Novel carbon product vibration forming machine

A vibration molding machine and carbon product technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of large degree of freedom in ballast guidance, uneven oil injection, and affecting work efficiency, so as to prevent internal Cracks and faults, improving balance and stability, and improving the uniformity of fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

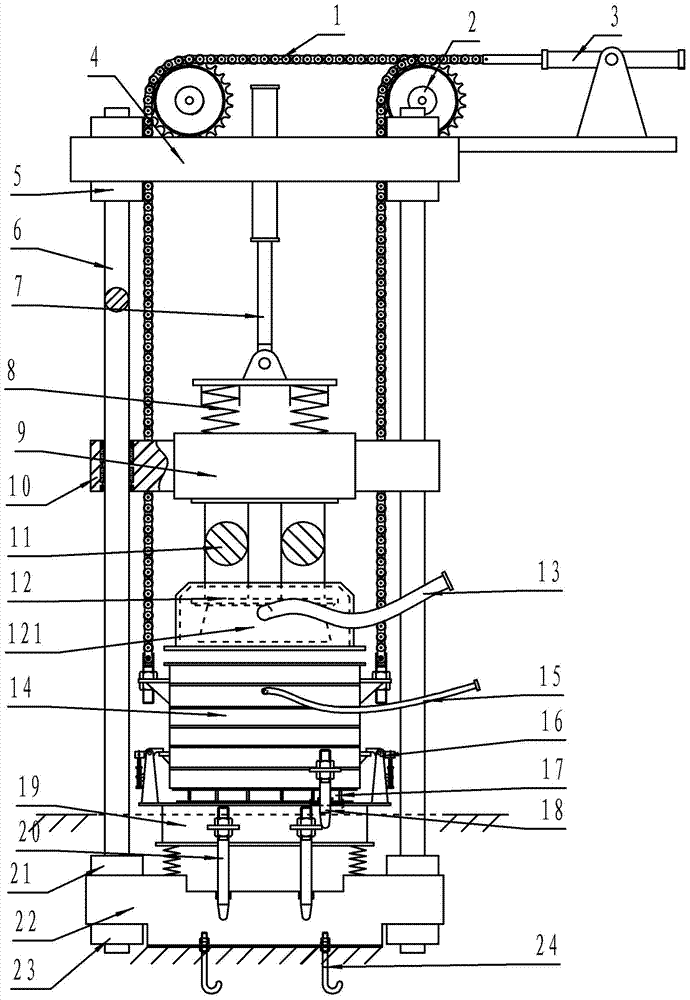

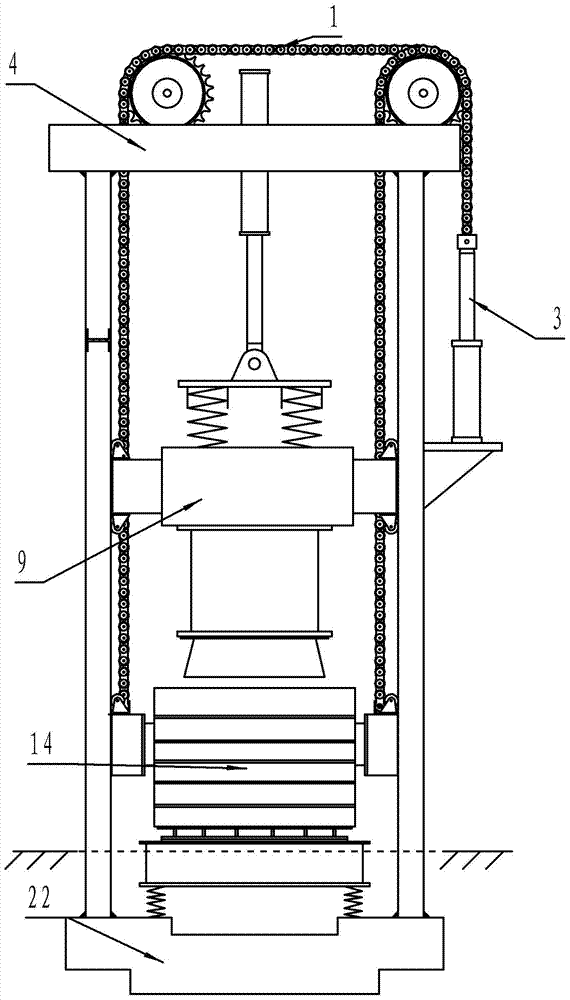

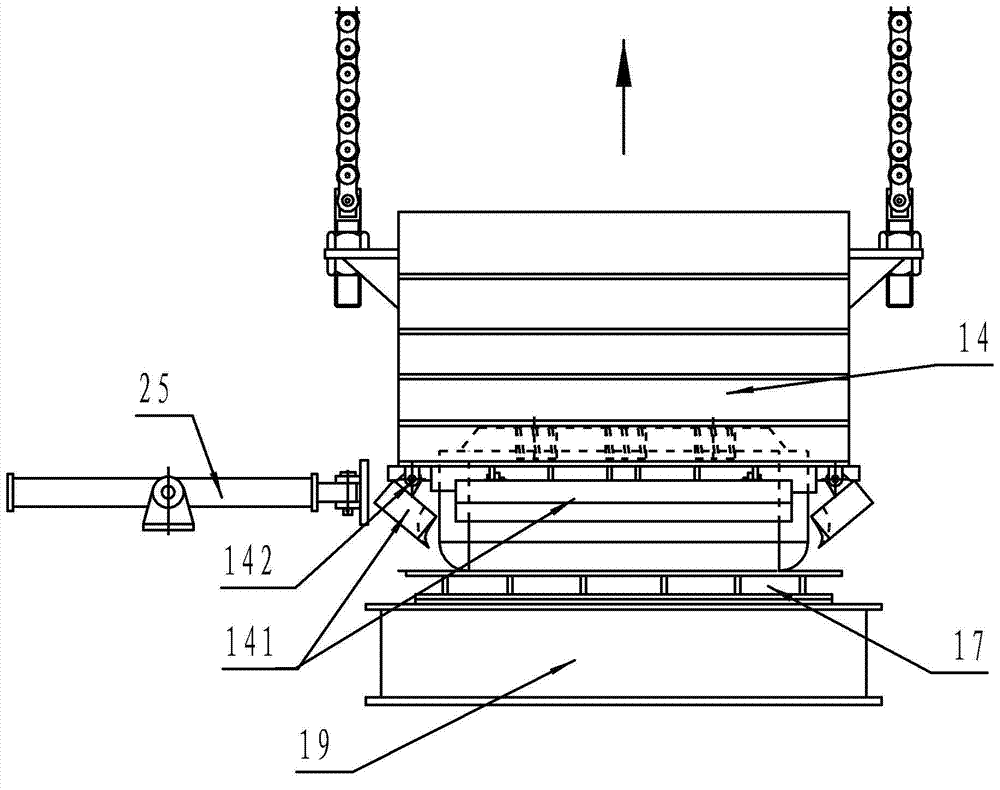

[0031] Embodiment 1, a new type of carbon product vibration molding machine, is characterized in that: a four-column frame structure consisting of an upper beam 4, a base 22, and four upright columns 6 is composed of a sprocket 2 installed on the four-column frame structure, and a mold lifting hydraulic pressure Cylinder 3, mold box lifting system composed of chain 1 fixed on mold box 14, counterweight lifting system composed of counterweight lifting hydraulic cylinder, pressure maintaining spring group 8, counterweight 9, composed of vibration platform 19, amplitude box, The vibration molding system composed of amplitude modulation box, power motor, cardan shaft, lubrication station, etc. also has a vacuum pumping system, an automatic oil spray system, a hydraulic control system and an electrical control system. A vacuum cover 12 with a mold gland 121 inside connected to the guide column 11 of the vacuum cover is provided. The vacuum cover is provided with an air extraction pi...

Embodiment 2

[0032] Embodiment 2, a new type of carbon product vibration molding machine, is characterized in that: a four-column frame structure consisting of an upper beam 4, a base 22, and four upright columns 6 is composed of a sprocket 2 installed on the four-column frame structure, and a mold lifting hydraulic pressure Cylinder 3, mold box lifting system composed of chain 1 fixed on mold box 14, counterweight lifting system composed of counterweight lifting hydraulic cylinder, pressure maintaining spring group 8, counterweight 9, composed of vibration platform 19, amplitude box, The vibration molding system composed of amplitude modulation box, power motor, cardan shaft, lubrication station, etc. also has a vacuum pumping system, an automatic oil spray system, a hydraulic control system and an electrical control system. A vacuum cover 12 with a mold gland 121 inside connected to the guide column 11 of the vacuum cover is provided. The vacuum cover is provided with an air extraction pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com