Vehicle interior decoration material VOC removal master batch and preparation method thereof

A technology of interior materials and masterbatches, applied in the field of materials, can solve problems such as air stripping agent component leakage, loss, and VOC improvement effect reduction, so as to reduce VOC volatile content, reduce manufacturing costs, and improve air quality in the car Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

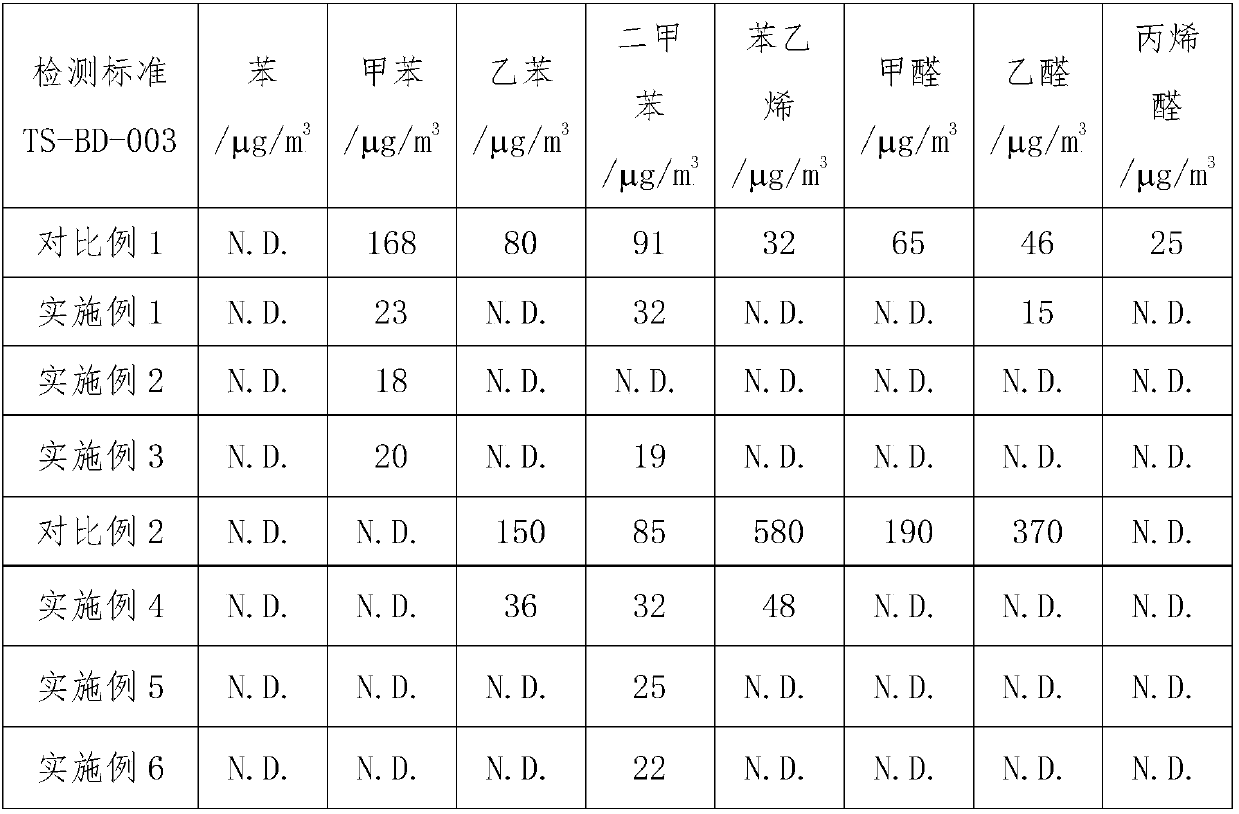

Examples

Embodiment

[0044] A preparation method for removing masterbatch of vehicle interior material VOC, comprising the following steps:

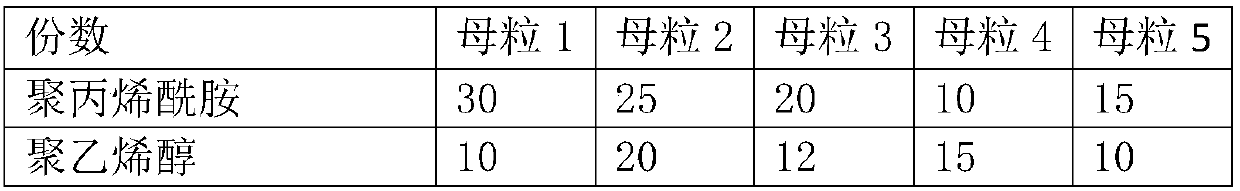

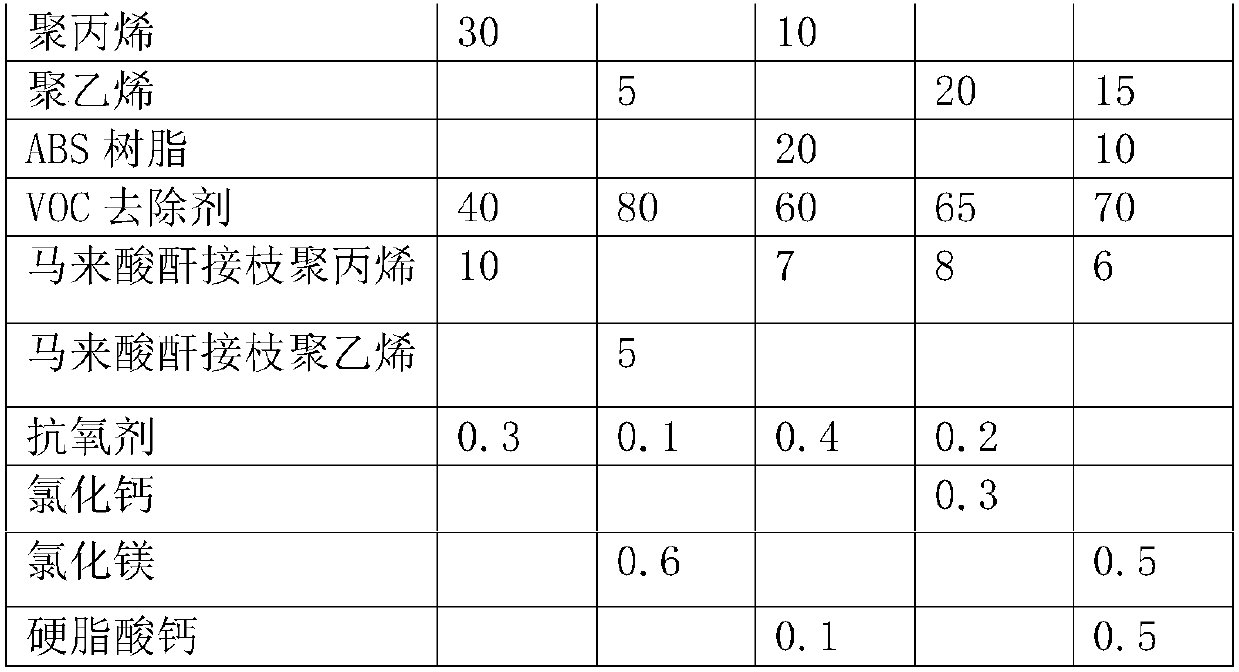

[0045] Step 1: Prepare raw materials: 10-30 parts of polyacrylamide, 10-20 parts of polyvinyl alcohol, 40-80 parts of VOC remover, 5-30 parts of polyolefin, 0-20 parts of ABS resin, 5-10 parts of compatibilizer parts, additives 0.3-1.0 parts;

[0046] Step 2: Fully mix polyacrylamide, polyvinyl alcohol, polyolefin, compatibilizer, ABS resin, and additives according to parts by weight to form a mixture, add this mixture into a twin-screw extruder, and prepare by extrusion Successful functional semi-finished masterbatch;

[0047] Step 3: Mix the semi-finished masterbatch and VOC remover in a certain proportion in a kettle-type container. The temperature of the container is 20-40°C, and the interaction between the masterbatch components and the remover is used for swelling. The time is 30-60min. Prepared as VOC removal masterbatch.

[0048] According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com