Composite grounding module and preparation method thereof

A grounding module and composite grounding technology, applied in the direction of connecting contact materials, etc., can solve the problems of short service life and easy damage to the grounding module, and achieve the effects of high mechanical strength, high bulk density, and good resistance reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

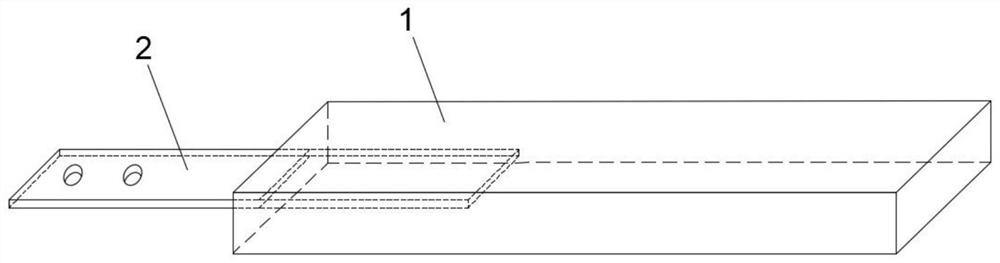

[0044] A composite grounding module, comprising a grounding module carrier 1 and a metal electrode 2 partially wrapped in the grounding module carrier 1, calculated by mass percentage, the grounding module carrier 1 is composed of 50% petroleum coke, 35% coal tar pitch coke, graphite 15% %composition. Such as figure 1 As shown, the grounding module carrier 1 is in the shape of a cuboid, and its length, width and height are 550mm, 110mm and 50mm respectively, and the metal electrode 2 is arranged at one end of the grounding module carrier 1 in the length direction.

[0045] A preparation method of a composite grounding module, comprising the following steps:

[0046] 1) Batching: batching the grounding module carrier 1 according to the composition of claim 1;

[0047] 2) Grinding: the raw materials are crushed and ground to make the particle size reach 0.075-0.7mm;

[0048] 3) Kneading: Put the milled raw materials into a kneading tank, add a certain amount of water, stir fo...

Embodiment 2

[0058] A composite grounding module, comprising a grounding module carrier 1 and a metal electrode 2 partially wrapped in the grounding module carrier 1, calculated by mass percentage, the grounding module carrier 1 is composed of 50% petroleum coke, 35% coal tar pitch coke, graphite 15% %composition.

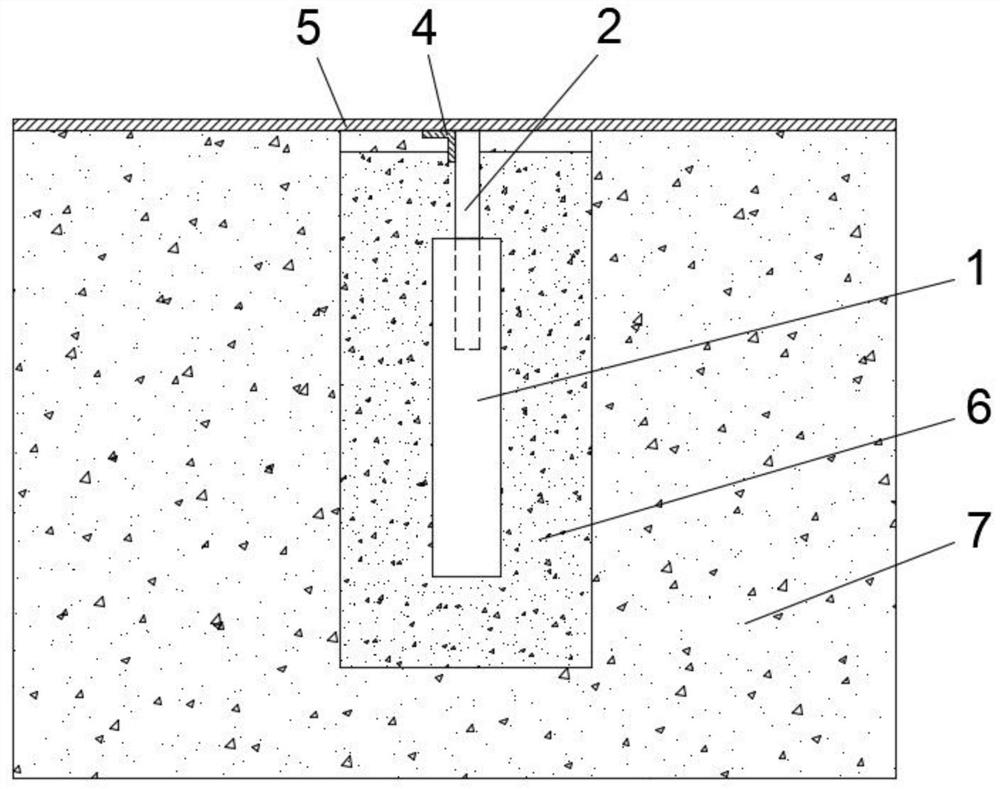

[0059] Such as Figure 4 As shown, the grounding module carrier 1 is in the shape of a cuboid, and its length, width and height are 550mm, 130mm and 50mm respectively. The metal electrode 2 is arranged at one end of the length direction of the grounding module carrier 1, and the other end of the The centralized ion chamber 3 inside the grounding module carrier 1, wherein the centralized ion chamber 3 can be made by machining or mold opening, wherein the number of the centralized ion chamber 3 is two, and the centralized ion chamber 3 is filled with a drag reducing agent .

[0060] The grounding module is to add two centralized ion chambers 3 to the grounding module in embodim...

Embodiment 3

[0062] A composite grounding module, comprising a grounding module carrier 1 and a metal electrode 2 partially wrapped in the grounding module carrier 1, calculated by mass percentage, the grounding module carrier 1 is composed of 50% petroleum coke, 35% coal tar pitch coke, graphite 15% %composition.

[0063] Such as Figure 6 As shown, the grounding module carrier 1 is in the shape of a cuboid, and its length, width and height are 550mm, 200mm and 50mm respectively. The metal electrode 2 is arranged at one end of the length direction of the grounding module carrier 1, and the other end of the The centralized ion chamber 3 inside the grounding module carrier 1, wherein the centralized ion chamber 3 can be made by machining or mold opening, wherein the number of the centralized ion chamber 3 is three, and the centralized ion chamber 3 is filled with a drag reducing agent .

[0064] This grounding module is based on the grounding module of Embodiment 2, increasing the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com