High-compaction iron phosphate and preparation method of high-compaction lithium iron phosphate

A real lithium iron phosphate, real iron phosphate technology, applied in the preparation/purification of carbon, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of small lithium iron phosphate particles and low compaction density, and achieve a primary particle size. Small, large BET, easy to grind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

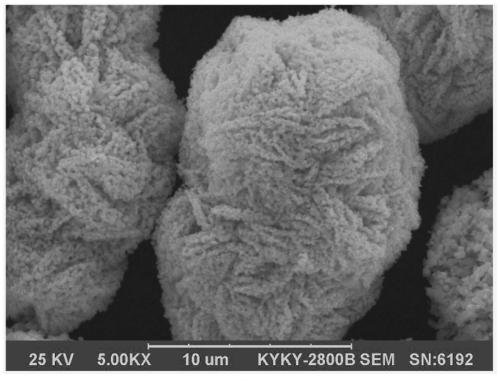

[0058] A preparation method of high compacted ferric phosphate, which comprises the following steps:

[0059] (1) Prepare ferrous sulfate solution, add the oxidant and ammonia water to the ferrous sulfate solution at the same time under agitation, adjust the final pH of the solution to 7.5, then continue to stir for 60min, keep the temperature of the whole process at 45°C, and the stirring speed Be 500r / min, obtain ferric hydroxide colloid;

[0060] (2) Warm up the ferric hydroxide colloid to a temperature of 95°C, then add ammonium bicarbonate solution and phosphoric acid solution simultaneously under stirring, the stirring speed is 400r / min, adjust the pH value of the solution to 1.8, and then continue to react for 60min, Then filter to obtain a filter residue and a filtrate, and the filter residue is washed to obtain a washed filter residue;

[0061] (3) adding the washed filter residue to the sucrose solution, then stirring and dispersing at a high speed, and spray-drying...

Embodiment 2

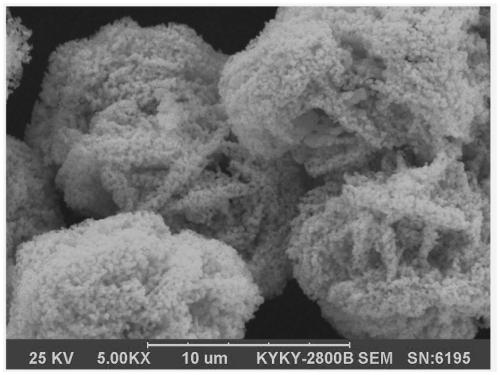

[0085] A preparation method of high compacted ferric phosphate, which comprises the following steps:

[0086] (1) Prepare the ferrous sulfate solution, add the oxidant and ammonia water to the ferrous sulfate solution at the same time under the condition of stirring, adjust the final pH of the solution to 8, then continue to stir for 60min, keep the temperature of the whole process at 25°C, and the stirring speed Be 300r / min, obtain ferric hydroxide colloid;

[0087] (2) Raise the temperature of the ferric hydroxide colloid to 90°C, then add the ammonium bicarbonate solution and the phosphoric acid solution simultaneously under stirring, the stirring speed is 400r / min, adjust the pH value of the solution to 2.2, and then continue the reaction for 50min, Then filter to obtain a filter residue and a filtrate, and the filter residue is washed to obtain a washed filter residue;

[0088] (3) adding the washed filter residue to the sucrose solution, then stirring and dispersing at ...

Embodiment 3

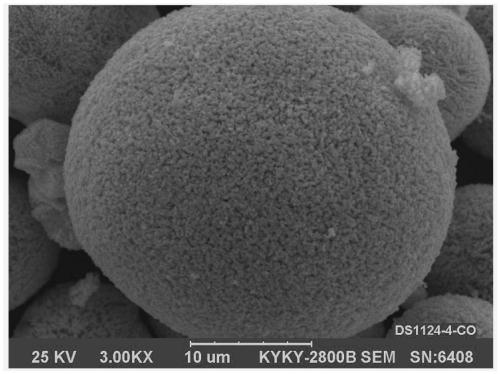

[0109] A preparation method of high compacted ferric phosphate, which comprises the following steps:

[0110] (1) Prepare ferrous sulfate solution, add the oxidant and ammonia water to the ferrous sulfate solution under stirring conditions, adjust the end point pH of the solution to 7.7, then continue to stir for 50min, keep the temperature of the whole process at 35°C, and the stirring speed Be 400r / min, obtain ferric hydroxide colloid;

[0111] (2) Warm up the ferric hydroxide colloid to a temperature of 93°C, then add ammonium bicarbonate solution and phosphoric acid solution simultaneously under stirring, the stirring speed is 300r / min, adjust the pH value of the solution to 2, and then continue the reaction for 50min, Then filter to obtain a filter residue and a filtrate, and the filter residue is washed to obtain a washed filter residue;

[0112] (3) adding the washed filter residue to the sucrose solution, then stirring and dispersing at a high speed, and spray-drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com