Self-assembly preparation method of lithium manganese phosphate positive electrode material and lithium manganese phosphate positive electrode material

A technology of lithium manganese phosphate, cathode material, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve problems such as low electrical conductivity, improve electrical conductivity, excellent electrochemical performance, improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

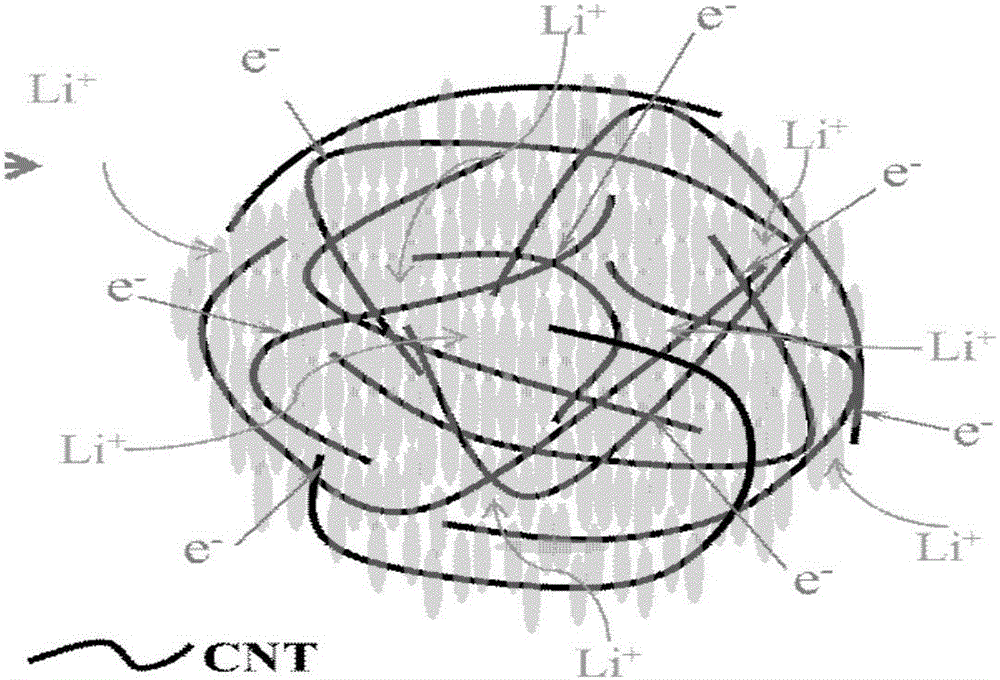

[0024] The self-assembly preparation method of the spherical lithium manganese phosphate composite cathode material of the present invention comprises:

[0025] Weigh an appropriate amount of carbon nanotubes, and ultrasonically disperse them in deionized water. The ultrasonic dispersion time is 0.5 to 12.0 hours, preferably 0.5 to 4.0 hours, most preferably 1 to 2 hours;

[0026] Weigh manganese sulfate and add it to the liquid to form a manganese sulfate / carbon nanotube liquid; control the concentration of manganese sulfate to 0.1-0.3mol / L, preferably 0.15mol / L;

[0027] Configure an aqueous ammonium persulfate solution, and control the concentration of the aqueous ammonium persulfate solution to be 0.1 to 0.4 mol / L, preferably 0.20 mol / L;

[0028] Under the constant temperature stirring condition of 70-90°C, the ammonium persulfate aqueous solution is added dropwise to the manganese sulfate / carbon nanotube liquid, wherein the ammonium persulfate aqueous solution and the man...

Embodiment 1

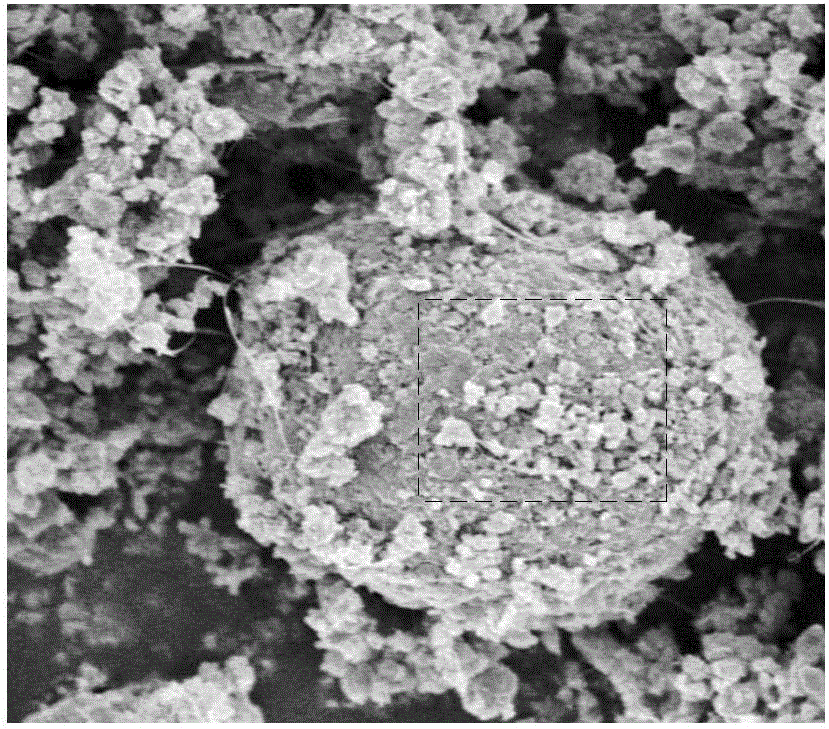

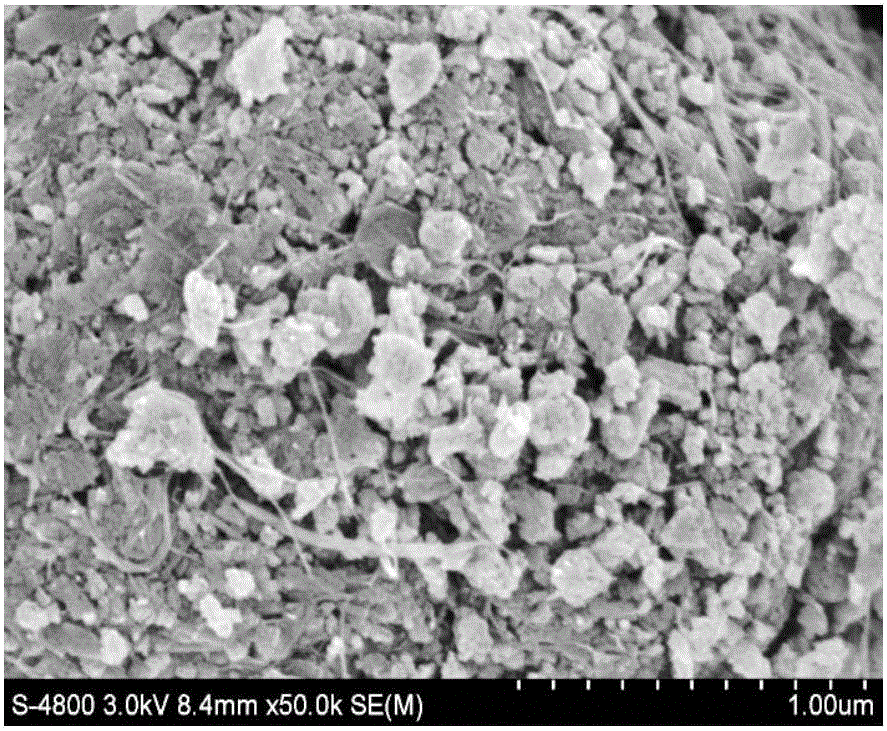

[0032] The carbon nanotubes were added into 50 ml of deionized water, and ultrasonically dispersed for 0.5 hour to make them uniformly dispersed to obtain a mixture of carbon nanotubes and deionized water. An appropriate amount of manganese sulfate is added to the above mixture to obtain a manganese sulfate / carbon nanotube liquid, and the concentration of manganese sulfate in the liquid is controlled to be 0.15 mol / L. Prepare 50 ml of 0.20 mol / L ammonium persulfate aqueous solution. The ammonium persulfate solution was added dropwise to the manganese sulfate / carbon nanotube liquid under constant temperature stirring at 70°C, wherein the volume ratio of the ammonium persulfate solution to the manganese sulfate / carbon nanotube liquid was 1:1. After reacting for 0.5 hours, the precipitate was collected by centrifugation, and the collected precipitate was dried in an oven at 150° C. for 12 hours to obtain a precursor. The above precursor, lithium carbonate, and ammonium dihydroge...

Embodiment 2

[0034]The carbon nanotubes were added into 100 ml of deionized water, and ultrasonically dispersed for 0.5 hour to make them uniformly dispersed to obtain a mixture of carbon nanotubes and deionized water. An appropriate amount of manganese sulfate is added to the above mixture to obtain a manganese sulfate / carbon nanotube liquid, and the concentration of manganese sulfate in the liquid is controlled to be 0.15 mol / L. Prepare 120 milliliters of 0.20 mol / L ammonium persulfate aqueous solution. Under constant temperature stirring at 70°C, the above-mentioned ammonium persulfate solution was added dropwise to the manganese sulfate / carbon nanotube liquid, wherein the volume ratio of the ammonium persulfate solution to the manganese sulfate / carbon nanotube liquid was 1.2 :1. After reacting for 1 hour, the precipitate was collected by centrifugation, and the collected precipitate was dried in an oven at 80° C. for 12 hours to obtain a precursor. Mix the above precursor with lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com