Preparation technology of high-strength graphite material

A technology of graphite material and preparation process, which is applied in the field of preparation process of high-strength graphite material, can solve the problems of high porosity, low density and strength, increased production cost, etc., and achieve large shrinkage, low preparation cost and short cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

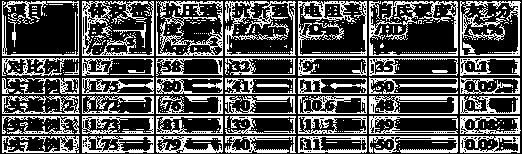

Examples

Embodiment 1

[0051] A preparation process of high-strength graphite material, comprising the following steps:

[0052] Step 1, selecting raw petroleum coke and putting the raw petroleum coke into the drum furnace;

[0053] Step 2, formulating a heating curve and conducting heat treatment to obtain semi-coke, wherein the upper limit of the heating curve is 550°C;

[0054] Step 3: Grind the semi-coke obtained in Step 2 to an average particle size of 5 μm, then put it into a kneading pot and add a dispersant to the kneading pot, raise the temperature to 140°C, knead for 45 minutes, and then put molten binder into the kneading pot , keep the temperature at 140°C, and knead for 45 minutes to obtain a paste;

[0055] Step 4, subjecting the primary paste to flaking for 2 times to obtain flaking;

[0056] Step 5, grinding the flakes to an average particle size of 20 μm, and then molding to obtain a green body;

[0057] Step 6, roasting the green body, and then graphitizing it to obtain a finish...

Embodiment 2

[0061] A preparation process of high-strength graphite material, comprising the following steps:

[0062] Step 1, selecting raw petroleum coke and putting the raw petroleum coke into the drum furnace;

[0063] Step 2, formulating a heating curve and conducting heat treatment to obtain semi-coke, wherein the upper limit of the heating curve is 550°C;

[0064] Step 3: Grind the semi-coke obtained in Step 2 to an average particle size of 6 μm, then put it into a kneading pot and add a dispersant to the kneading pot, raise the temperature to 145°C, knead for 45 minutes, and then put molten binder into the kneading pot , keep the temperature at 150°C, and knead for 45 minutes to obtain a paste;

[0065] Step 4, subjecting the primary paste to flaking for 2 times to obtain flaking;

[0066] Step 5, grinding the flakes to an average particle size of 22 μm, and then molding to obtain a green body;

[0067] Step 6, roasting the green body, and then graphitizing it to obtain a finished...

Embodiment 3

[0071] A preparation process of high-strength graphite material, comprising the following steps:

[0072] Step 1, selecting raw petroleum coke and putting the raw petroleum coke into the drum furnace;

[0073] Step 2, formulating a heating curve and conducting heat treatment to obtain semi-coke, wherein the upper limit of the heating curve is 550°C;

[0074] Step 3: Grind the semi-coke obtained in Step 2 until the average particle size is 5 μm, then put it into the kneading pot and add the dispersant to the kneading pot, raise the temperature to 150°C, knead for 45 minutes, and then put the molten binder into the kneading pot , keep the temperature at 140°C, and knead for 45 minutes to obtain a paste;

[0075] Step 4, subjecting the primary paste to flaking for 2 times to obtain flaking;

[0076] Step 5, grinding the flakes to an average particle size of 21 μm, and then molding to obtain a green body;

[0077] Step 6, roasting the green body, and then graphitizing it to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com