Preparation method of alumina milling balls

A technology of alumina ceramics and alumina balls, applied in the field of grinding, can solve the problems of unstable product purity and wear, unfavorable market competition, low purity of additives, etc., and achieves environmental protection and pollution-free color, pure white color, and particle size activity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

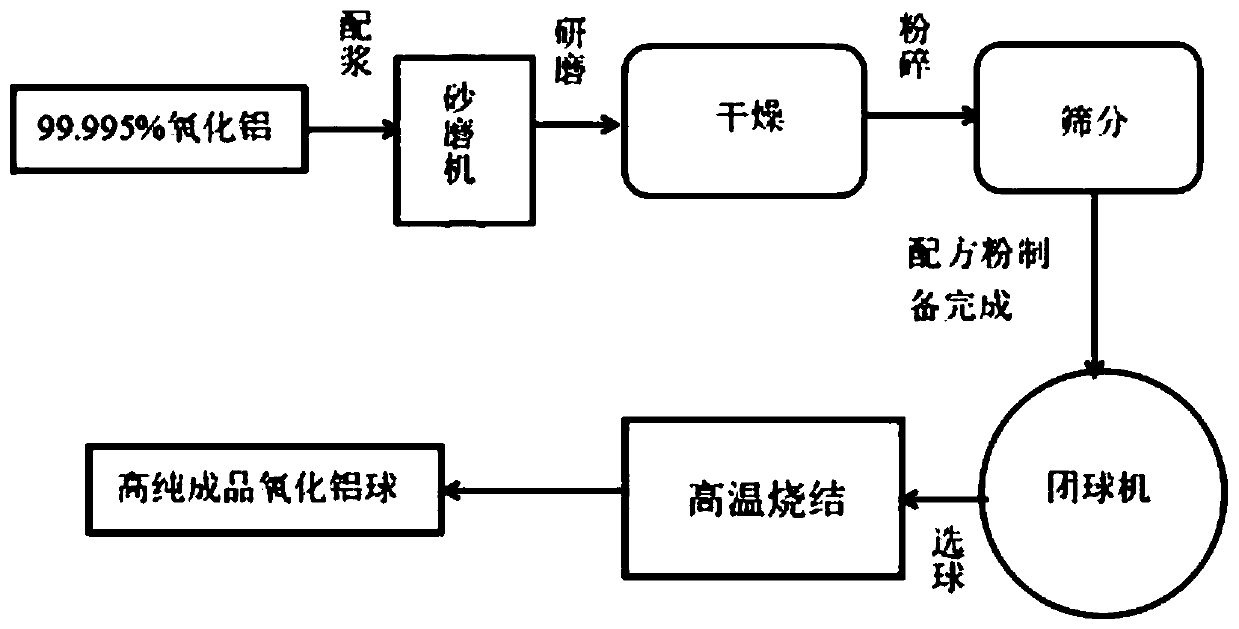

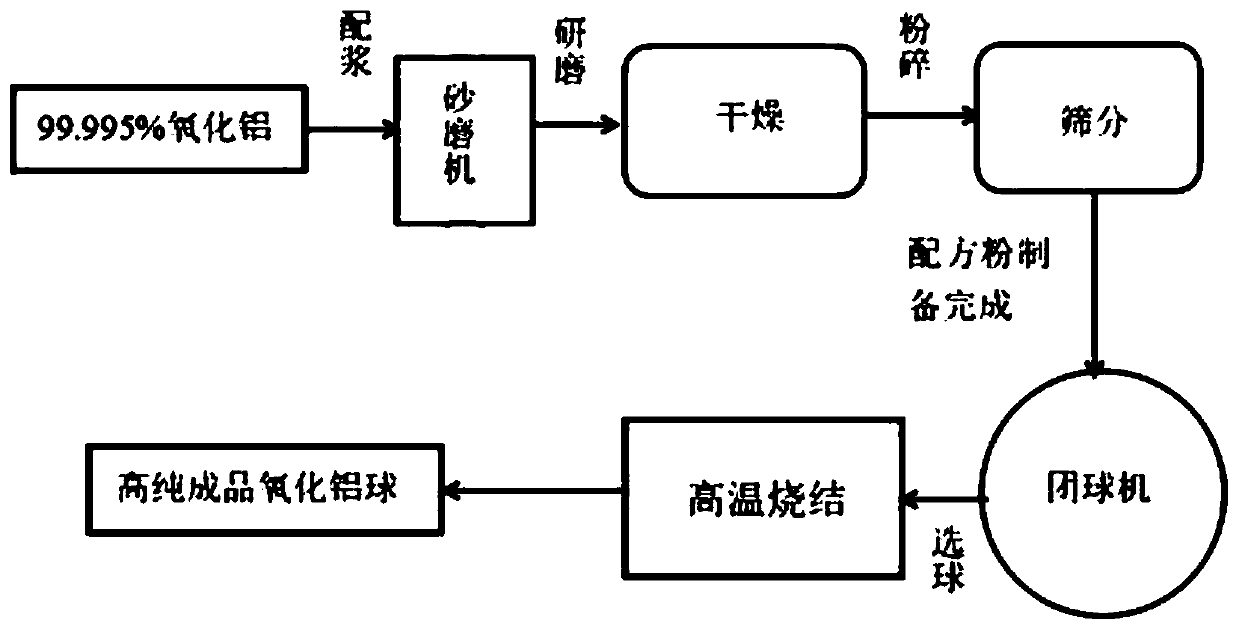

[0031] Such as figure 1 Shown, a kind of preparation method of alumina ceramic grinding ball, described preparation method comprises the following steps:

[0032] High-purity alumina (>99.995%) is used as raw material, the particle size D50 of alumina powder is required to be 0.60 μm, the ratio of alumina powder is less than 7.9㎡ / g, and the alumina powder filtered through a 100-mesh screen is used as the preparation of high-purity alumina powder. Alumina ceramic grinding ball raw material.

[0033] Preparation of high-purity alumina ceramic grinding balls: Add 5% pure water to the above spare alumina powder according to the weight of the powder, and prepare ball seeds in the pellet machine. The frequency of the pellet machine is required to be 10Hz. No large particles, the particle size of the ball seed should reach 0.1-0.3mm. When the particle size of the ball seed reaches the requirement, start to sprinkle the long ball of spare alumina powder on the ball seed in the pellet...

Embodiment 2

[0035] Such as figure 1 Shown, a kind of preparation method of alumina ceramic grinding ball, described preparation method comprises the following steps:

[0036] High-purity alumina (>99.995%) is used as raw material, the particle size D50 of alumina powder is required to be 0.85 μm, the ratio of alumina powder is less than 5.7㎡ / g, and the alumina powder filtered through a 100-mesh screen is used as the preparation of high-purity alumina powder. Alumina ceramic grinding ball raw material. Preparation of high-purity alumina ceramic grinding balls: add 5% pure water to the above spare alumina powder according to the weight of the powder, and prepare ball seeds in the pellet machine. The frequency of the pellet machine is required to be 15Hz. No large particles, the particle size of the ball seed should reach 0.1-0.3mm. When the particle size of the ball seed reaches the requirement, start to sprinkle the long ball of spare alumina powder on the ball seed in the pellet machine ...

Embodiment 3

[0038] Such as figure 1 Shown, a kind of preparation method of alumina ceramic grinding ball, described preparation method comprises the following steps:

[0039] High-purity alumina (>99.995%) is used as raw material, the particle size D50 of alumina powder is required to be 1.0 μm, the ratio of alumina powder is less than 8㎡ / g, and the alumina powder filtered through a 100-mesh sieve is used as the preparation of high-purity Alumina ceramic grinding ball raw material. Preparation of high-purity alumina ceramic grinding balls: Add the above spare alumina powder to 20% pure water according to the weight of the powder, and prepare ball seeds in the pellet machine. The frequency of the pellet machine is required to be 25Hz. No large particles, the particle size of the ball seed should reach 0.1-0.3mm. When the particle size of the ball seed reaches the requirement, start to sprinkle the long ball of spare alumina powder on the ball seed in the pellet machine at an interval of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com