Oily sludge concentrating agent as well as preparation and application thereof

A sludge concentration and thickener technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor concentration effect, slow sedimentation speed, and large dosage of chemicals, and achieve convenient dosing, fast sedimentation speed, and less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

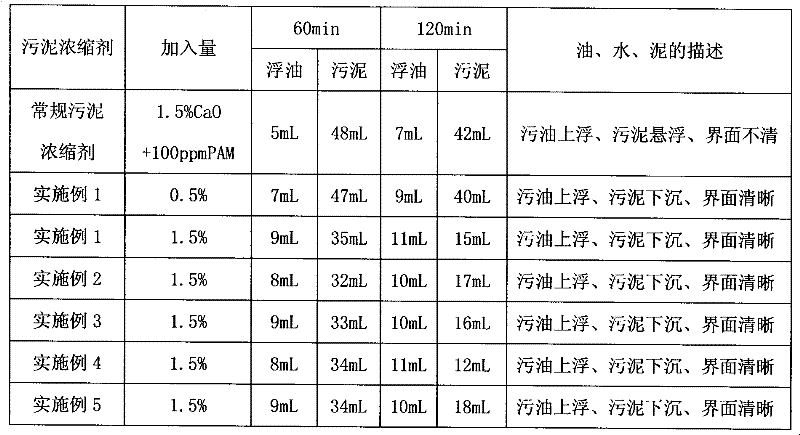

[0013] Use 425# slag cement, 160-mesh fly ash powder, diatomaceous earth and polyaluminum according to the ratio of 1:0.8:0.8:0.0125 to mix and stir until uniform to prepare 1# high-efficiency oily sludge thickener. See Table 1 for the experimental data.

Embodiment 2

[0015] Use 425# Portland cement, 200-mesh fly ash powder, diatomaceous earth and polyaluminum according to the ratio of 1:1.5:1:0.02 to mix and stir until uniform to prepare 2# high-efficiency oily sludge thickener. See Table 1 for the experimental data.

Embodiment 3

[0017] Use 425# slag cement, 250-mesh fly ash powder, diatomaceous earth and polyaluminum according to the ratio of 1:1.5:1.5:0.03 to mix and stir until uniform to prepare 3# high-efficiency oily sludge thickener. See Table 1 for the experimental data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com