Boron-silicon phenolic resin suitable for hot-melt preimpregnation process, composite material and preparation methods of boron-silicon phenolic resin and composite material

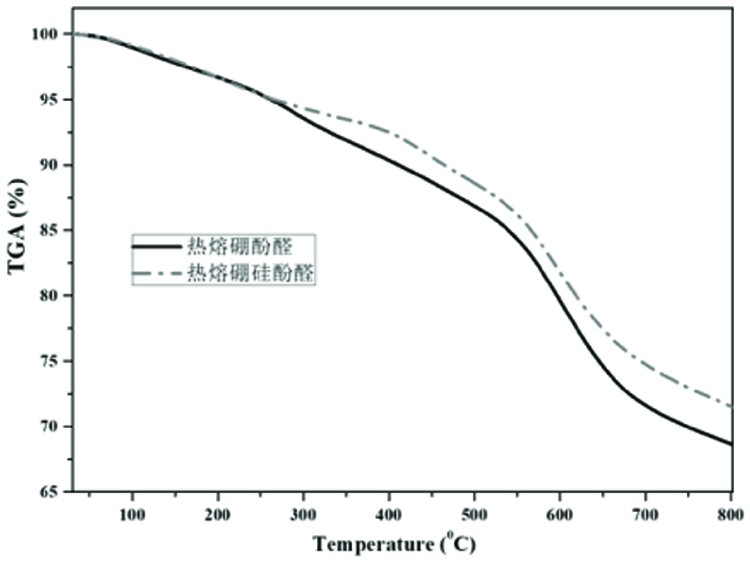

The technology of boron phenolic resin and phenolic resin is applied in the fields of borosilicate phenolic resin, composite materials and their preparation, which can solve the problems of high porosity, poor ablation resistance, and poor fiber adhesion of composite materials, and achieves molding processability. Good, low porosity, low volatile content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

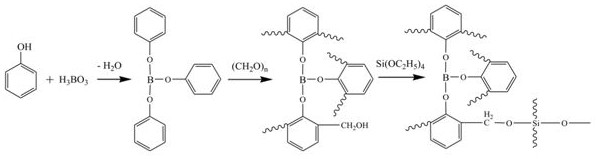

Method used

Image

Examples

Embodiment 1

[0055] The borosilicate phenolic resin suitable for the hot-melt prepreg process described in this embodiment is calculated according to the molar ratio, and the preparation raw materials of the borosilicate phenolic resin include the following components:

[0056] 100 parts of phenol, 119 parts of paraformaldehyde, 14.7 parts of boric acid, 9.8 parts of ethyl orthosilicate;

[0057] Also includes modifier glass microspheres and toughening agent polyetherimide; the dosage relationship with phenol is:

[0058] 100 parts by weight of phenol, 1.26 parts by weight of glass microspheres, and 0.84 parts by weight of polyetherimide.

[0059] The borosilicate phenolic resin suitable for the hot-melt prepreg process described in the present embodiment, the preparation method comprises the following steps:

[0060] S1. First put 956g of molten phenol into the flask, add 93g of boric acid while stirring, slowly heat up to 140°C at a rate of 0.5°C / min, and react for 1 hour; then graduall...

Embodiment 2

[0069] The borosilicate phenolic resin suitable for the hot-melt prepreg process described in this embodiment is calculated according to the molar ratio, and the preparation raw materials of the borosilicate phenolic resin include the following components:

[0070] 95 parts of phenol, 5 parts of resorcinol, 105 parts of 37wt% formaldehyde solution, 10 parts of phenylboronic acid, 19.6 parts of methyltriethoxysilane;

[0071] Also includes modifying agent aluminum hydroxide and toughening agent polyvinyl butyral; the dosage relationship with phenol and resorcinol is:

[0072] 100 parts by weight of phenol, 1.63 parts by weight of aluminum hydroxide, and 2.18 parts by weight of polyvinyl butyral.

[0073] The borosilicate phenolic resin suitable for the hot-melt prepreg process described in the present embodiment, the preparation method comprises the following steps:

[0074] S1. First add 447g of phenol and 28g of resorcinol into the flask, add 61g of phenylboronic acid while ...

Embodiment 3

[0080] The borosilicate phenolic resin suitable for the hot-melt prepreg process described in this embodiment is calculated according to the molar ratio, and the preparation raw materials of the borosilicate phenolic resin include the following components:

[0081] 100 parts of α-naphthol, 105 parts of paraformaldehyde, 50 parts of boric acid, 2 parts of phenyltriethoxysilane;

[0082] Also include modifying agent phenylboronic acid and toughening agent chloroprene rubber; the consumption relation with α-naphthol is:

[0083] 100 parts by weight of α-naphthol, 2 parts by weight of phenylboronic acid, and 0.5 parts by weight of chloroprene rubber.

[0084] The borosilicate phenolic resin suitable for the hot-melt prepreg process described in the present embodiment, the preparation method comprises the following steps:

[0085] S1. First put 721g of α-naphthol into the flask, add 154.6g of boric acid while stirring, slowly heat up to 140°C at a rate of 0.5°C / min, and react for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com