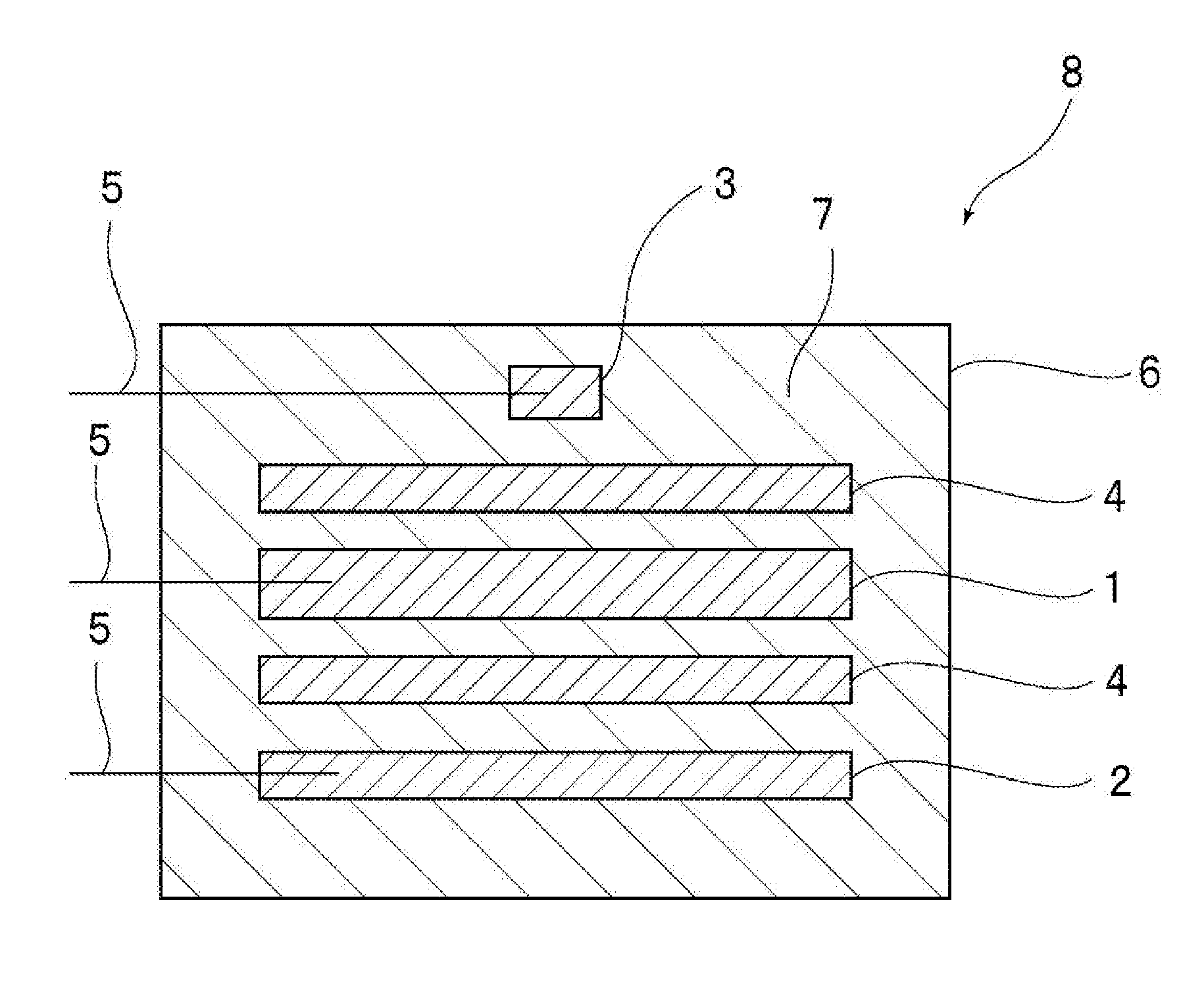

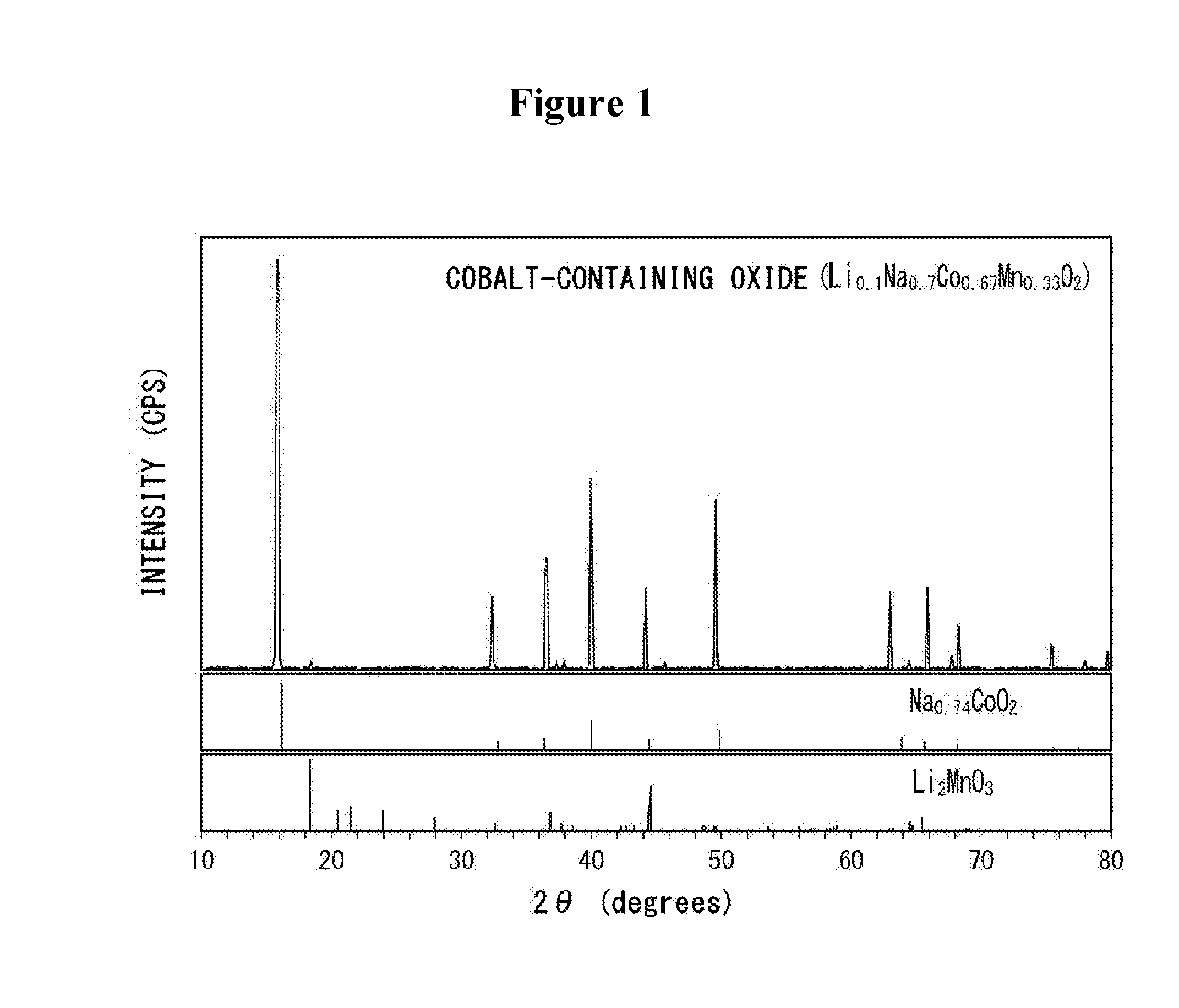

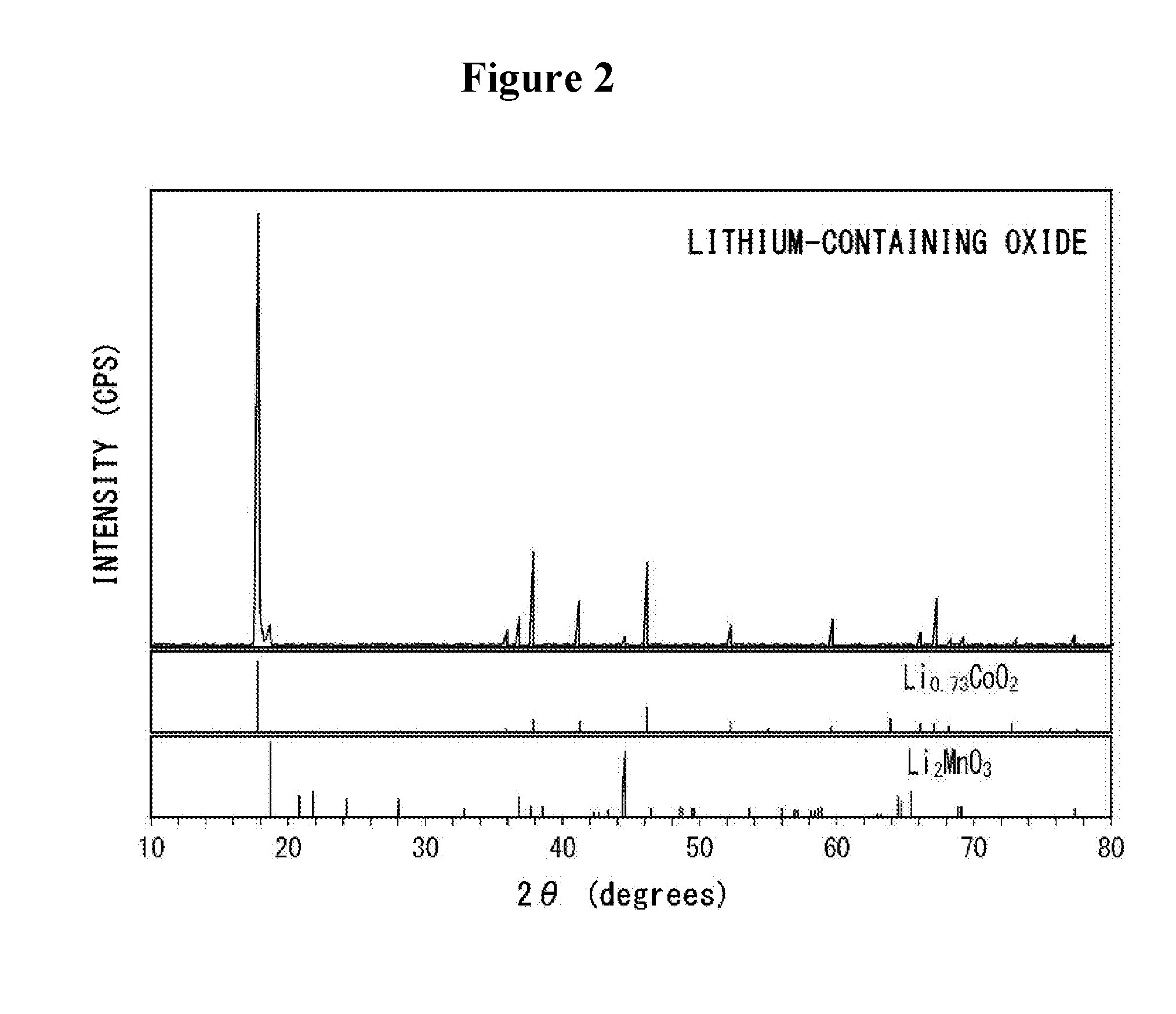

A non-aqueous electrolyte secondary battery has a positive electrode containing a positive electrode active material, a negative electrode, and a non-aqueous electrolyte. The positive electrode active material includes a lithium-containing oxide obtained by ion exchanging a portion of sodium contained in a cobalt-containing oxide with lithium, the cobalt-containing oxide represented by the formula Lix1Nay1CoαMnβMzOγ where: M is at least one element selected from the group consisting of Mg, Ni, Zr, Mo, W, Al, Cr, V, Ce, Ti, Fe, K, Ca, and In; 0<x1<0.45; 0.66<y1<0.75; 0.62≦α≦0.72; 0.28≦β≦0.38; 0≦z≦0.1; and 1.9≦γ≦2.1.

Owner:SANYO ELECTRIC CO LTD

Preparation method of high purity aluminium oxide powder

InactiveCN1903728AHigh chemical purityReduce sodiumAluminium oxide/hydroxide preparationWater bathsAluminium hydroxide

The present invention relates to a preparation method of high-purity aluminium oxide powder body. It is characterized by that it adopts aluminium sheet whose purity is 99.9999% and organic alkal; and makes them be mutually reacted in hot water bath to obtain the precipitate of aluminium hydroxide, then the precipitate is calcined at 1100-1200deg.C and ground so as to obtain high-purity ultrafine aluminium oxide powder body. The described organic alkal; includes any one of choline, hexamethohydrotetramine and dopamine.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

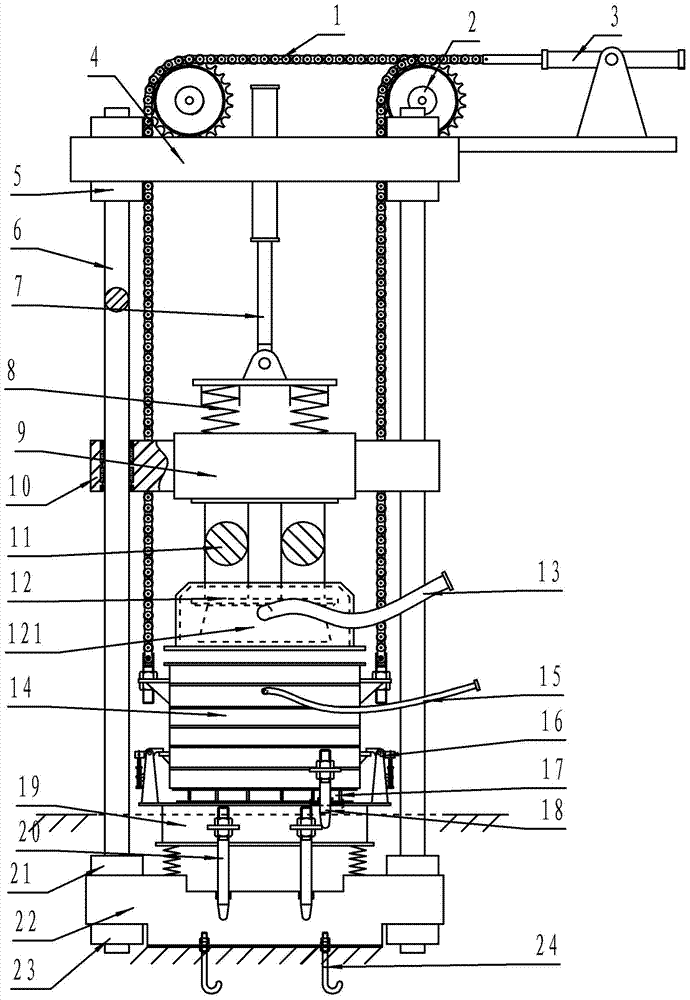

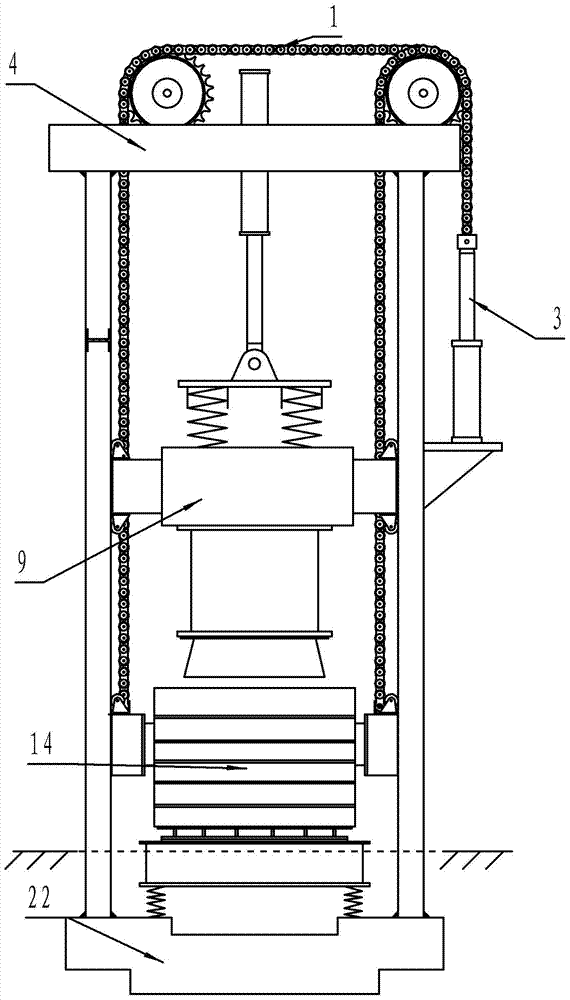

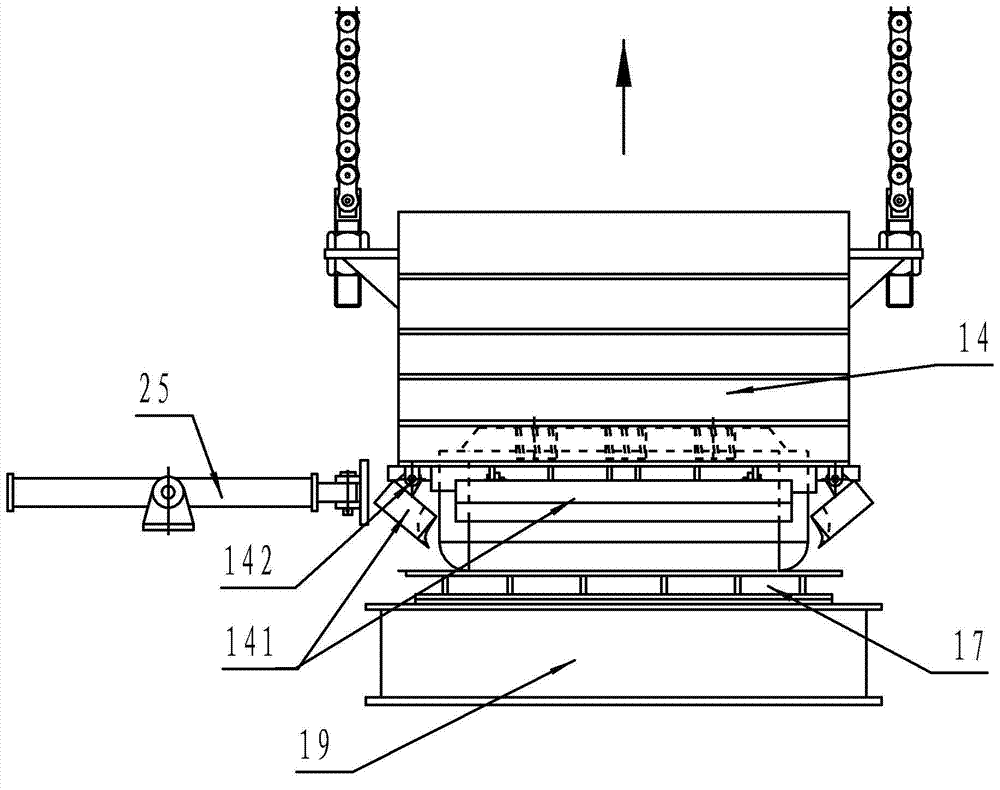

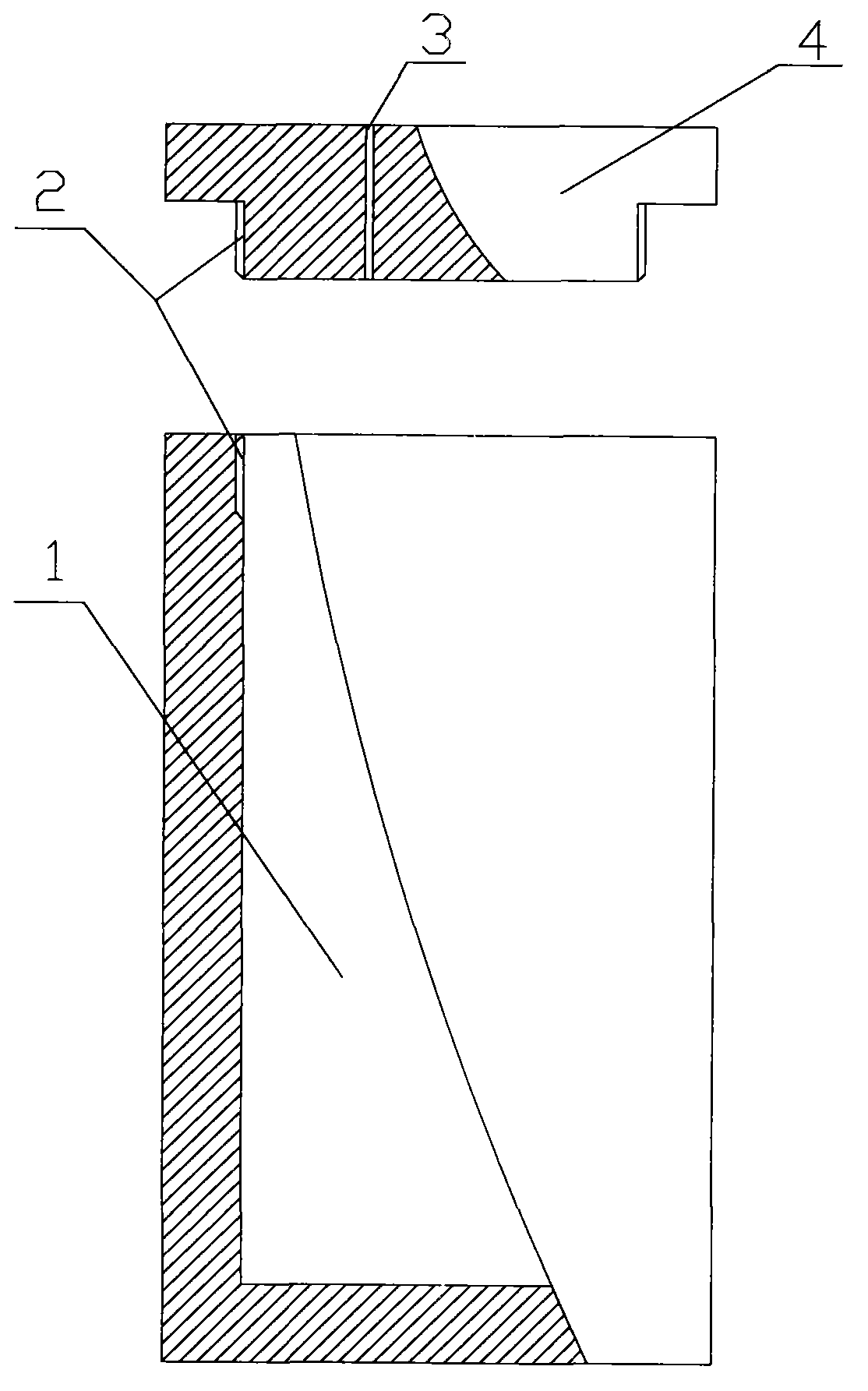

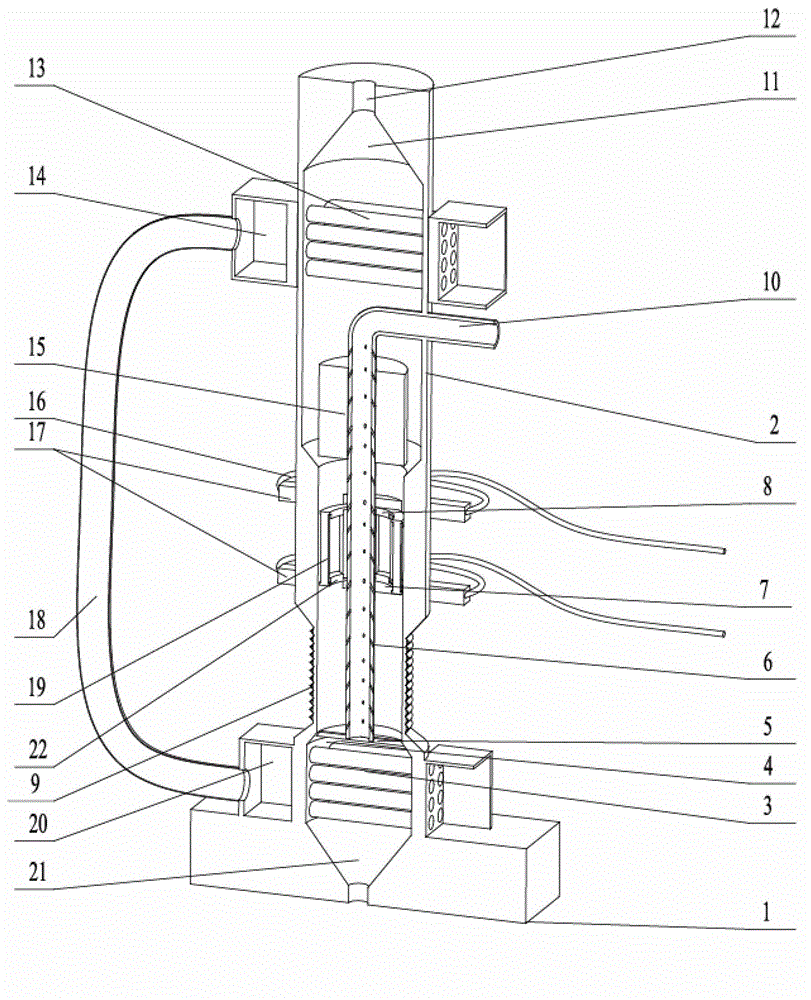

Novel carbon product vibration forming machine

The invention discloses a novel carbon product vibration forming machine, belongs to carbon production equipment, and particularly relates to a device used for carbon product vibration forming. By means of a four-column frame structure in a novel carbon product vibration forming machine, a balance weight lifting system can stably rise and fall, and it is ensured that a die gland arranged on a balance weight is accurately positioned. In the vibration forming process, a vacuum pumping device is started, and therefore air and pitch smoke in a thickener gap are pumped away, the true density of carbon blocks is increased, and cracks are reduced. A die box bottom chamfering die is arranged on the periphery of the bottom of a die box and can execute automatic opening and complete automatic reset along with rising and falling of a die sleeve. An automatic oil mist spraying system can automatically spray oil mist onto the inner wall of the die through an oil mist nozzle arranged on the die box. The balance weight lifting system has a slowly-entering function before block pressing is conducted and has a slowly-retreating function when demolding is started, gas in a clinker gap can be lost in the block pressing process due to the slowly-entering function. Due to the slowly-retreating function, external gas enters the novel carbon product vibration forming machine to damage the vacuum state of the die gland and the carbon block contact face, and the cracks, caused by vacuum suction force when the die gland is lifted, of the carbon block are reduced.

Owner:JINAN AOHAI CARBON PROD +1

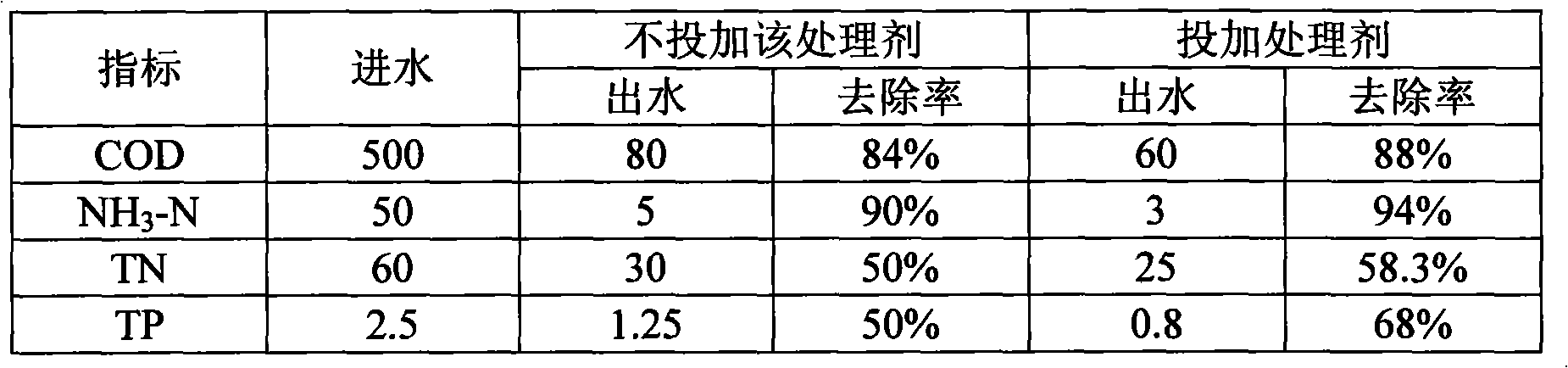

Primer for improving biochemical and purifying efficacy of sewage and preparation method and application method thereof

ActiveCN101654298AImprove biochemical purification efficiencyPromote degradationTreatment with anaerobic digestion processesActivated sludgeSewage

The invention discloses a primer for improving biochemical and purifying efficacy of sewage, comprising the following components in parts by weight: 50-100 parts of carrier, 1-20 parts of biological growth stimulant and 10-150 parts of biological nutritional agent. The invention also discloses a preparation method and an application method of the above primer. The primer of the invention is used in the middle and rear stages for processing structures by an activated sludge method so as to improve the activation of activated sludge and improve purification effect.

Owner:PHOTON ECO CAPTURE

Combined process method of lightening residual oil/ medium and low temperature coal tar

ActiveCN103305271AHigh yieldImprove cracking performanceTreatment with hydrotreatment processesWaxHydrogenation reaction

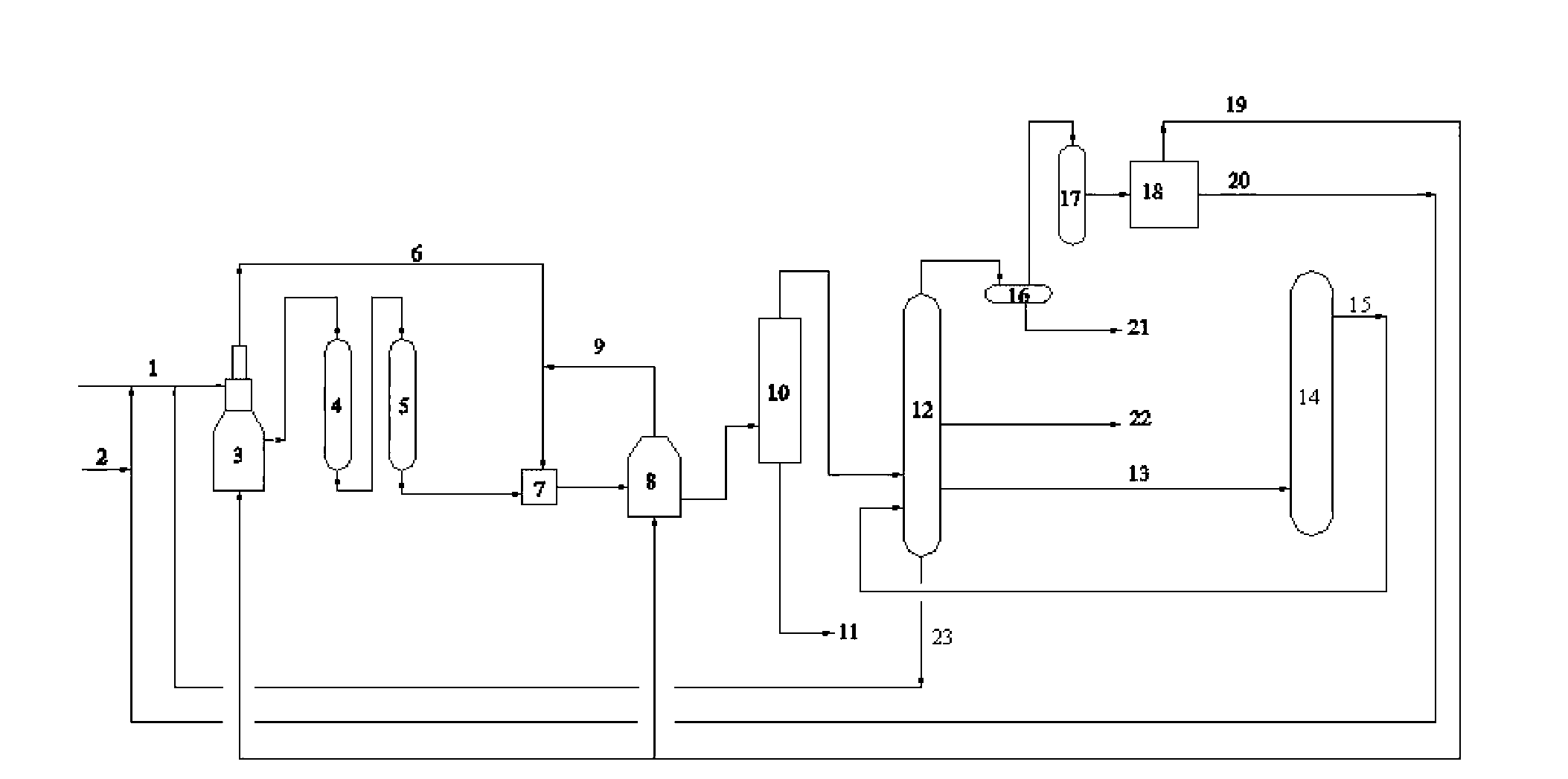

The invention discloses a combined process method of lightening residual oil / medium and low temperature coal tar. Raw material oil enters a hydrotreating unit after being mixed with hydrogen to perform a hydrogenation reaction in the presence of a hydrogenation catalyst; all hydrogenation products enter a delayed coking unit without being separated to perform a thermal cracking reaction so as to prepare high quality coke; tower top oil gas obtained by a coke chamber of the delayed coking unit enters a fractionating system to be fractionated so as to separate out dry coking gas, gasoline, diesel oil, wax oil and heavy distillate oil; all wax oil enters a catalytic cracking unit to perform a catalytic cracking reaction, the catalytic cracking unit and the delayed coking unit share one fractionating system, and the oil gas obtained by catalytic cracking enters the fractionating system; and the dry coking gas enters a PSA purification unit after being desulfurized, and the obtained hydrogen is recycled in the hydrotreating unit. The method can be used for maximizing the production of light oil, obtaining clean finished product oil, producing high quality coke, simplifying the process procedures, saving the consumption of new hydrogen and reducing overall energy consumption.

Owner:SINOPEC NANJING ENG & CONSTR +1

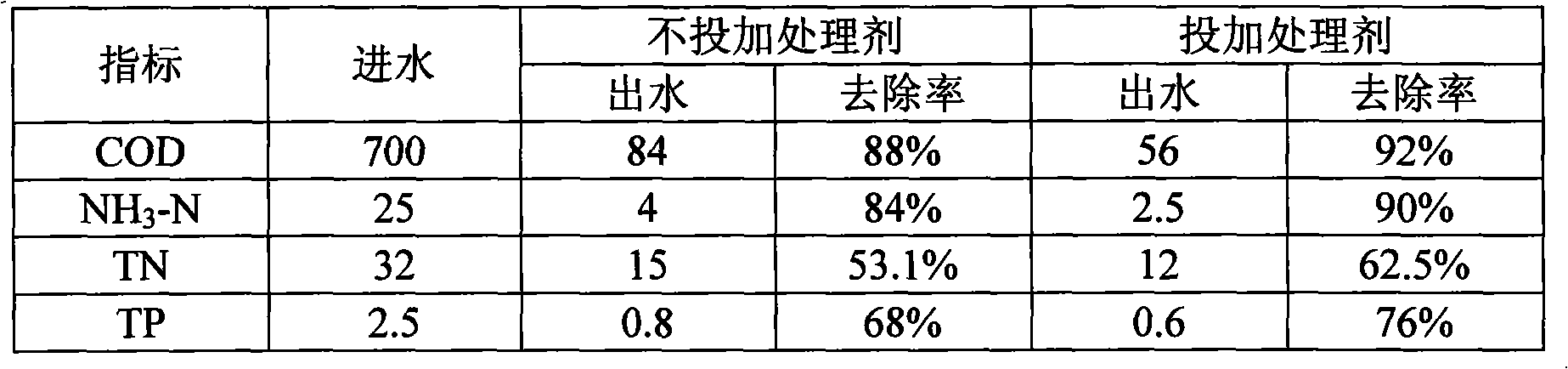

Reeling waste water deep treating method and apparatus

ActiveCN103588363AImprove removal efficiencyExtended service lifeMultistage water/sewage treatmentChemistryBackflow

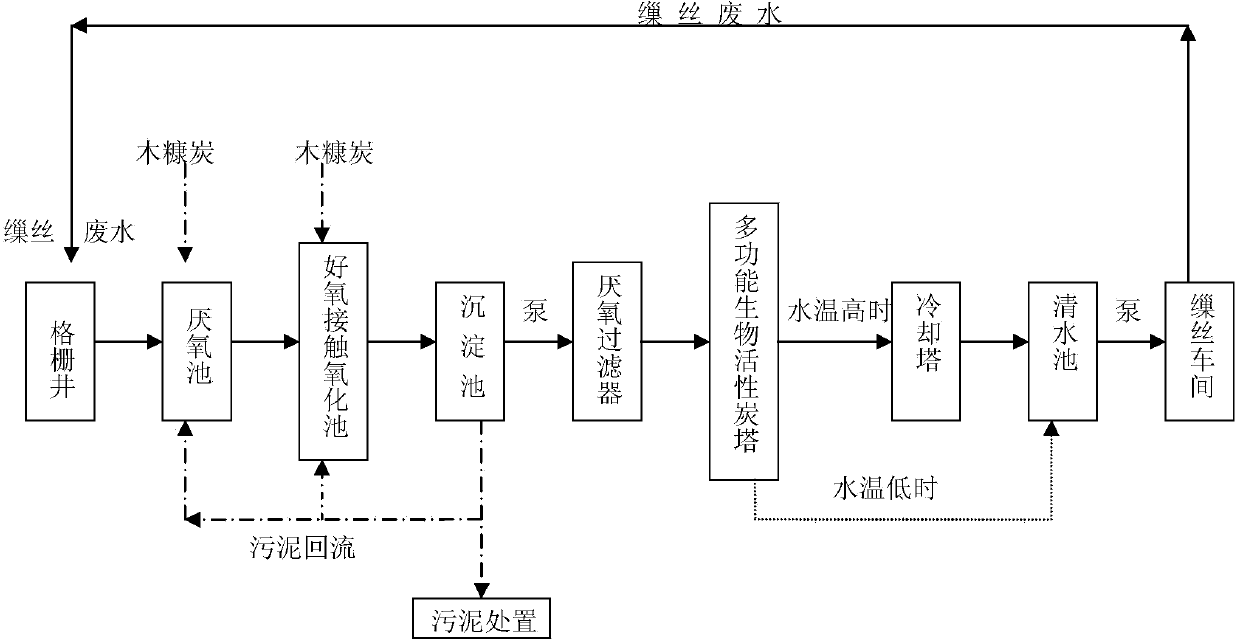

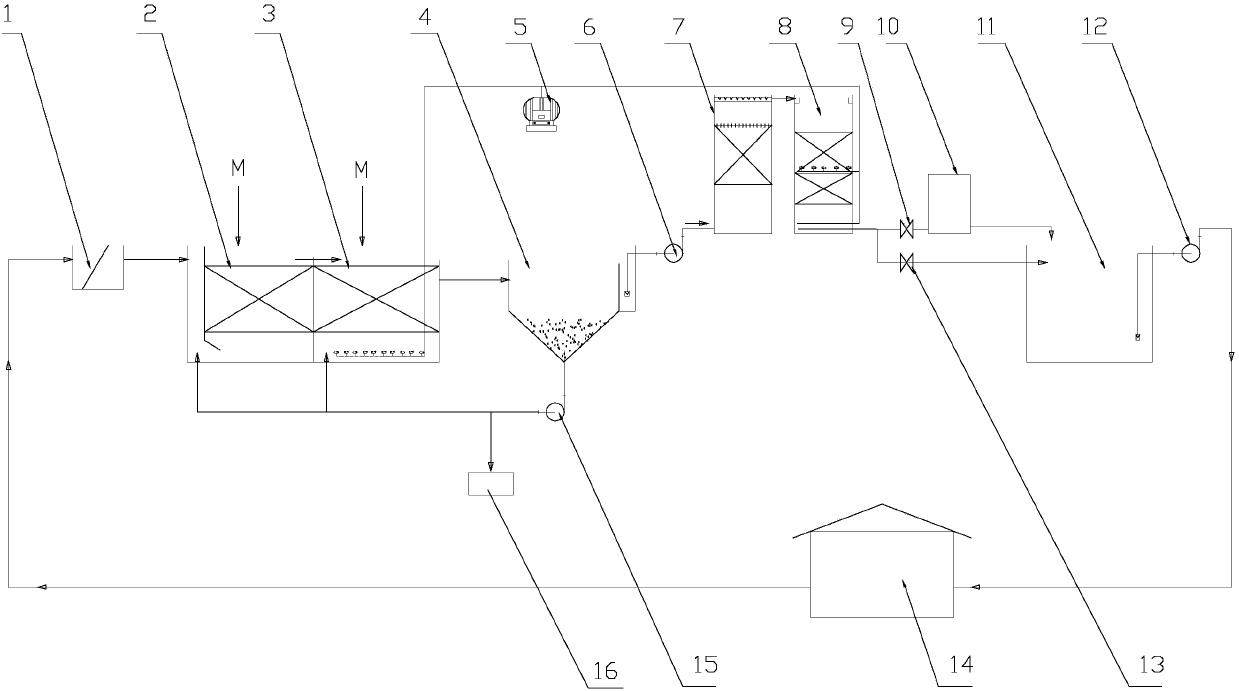

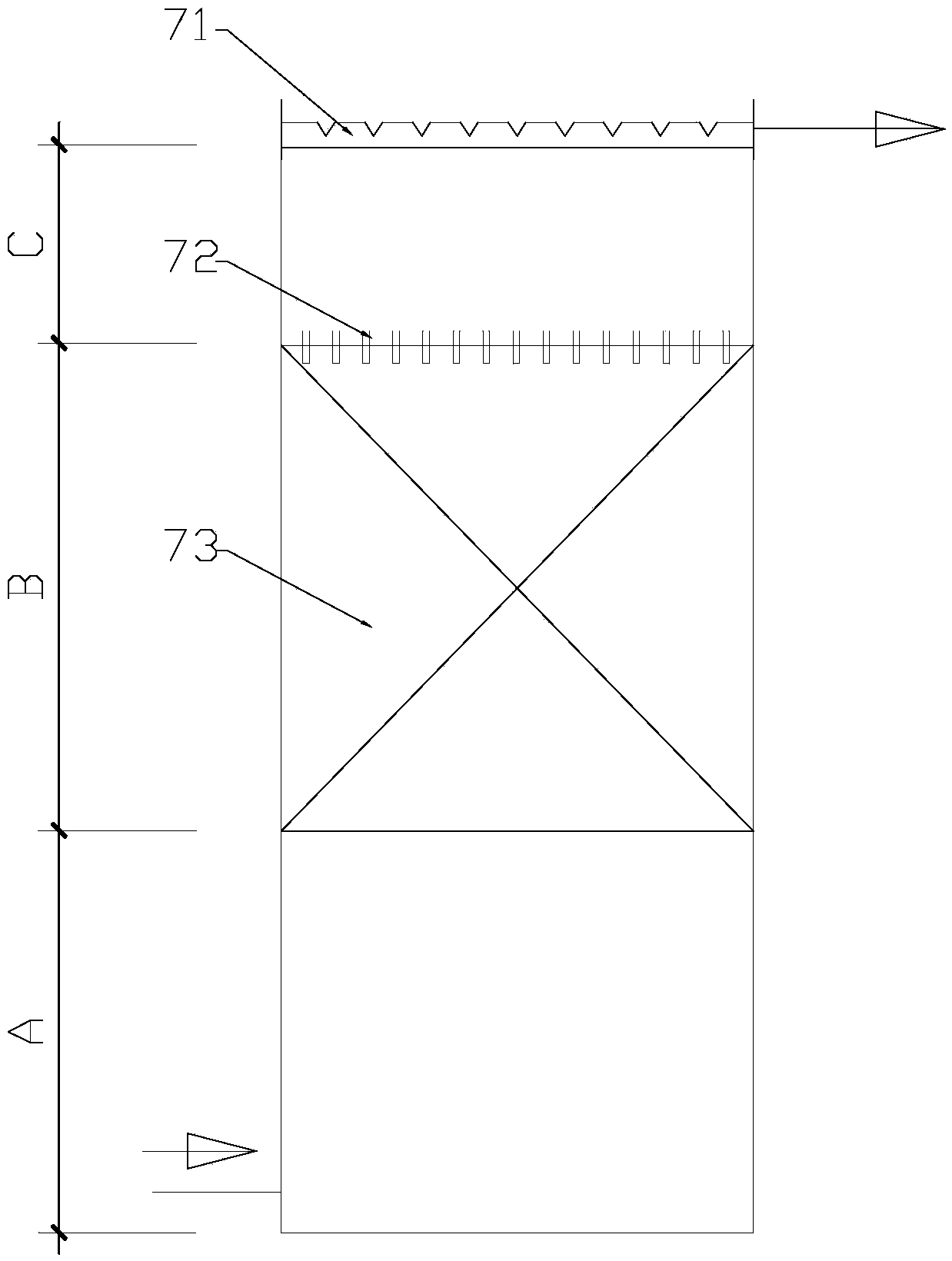

The invention relates to a reeling waste water deep treating method and an apparatus, the method comprises the following steps: A) the reeling waste water is passed through a grating well, then enters into an anaerobic pond, sawdust carbon is put into the anaerobic pond; B) effluent from the anaerobic pond enters into an aerobic contacting oxidation pond, the sawdust carbon is put into the anaerobic contacting oxidation pond; C) effluent from the anaerobic contacting oxidation pond enters into a sedimentation pond; naturally deposited activated sludge containing sawdust carbon is directly discharged or performed with backflow to the above anaerobic pond or / and aerobic contacting oxidation pond, a supernatant is lifted in the sedimentation pond to an anaerobic filter for treating; D) effluent from the anaerobic filter enters into a multifunctional biological active carbon tower; and E) effluent from the multifunctional biological active carbon tower enters into a clean water pond for recycling or directly discharging in a silk reeling workshop. The method and the apparatus have the advantages of low operation cost, high circular reuse rate, good water quality, simple operation management and the like, utilization rate of water resource can be increased, pollution of reeling waste water on environment can be mitigated, and the silkworm industry has a good and fast development.

Owner:GUANGXI CHUNHUI ENVIRONMENTAL PROTECTION ENG

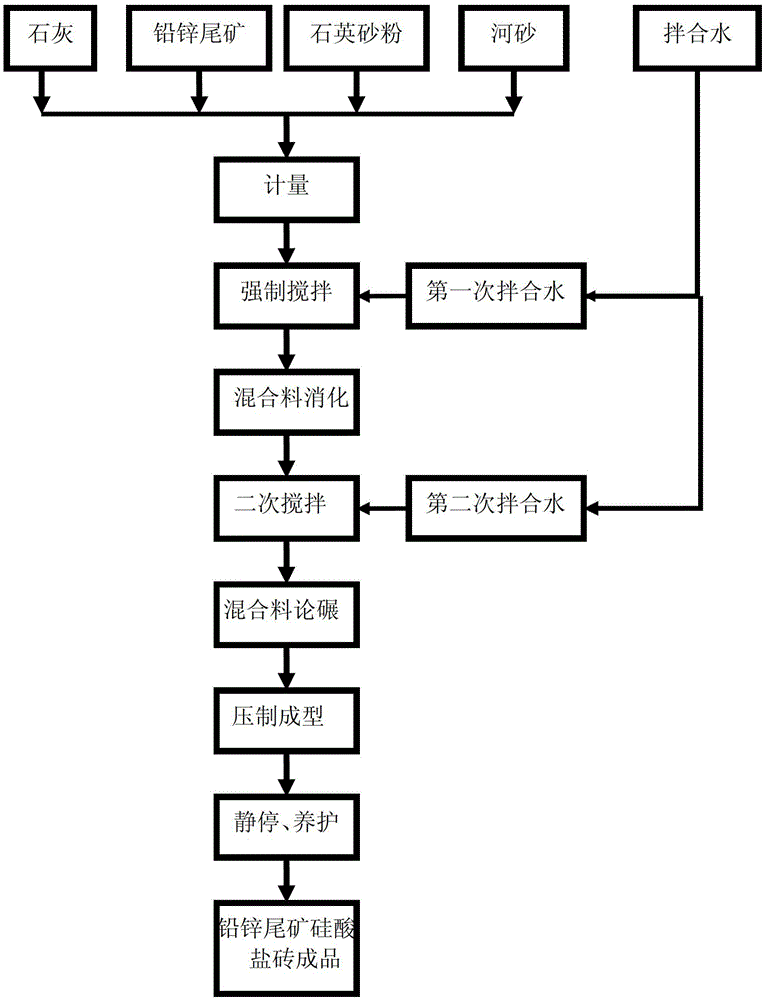

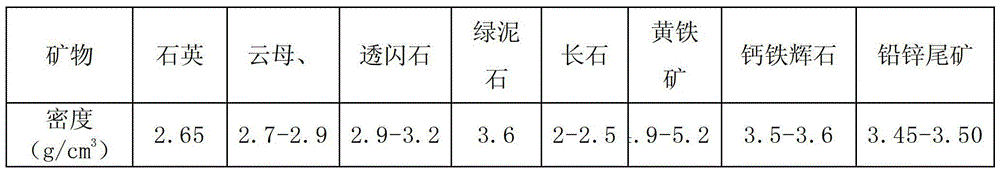

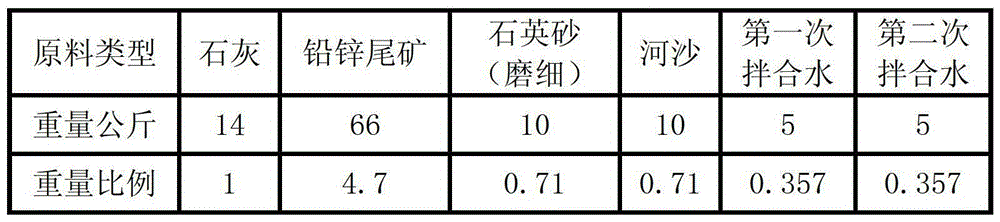

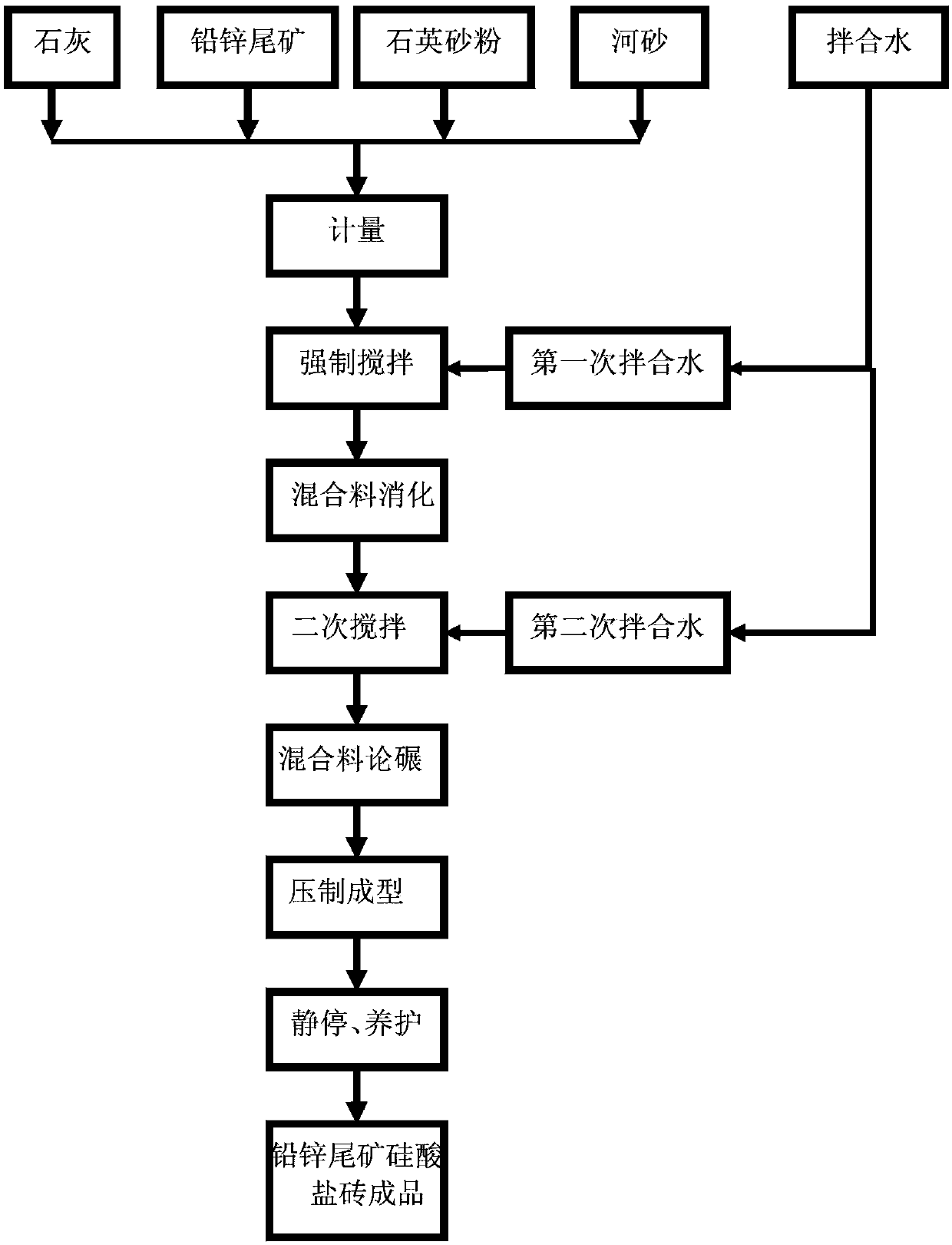

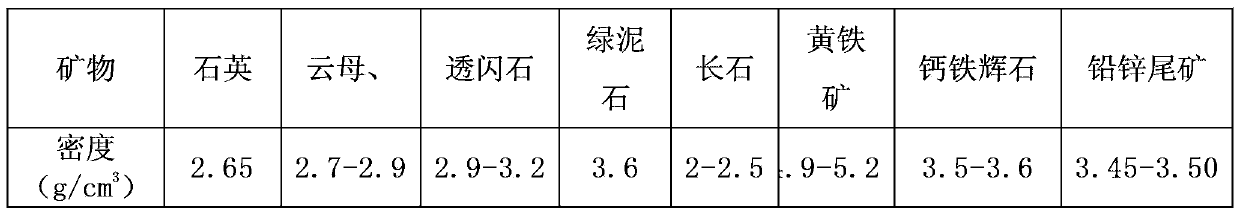

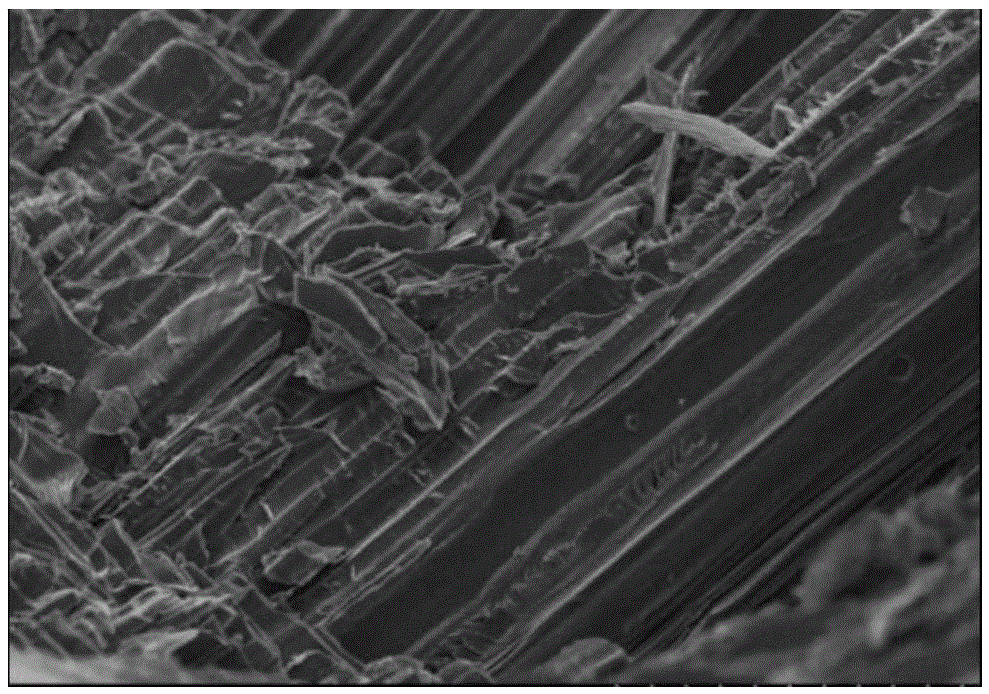

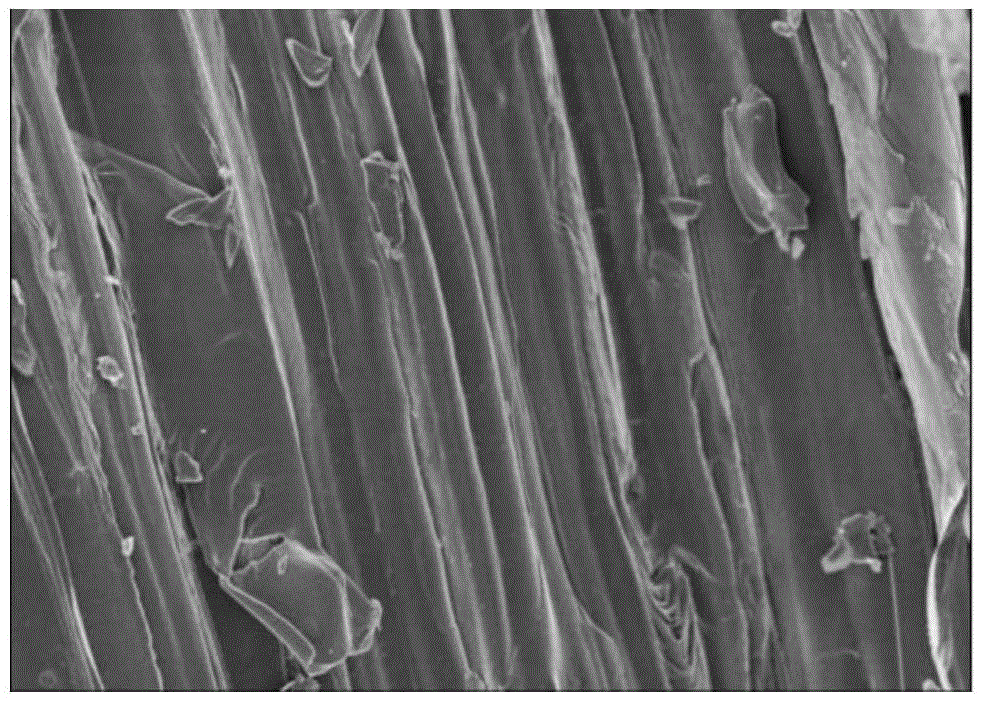

Method of manufacturing silicate bricks with lead-and-zinc tailings

InactiveCN103058618AHigh strengthIncrease the defect of insufficient silica contentSolid waste managementBrickPrill

The invention aims at features to the lead-and-zinc tailings and provides a method of manufacturing steaming-and-pressing silicate wall materials, wherein the features include low content of silica, large density, coarse granules and the like. The method of manufacturing silicate bricks with lead-and-zinc tailings has the advantages that the lead-and-zinc tailings with high true density, containing a certain number of coarse granules and high bulk density is used and can be used for aggregates of the silicate bricks with good effects of moulding pressure transition and beneficial for compression moulding. High compression moulding density can be obtained. The defect that the content of the silica in the lead-and-zinc tailings is not enough can be overcome through adulteration partial ground fine quartz sands. The method of manufacturing silicate bricks with the lead-and-zinc tailings is a processing method of the lead-and-zinc tailings that the technology is simple and the cost is low.

Owner:JIANGSU EAST CHINA MINE TAILINGS MANAGEMENT ENG +1

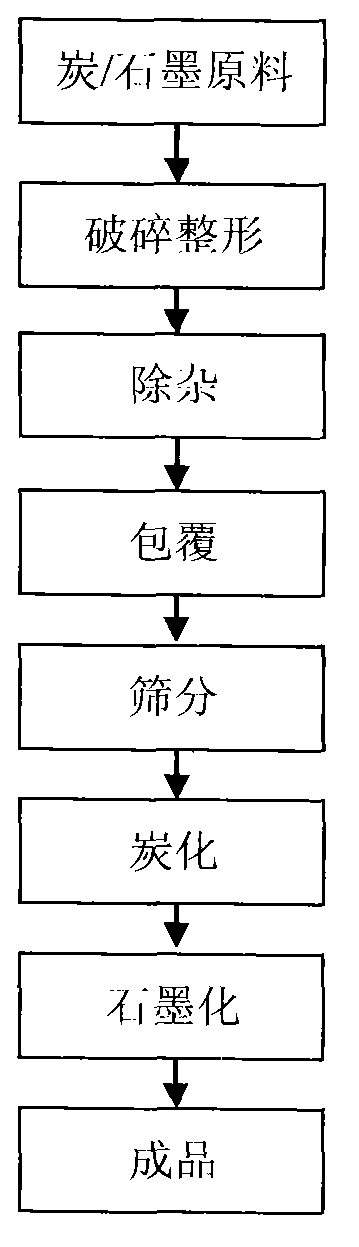

Method for preparing lithium battery anode material by internal thermal lengthwise graphitization furnace

InactiveCN103066291AIncrease productionQuick exclusionCell electrodesDischarge efficiencyThermal insulation

The invention discloses a method for preparing lithium battery anode material by an internal thermal lengthwise graphitization furnace. At first, graphite crucibles are adopted, and are filled with anode material semi-finished products, and crucible covers (4) are tightened up after the anode material semi-finished products are compacted; then, the crucibles are horizontally placed in the internal thermal lengthwise graphitization furnace, and are connected through flexible graphite annuluses, and thermal insulation materials cover the crucibles after the crucibles are loaded in the whole internal thermal lengthwise graphitization furnace; next, the power-on heating operation is carried out, and the heating curve is as follows: the room temperature is 3,200 DEG C and the heating speed is 5 to 8 DEG C / min; and at last, the natural cooling is carried out after the heating is finished, and the graphitization operation is over after the cooling is finished. The graphitization temperature is high, which is beneficial for reducing the special surface area of the anode material, and improving the true density of the material and the initial charging / discharging efficiency. The original production period is about 15 days, and is shortened to 7 days at present, and meanwhile, the energy consumption of the graphitization stage of the product can be reduced.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

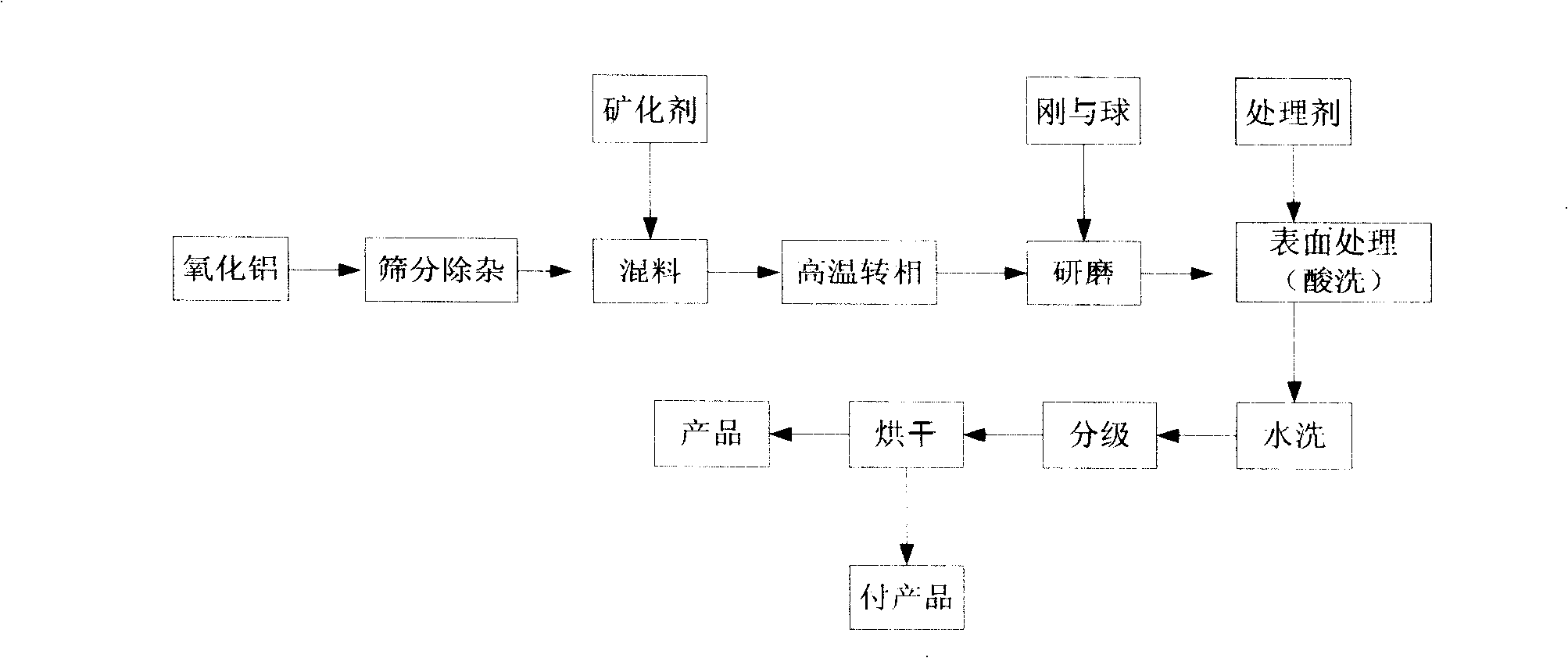

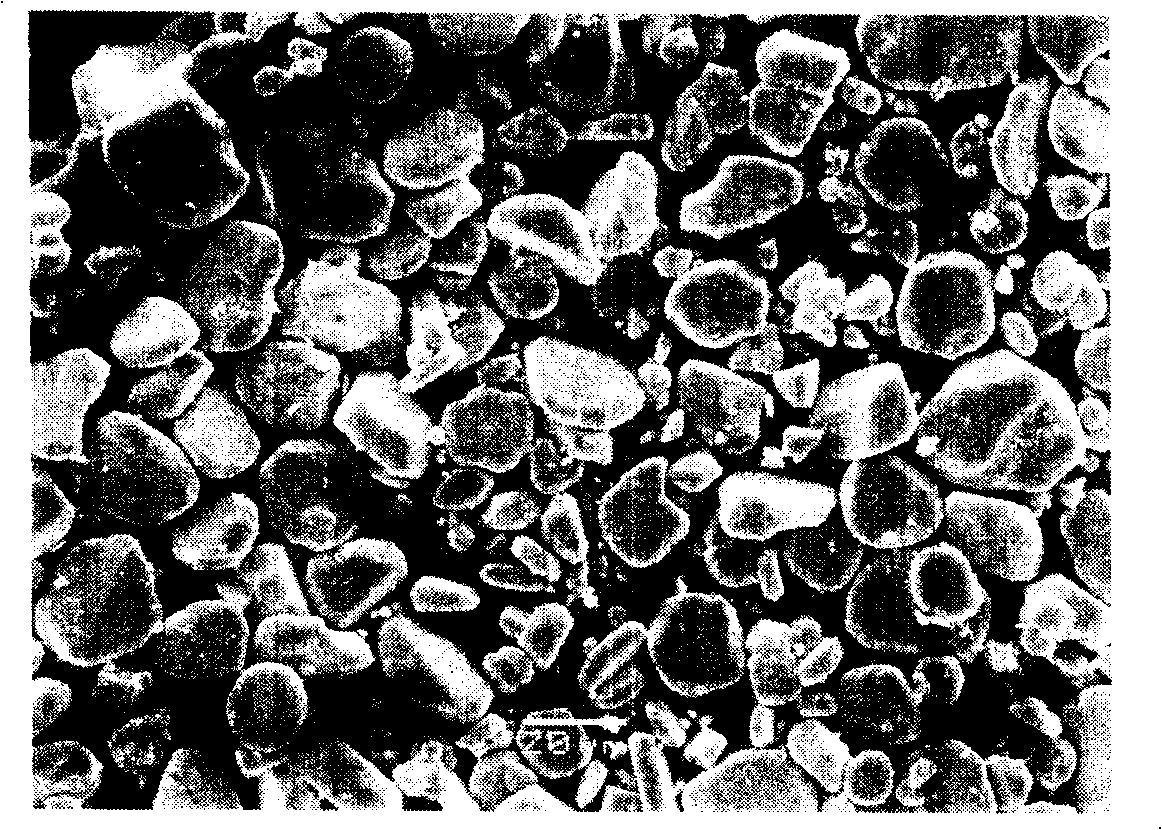

Process for preparing alpha-alumina powder for ceramic film support

The invention discloses a process for preparing ceramic membrane support used Alpha-powdered alumina. The manufacturing process is that: after alumina is screened and decontaminated, a compound mineralizer is added to and mixed with alumina, thus preparing alumina mixture; the alumina mixture is put in a high temperature furnace for calcining and phase inversion at 1500 to 1700 DEG C; the mixtureis kept at the temperature for two to fifteen hours; after the mixture is cooled, corundum balls of one to three times of the mixture is added to a ball mill for milling; a finishing agent is added for surface treatment; the obtained product is washed with water and graded before the product is dried at 100 DEG C. The crystal of Alpha alumina is large; the true density of crystal is large; inversion percent of Alpha phase is high; the purity is high; the Alpha-powdered alumina has sintering activity; and the crystal is nearly spherical.

Owner:HENAN CHANGXING IND CO LTD

Sewage biological purification agent

InactiveCN105271529APromote degradationIncrease true densityBiological water/sewage treatmentRare-earth elementActivated sludge

The invention discloses a sewage biological purification agent comprising the following components, by weight: 50-100 parts of a carrier, 1-20 parts of a biological growth stimulant, and 10-150 parts of a biological nutritional agent. The carrier is any one or more selected from diatomaceous earth, activated carbon and zeolite powder. The biological growth stimulant is a mixture of a rare earth element compound and iron salt with a weight ratio of 1: (1-10). The biological nutritional agent is a mixture of glucose and acetate with a weight ratio of (1-20): (1-60), wherein the rights of glucose and sodium acetate are respectively calculated according to the weight of carbon element. The rare earth element compound is one or more selected from nitrate or chloride of lanthanum, cerium and rubidium. The sewage biological purification agent is used in the middle-late section of an active sludge treatment structure, and is used for improving active sludge activity and thus improving the purification effect.

Owner:严兴扬

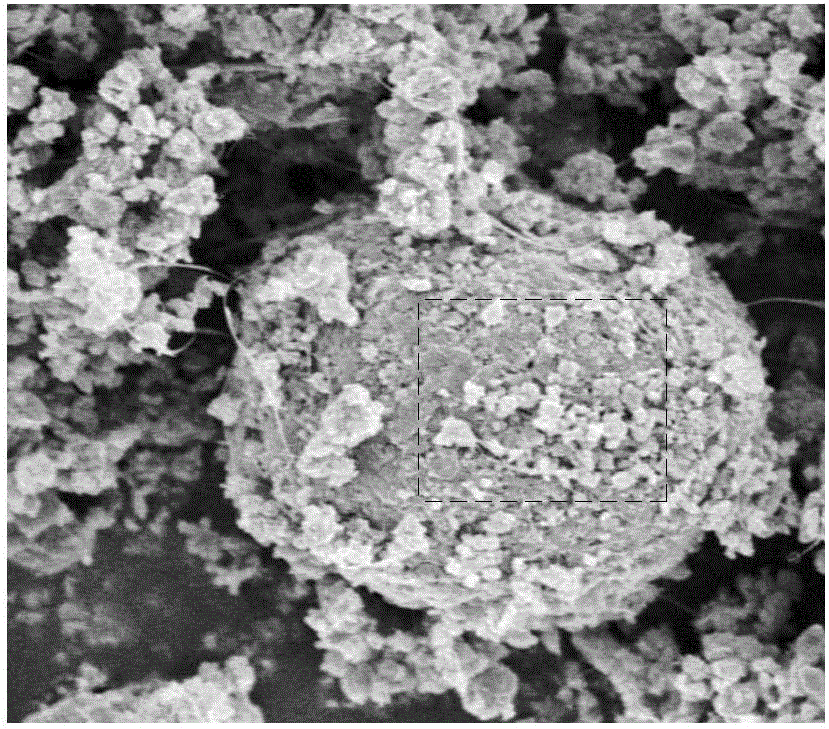

High-compaction iron phosphate and preparation method of high-compaction lithium iron phosphate

InactiveCN111533103ASmall particlesSmall particle sizeCell electrodesCarbon preparation/purificationFerric hydroxideO-Phosphoric Acid

The invention discloses high-compaction iron phosphate and a preparation method of high-compaction lithium iron phosphate. Firstly, ferric hydroxide colloid is prepared; subsequently, the ferric hydroxide colloid is used as a matrix, phosphoric acid and ammonium bicarbonate are added at high temperature, and iron phosphate with smaller primary particles is obtained; meanwhile, a process of removing crystal water from the obtained ferric phosphate dihydrate is carried out; spray drying after slurrying is performed by adopting a glucose solution, and calcining is performed to obtain iron phosphate. The method comprises the following steps: taking high-compaction iron phosphate as a raw material, grinding slurry by adopting a composite carbon source, carrying out spray drying and primary sintering, adding a dispersing agent (polyethylene glycol solution), carrying out spray drying, coating the surface of lithium iron phosphate with the dispersing agent, and sintering at a higher temperature for a shorter time, thereby obtaining the high-compaction lithium iron phosphate. The obtained high-compaction lithium iron phosphate is small in primary particle size, large in BET, less in particle adhesion and easy to grind, and the prepared high-compaction lithium iron phosphate is high in compaction density, small in primary particle size and good in capacity and cycle performance.

Owner:蒋达金

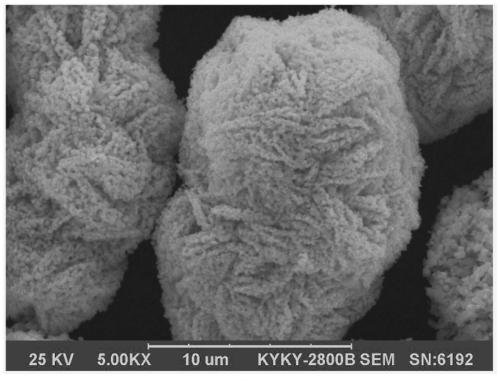

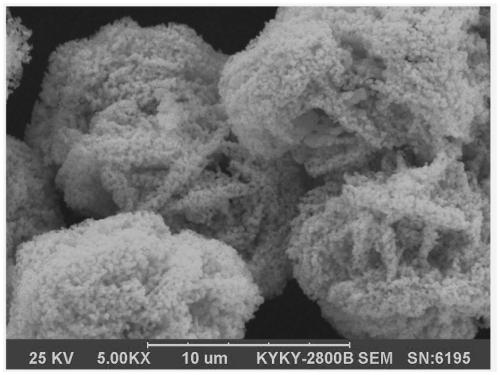

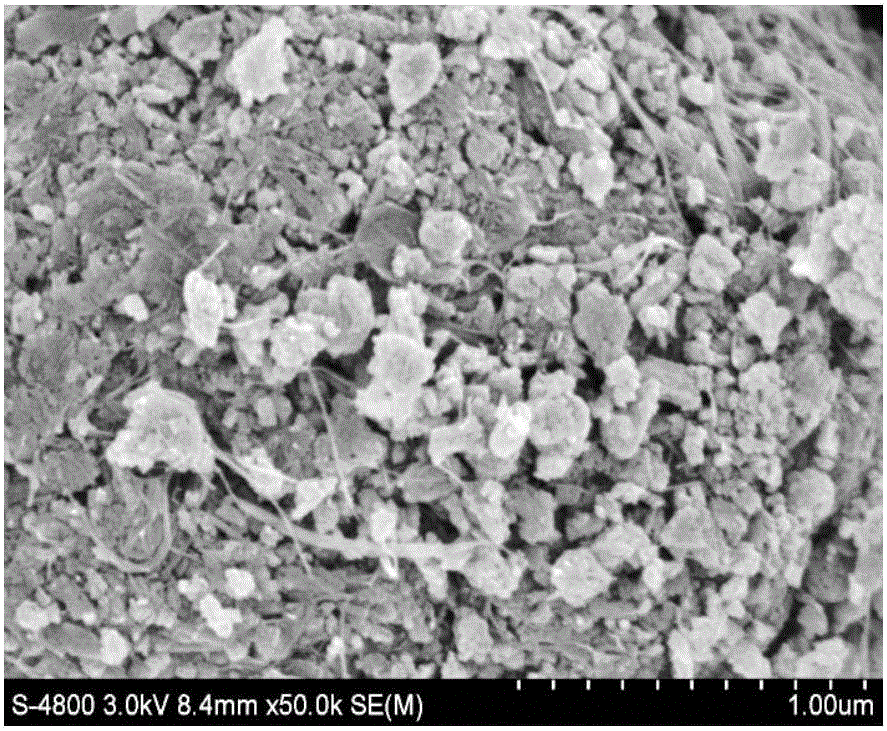

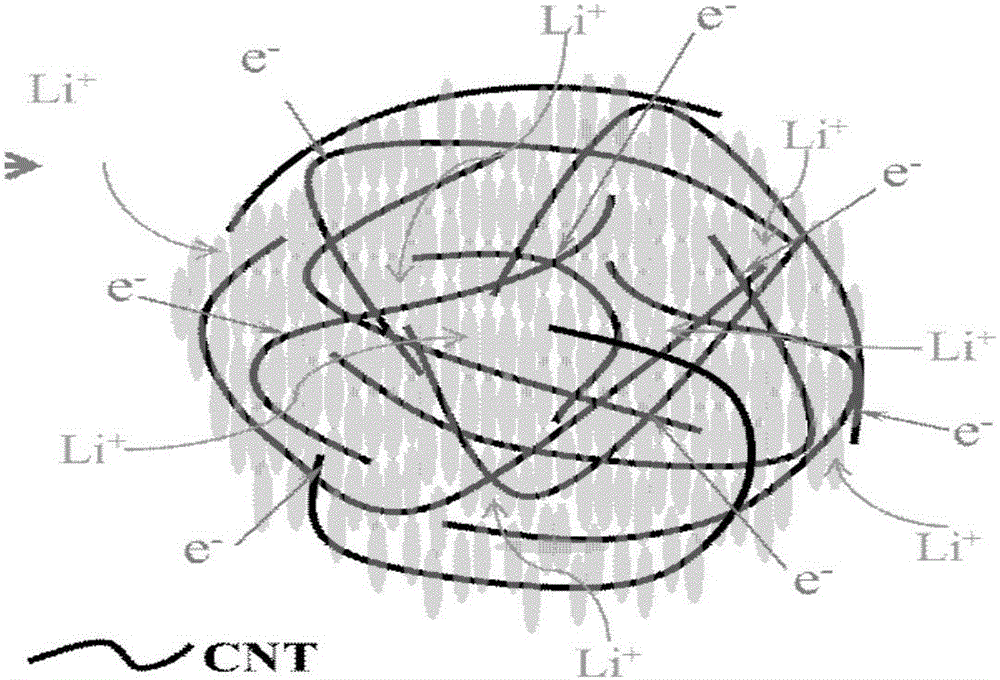

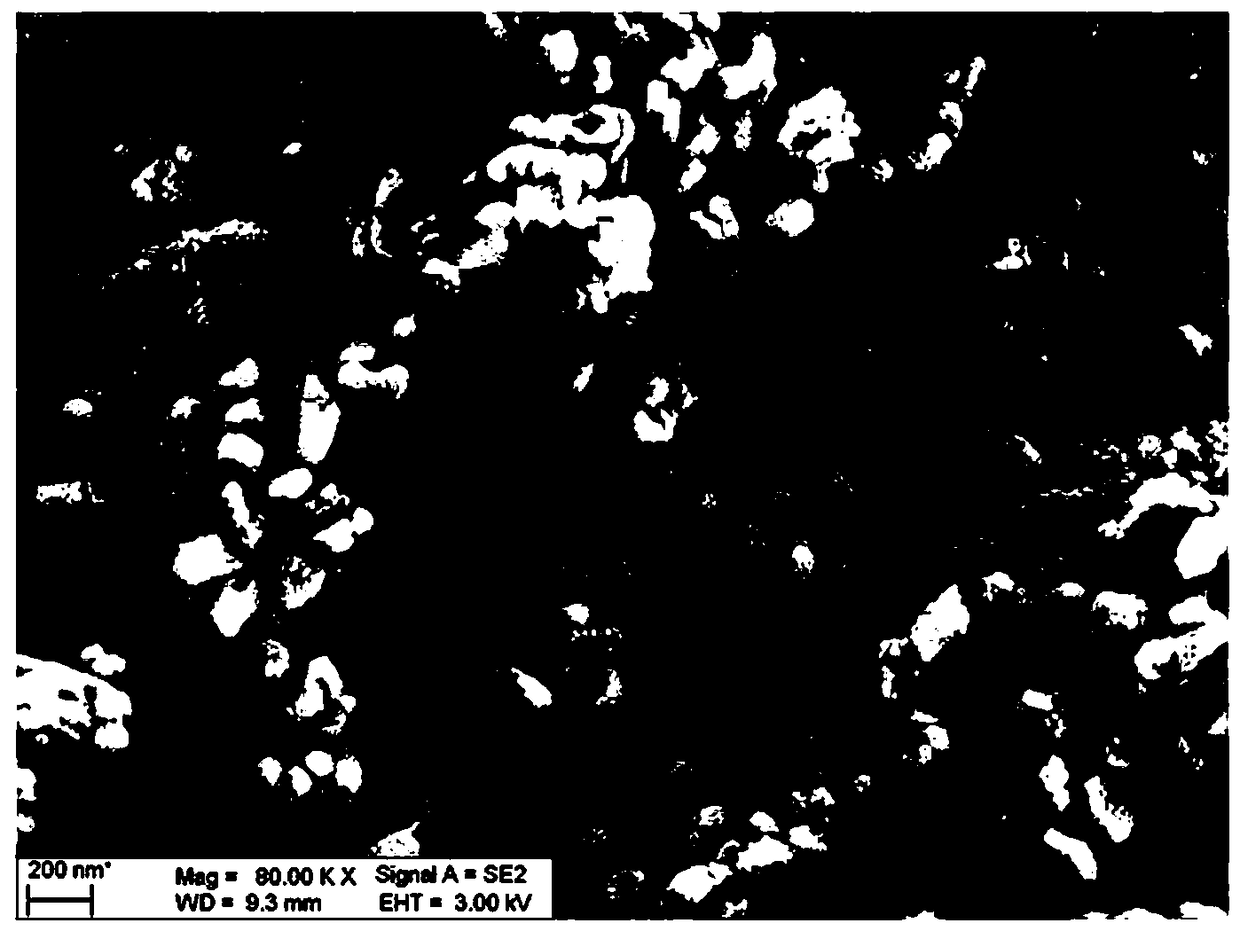

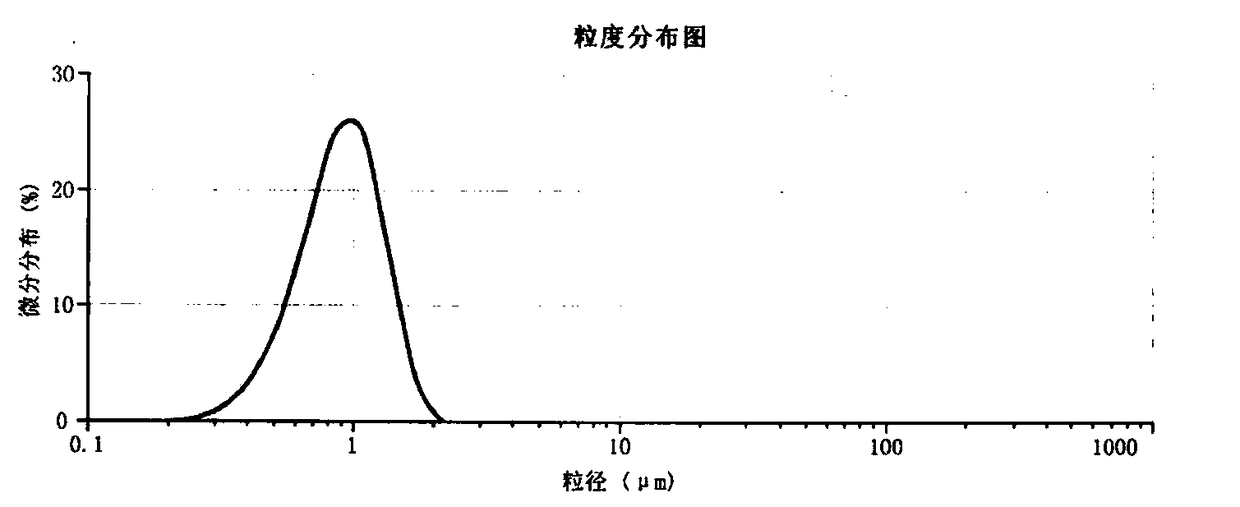

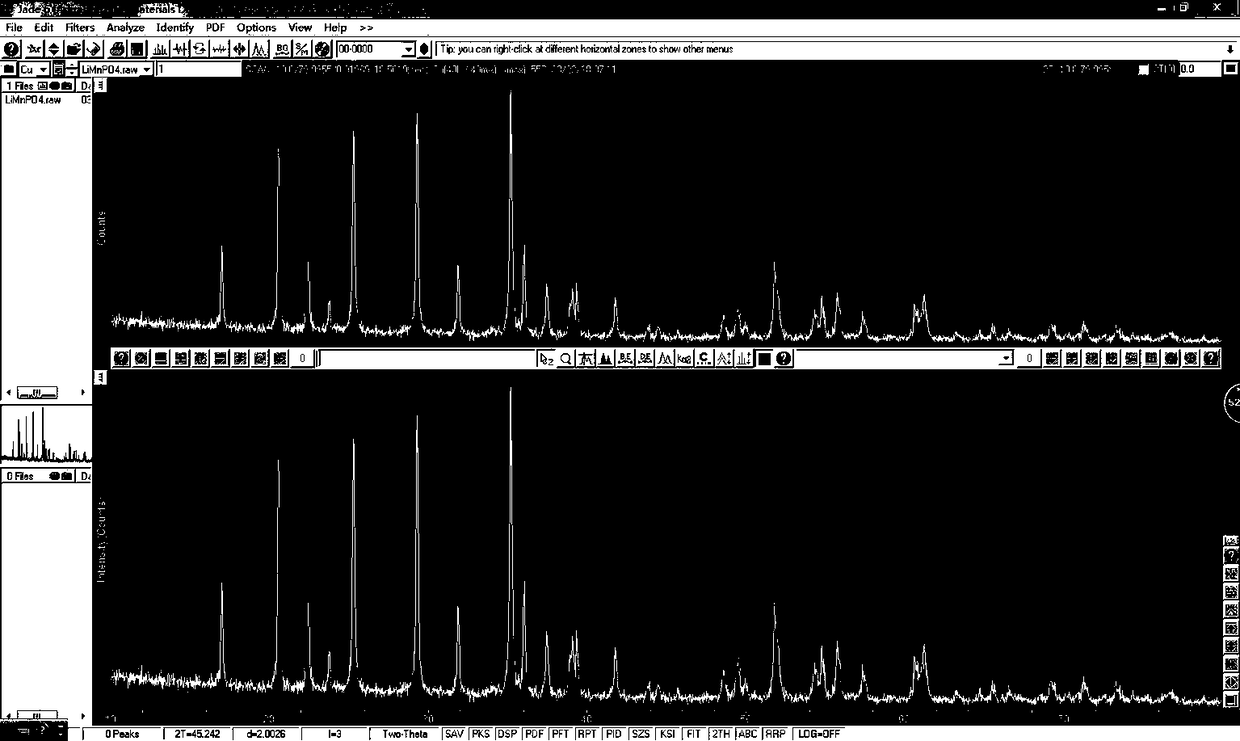

Self-assembly preparation method of lithium manganese phosphate positive electrode material and lithium manganese phosphate positive electrode material

ActiveCN106602008AEvenly dispersedImprove conductivityMaterial nanotechnologyCell electrodesCarbon nanotubeSpherical shaped

The invention provides a self-assembly preparation method of a spherical lithium manganese phosphate positive electrode material. Carbon nano tubes are compounded with the lithium manganese phosphate material, and the conductivity of the lithium manganese phosphate is improved by using ultrahigh conductivity of the carbon nano tubes. According to the method, the carbon nano tubes are taken as crystal nucleuses, spherical lithium manganese phosphate particles are self-assembled and formed from nano lithium manganese phosphate particles through in-situ preparation, and the carbon nano tubes are interpenetrated among spherical secondary particles. The invention also provides a compounded positive electrode material containing the self-assembly spherical lithium manganese phosphate and the carbon nano tubes prepared through the preparation method.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

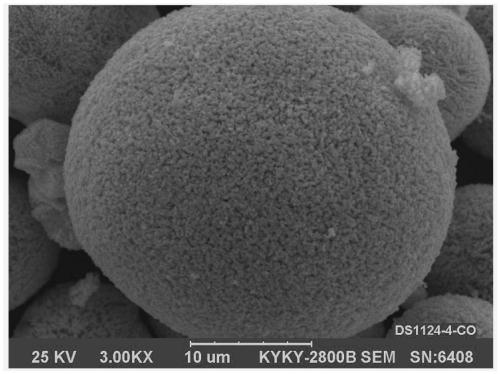

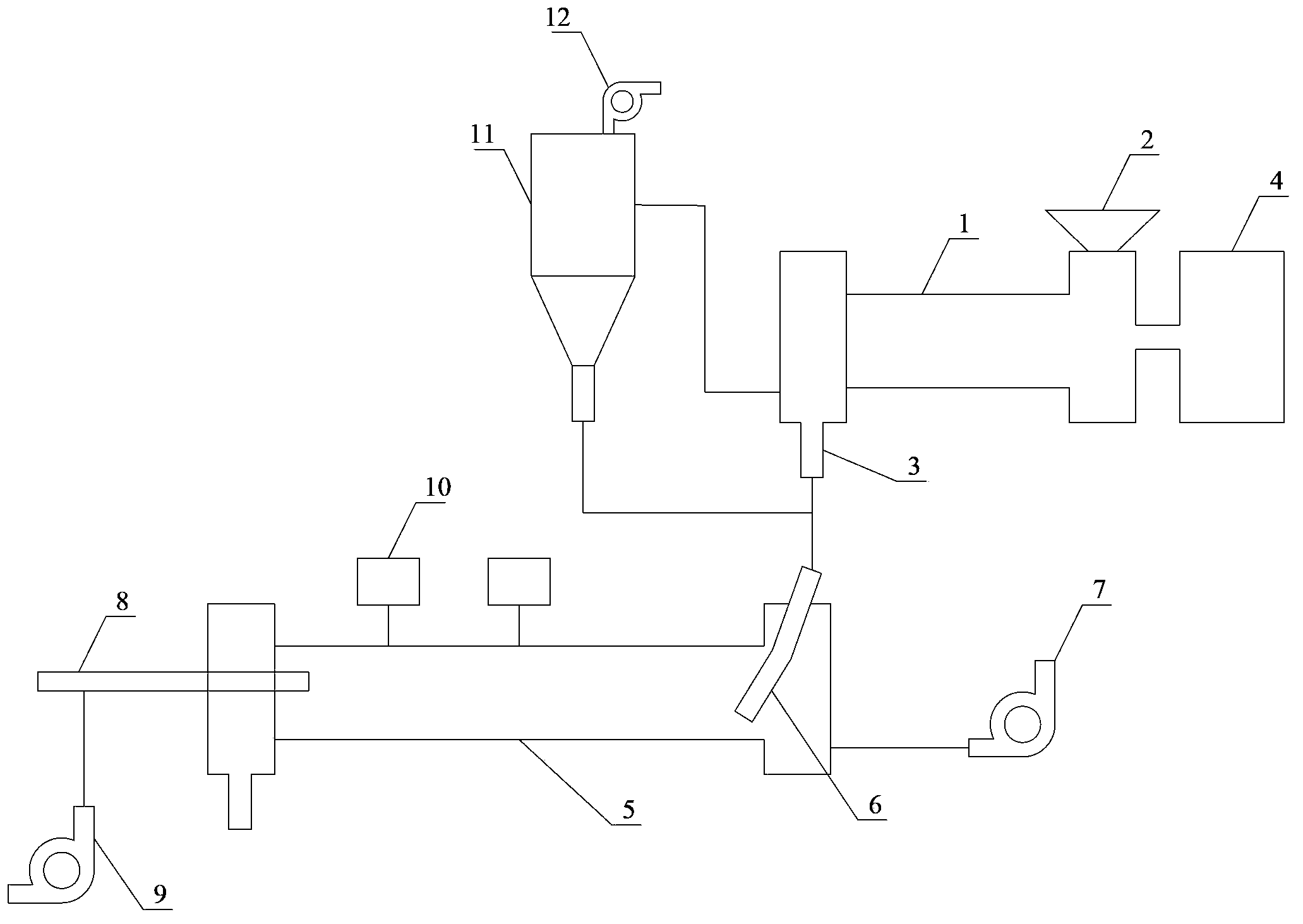

Spherical graphite with median diameter of 6 to 14 mu m and preparation method thereof

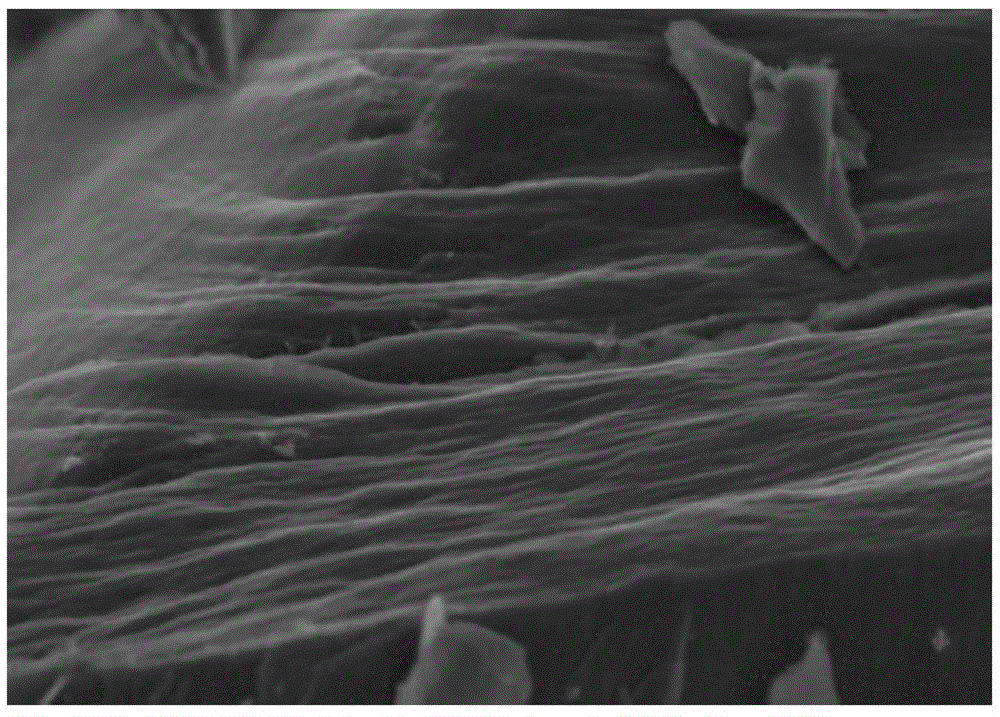

ActiveCN101850966AIncrease true densityHigh first reversible capacityCell electrodesGraphiteVolumetric Mass Density

The invention discloses a preparation method of spherical graphite with a median diameter of 6 to 14 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the actual density of 2.28 to 2.3g / cm<3>. The number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high, the electrochemical performance is obviously improved, and the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 85 percent, lower the cost by 45 percent, save the power consumption by 40 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

Low-temperature sintered zirconium silicate grinding medium and preparation method thereof

The invention discloses a low-temperature sintered zirconium silicate grinding medium and a preparation method thereof. The low-temperature sintered zirconium silicate grinding medium comprises the following components in parts by weight: 75-90 parts of zirconium silicate, 5-15 parts of Hengyang mud, 1-3 parts of calcium carbonate, 5-15 parts of aluminum oxide, 0.1-1 part of magnesium oxide and 1-10 parts of zirconium oxide. The low-temperature sintered zirconium silicate grinding medium has the advantages of low abrasion, high true density, high hardness and high compressive strength and has rather ideal economic and social benefits.

Owner:ZHEJIANG HUMO POLISHING GRINDER MFG

Method for preparing high-quality needle coke by volume exclusion separation-grading carbonization of heavy oil

ActiveCN111575036AWide variety of sourcesLow priceTreatment with plural serial stages onlyCoking carbonaceous materialsChromatographic separationPhysical chemistry

The invention belongs to the technical field of petroleum deep processing and the field of novel high-grade carbon material preparation, and belongs to a method for preparing high-quality needle cokethrough the volume exclusion separation-grading carbonization of heavy oil. The method comprises the following steps of: carrying out volume exclusion chromatographic separation on heavy oil to obtaina component with the relative molecular mass of 400-1000, and carrying out first-stage carbonization reaction for 1-5 hours at the temperature of 360-420 DEG C and under the pressure of 6-10 MPa; andafter the first-stage carbonization reaction, carrying out second-stage carbonization reaction for 5-12 hours at the temperature of 420-480 DEG C and under the pressure of 0-5 MPa to obtain a high-quality needle coke product with the true density of more than 2.13 g / cm <3> and the thermal expansion coefficient of less than 1.15*10<-6> / DEG C. The separation method adopted by the invention is accurate, time-saving, labor-saving, remarkable in effect, simple in process operation, environment-friendly, low in equipment requirement and easy to realize industrialization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Calcined petroleum coke rotary kiln

InactiveCN103627419AReduce burning lossIncrease true densityCoke ovensRotary drum furnacesFlue gasAir blower

The invention provides a calcined petroleum coke rotary kiln, including a drying device and a rotary kiln. The drying device comprises a cylinder body, and a feeding port and a discharge port, which are arranged respectively on the front end and the rear end of the cylinder body; and the front end of the cylinder body is also provided with a high temperature flue gas chamber. The rotary kiln comprises a kiln rotary kiln body, a feed chute and a rotary induced draught fan, which are arranged on the feed end of the rotary kiln body, and a fuel nozzle and a fuel air blower, which are arranged at the discharge end of the rotary kiln body; and the middle section of the rotary kiln body is provided with at least two kiln air blowers. The discharge port of the cylinder body is connected with the feed chute of the rotary kiln. The invention has the beneficial effects that the calcined petroleum coke rotary kiln has large output and small burning loss of the calcined petroleum coke, does not consume extra fuel for normal production, significantly reduces petroleum coke burning loss, enhances the true density of the calcined petroleum coke, reduces ash and improves the quality of the calcined petroleum coke.

Owner:TIANJIN GERUICHAO CARBON PROD

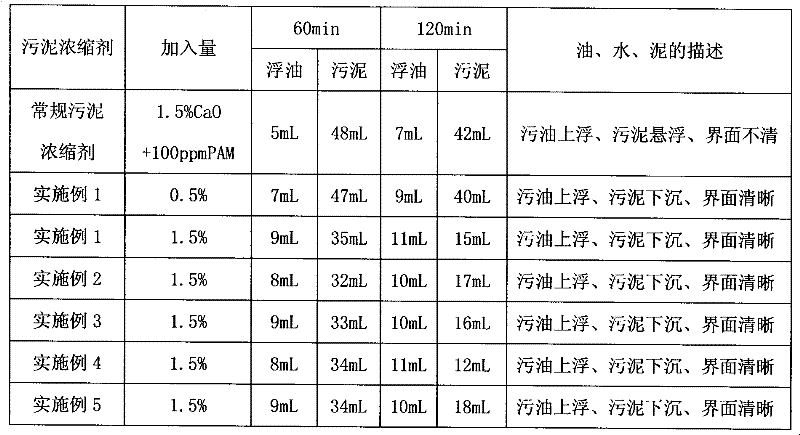

Oily sludge concentrating agent as well as preparation and application thereof

ActiveCN102050559AIncrease true densityLarger than the areaSludge treatment by de-watering/drying/thickeningSludgeFly ash

The invention relates to an oily sludge concentrating agent as well as preparation and application thereof. The oily sludge concentrating agent comprises cement, fly ash, diatomite and polyaluminum, wherein the proportion by mass of the cement, the fly ash, the diatomite and the polyaluminum is 1:(0.5-2.5):(0.5-2.5):(0.005-0.05); and a production method of the oily sludge concentrating agent comprises the following steps of: firstly grinding the fly ash into fly ash powder in 100-300 meshes, mixing with the diatomite in 100-300 meshes, the cement in 100-300 meshes and the polyaluminum in 100-300 meshes according to the proportion by mass and uniformly stirring. Oil, water and sludge can be thoroughly separated by adding 0.5-1.5 percent by mass of oily sludge concentrating agent into oily sludge containing 99 percent of water; and the oily sludge concentrating agent has the advantages of high settling velocity, good sludge concentrating effect, less dosage, low cost and convenience in feeding.

Owner:PETROCHINA CO LTD +2

Coking method for coal-oil mixed pitch

ActiveCN103965928ALow impurity contentLow densityCoking carbonaceous materialsCross-linkQuality level

The invention relates to a coking method for coal-oil mixed pitch. The coking method comprises the following steps: coal pitch and oil pitch are mixed in accordance to appropriate proportion and pretreated under certain condition to prepare refined pitch; the refined pitch is taken as a preparation raw material for needle coke; the characteristics of the coal pitch such as macromolecular aromatics structure and being capable of forming favorable organization structure are fully utilized and lower impurity content of the oil pitch, particularly lower QI content and impurity atom content as well as the cross-linked effect of micro-molecules are combined. According to the coking method, the negative influence caused by too much impurities and light constituent in the oil pitch is effectively avoided, the quality level of green coke is effectively improved, the carbon content is improved, the volatile component and ash content are reduced, therefore, the obtained needle coke is low in impurity content, favorable in organization structure, simultaneously procedures in the whole coking process is simple and the operation is convenient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Hydrogen storage alloy

InactiveCN1953251AHigh hydrogen storageIncrease capacitanceSecondary cellsAlkaline accumulator electrodesMaterials scienceNumeric Value

Owner:SANYO ELECTRIC CO LTD

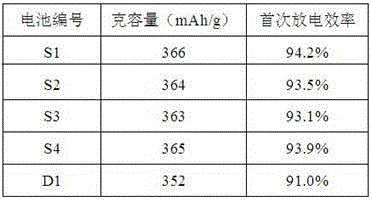

High-compaction-density and high-first-effect ternary positive electrode material and preparation method thereof

InactiveCN110993937AIncrease true densityIncrease compaction densityCell electrodesSecondary cellsLithiumRubidium

The invention relates to a high-compaction-density and high-first-effect ternary positive electrode material and a preparation method thereof, the theoretical chemical expression of the high-compaction-density and high-first-effect ternary positive electrode material is Li<1-a> baNi<0.8>Co<0.1>Mn<0.1>O<2>, and a is greater than or equal to 0.001 and less than or equal to 0.1. The preparation method of the ternary positive electrode material is characterized by comprising: mixing a nickel source, a cobalt source and a manganese source according to a certain proportion; obtaining a ternary material mixture; adding the mixture into water according to a certain proportion to obtain a water phase; introducing ammonia gas, adding an oil phase, preparing a precursor by using a reversed-phase microemulsion method; and uniformly mixing and sintering the precursor, a lithium source and rubidium salt at a certain temperature to obtain a high-compaction-density rubidium ion doped material with uniform particle size, replacing lithium ions in the ternary material in a rubidium ion doping manner, and enabling an active material to be in better contact, so that the ternary material has better compaction density and higher charge-discharge first effect.

Owner:WUHAN UNIV OF TECH

Preparation technology of high-strength graphite material

The invention relates to the field of preparation of graphite materials, in particular to a preparation technology of a high-strength graphite material. The preparation technology comprises the following steps: selecting raw petroleum coke and putting the raw petroleum coke into a rotary drum furnace; formulating a heating curve and carrying out heating treatment to obtain semicoke, wherein the heating upper limit of the heating curve is 500 to 600 DEG C; grinding the semicoke until the average granularity is 5 to 6 mu m; then putting powder into a kneading pot and adding a dispersing agent into the kneading pot, raising the temperature to 140 to 150 DEG C and kneading for 45 to 50 minutes; then putting a melt binder into the kneading pot, keeping the temperature at 140 to 150 DEG C and kneading for 45 to 50 minutes to obtain paste; carrying out flaking treatment on the paste for two times to obtain flakes; grinding the flakes until the average granularity is 20 to 22 mu m and moldingto obtain a green body; calcining the green body and graphitizing to obtain a finished product of the high-strength graphite material. The production cycle is short, the production cost is low and theobtained high-strength graphite material has high performance.

Owner:PINGDINGSHAN ORIENTAL CARBON

Preparation method of pollution-free low-cost lithium manganese ferric phosphate crystal material

ActiveCN108408709AImprove the level ofWidely sourced, non-toxic and cheapCell electrodesPhosphorus compoundsEnvironmental resistanceLithium hydroxide

The invention discloses a preparation method of a pollution-free low-cost lithium manganese ferric phosphate crystal material. The preparation method includes following steps: selecting iron powder and manganese powder high in purity, wherein granularity is selected from 20-20000 meshes; taking the manganese powder, the iron powder, phosphoric acid and a lithium source solution according to a certain mass ratio, diluting, putting them into an acid-resistant reactor, and stirring to enable the iron powder, the manganese powder and the phosphoric acid to be in sufficient reaction; adding the lithium source solution into obtained reaction precursor size, and sufficiently stirring, wherein the lithium source solution is soluble lithium source lithium hydroxide or lithium acetate; transferringobtained size into a reaction kettle, and starting hydrothermal reaction; performing solid-liquid separation on size obtained after reaction, and subjecting solid lithium manganese ferric phosphate which is separated out to clathration carbonization annealing treatment to obtain the lithium manganese ferric phosphate crystal material. Compared with the prior art, the preparation method has the advantages that cost is low, process operation is convenient, the material is high in commercial value, the preparation process is free of pollution, and current requirements on environment protection are met.

Owner:南阳逢源新能源科技有限公司

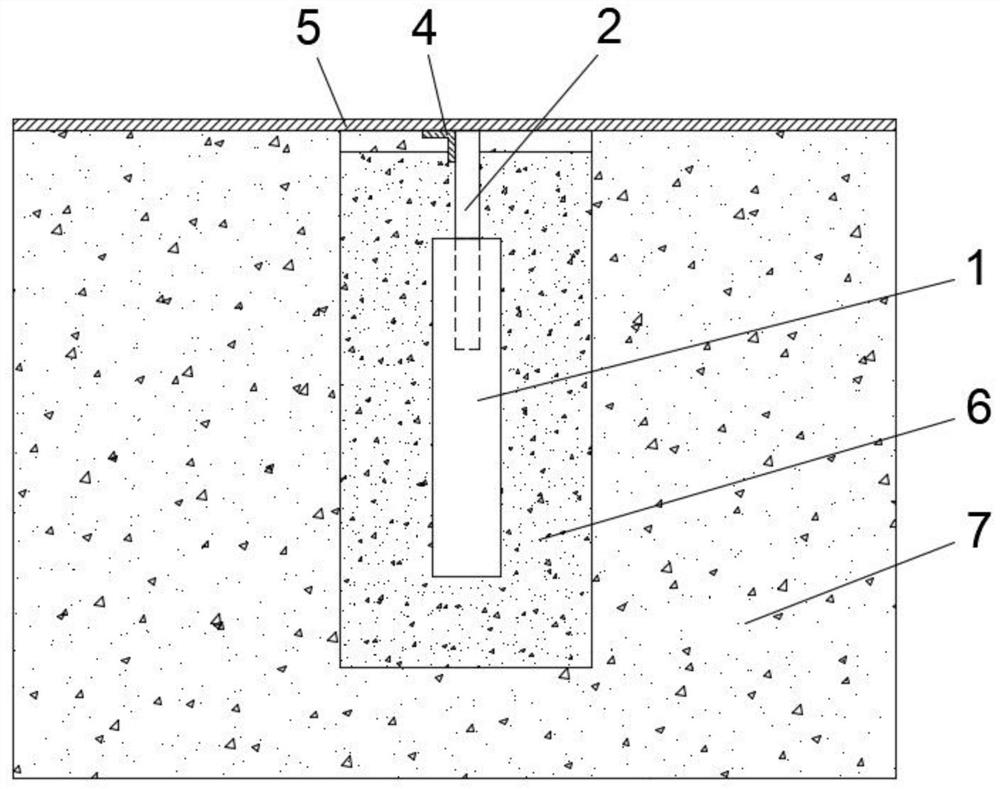

Composite grounding module and preparation method thereof

ActiveCN112079637AIncrease true densityHigh bulk densityConnection contact member materialMetallic electrodeProcess engineering

The invention relates to the technical field of grounding devices, in particular to a composite grounding module and a preparation method thereof. The composite grounding module comprises a groundingmodule carrier and a metal electrode partially wrapped in the grounding module carrier, and the grounding module carrier is composed of, in percentage by mass, 50% of petroleum coke, 35% of coal tar pitch coke and 15% of graphite. The composite grounding module is prepared by sequentially performing burdening, grinding, kneading, forming, roasting, calcining, graphitizing and maintaining. The composite grounding module has the advantages of high strength, corrosion resistance, good resistance reduction effect and long service life.

Owner:大连法伏安电器有限公司

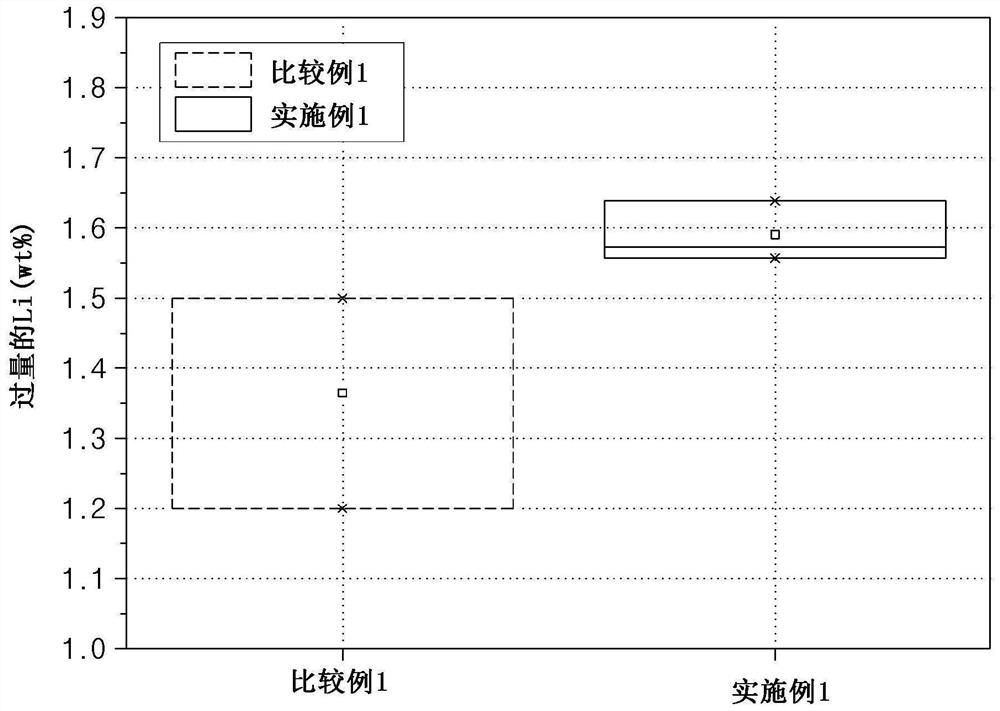

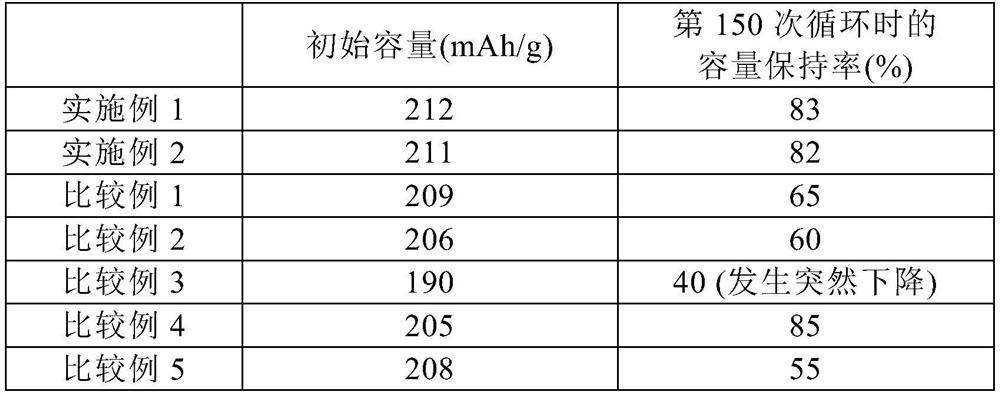

Method for preparing positive electrode active material for lithium secondary battery, positive electrode comprising positive electrode active material prepared by method, and lithium secondary battery

PendingCN113767070AReduce qualityUniform and excellent qualityElectrode thermal treatmentPositive electrodesBattery cellMaterials science

The present invention provides a method for manufacturing a positive electrode active material for a lithium secondary battery, and a positive electrode for the lithium secondary battery and the lithium secondary battery comprising the positive electrode active material manufactured by the manufacturing method. The method comprises a first step of dry-mixing a transition metal hydroxide and an anhydrous lithium raw material; a second step of firing the mixture of the transition metal hydroxide and the anhydrous lithium raw material for the first time; and a third step of finely grinding and mixing the primarily fired material, and performing secondary firing to obtain a lithium transition metal oxide, wherein the anhydrous lithium raw material is mixed in an amount of 40 parts by weight or less based on 100 parts by weight of the transition metal hydroxide.

Owner:LG CHEM LTD

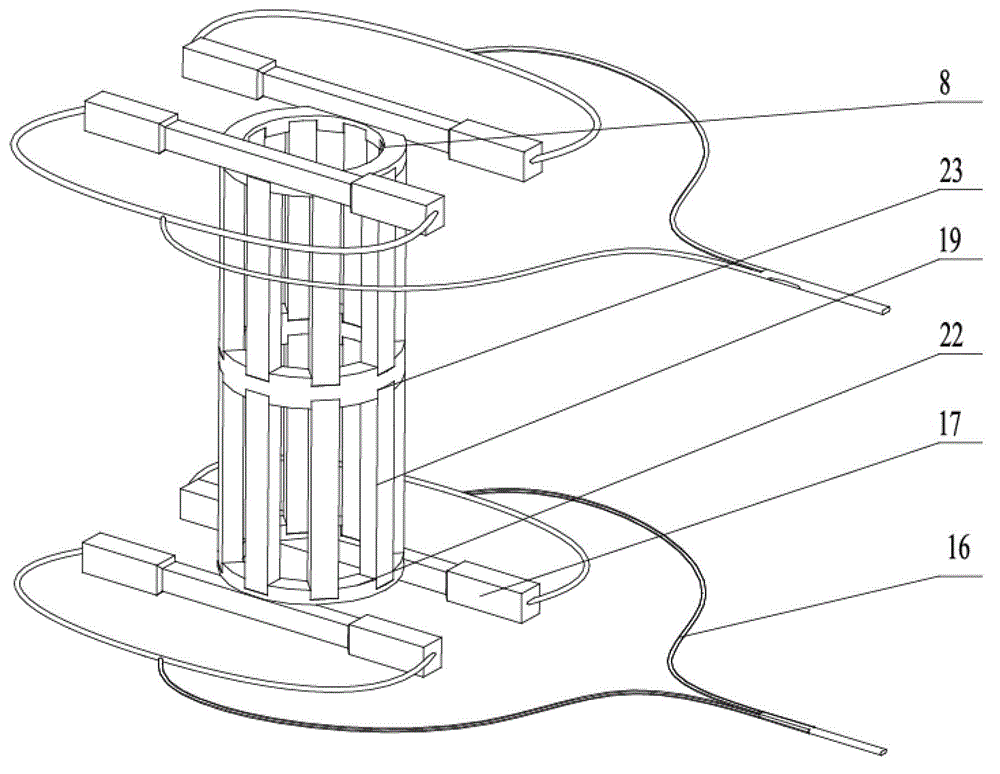

Novel carbon calcining furnace

ActiveCN102980393AEffective corrosionEffectively prevent corrosionFurnace typesLower gradeLow graded

The invention discloses a novel carbon calcining furnace, which comprises a furnace body (2), and is characterized in that: a heating bin (7) is arranged in the furnace body (2), and adopts a carbon liner; an upper heating connecting ring (8) and a lower heating connecting ring (22) are arranged in the heating bin (7); a heating body (19) is arranged between the upper heating connecting ring (8) and the lower heating connecting ring (22); and the upper heating connecting ring (8) and the lower heating connecting ring (22) are respectively connected with a graphite cross beam (17). According to the calcining furnace, the furnace body adopts the carbon liner, so that the corrosion of fluorine can be effectively prevented, and the furnace body is high temperature resistant; and the furnace body is used for preheating materials to be heat through a preheating bin, so that the heat energy is saved. The calcining furnace can be used for calcining, electrolytic aluminium wastes, low-grade inferior graphite, coal, petroleum coke and other carbon materials at high temperature, for desulfurizating and devolatilizing, so that the quality of the carbon materials is improved.

Owner:周俊和 +1

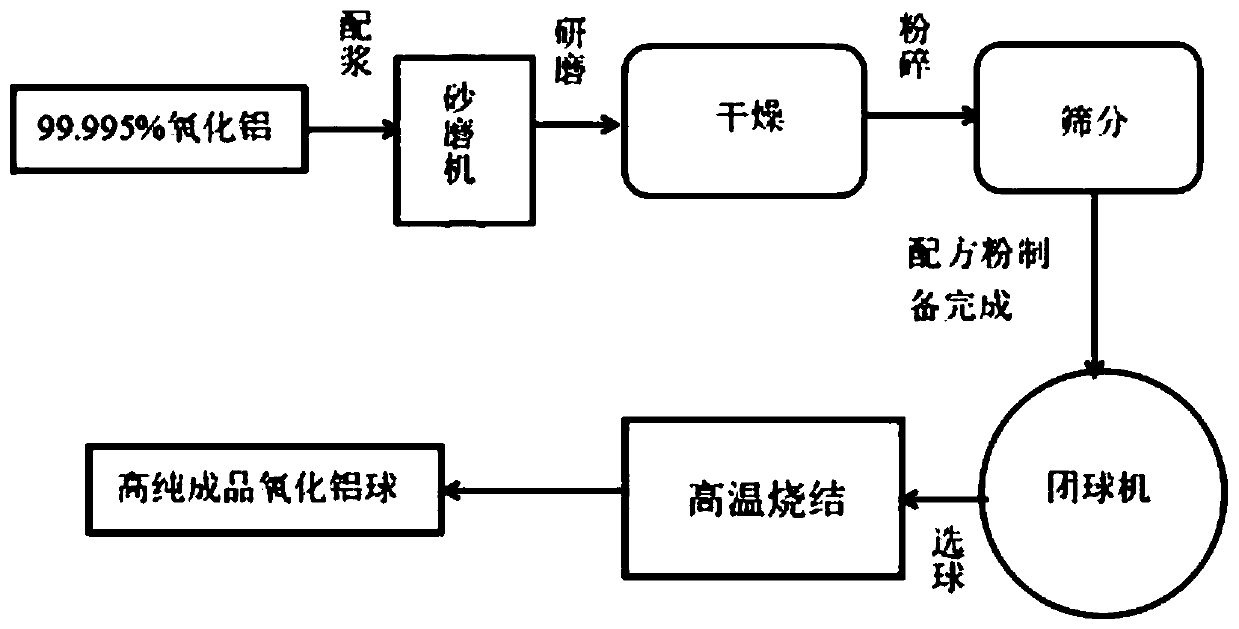

Preparation method of alumina milling balls

The invention discloses a preparation method of an alumina milling balll. The preparation method comprises the following steps: 1) sieving aluminum oxide powder with the purity of more than or equal to 99.995%, the particle size D50 value of 0.6-1.0 [mu]m and the specific surface area of less than or equal to 8 m<2> / g to obtain sieved aluminum oxide powder; 2) collecting the sieved alumina powder,adding pure water accounting for 5-20% of the weight of the sieved alumina powder, and preparing ball seeds in a ball forming machine, when the particle size of the ball seeds reaches 0.1-0.3 mm, adding sieved aluminum oxide powder on the ball seeds in the ball forming machine to start to grow balls, when the ball diameter is increased to 0.5-0.6 mm, adjusting the rolling moving track of the ball, and adding sieved alumina powder to continuously grow the ball, when the ball diameter is increased to 0.7-0.8 mm, adjusting the rolling moving track of the ball, and adding sieved aluminum oxide powder to grow the ball continuosuly, when the ball diameter is increased to 0.8-0.9 mm and the apparent density of the alumina ball after ball repairing and pressing reaches 1.5 g / cm<3> or above, drying and sintering the balls at 1300-1400 DEG C for 15-25 hours to obtain the alumina milling ball. The alumina milling ball has the characteristics of high purity, low abrasion, high strength and smoothand round surface.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

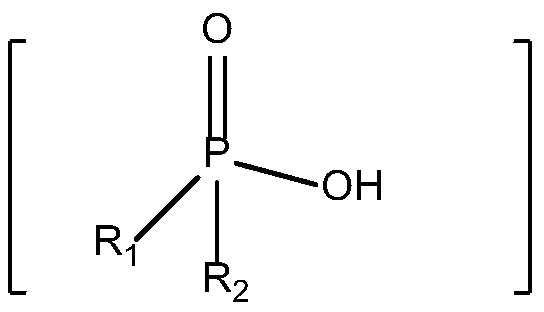

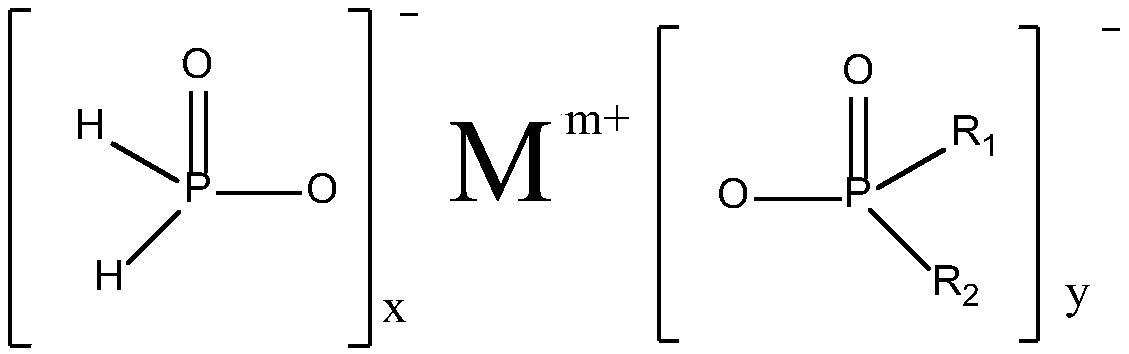

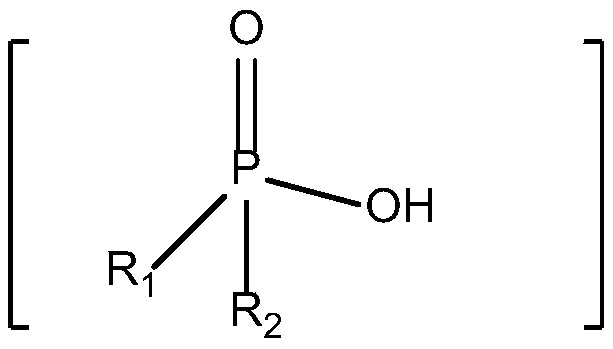

Organic phosphide flame retardant as well as preparation and application thereof

ActiveCN111320781AIncrease true densitySolve densityGroup 5/15 element organic compoundsPhosphoric acidPhosphate

The invention relates to an organic phosphide flame retardant as well as a preparation method and an application thereof. The technical problem that a halogen-free flame retardant is low in stacking density and true density is solved. The organic phosphide flame retardant is obtained by dropwise adding one or more of dialkyl hypophosphorous acid, monoalkyl hypophosphorous acid, alkoxy hypophosphorous acid and dialkoxy hypophosphorous acid and hypophosphorous acid into at least one of 2-8 valent metal oxide or metal hydroxide for a reaction, or dropwise adding one or more of a dialkyl hypophosphorous acid soluble salt solution, a monoalkyl hypophosphite soluble salt solution, an alkoxy hypophosphorous acid soluble salt solution and a dialkoxy hypophosphorous acid soluble salt solution intoa 2-8 valent metal non-halogen soluble salt solution for the reaction to obtain the product. The method can be widely applied to the technical field of flame retardants.

Owner:WEIHAI HELEN NEW MATERIAL TECH CO LTD

A kind of preparation method of graphite material for lithium ion battery

ActiveCN103618088BIncrease true densityIncrease gram capacityCell electrodesSecondary cellsDischarge efficiencyCarbonization

Owner:刘铁建

Method of manufacturing silicate bricks with lead-and-zinc tailings

InactiveCN103058618BHigh strengthMake up for the deficiency of insufficient silica contentSolid waste managementBrickSilicon dioxide

The invention aims at features to the lead-and-zinc tailings and provides a method of manufacturing steaming-and-pressing silicate wall materials, wherein the features include low content of silica, large density, coarse granules and the like. The method of manufacturing silicate bricks with lead-and-zinc tailings has the advantages that the lead-and-zinc tailings with high true density, containing a certain number of coarse granules and high bulk density is used and can be used for aggregates of the silicate bricks with good effects of moulding pressure transition and beneficial for compression moulding. High compression moulding density can be obtained. The defect that the content of the silica in the lead-and-zinc tailings is not enough can be overcome through adulteration partial ground fine quartz sands. The method of manufacturing silicate bricks with the lead-and-zinc tailings is a processing method of the lead-and-zinc tailings that the technology is simple and the cost is low.

Owner:JIANGSU EAST CHINA MINE TAILINGS MANAGEMENT ENG +1

A kind of coking method of coal-oil system mixed asphalt

ActiveCN103965928BLow impurity contentLow densityCoking carbonaceous materialsCross-linkQuality level

The invention relates to a coking method for coal-oil mixed pitch. The coking method comprises the following steps: coal pitch and oil pitch are mixed in accordance to appropriate proportion and pretreated under certain condition to prepare refined pitch; the refined pitch is taken as a preparation raw material for needle coke; the characteristics of the coal pitch such as macromolecular aromatics structure and being capable of forming favorable organization structure are fully utilized and lower impurity content of the oil pitch, particularly lower QI content and impurity atom content as well as the cross-linked effect of micro-molecules are combined. According to the coking method, the negative influence caused by too much impurities and light constituent in the oil pitch is effectively avoided, the quality level of green coke is effectively improved, the carbon content is improved, the volatile component and ash content are reduced, therefore, the obtained needle coke is low in impurity content, favorable in organization structure, simultaneously procedures in the whole coking process is simple and the operation is convenient.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com