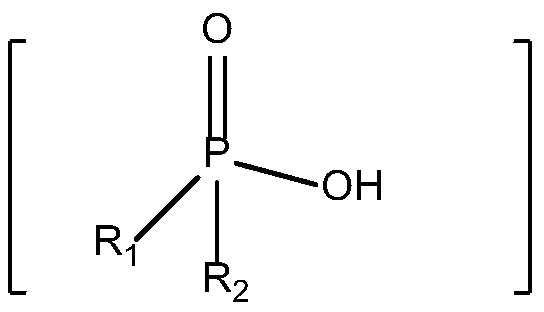

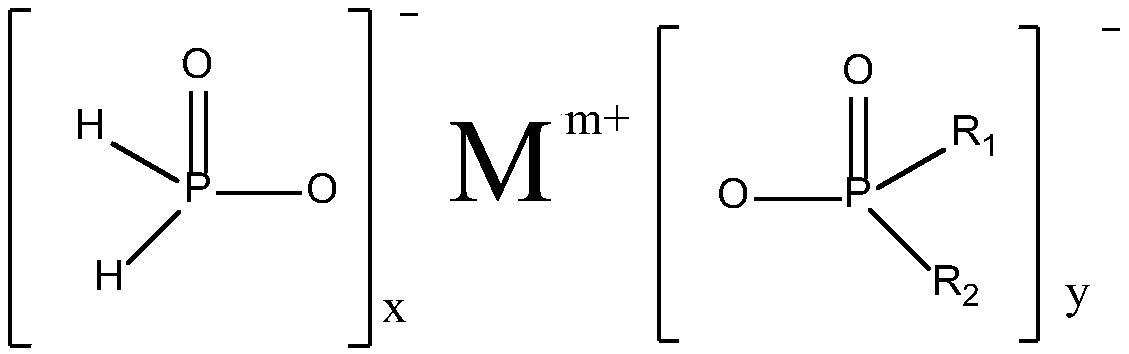

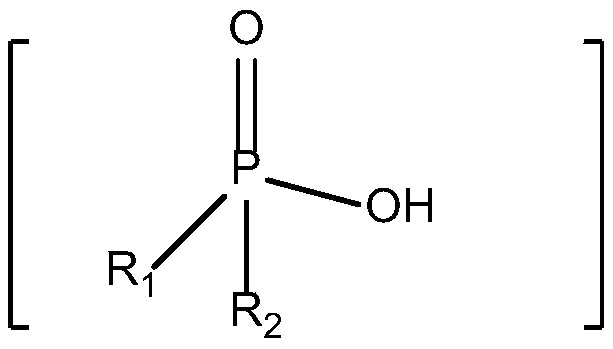

Organic phosphide flame retardant as well as preparation and application thereof

A flame retardant and phosphide technology, applied in the field of organic phosphide flame retardants, can solve the problems of difficult processing, large proportion of ADP volume fraction, decreased flame retardant performance, etc., to achieve multiple physical and chemical properties, excellent flame retardant effect , the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 122g of diethyl hypophosphorous acid and 132g of hypophosphorous acid (50%) in 500g of water at the same time to obtain solution A, add 52g of aluminum hydroxide to 800g of water and stir to obtain suspension B; add solution A to the end of the speed of 8h dropwise Add it dropwise to the B suspension for reaction to obtain a suspension solution. After the dropwise addition, continue to stir for 10 hours. The entire reaction temperature is controlled at 0°C. Finally, the obtained suspension solution is filtered, washed, dried, and pulverized to obtain a particle size of 0.001 μm~100μm compound salt ADYP.

Embodiment 2

[0043] Dissolve 144g sodium diethyl hypophosphite and 106g sodium hypophosphite monohydrate in 500g water at the same time to obtain solution A, add 444g aluminum sulfate octadecahydrate to 1600g water and stir to obtain solution B; add solution A at the speed of 8h Add dropwise to solution B for reaction to obtain a suspension solution. After the dropwise addition, continue to stir for 10 hours. The entire reaction temperature is controlled at 20°C. Finally, filter, wash, dry, and pulverize the obtained turbid solution to obtain a particle size of 0.001 μm to 100 μm. Compound salt ADYP.

Embodiment 3

[0045] Dissolve 216g of methyl ethyl hypophosphorous acid and 132g of hypophosphorous acid in 1500g of water at the same time to obtain solution A, and dissolve 210g of pseudoboehmite in 1500g of water to obtain solution B; add solution A to the React in solution B to obtain a suspension solution. After the dropwise addition, continue to stir for 6 hours. The entire reaction temperature is controlled at 50°C. Finally, filter, wash, dry, and pulverize the obtained suspension solution to obtain a compound salt with a particle size of 0.001 μm to 100 μm. ADYP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com