Calcined petroleum coke rotary kiln

A technology for calcining petroleum coke and rotary kiln, which is applied in the petroleum industry, coke oven, rotary drum furnace, etc., can solve the problems of energy consumption, quality reduction of petroleum coke, burning loss of petroleum coke, etc. Ash reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

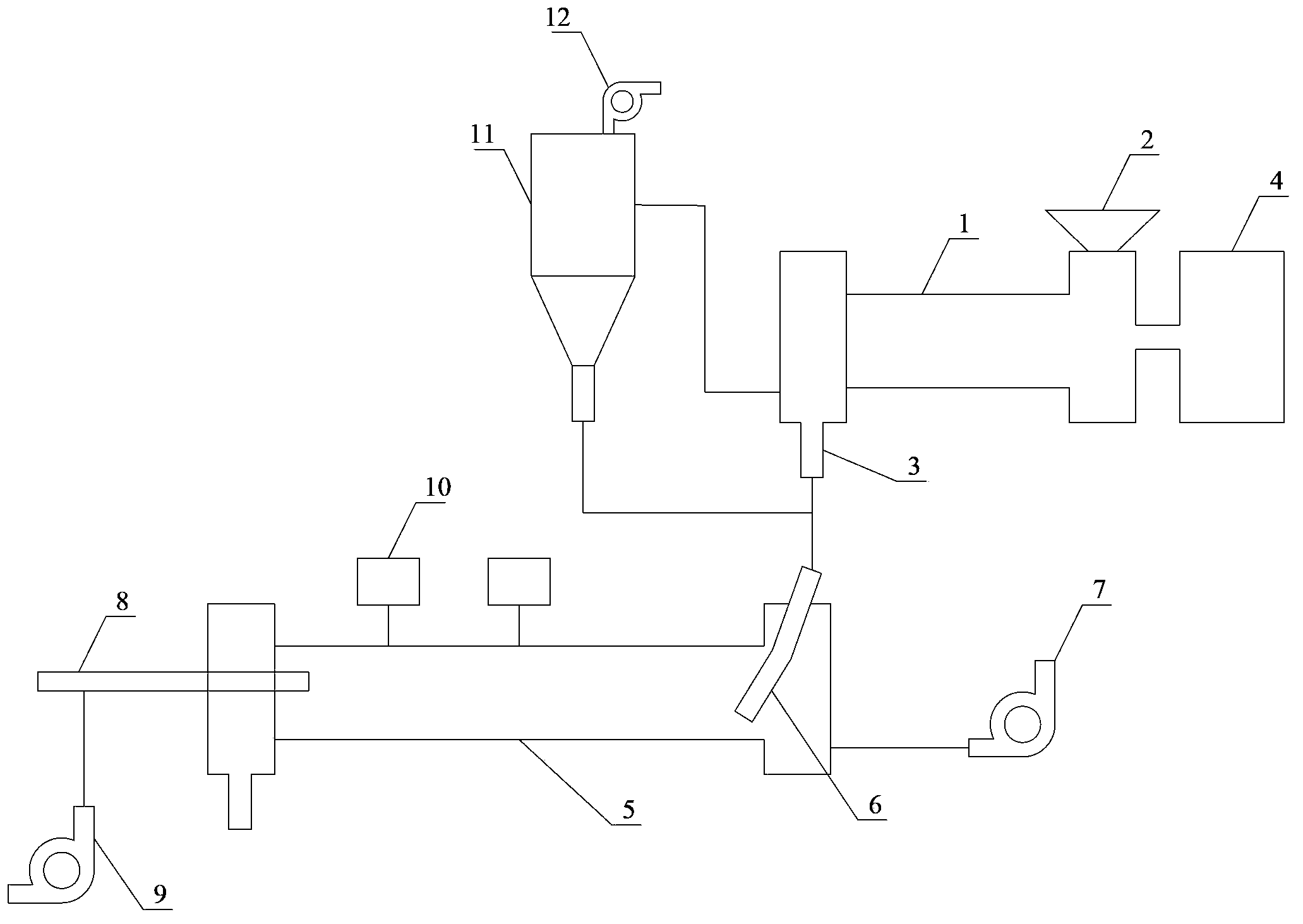

[0023] Such as figure 1 As shown, the present invention includes a drying device and a rotary kiln,

[0024] The drying device includes a cylinder body 1, a feed port 2 arranged at the front end of the cylinder body 1 and a discharge port 3 at the rear end, and a high-temperature flue gas chamber 4 is provided at the front end of the cylinder body 1,

[0025] The rotary kiln comprises a rotary kiln body 5, a feed chute 6 and a rotary induced draft fan 7 arranged at the feed end of the rotary kiln body 5, a fuel burner 8 and a fuel blower 9 arranged at the discharge end of the rotary kiln body, The middle section of body 5 is provided with at least two kiln body blowers 10,

[0026] The discharge opening 3 of the cylinder body 1 is connected with the feed chute 6 of the rotary kiln body 5 .

[0027] The rear end of the drying device is provided with a dust collector 11 with a drying induced draft fan 12, the inlet of the dust collector 11 is connected to the rear end of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com