Special low-volatility migration-resistant nano composite anti-aging master batch for polypropylene and preparation method

A nano-composite, polypropylene technology, applied in the anti-migration nano-composite anti-aging masterbatch and its preparation process, the low-volatility field dedicated to polypropylene, can solve the problem of no effective method for suppressing volatile organic compounds in masterbatches, increased use of masterbatches, Increase the customer's formulation cost and other issues to achieve long-term UV shielding, improve weather resistance, improve storage temperature and precipitation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: Step 1: After drying the zinc oxide powder with an average particle size of 20-40nm at a temperature of 90-100°C for 4 hours, mix it with surface treatment agent KH570 at a temperature of 50-60°C at a ratio of 1:1 to Mix at a speed of 800r / min for 30 minutes and then treat with ultrasonic wave for 30 minutes before use.

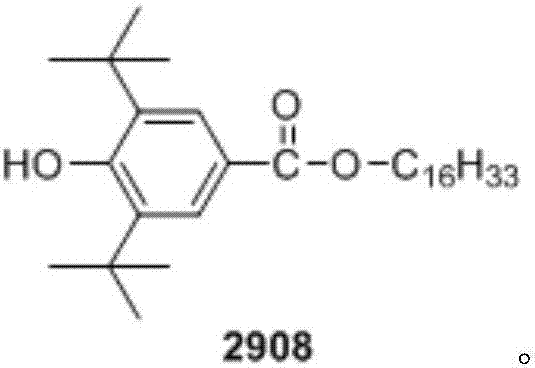

[0032] Step 2: Mix UV Absorber 2908, Light Stabilizer 2020 and EBS Lubricant as described in Tables 1 and 2 at room temperature for 5 minutes at a high speed at a speed of 800 r / min and set aside for use.

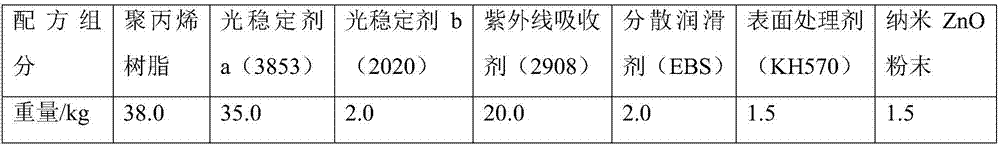

[0033] Formulation Table 1 (special masterbatch for non-filled polypropylene material)

[0034]

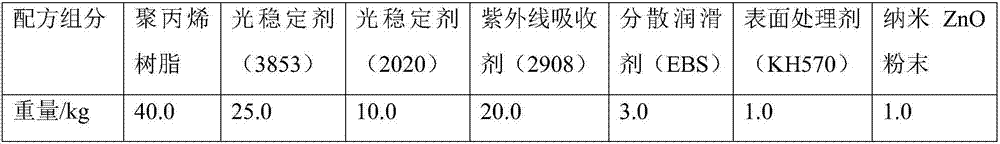

[0035] Formulation Table 2 (Special masterbatch for filled polypropylene material)

[0036]

[0037] Step 3: Add the polypropylene resin prepared in steps 1 and 2 into weight loss scales 1, 2, and 3 respectively, add the heated and melted 3853 into the liquid weight loss scale, and use 160 After melting and extruding at a temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com