Combined process method of lightening residual oil/ medium and low temperature coal tar

A low-temperature coal tar and combined process technology, applied in the fields of oil refining, coal chemical industry, and petrochemical industry, can solve the problems of low gasoline yield, large heat energy loss, and high equipment investment, and achieve improved cracking performance, increased yield, and simplified process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

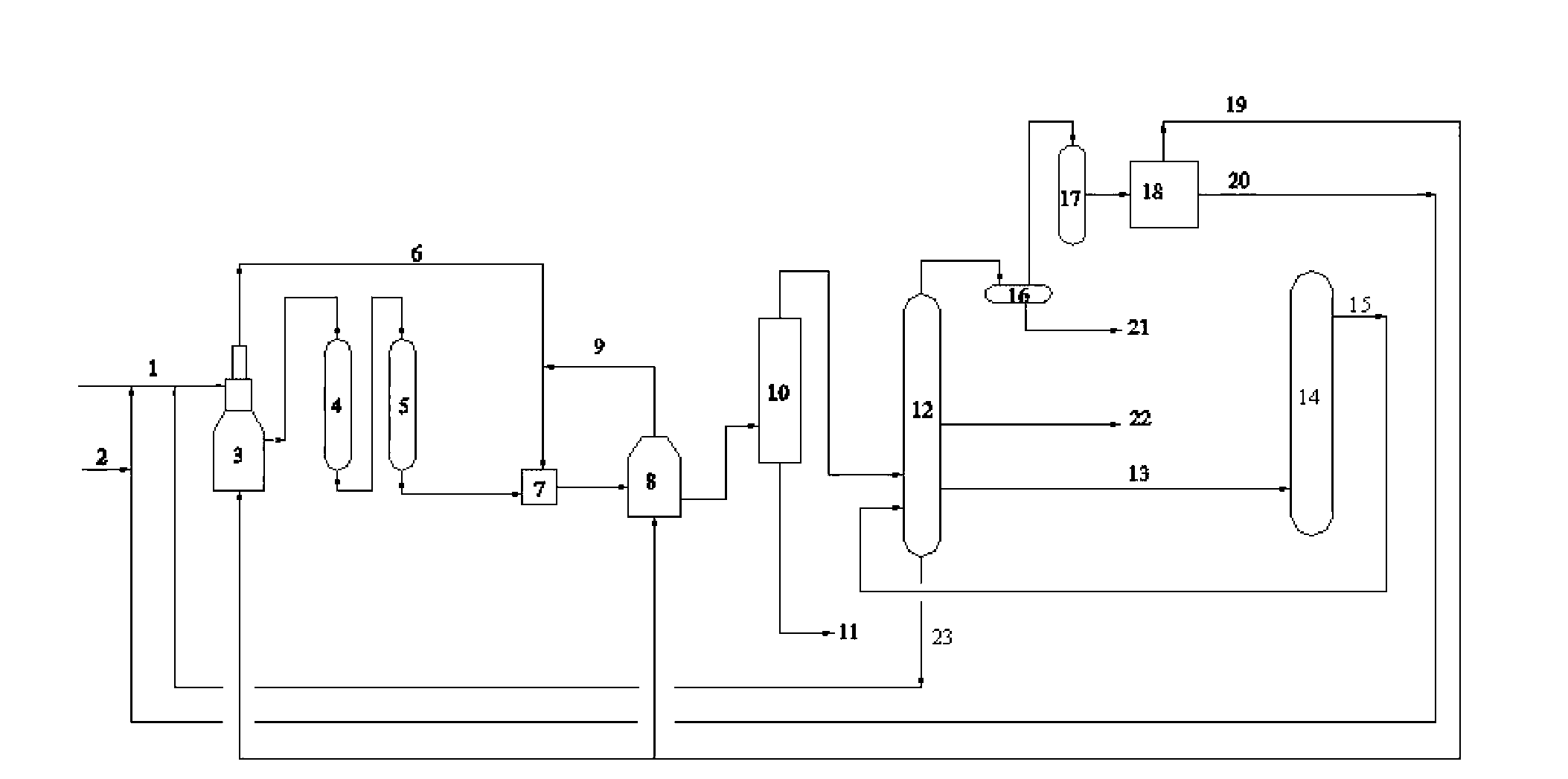

[0046]In this embodiment, the vacuum residue A is used as the raw material, and the operation is carried out by organically combining the four units of residue hydrotreatment-delayed coking-catalytic cracking-PSA purification. After the vacuum residue passes through the hydrotreating unit, all products of the hydrotreating are directly sent to the delayed coking unit without separation. In the delayed coking unit, the residual oil after hydrogenation first enters the waste heat recovery device to exchange heat with the flue gas from the heating furnace, and then enters the coking heating furnace, coke tower and fractionation system in sequence after the heat exchange. All the wax oil obtained from the fractionation system enters the catalytic cracking unit, and the catalytic cracking unit only has a reaction-regeneration system. The oil and gas obtained from the reaction enter the fractionation system, and are fractionated together with the oil and gas from the coke tower.

[...

Embodiment 2

[0051] In this example, the vacuum residue B is used as the raw material, and the process method adopted is the same as in Example 1. The operating conditions, product distribution and coke properties are shown in Tables 3, 4 and 5, respectively.

[0052] Comparing the results of the invention, it can be seen that by adopting the method of organically combining the four units of residual oil hydrotreating-delayed coking-catalytic cracking-PSA purification, the raw material oil can be converted into finished gasoline and diesel oil and high-quality coke to the greatest extent, and the raw material utilization rate is 100%. Compared with the conventional residual oil hydrogenation-delayed coking-catalytic cracking process, the process can save energy by 40%, save new hydrogen consumption by 50%, and save equipment investment by 40%.

[0053] Table 1 Properties of vacuum residue

[0054] Raw oil number

Vacuum residue A

Vacuum residue B

Density at 20°C, g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com