Method for preparing positive electrode active material for lithium secondary battery, positive electrode comprising positive electrode active material prepared by method, and lithium secondary battery

A cathode active material, lithium secondary battery technology, applied in the direction of secondary batteries, lithium storage batteries, battery electrodes, etc., can solve problems such as yield reduction, reactivity reduction, productivity reduction, etc., to achieve productivity improvement, reactivity improvement, The effect of increasing true density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] Lithium hydroxide hydrate (LiOH·H 2 O) crush once until the average particle size (D 50 ) to 100 μm, vacuum-dry at 130°C for 24 hours, and then carry out secondary crushing until the average particle size (D 50 ) reached 15 μm, thereby obtaining anhydrous lithium hydroxide (LiOH).

[0138] As the positive active material precursor, 4750g Ni 0.88 co 0.05 mn 0.07 (OH) 2 , 82gAl(OH) 3Mix with 1343 g of anhydrous lithium hydroxide (LiOH) prepared above. 5 kg of subdivided parts of the mixed powder were put into each of the upper and lower parts of a container with a size of 330 mm x 330 mm, and primary fired at 630° C. for 8 hours in an oxygen atmosphere having an oxygen partial pressure of 80% by volume or more.

[0139] The primary fired material (cake) obtained by the primary firing was finely pulverized using an ACM instrument (Hosokawa Micron Corporation, model name: 15BC). 9 kg of subdivided portions of the resultant were put into a container having a size of ...

Embodiment 2

[0143] A cathode active material was produced in the same manner as in Example 1 above except that the input amount of anhydrous lithium was adjusted to 1318 g.

experiment example 1

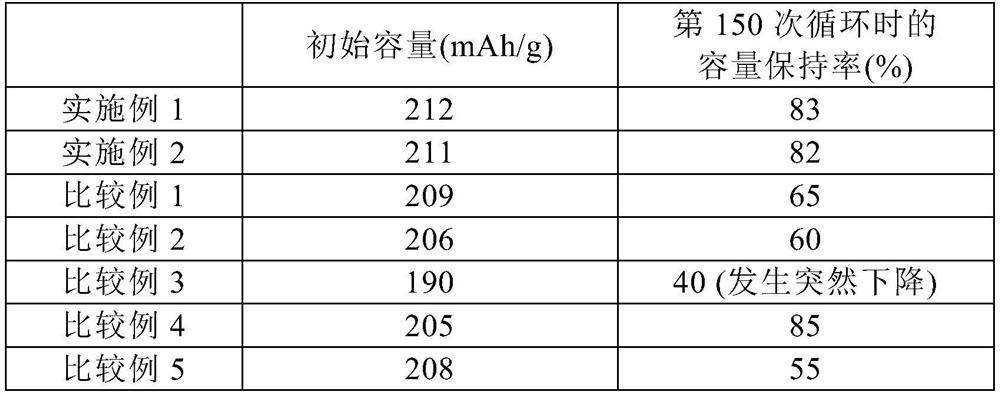

[0157] In order to compare the productivity of the positive electrode active material manufactured in the above-mentioned Examples 1 and 2 and Comparative Examples 1-5, in the batch production furnace of the same volume by the method of Examples 1 and 2 and Comparative Examples 1-5 in The amount of positive electrode active material produced in one month was measured, and the results are shown in Table 1 below.

[0158] [Table 1]

[0159] Productivity (ton / month) Example 1 900 Example 2 900 Comparative example 1 90 Comparative example 2 700 Comparative example 3 700 Comparative example 4 900 Comparative Example 5 355

[0160] Referring to the above Table 1, it can be seen that compared with the positive electrode active materials produced in Comparative Examples 1 to 3 using hydrated lithium hydroxide as a lithium raw material and Comparative Example 5 in which a firing step was performed, the positive electrode active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com