A kind of preparation method of graphite material for lithium ion battery

A technology for lithium-ion batteries and graphite materials, which is applied in the field of preparation of graphite materials for lithium-ion batteries, can solve the problems of reducing battery safety performance and energy reduction, and achieve high production efficiency, short heating time, and good sealing of the furnace body Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

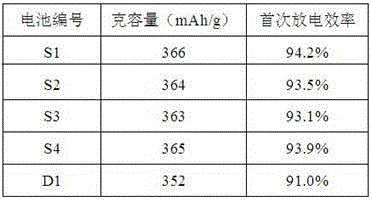

Examples

Embodiment 1

[0030] The preparation method of a kind of lithium-ion battery graphite material that present embodiment provides, comprises the following steps:

[0031] Step 1: Add coconut shell charcoal into a high-temperature carbonization furnace with a pressure of 0.5 MPa under an argon gas atmosphere, heat to 1000°C and keep at this temperature for 5 hours to carbonize coconut shell charcoal, and at the same time vacuumize the carbonization furnace The vacuum inside is -20KPa, after cooling, the coconut shell charcoal after carbonization is obtained;

[0032] Step 2: Add the carbonized coconut shell carbon obtained in Step 1 into the graphitization furnace under an argon atmosphere, and then inject coal tar pitch, which has a dynamic viscosity of 90 Pa·s at 60°C, and stir thoroughly , and vacuumize at the same time, so that the vacuum degree in the graphitization furnace is -10KPa, and then graphitize at 2600°C. The duration of graphitization is 5h, and graphite is obtained after cooli...

Embodiment 2

[0035] The preparation method of a kind of lithium-ion battery graphite material that present embodiment provides, comprises the following steps:

[0036] Step 1: In a nitrogen gas atmosphere, add fruit shell charcoal to a high-temperature carbonization furnace with a pressure of 0.8 MPa, heat to 1100°C and continue at this temperature for 10 hours to carbonize the shell charcoal, and at the same time vacuumize the carbonization furnace. The vacuum degree is -30KPa, after cooling, obtain the shell charcoal after carbonization;

[0037] Step 2: Add the carbonized coconut shell charcoal obtained in Step 1 into the graphitization furnace under a nitrogen gas atmosphere, and then inject petroleum pitch, which has a dynamic viscosity of 70 Pa·s at 60°C. Vacuumize the graphitization furnace so that the vacuum degree in the graphitization furnace is -1KPa, and then graphitize at 2500°C. The duration of graphitization is 10h, and graphite is obtained after cooling.

[0038] Wherein, ...

Embodiment 3

[0040]The preparation method of a kind of lithium-ion battery graphite material that present embodiment provides, comprises the following steps:

[0041] Step 1: Add wood charcoal into a high-temperature carbonization furnace with a pressure of 1 MPa in a nitrogen gas atmosphere, heat to 1000°C and keep at this temperature for 15 hours to carbonize the wood charcoal, and at the same time vacuumize the carbonization furnace. It is -1KPa, after cooling, the charcoal after carbonization is obtained;

[0042] Step 2: Add the carbonized wood charcoal obtained in Step 1 into the graphitization furnace under a nitrogen gas atmosphere, and then inject natural pitch whose dynamic viscosity at 60°C is 60 Pa·s. Vacuum, make the vacuum degree in the graphitization furnace be -80KPa, then graphitize at 2700°C, the duration of graphitization is 1h, and obtain graphite after cooling.

[0043] Wherein, the mass ratio of wood charcoal and natural asphalt is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com