Method of manufacturing silicate bricks with lead-and-zinc tailings

A silicate, tailings technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of improving compactness, increasing content, and high-pressure molding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

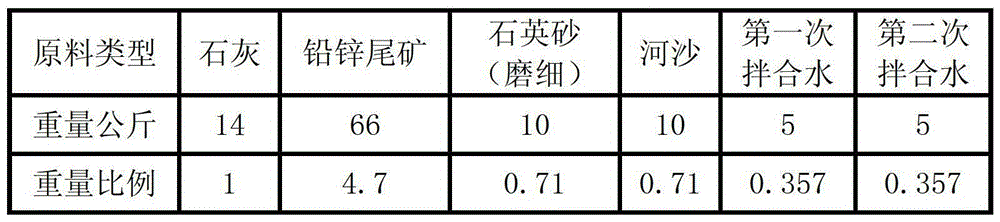

[0040] Embodiment 1: the mixture ratio is shown in Table 3

[0041] Table 3 Embodiment 1 Mixture ratio

[0042]

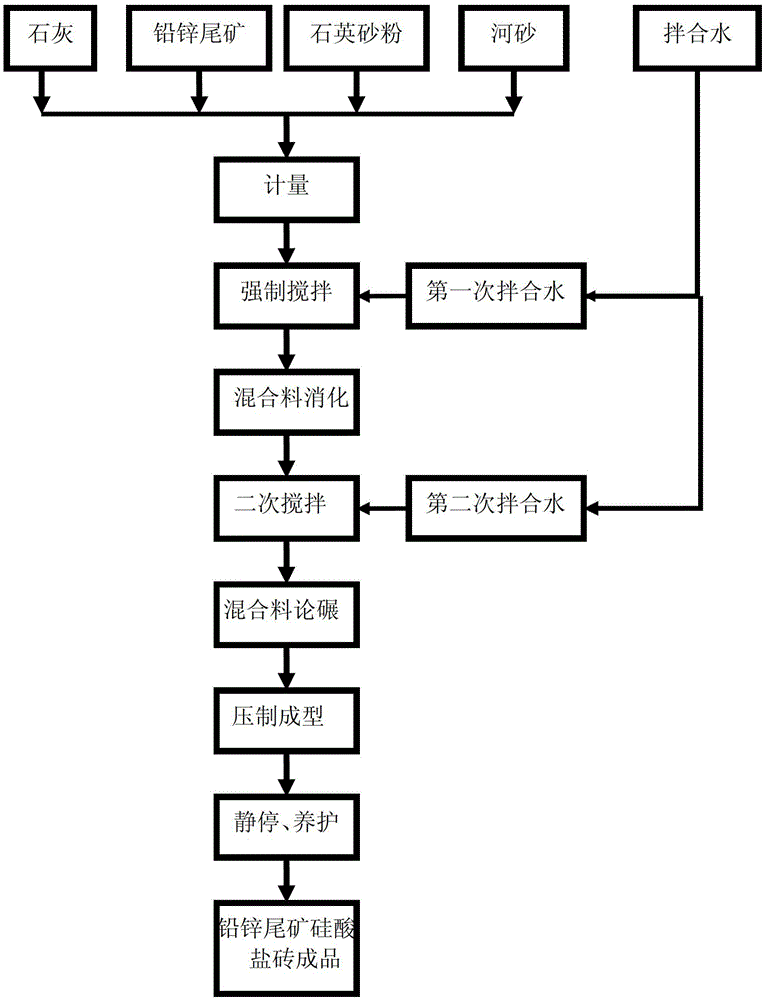

[0043] Step 1: Mixture Preparation

[0044] Put 14 kg of lime, 10 kg of quartz sand powder, 66 kg of lead-zinc tailings, 10 kg of river sand and 5 kg of half of the mixing water into a forced mixer and stir for 4-8 minutes until the materials are mixed evenly and become wet Stirring is stopped during the state, and the mixture is obtained;

[0045] Step Two: Mixture Digestion

[0046] Leave the mixture for 3-6 hours to allow the lime to be fully digested. When the temperature of the mixture reaches the highest temperature (60-70°C), the lime digestion is complete.

[0047] The third step: the second mixing of the mixture

[0048] Add 5 kg of the remaining half of the mixing water to the digested mixture and put it into a forced mixer and stir for 2-4 minutes.

[0049] Step Four: Grinding the Mixture

[0050] The agglomerated mixture is rolled and compacted...

Embodiment 2

[0057] Embodiment 2: See Table 4 for the mixture ratio.

[0058] Table 4 Embodiment 2 Mixture ratio

[0059]

[0060] Step 1: Mixture Preparation

[0061] Put 17 kg of lime, 15 kg of quartz sand powder, 53 kg of lead-zinc tailings, 15 kg of river sand and 5.5 kg of half of the mixing water into a forced mixer and stir for 4-8 minutes until the materials are mixed evenly and become wet Stirring is stopped during the state, and the mixture is obtained;

[0062] Step Two: Mixture Digestion

[0063] Leave the mixture for 3-6 hours to allow the lime to be fully digested. When the temperature of the mixture reaches the highest temperature (60-70°C), the lime digestion is complete.

[0064] The third step: the second mixing of the mixture

[0065] Add 5.5 kg of the remaining half of the mixing water to the digested mixture and put it into a forced mixer and stir for 2-4 minutes.

[0066] Step Four: Grinding the Mixture

[0067] The agglomerated mixture is rolled and compacted ...

Embodiment 3

[0074] Embodiment 3: See Table 5 for the mixture ratio.

[0075] Table 5, embodiment 3 mixture ratio

[0076]

[0077] Step 1: Mixture Preparation

[0078] Put 20 kg of lime, 15 kg of quartz sand powder, 45 kg of lead-zinc tailings, 20 kg of river sand and 6 kg of half of the mixing water into a forced mixer and stir for 4-8 minutes until the materials are mixed evenly and become wet Stirring is stopped during the state, and the mixture is obtained;

[0079] Step Two: Mixture Digestion

[0080] Leave the mixture for 3-6 hours to allow the lime to be fully digested. When the temperature of the mixture reaches the highest temperature (60-70°C), the lime digestion is complete.

[0081] The third step: the second mixing of the mixture

[0082] Add 6 kg of the remaining half of the mixing water to the digested mixture and put it into a forced mixer and stir for 2-4 minutes.

[0083] Step Four: Grinding the Mixture

[0084] The agglomerated mixture is rolled and compacted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com