Patents

Literature

49results about How to "Excellent resistance to precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

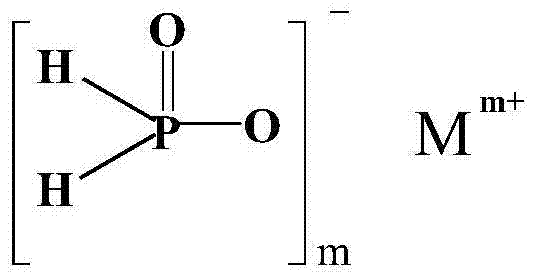

Transparent cold-resistant flame-retardant polypropylene material and preparation method thereof

InactiveCN103113705ASimple production processEasy to implementHydrobromideLinear low-density polyethylene

The invention discloses a transparent cold-resistant flame-retardant polypropylene material and a preparation method thereof. The material comprises the following components in parts by weight: 65-85 parts of polypropylene resin, 0.1-0.3 part of white oil, 5-20 parts of ethylene-octene copolymer, 3-10 parts of linear low-density polyethylene, 1-5 parts of phosphorus-nitrogen-bromine composite flame retardant, 0.1-0.4 part of flame-retardant synergist, 0.1-0.4 part of nucleating agent, 0.2-0.5 part of antioxidant and 0.2-0.5 part of lubricant. The phosphorus-nitrogen-bromine composite flame retardant comprises the following components in parts by weight: 60-90 parts of organic or inorganic hypophosphite, 10-30 parts of phosphoric-acid-containing piperazidine hydrobromide and 0.5-5 parts of silane coupling agent. The polypropylene material disclosed by the invention has high transparency and high cold resistance as well as flame retardancy. The material has the advantages of favorable compatibility and precipitation resistance, and can be used for preparing plastic products requiring high transparency, high cold resistance and flame retardancy.

Owner:GUANGDONG JUSHI CHEM CO LTD

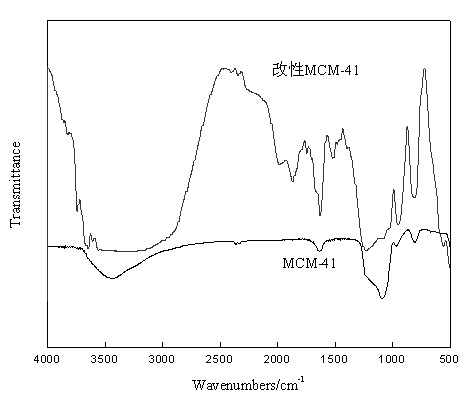

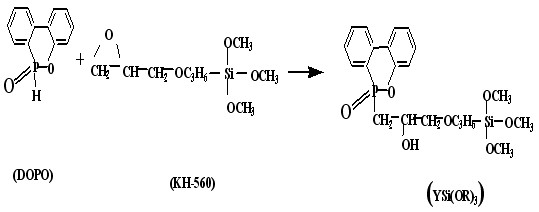

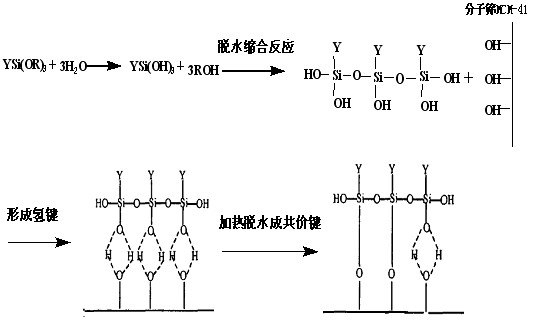

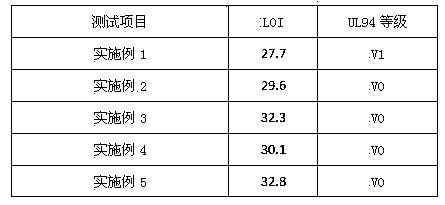

Flame-retardant composite material with DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified nano mesoporous molecular sieve

InactiveCN102675895AImprove compatibilityGood resistance to precipitationMolecular-sieve and base-exchange compoundsPigment treatment with organosilicon compoundsMolecular sieveChemistry

The invention discloses a flame-retardant composite material with DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) modified nano mesoporous molecular sieve, belongs to the fields of nano mesoporous molecular sieve flame-retardant synergists and halogen-free flame-retardant composite materials, and particularly relates to the preparation method of the DOPO modified nano mesoporous molecular sieve and the flame-retardant composite material with the DOPO modified nano mesoporous molecular sieve. The DOPO is of a hexahydric phosphorus-heterocyclic-ring structure, and is a novel flame retardant intermediate. The nano mesoporous molecular sieve is the flame-retardant synergist. The invention discloses the method for preparing the DOPO modified nano mesoporous molecular sieve and the flame-retardant composite material with the DOPO modified nano mesoporous molecular sieve. Since the compound flame-retardant synergist plays a role in phosphorus / silicon synergistic flame retardance, the obtained product has good expandable carbon forming property, the flame-retardant efficiency of the material is obviously increased, the remaining amount of the residual carbon and the compact degree of a carbon layer are increased, and further the flame redardancy of the composite material is improved to a greater degree.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

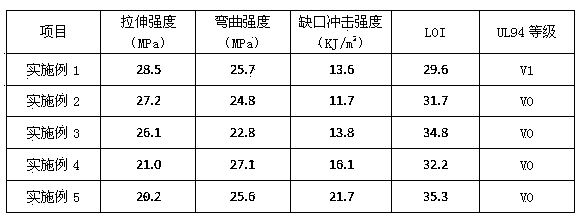

Precipitation resistant, toughening and flame-retardant polypropylene composite material and preparation method thereof

InactiveCN104194161AExcellent resistance to precipitationShorten the production cycleAmmonium polyphosphateMelamine cyanurate

The invention discloses a precipitation resistant, toughening and flame-retardant polypropylene composite material and a preparation method thereof. The precipitation resistant, toughening and flame-retardant polypropylene composite material comprises the following raw materials ( taking100 parts as a measurement unit ): 50-75 parts of polypropylene, 2-15 parts of a toughening agent, 2-8 parts of a compatilizer, 10-25 parts of flame retardant silicane coated ammonium polyphosphate, 5-10 parts of flame retardant melamine cyanurate, 0.2-2 part (s) of an associative-effect flame retardant, 0.1-0.5 part of an anti-oxidant 168 and 0.1-0.8 part of an anti-oxidant 1010. According to the precipitation resistant, toughening and flame-retardant polypropylene composite material and the preparation method thereof, the manufacturing process has zero hydrolysis, excellent precipitation resistant performance and short production cycle; a produced material has superior performances. The preparation method for the halogen-free flame-retardant composite material, provided by the invention, is simple in the preparation method, easy to operate and relatively low in the cost.

Owner:江苏力达塑料托盘制造有限公司

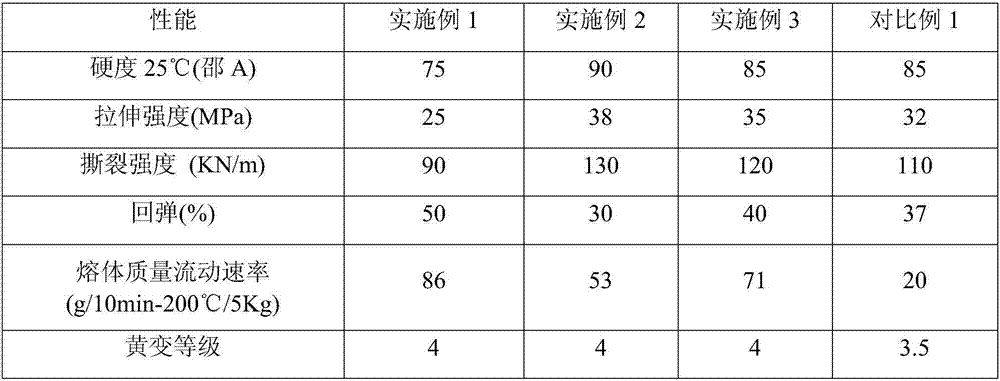

Special TPU material for encapsulation, and preparation method thereof

The invention relates to a special TPU material for encapsulation, and a preparation method thereof, and belongs to the technical field of thermoplastic polyurethane elastomers. The special TPU material for encapsulation is prepared from, by weight, 48.6-79.3% of polymer polyol, 15.7-38.6% of diisocyanate , 3.7-11% of a chain extender, 0.3-0.8% of an antioxidant, 0.3-0.8% of a light stabilizer, 0.3-1% of a lubricant and 0.01-0.04% of a catalyst. The TPU material for encapsulation has excellent fluidity and wide processing temperature zone when used for producing encapsulation products, is simple and stable to operate, has excellent adhesion performance with various substrates, and can be mixed with various color master batch powders to form the products with different colors. The invention also provides the simple and easy preparation method of the special TPU material.

Owner:SHANDONG INOV POLYURETHANE

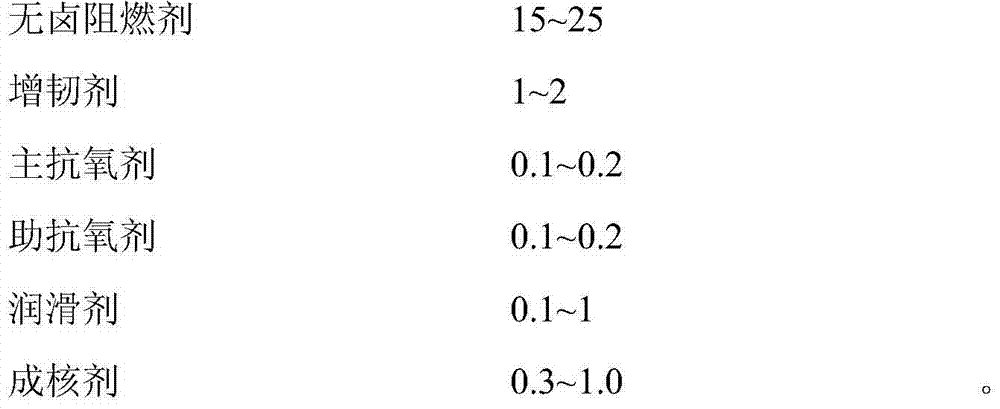

Halogen-free and phosphorus-free PBT enhanced composite material and preparation method thereof

ActiveCN104231575AExcellent resistance to precipitationImprove flame retardant performanceGlass fiberAntioxidant

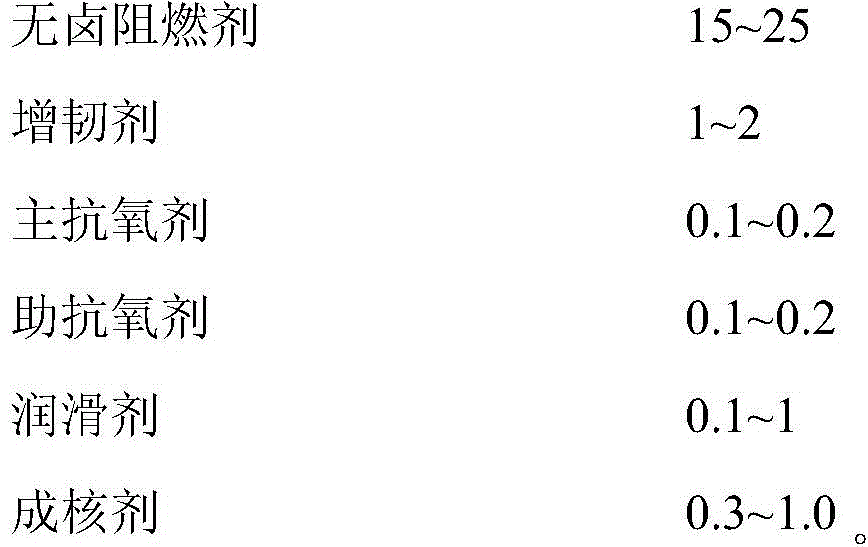

The invention discloses a halogen-free and phosphorus-free PBT (polybutylece terephthalate) enhanced composite material and a preparation method thereof, and belongs to the technical field of composite flame-retardant enhanced materials. The halogen-free and phosphorus-free PBT enhanced composite material consists of the following components: 45-65 pats of PBT, 15-30 parts of glass fibers, 15-25 parts of a halogen-free flame retardant, 1-2 parts of a toughening agent, 0.1-0.2 part of a main antioxidant, 0.1-0.2 part of an auxiliary antioxidant, 0.1-1 part of a lubricating agent and 0.3-1.0 part of a nucleating agent. The preparation method comprises the steps of uniformly mixing PBT, the halogen-free flame retardant, the toughening agent, the main antioxidant, the auxiliary antioxidant, the lubricating agent and the nucleating agent according to the weight part to obtain a mixture, and performing melting, coblending and extruding granulation on the mixture and the glass fibers to obtain the halogen-free and phosphorus-free PBT enhanced composite material. The halogen-free and phosphorus-free PBT enhanced composite material prepared by the method is excellent in anti-separation performance, flame retardancy, mechanical property and creepage cracking resistance, does not release hydrogen phosphide poisonous gas and can totally meet a limiting requirement of Samsung on hydrogen phosphide emission concentration.

Owner:JINAN TAIXING FINE CHEM

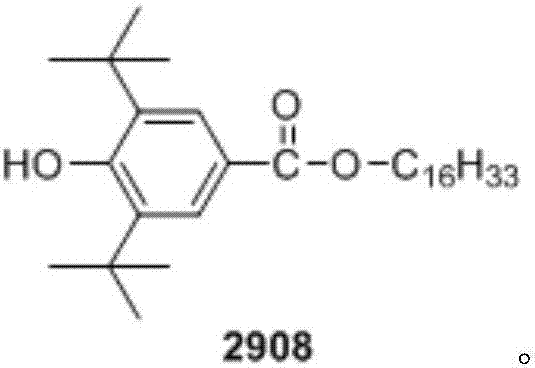

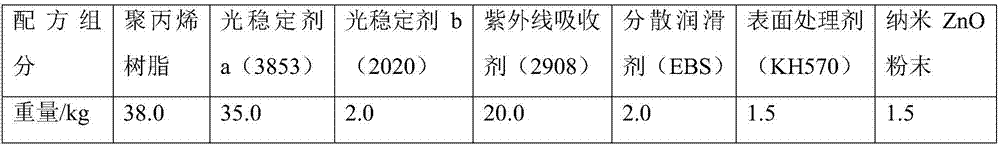

Special low-volatility migration-resistant nano composite anti-aging master batch for polypropylene and preparation method

ActiveCN106977811AEfficient Shielding CapabilityLong-term shielding abilityUltraviolet lightsZno nanoparticles

The invention discloses a special low-volatility migration-resistant nano composite anti-aging master batch for polypropylene. The master batch comprises the following components in parts by weight: 35 to 45 parts of carrier resin polypropylene, 35 to 45 parts of light stabilizer a, 0 to 10 parts of light stabilizer b, 20 to 30 parts of ultraviolet light absorber, 1 to 2 parts of nano zinc oxide, 0.5 to 2 parts of dispersed lubricant and 0.5 to 5 parts of surface treating agent. In the master batch disclosed by the invention, a broadband as well as efficient and long-acting ultraviolet screening capacity of the nano zinc oxide are used to take a synergistic effect with the organic light stabilizer, so that weather resistance of a target product is greatly improved; a universal formula is adopted, and by an ultrahigh adsorption effect brought by a high specific surface area of the nano zinc oxide, content of volatile matter in the master batch and a subsequent plastic product is effectively reduced, the low VOC (Volatile Organic Compound) requirement on the product is met, and the master batch accords with the national standard.

Owner:宿迁联盛科技股份有限公司

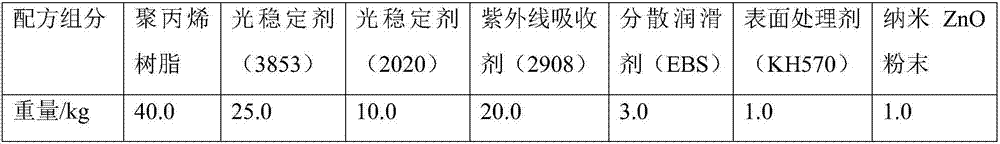

Flame-retardant photodiffusion polypropylene composite material for LED and workpiece thereof

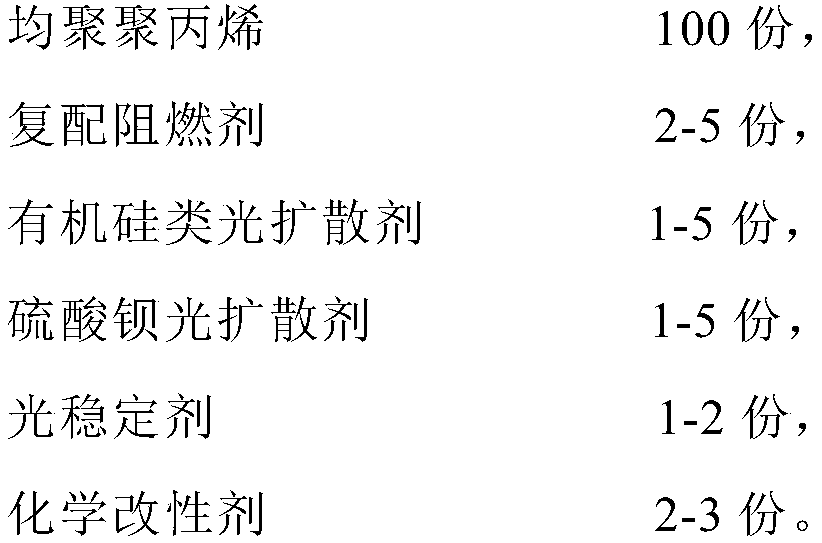

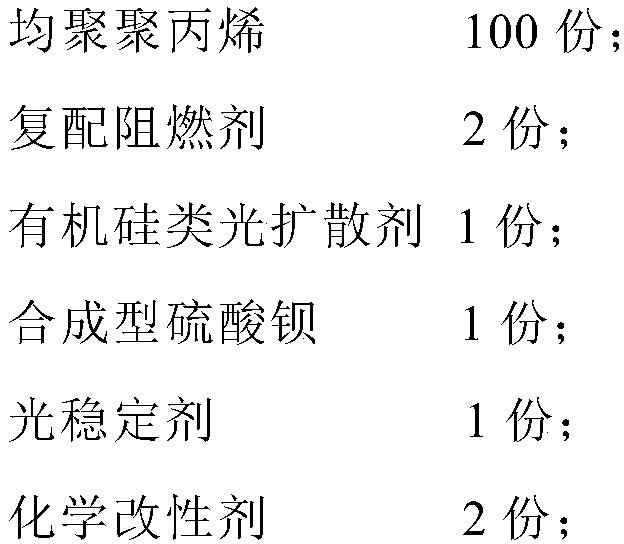

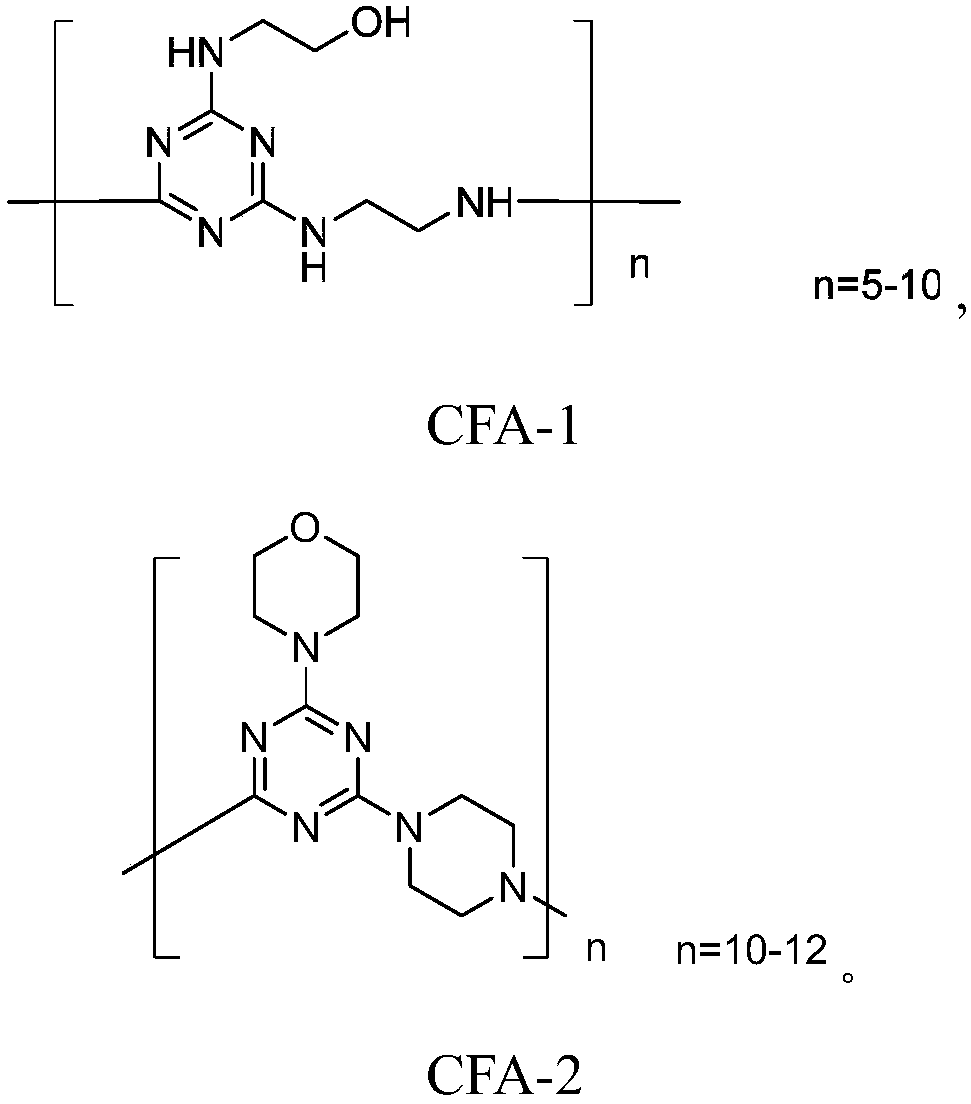

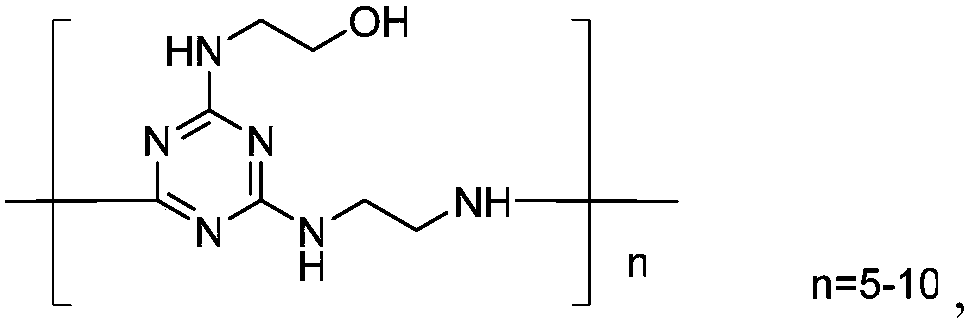

ActiveCN109422961AExcellent flame retardant precipitation resistanceHigh crystallinityNon-electric lightingPoint-like light sourceTransmittanceFire retardant

The invention relates to a flame-retardant photodiffusion polypropylene composite material for an LED and a workpiece thereof. The composite material is prepared from the following components in partsby weight: 100 parts of homo-polypropylene, 2 to 5 parts of compound flame retardant, 1 to 5 parts of organic silicone photodiffusion agent, 1 to 5 parts of barium sulfate photodiffusion agent, 1 to2 parts of light stabilizer, and 2 to 3 parts of chemical modifier. Compared with the prior art, the flame-retardant photodiffusion polypropylene composite material prepared in the invention is excellent in mechanical performance, high in light transmittance, excellent in flame retardant performance, and free from precipitation of flame retardant.

Owner:上海日之升科技有限公司

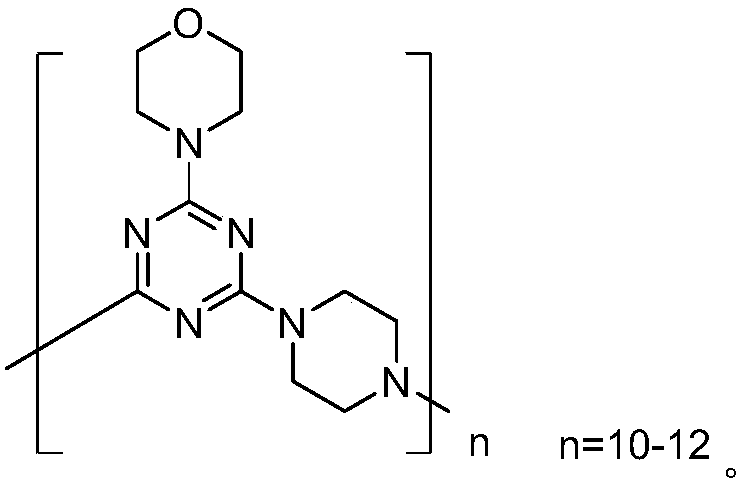

Highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition and preparation method thereof

ActiveCN109206829ASolve easy yellowingExcellent resistance to precipitationProcedure AgentsPolyolefin

The invention discloses a highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition and a preparation method thereof. The highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition comprises the following raw material components by mass percentage: 15-30% a styrene-based thermoplastic elastomer, 10 to 25% of polyolefin resin, 15 to 25% of a plasticizer, 10 to 20% of a char forming agent, 15 to 30% of a phosphorus-nitrogen flame retardant, 0.5 to 3% of a flame retardant synergist, 0.1 to 1% of an anti-oxygen agent, 0.1 to 1% of an anti-aging agent and 0.1 to 1% of a processing aid. Through high char forming property of crosslinked polystyrene powder, a triazine char forming agent is compounded, the triazine char forming agent replaces traditional polyphenylene ether to act as the char forming agent of the thermoplastic elastomer TPE, and the highly-anti-yellowing anti-precipitation halogen-free flame-retardant thermoplastic elastomer composition has good flame retardant property and physical property, solves the problem that use of the polyphenylene ether is liable to cause yellowing, hasexcellent UV resistance, and can pass anti-precipitation tests with higher requirements.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

Weather-proof environment-friendly flame-retardant polymer material for flexible cable and preparation method thereof

InactiveCN104059321AWon't releaseEasy to processInsulated cablesInsulated conductorsTetrabromobisphenol AAntimony trioxide

The invention discloses a weather-proof environment-friendly flame-retardant polymer material for a flexible cable and a preparation method thereof. The polymer material comprises the following components by weight: 100 parts of a component A, 20 to 200 parts of a component B and 50 to 130 parts of a component C, wherein the component A is TPE, the component B is TPV, the component C is a fire retardant and comprises C1 and C2, C1 is one selected from the group consisting of decabromodiphenylethane, 1,2-bis(tribromophenoxy)ethane, tetrabromobisphenol A, tetrabromo-benzene anhydride, octabromo-ether, bis(tetrabromo-o-benzene-dimethyl ether imide)ethane and hexabromocyclododecane and has a particle size in a range of 10 to 30 mu m, and C2 is one selected from the group consisting of antimony trioxide, zinc borate and zinc oxide. The polymer material provided by the invention has improved processing performance and tensile strength, high usage temperature and excellent weatherability, environmental protection performance and flame resistance and is especially applicable to outdoor usage in a severe environment.

Owner:SINOTEX INVESTMENT & DEV CO LTD

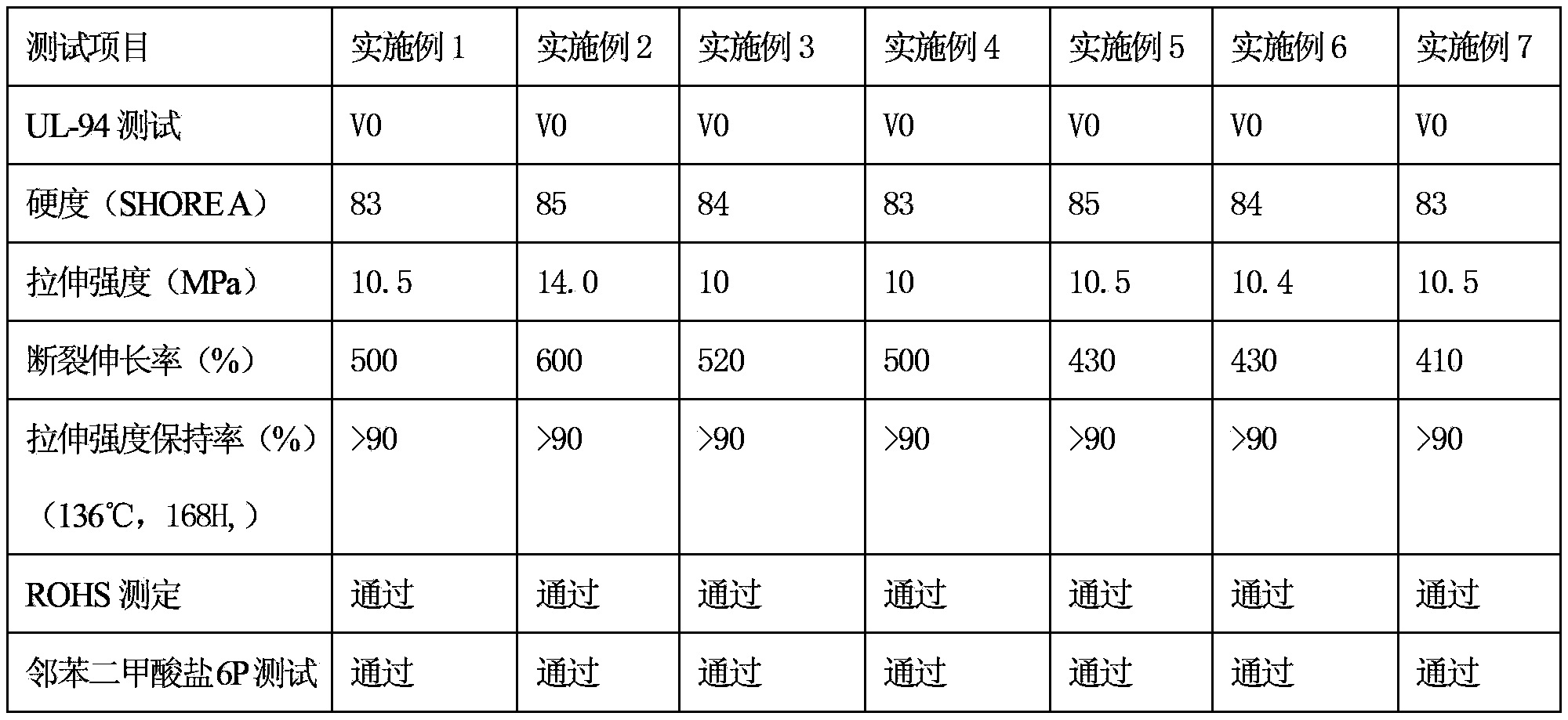

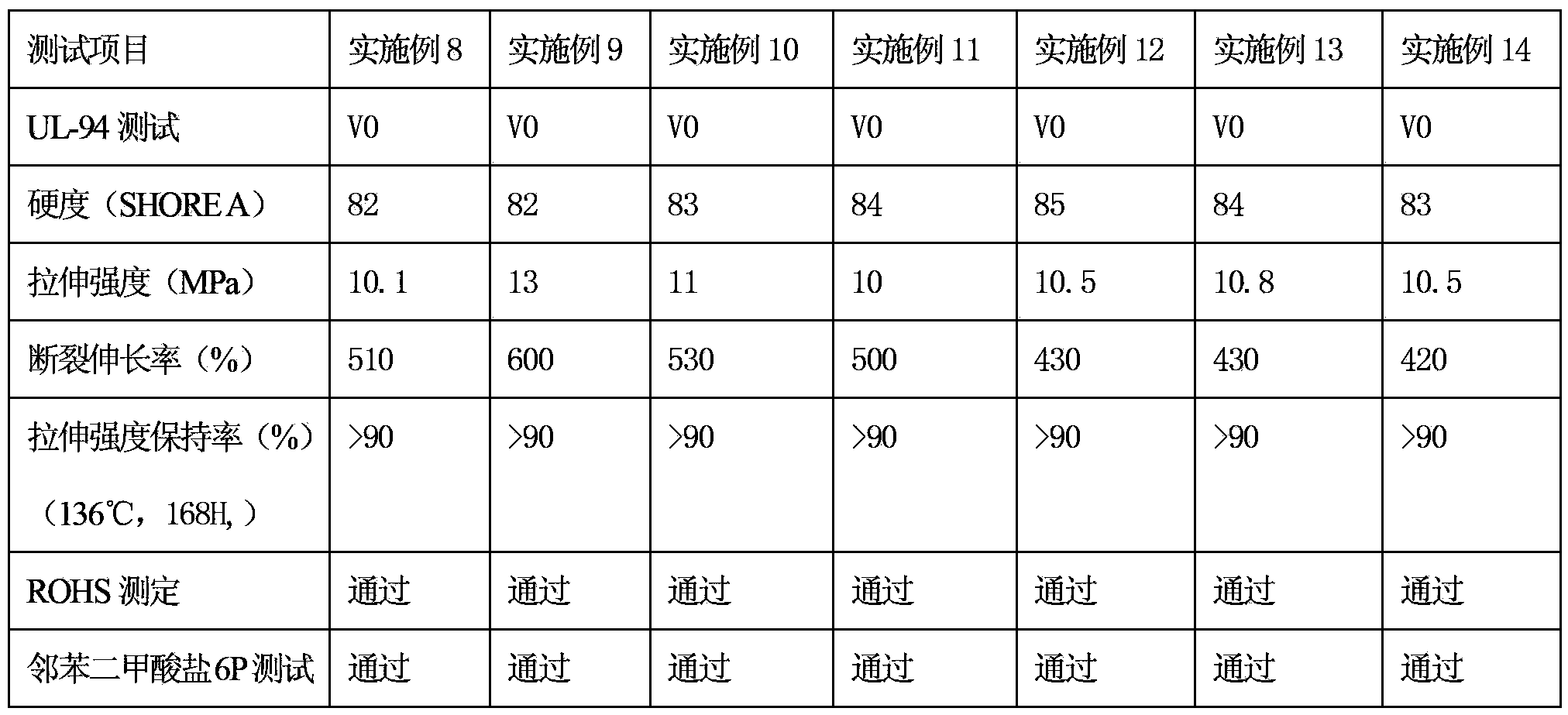

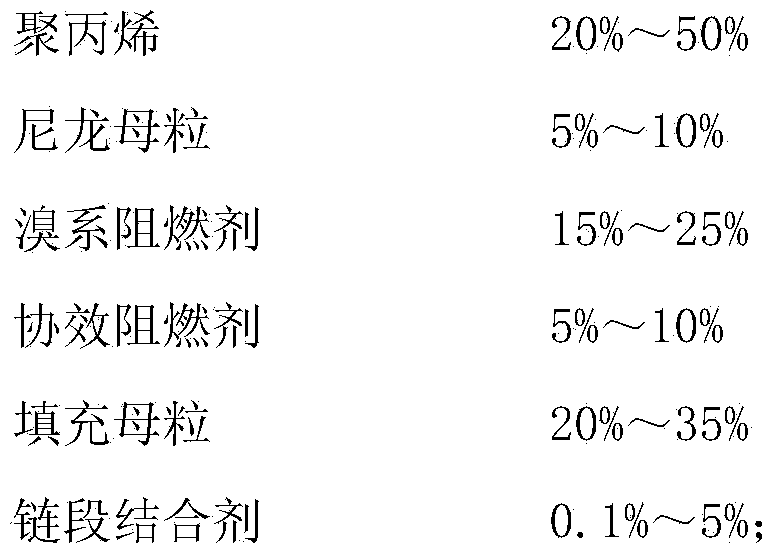

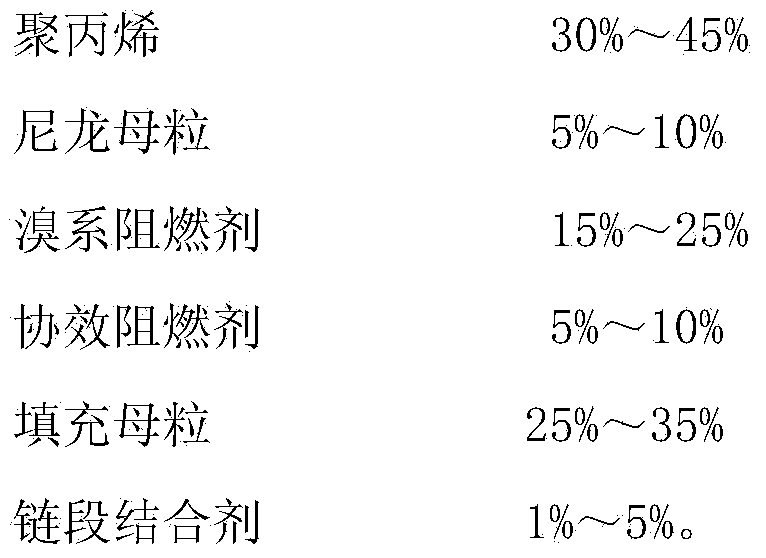

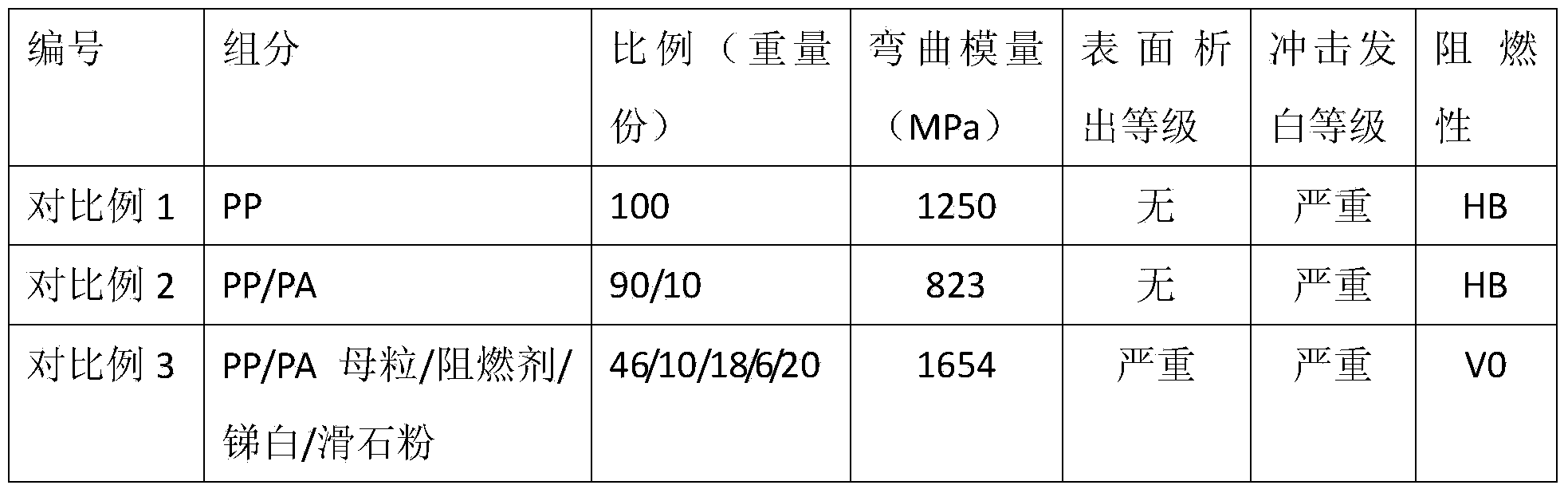

Flame-retardant polypropylene-nylon complex with high rigidity, high heat resistance and impact whitening resistance and preparation method thereof

The invention discloses a flame-retardant polypropylene-nylon composite material with high rigidity, high heat resistance and impact whitening resistance. The composite material contains the following base material components in percentage by weight: 20-50% of polypropylene, 5-10% of a nylon master batch, 15-25% of a brominated flame retardant, 5-10% of a synergic flame retardant, 20-35% of a filling master batch and 0.1-5% of a chain segment binder; the composite material further contains an antioxidant and a processing aid, wherein a base material of the nylon master batch consists of nylon resin, polypropylene resin and a polyolefin thermoplastic elastomer graft; and a base material of the filling master batch consists of polypropylene resin, an inorganic filler, a coupling agent and a polypropylene graft. A preparation method comprises the steps of mixing raw materials uniformly, then adding the mixture into a screw extruder, performing melt blending reaction, extruding and granulating to obtain the composite material. The composite material disclosed by the invention has relatively high rigidity and toughness, high-temperature low precipitation performance and good impact whitening resistance, and can be applied in the fields of household appliances, automobile parts, electric tools and the like.

Owner:SHANGHAI KINGFA SCI & TECH

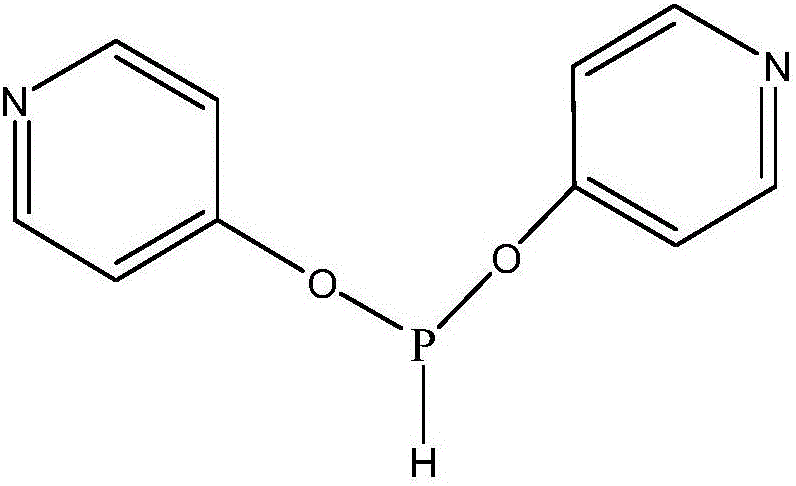

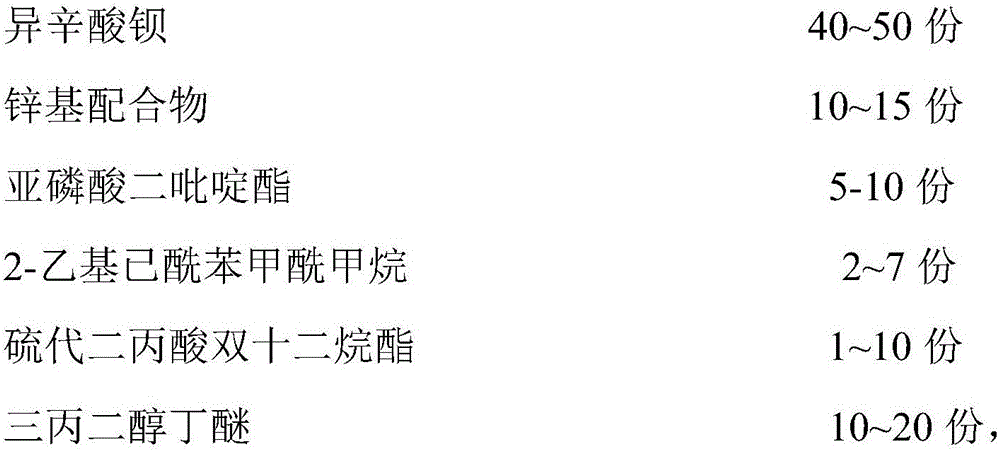

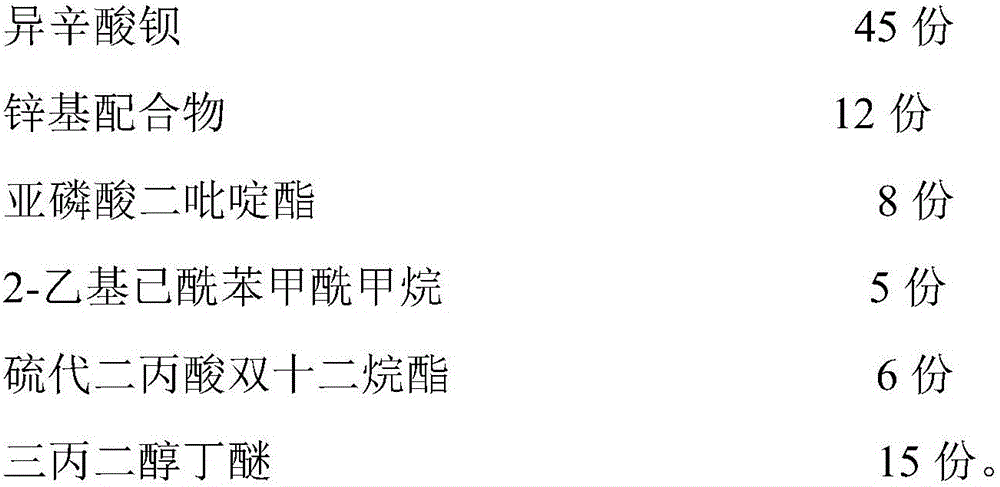

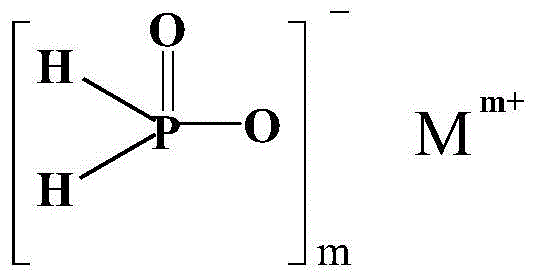

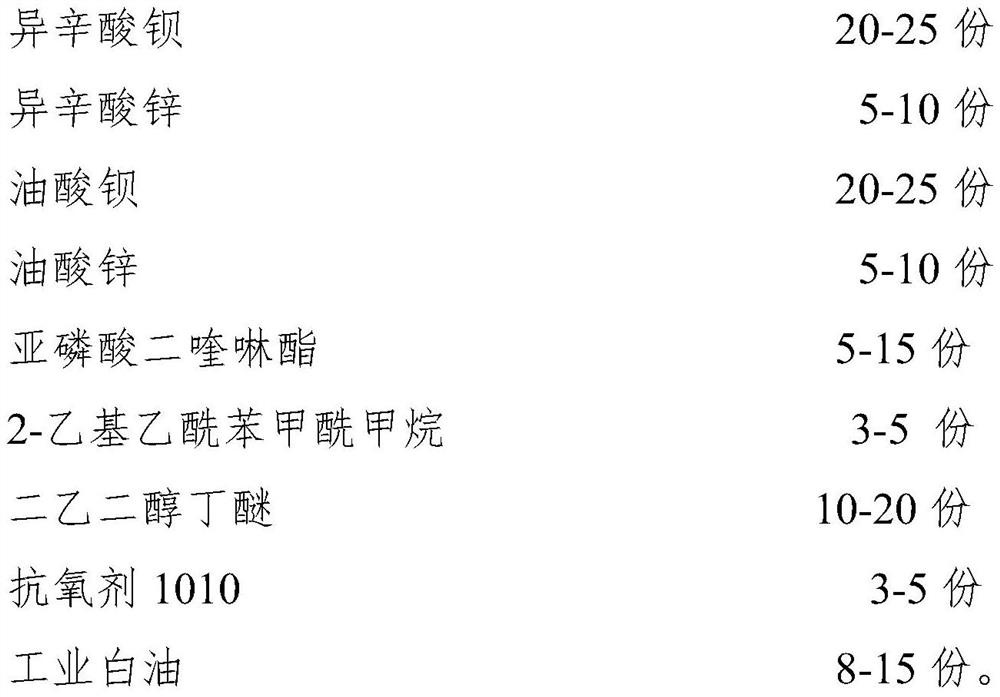

Application of bipyridine ester phosphite to PVC heat stabilizer

ActiveCN106046618AExcellent resistance to precipitationAuxiliary Stabilization ImprovementNitrogen atomEther

The invention relates to the application of bipyridine ester phosphite to a PVC heat stabilizer. bipyridine ester phosphite can be applied to preparation of a liquid barium-zinc stabilizer, a liquid barium-cadmium-zinc stabilizer and a liquid calcium-zinc stabilizer. The liquid barium-zinc stabilizer is prepared from, by weight, 40-50 parts of barium isotanoate, 10-15 parts of zinc-based complex, 5-10 parts of bipyridine ester phosphite, 2-7 parts of 2-ethyl acetyl benzoyl methane, 1-10 parts of thiodipropionicacid dilauryl ester and 10-20 parts of tripropylene glycol n-butyl ether. The bipyridine ester phosphite compound has a higher anti-precipitation property than aliphatic or aromatic phosphite ester by means of a novel heterocyclic perssad replacing the aliphatic or aromatic perssad during preparation of the liquid barium-zinc stabilizer, the liquid barium-cadmium-zinc stabilizer and the liquid calcium-zinc stabilizer. By introducing nitrogen atoms to the heterocyclic ring, the auxiliary stabilization effect on phosphite ester is improved remarkably, and then the printing performance and stability of a modified PVC product are improved.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

PVC environment-friendly calcium-zinc stabilizer

The invention relates to the technical field of materials, and discloses a PVC environment-friendly calcium-zinc stabilizer. The PVC environment-friendly calcium-zinc stabilizer comprises the following components in parts by weight: 10-30 parts of a calcium salt main stabilizer, 10-30 parts of a zinc salt main stabilizer, 15-25 parts of modified hydrotalcite, 10-20 parts of a lubricant, 5-10 partsof modified halloysite nanotubes, 1-5 parts of an antioxidant, 1-5 parts of an auxiliary stabilizer and 1-5 parts of an ultraviolet absorber. The PVC environment-friendly calcium-zinc stabilizer provided by the invention has the advantages of high stability, strong initial coloring power and good precipitation resistance, and overcomes the defect of easiness in precipitation in a traditional calcium-zinc processing process. According to the PVC environment-friendly calcium-zinc stabilizer, aiming at different products, a plasticization degree adjustment range is wide, and the defect that thetraditional calcium-zinc stabilizer is earlier and faster in plasticization is overcome. The PVC environment-friendly calcium-zinc stabilizer provided by the invention has high weather resistance, theweather resistance of the PVC environment-friendly calcium-zinc stabilizer is equivalent to the weather resistance of a traditional lead salt system, and the requirements for outdoor use of PVC products are met.

Owner:杭州凌洲塑胶科技有限公司

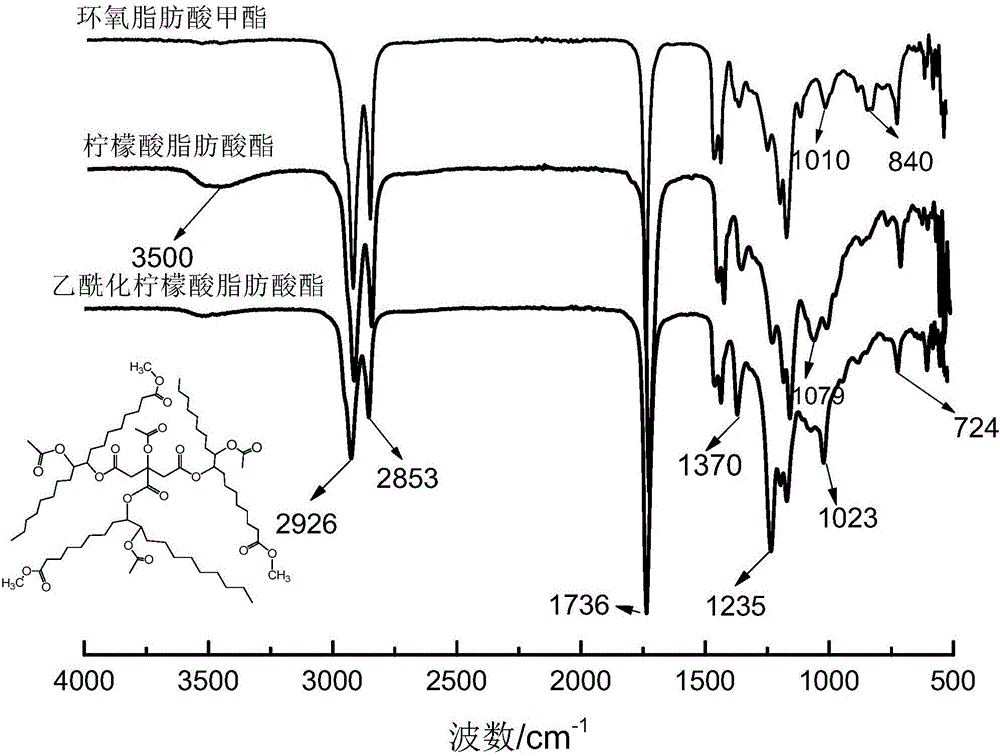

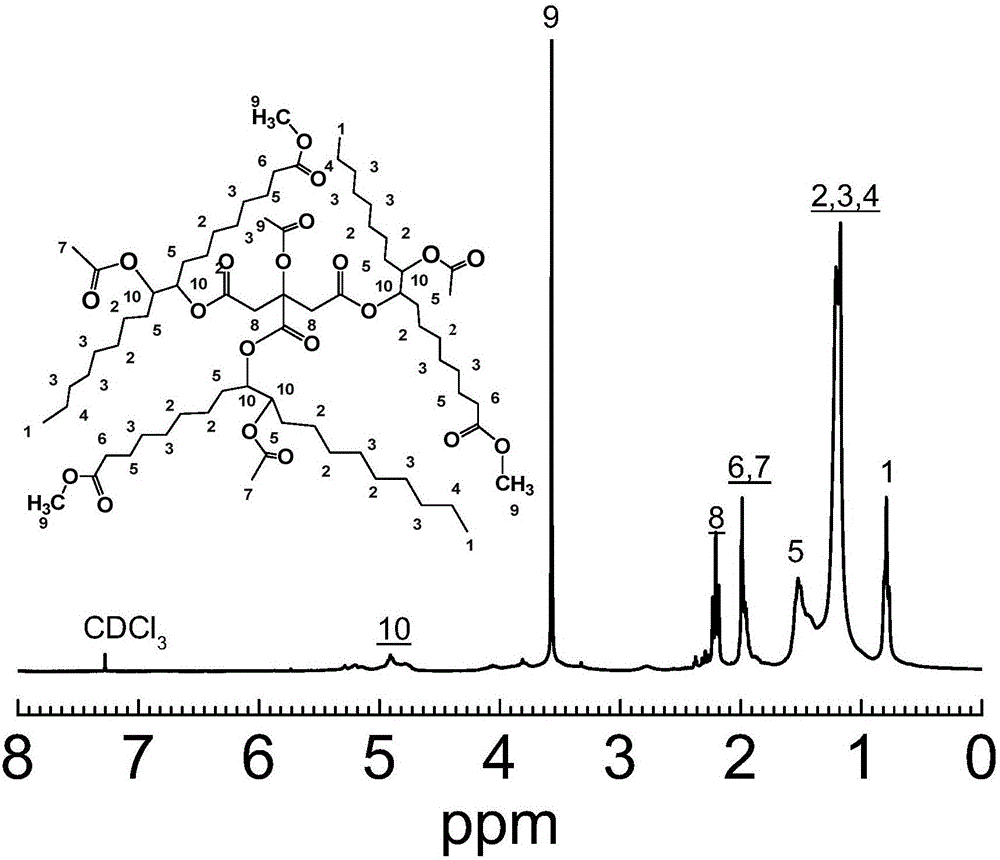

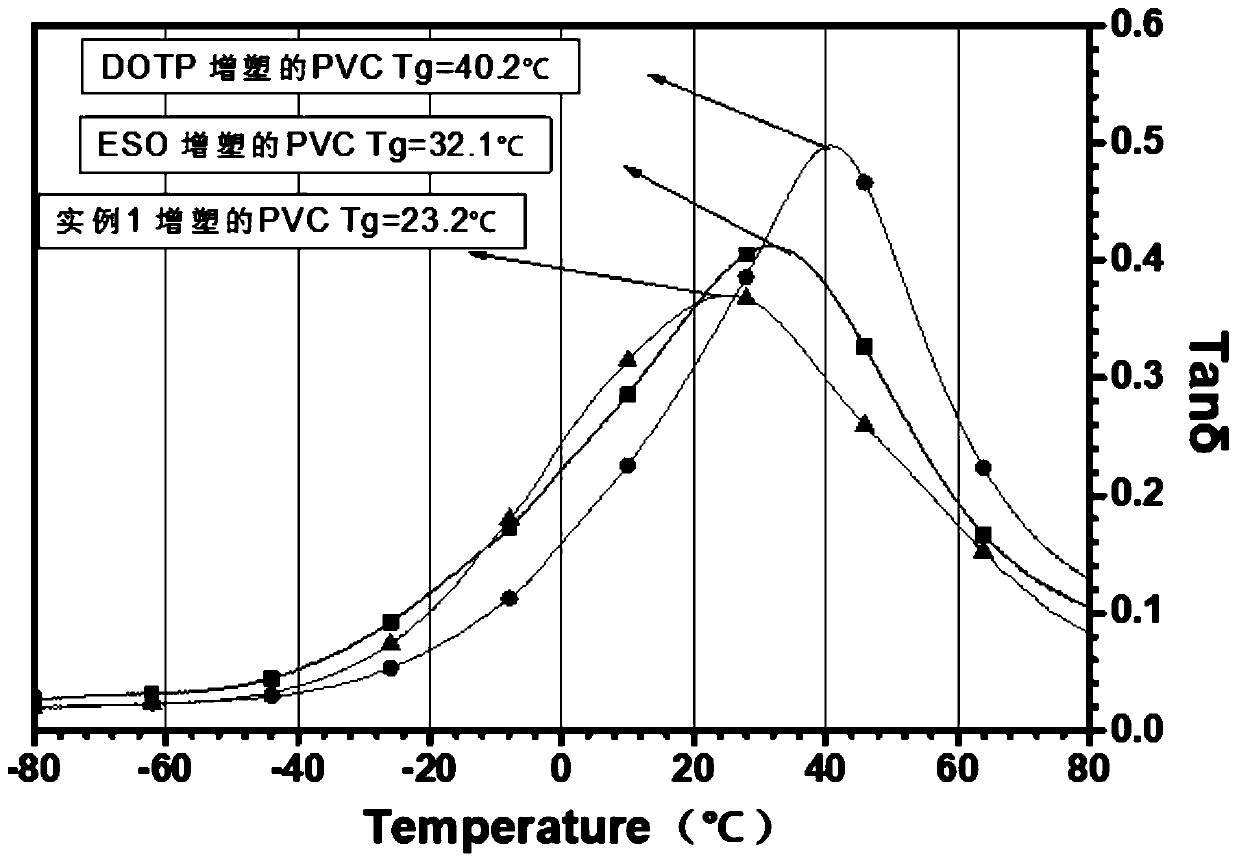

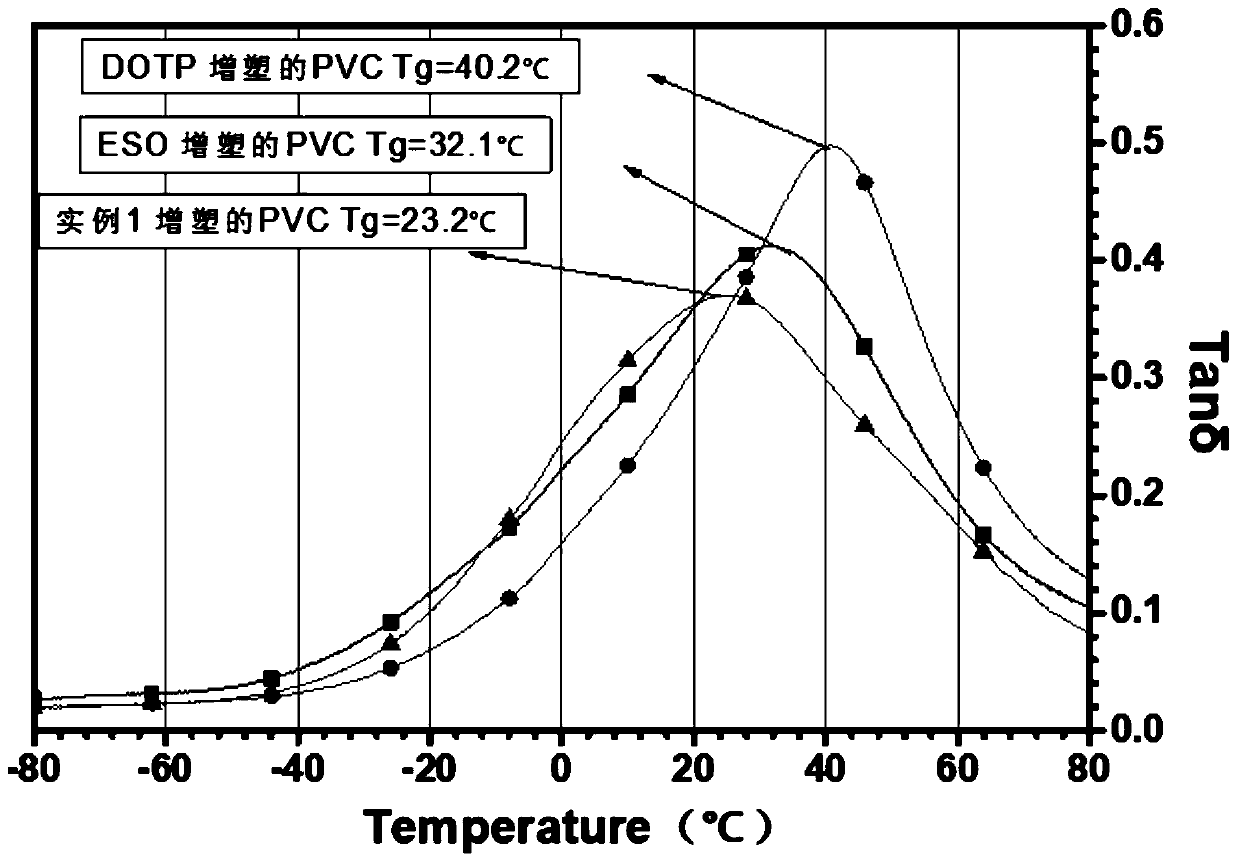

Acetylated citric acid fatty acid ester plasticizer, preparation method thereof and application

InactiveCN107176910ARaw materials are cheap and easy to getReduce dependenceOrganic compound preparationCarboxylic acid esters preparationPetrochemicalEnvironmentally friendly

The invention discloses an acetylated citric acid fatty acid ester plasticizer, a preparation method thereof and an application. The preparation method includes the steps: preparing epoxidation fatty acid ester; performing ring-opening reaction on citric acid and fatty acid ester to prepare citric acid fatty acid ester; performing acetylation reaction to obtain the acetylated citric acid fatty acid ester plasticizer. According to the plasticizer, the citric acid and the fatty acid ester serve as main materials to prepare a biological base plasticizer, the raw materials are low in cost, easy to acquire, green and environmentally friendly, dependence on petrochemical resources can be relieved, molecular weight is high, the content of polar bonds is high, a long fatly chain exists, so that the plasticizer is high in flashing point, resistant in precipitation and cold and good in plasticizing efficiency as compared with acetyl tributyl citrate and epoxidized fatty acid methyl ester, thermal stability of PVC (polyvinyl chloride) products can be improved, and the plasticizer can completely replace DOP (dioctyl-phthalate) to prepare the PVC products with special performance. The preparation method is simple in process, mild in condition and quite suitable for industrial production, and the plasticizer can be directly produced without changing production devices.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

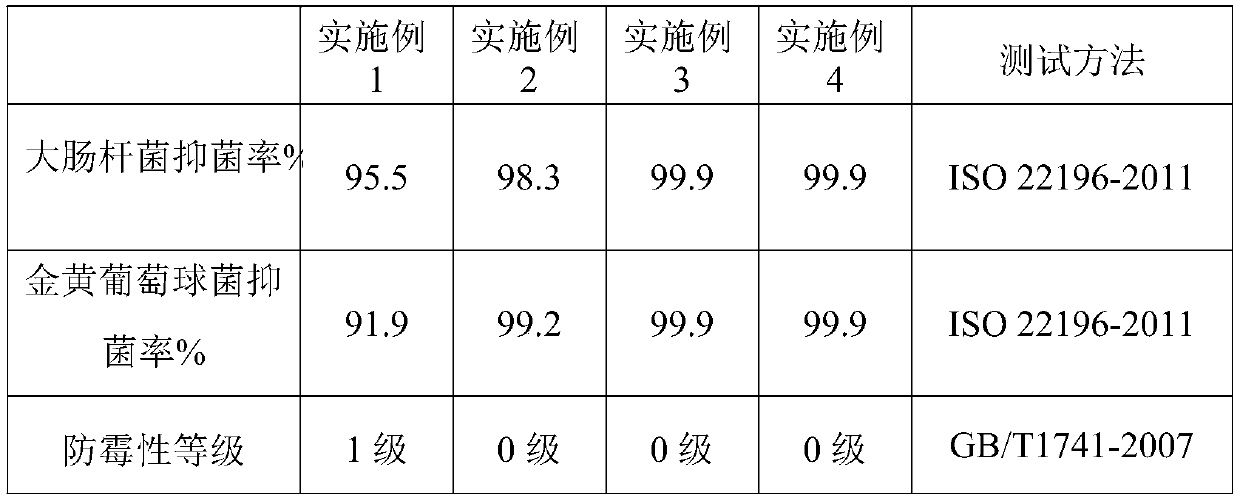

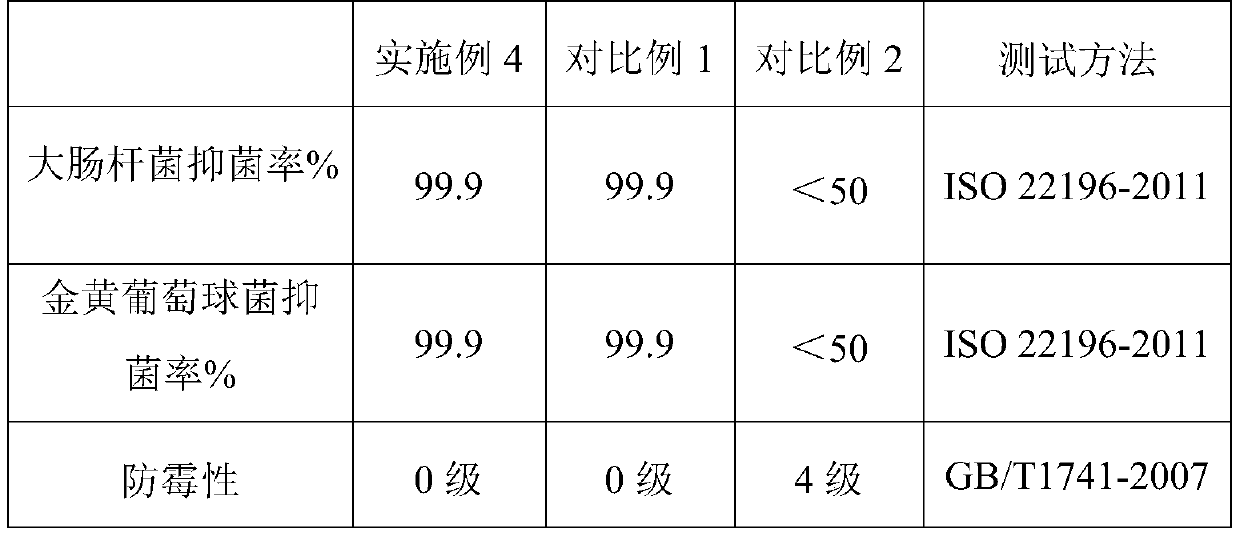

Modified polyguanidine salt antibacterial and mildew-proof agent, preparation method thereof and application thereof in silicone structural sealant

ActiveCN111393637AGood resistance to precipitationIncrease resistance to precipitationMacromolecular adhesive additivesSide chainAnti bacterial

The invention relates to a modified polyguanidine salt antibacterial and antifungal agent, a preparation method thereof and an application thereof in a silicone structural sealant, and the preparationmethod comprises the following steps: dissolving a benzyl halide compound in absolute ethyl alcohol, and gradually dropwise adding the benzyl halide compound into a heated polyguanidine salt aqueoussolution to prepare the modified polyguanidine salt antibacterial and antifungal agent with better precipitation resistance and side chain grafted benzene ring groups; applying the material in the preparation process of the silicone structural sealant, adding the material and other raw materials together so that the material is uniformly dispersed in the silicone structural sealant, and then preparing the long-acting antibacterial mildew-proof silicone structural sealant. The modified polyguanidine salt antibacterial and mildew-proof agent and the silicone structural sealant prepared by the invention have killing and inhibiting effects on common bacteria and mildew, can prolong the service life of the sealant to a certain extent, and are simple and convenient in preparation process, green,environment-friendly, low in cost and suitable for industrial large-scale production.

Owner:安阳崇高纳米材料科技有限公司 +1

Flame-retardant TPE sheath material, and preparation method and application thereof

PendingCN110951204AImprove flame retardant performanceGood mechanical propertiesChemistryPolypropylene

The invention discloses a flame-retardant TPE sheath material, and a preparation method and an application thereof, and belongs to the technical field of halogen-free flame-retardant materials. The flame-retardant TPE sheath material is prepared from, by weight, 25-30 parts of SEBS, 8-12 parts of POE, 8-12 parts of polypropylene, 20-30 parts of an organic flame retardant, 5-10 parts of a flame retardant synergist, 3-5 parts of a scratch-resistant agent, 0.1-0.3 part of an antioxidant, 10-15 parts of filling oil, 1-3 parts of a processing aid, and the balance of deionized water. The TPE sheathmaterial developed in the invention has the characteristics of high flame retardant property, scratch resistance, no precipitation, high weather resistance, good mechanical properties, stress fatigueresistance, weather aging resistance and other excellent properties, can effectively solve the contradiction between flame retardancy and physical and mechanical properties in the existing halogen-free flame-retardant TPE sheath materials, can be well used as a new energy electric vehicle charging pile cable material, and has great market application and promotion values.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Thermochromic thermoplastic elastomer (TPE) with V0 flame-retardant grade and preparation method thereof

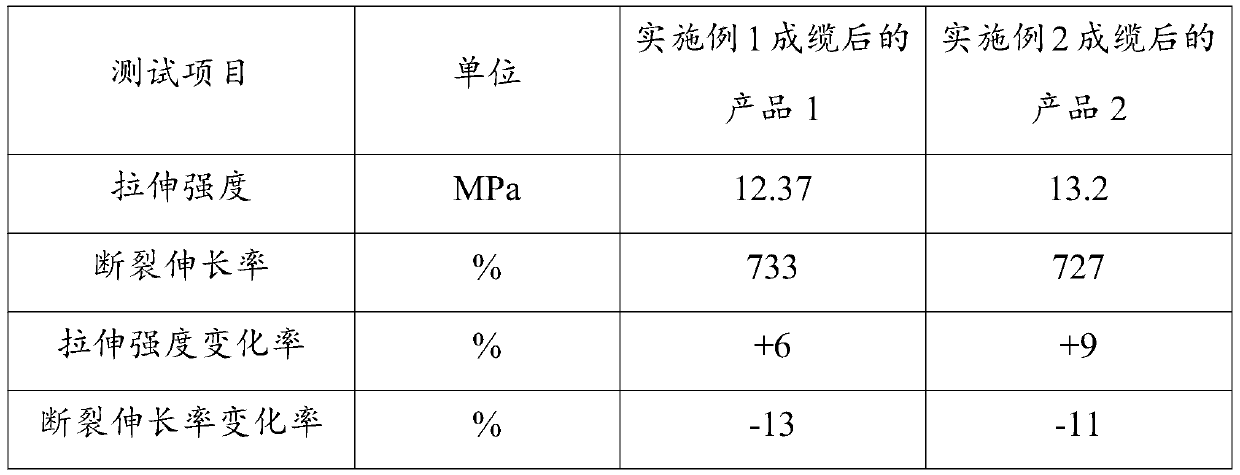

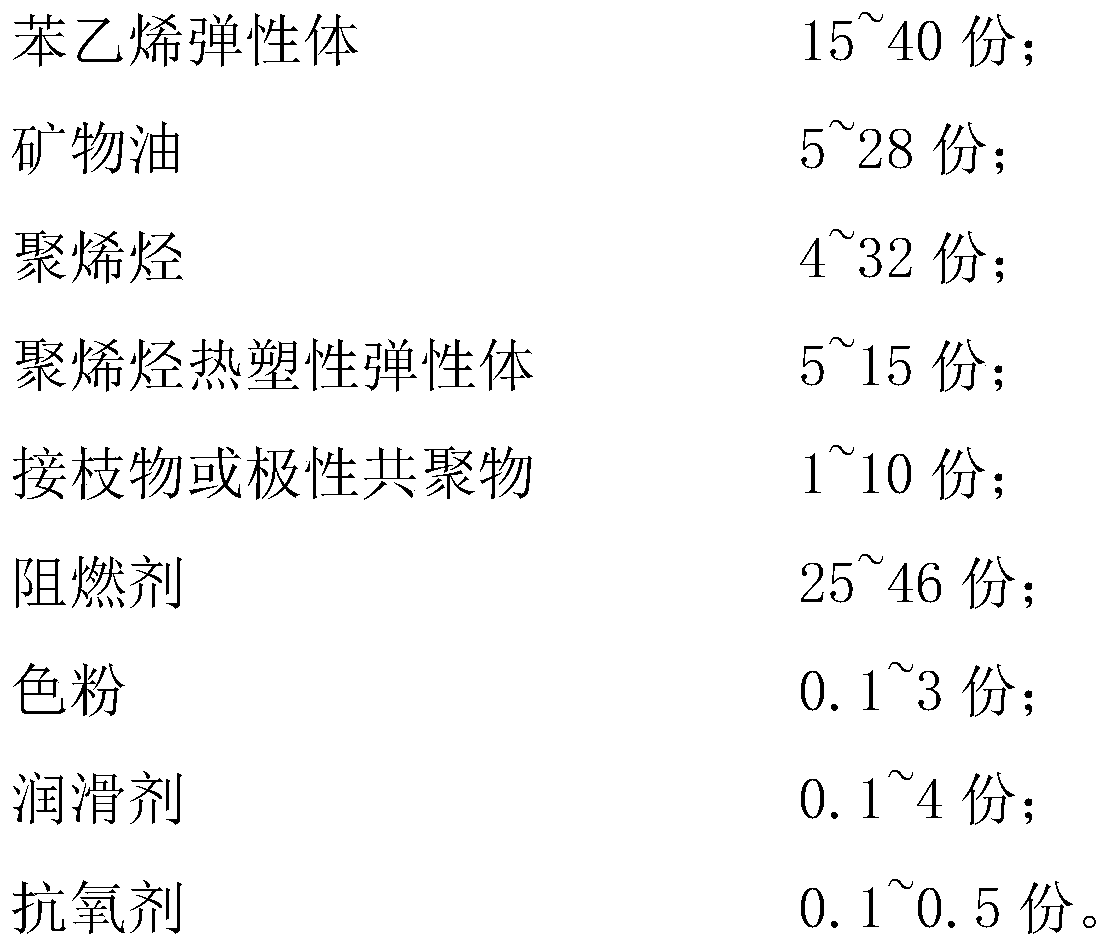

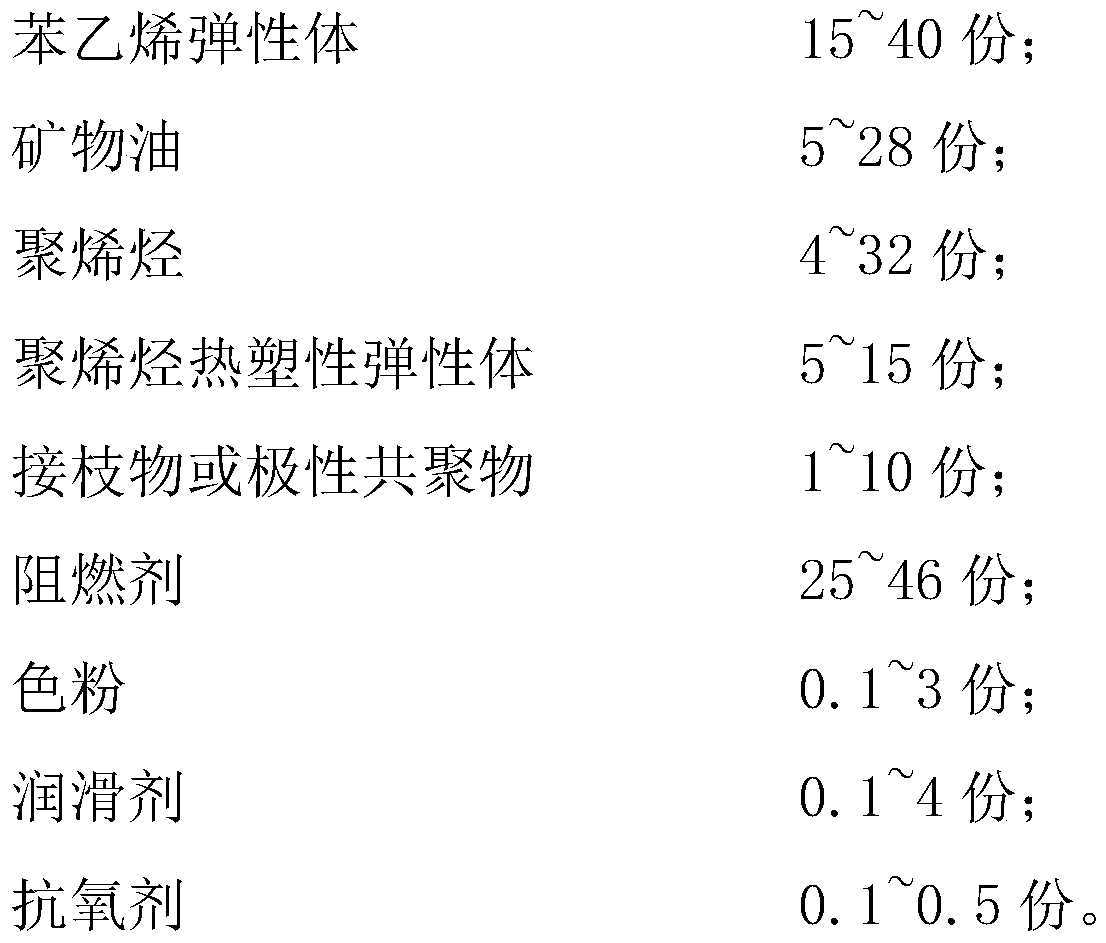

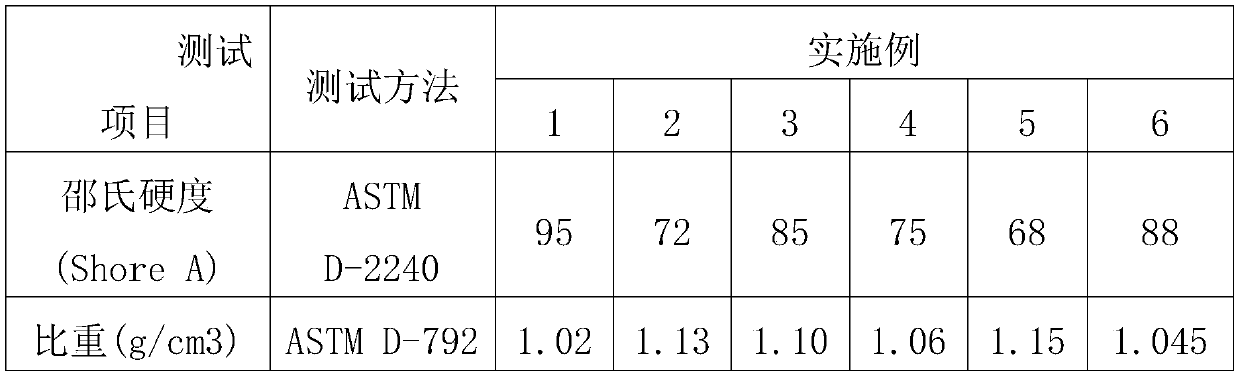

The invention provides a thermochromic thermoplastic elastomer (TPE) with a V0 flame-retardant grade and a preparation method thereof. The thermochromic thermoplastic elastomer (TPE) with a V0 flame-retardant grade comprises the following components in parts by weight: 15-40 parts of styrene elastomer, 5-28 parts of mineral oil, 4-32 parts of polyolefin, 5-15 parts of polyolefin thermoplastic elastomers, 1-10 parts of a graft or a polar copolymer, 25-46 parts of a flame retardant, 0.1-3 parts of toner, 0.1-4 parts of a lubricant and 0.1-0.5 part of an antioxidant. The thermochromic thermoplastic elastomer (TPE) with a V0 flame-retardant grade has the advantages of environmental protection, soft handfeel, precipitation resistance, aging resistance, excellent flame retardancy, capability ofchanging color under a certain temperature threshold value, and the like. In addition, vulcanization crosslinking is not needed, the processing process is simple, cold resistance is excellent, and better size precision and surface fineness are achieved.

Owner:东莞市汇泽实业有限公司

Antioxidant master batch, and application thereof in production of PEX tubes

The invention provides an antioxidant master batch, and an application thereof in the production of PEX tubes. The antioxidant master batch is prepared from, by weight, 100 parts of high density polyethylene, 0.1-4 parts of peroxide, 0-4 parts of an assistant crosslinker, and 0-10 (0 excluded, 10 included) parts of an antioxidant. When the antioxidant master batch is used to produce PEX-a tubes, the production efficiency is improved.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

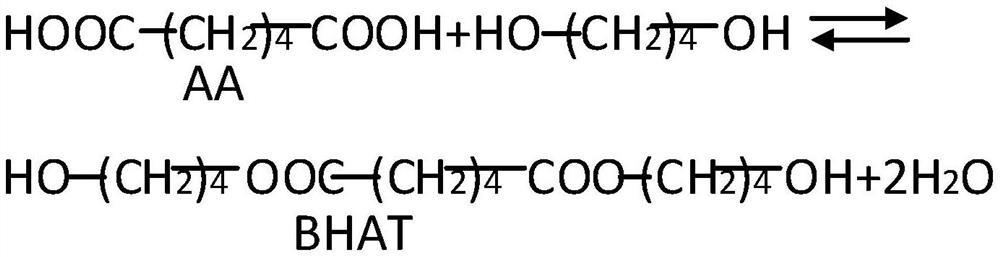

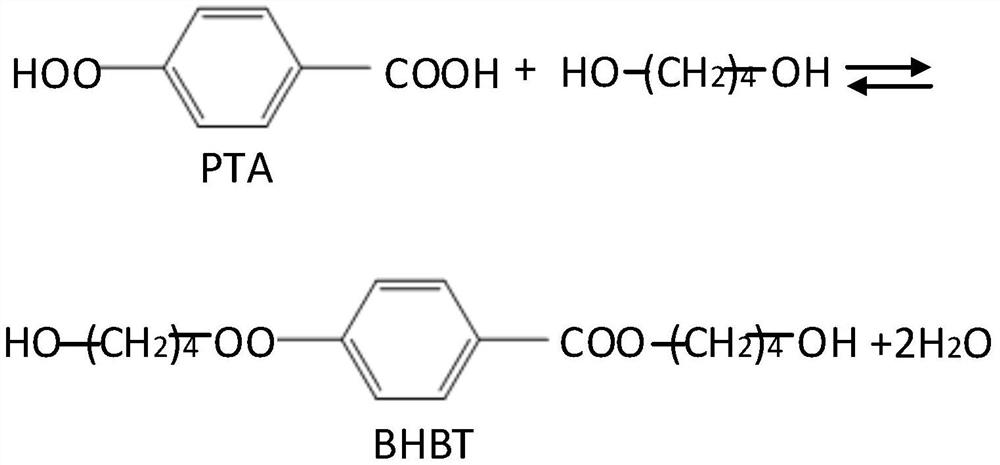

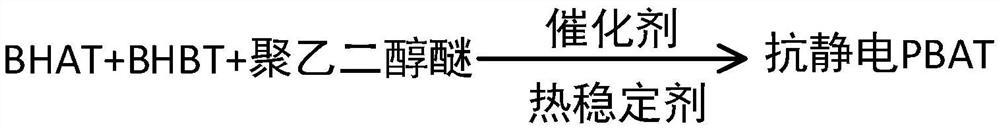

Preparation method of antistatic PBAT polymer and antistatic PBAT polymer

PendingCN112280018AExcellent resistance to precipitationImprove antistatic performancePolymer sciencePtru catalyst

The invention discloses a preparation method of an antistatic PBAT polymer and the antistatic PBAT polymer, and belongs to the technical field of polymer preparation. The method comprises the steps ofmixing p-adipic acid, butanediol and a first catalyst, and carrying out a first esterification reaction to obtain a first intermediate product; mixing terephthalic acid, butanediol and a second catalyst, and carrying out a second esterification reaction to obtain a second intermediate product; carrying out pre-polycondensation reaction on the first catalyst, the second catalyst, a set dosage of polyethylene glycol ether and a polycondensation catalyst in a polymerization reaction kettle to obtain a pre-polycondensation product; and carrying out final polycondensation reaction on the pre-polycondensation product to obtain the antistatic PBAT polymer. The polymer is prepared by the method. According to the method, the polyethylene glycol ether is introduced to the PBAT main chain, the polyethylene glycol ether can improve the antistatic property of the PBAT copolymer, and the antistatic effect is good in durability. In addition, the first esterification reaction and the second esterification reaction are separately carried out, so that more byproducts are prevented from being generated.

Owner:CHINESE TEXTILE ACAD +1

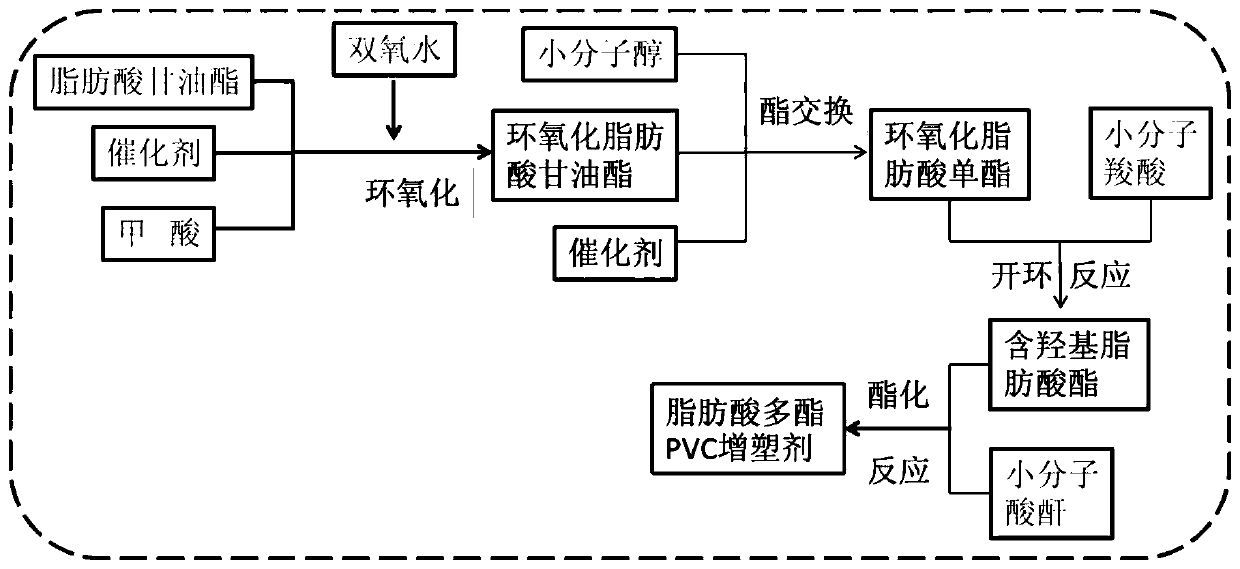

Fatty acid polyester PVC plasticizer and preparation method thereof

InactiveCN110041195AReduce dependenceRaw materials are cheap and easy to getOrganic compound preparationCarboxylic acid esters preparationPolyesterEpoxy

The invention discloses a fatty acid polyester PVC plasticizer and a preparation method thereof, which is mainly applied to soft PVC plastic products. The method mainly comprises processes as follows:(1) epoxidation preparation process of fatty glyceride, (2) preparation of epoxy fatty acid monoester through a transesterification of the epoxy fatty glyceride and (3) preparation of the fatty acidpolyester PVC plasticizer through ring opening and esterification reactions of the epoxy fatty acid monoester. The prepared plasticizer is a light yellow (hazen smaller than or equal to 350) transparent liquid have the viscosity range of 500-1,500 mPa.s, acid value smaller than 1.0 mg / g and open flash point larger than 200 DEG C. Used raw materials are widely sourced and can be regenerated, the plasticizer has the advantages of high flash point, volatility resistance, precipitation resistance, cold resistance and better plastification efficiency due to high polar bond content and existence oflong aliphatic chains in molecules of the plasticizer, can improve thermal stability of PVC products and can completely replace DOP to prepare PVC products with special performance.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

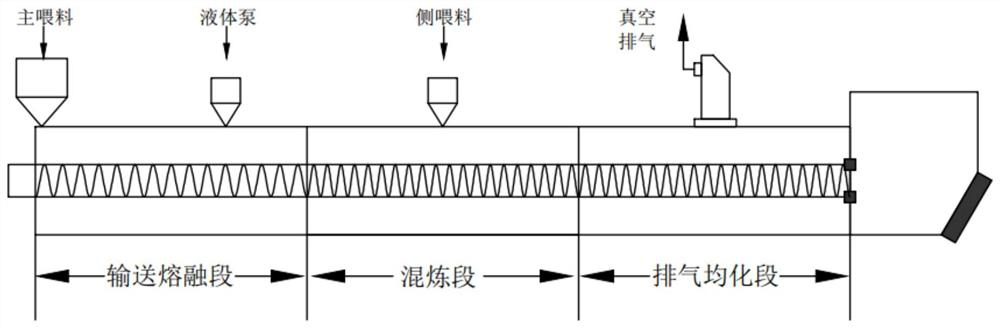

Halogen-free flame-retardant TPU cable material as well as preparation method and application thereof

InactiveCN112724656AReduce dosageReduce uneven mixingPlastic/resin/waxes insulatorsPolymer scienceThermoplastic polyurethane

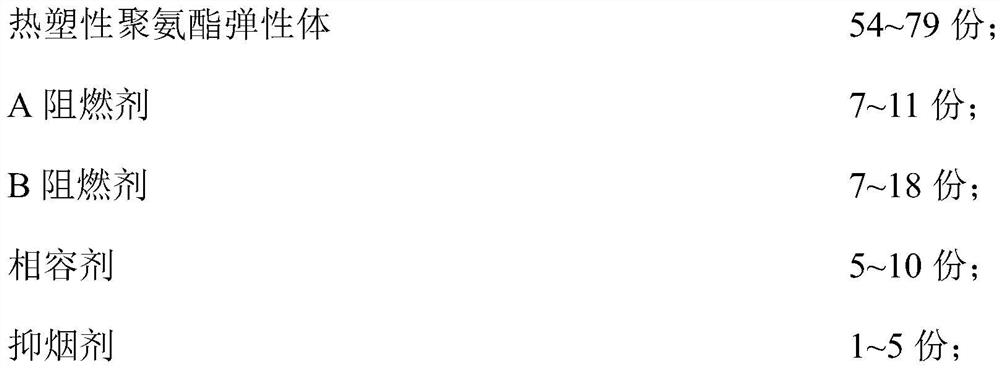

The invention provides a halogen-free flame-retardant TPU (thermoplastic polyurethane) cable material as well as a preparation method and application thereof. The halogen-free flame-retardant TPU cable material is prepared from the following raw materials in parts by weight: 54 to 79 parts of a thermoplastic polyurethane elastomer, 7 to 11 parts of a flame retardant A, 7 to 18 parts of a flame retardant B, 5 to 10 parts of a compatilizer and 1 to 5 parts of a smoke suppressant, The flame retardant A is a phosphorus flame retardant, and the flame retardant B is a modified phosphorus-nitrogen composite flame retardant. The halogen-free flame-retardant TPU cable material disclosed by the invention not only has good flame retardance and smoke suppression, but also has the characteristics of migration resistance, hydrolysis resistance and high flexibility, and is suitable for multiple fields of cables, shoe materials or medical materials and the like.

Owner:福建汇得新材料有限公司

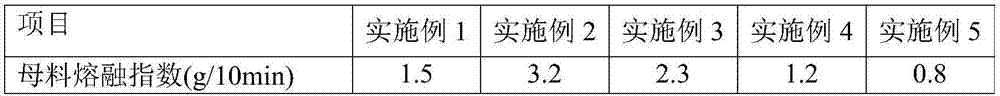

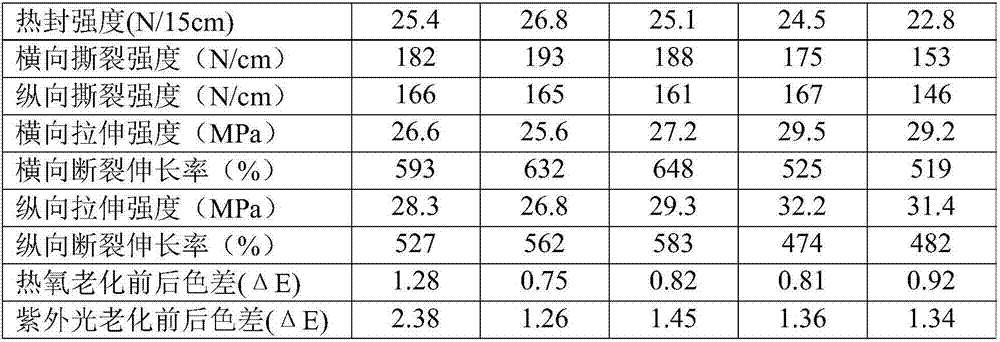

Thin film master batch with low-precipitation and yellowing-resisting special functions and preparation method thereof

The invention discloses thin film master batch with low-precipitation and yellowing-resisting special functions and a preparation method thereof and belongs to the technical field of processing and modification of high molecular materials. The thin film master batch is prepared from the following components in parts by weight: 14 to 60 parts of polyethylene, 5 to 20 parts of a POP (p-tert-octyl phenol) plastic elastomer, 1 to 75 parts of a coloring agent, 0.1 to 5 parts of an antioxidant, 0.1 to 5 parts of an ultraviolet stabilizer, 0.5 to 5 parts of a micro-pore adsorbent, 0.2 to 5 parts of ahigh molecular acid removing agent and 0 to 70 parts of a filling agent. According to the thin film master batch disclosed by the invention, middle and low molecular plasticizers including wax, stearic acid and the like are not added, and low molecular components which are possibly generated in a processing process are removed by adding the porous adsorbent, so that a colored thin film product has good precipitation-resisting performance and can adapt to high-speed heat sealing requirements, and good heat sealing strength is obtained. The thermal oxygen stability of a material is improved through adding the efficient antioxidant and the ultraviolet light ageing performance of the material is improved by adding the ultraviolet stabilizer with high molecular weight, and good yellowing-resisting performance is obtained.

Owner:广东波斯科技股份有限公司

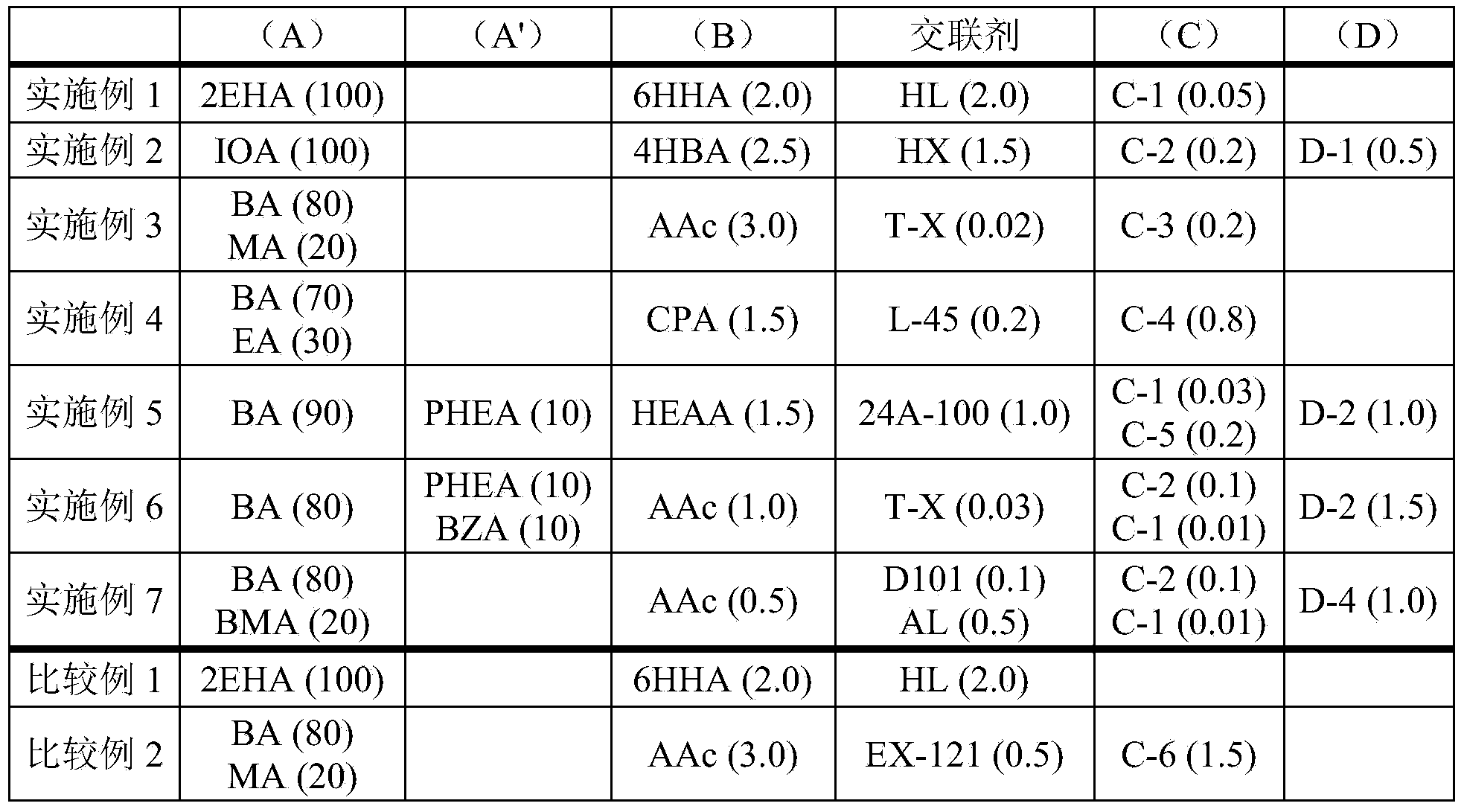

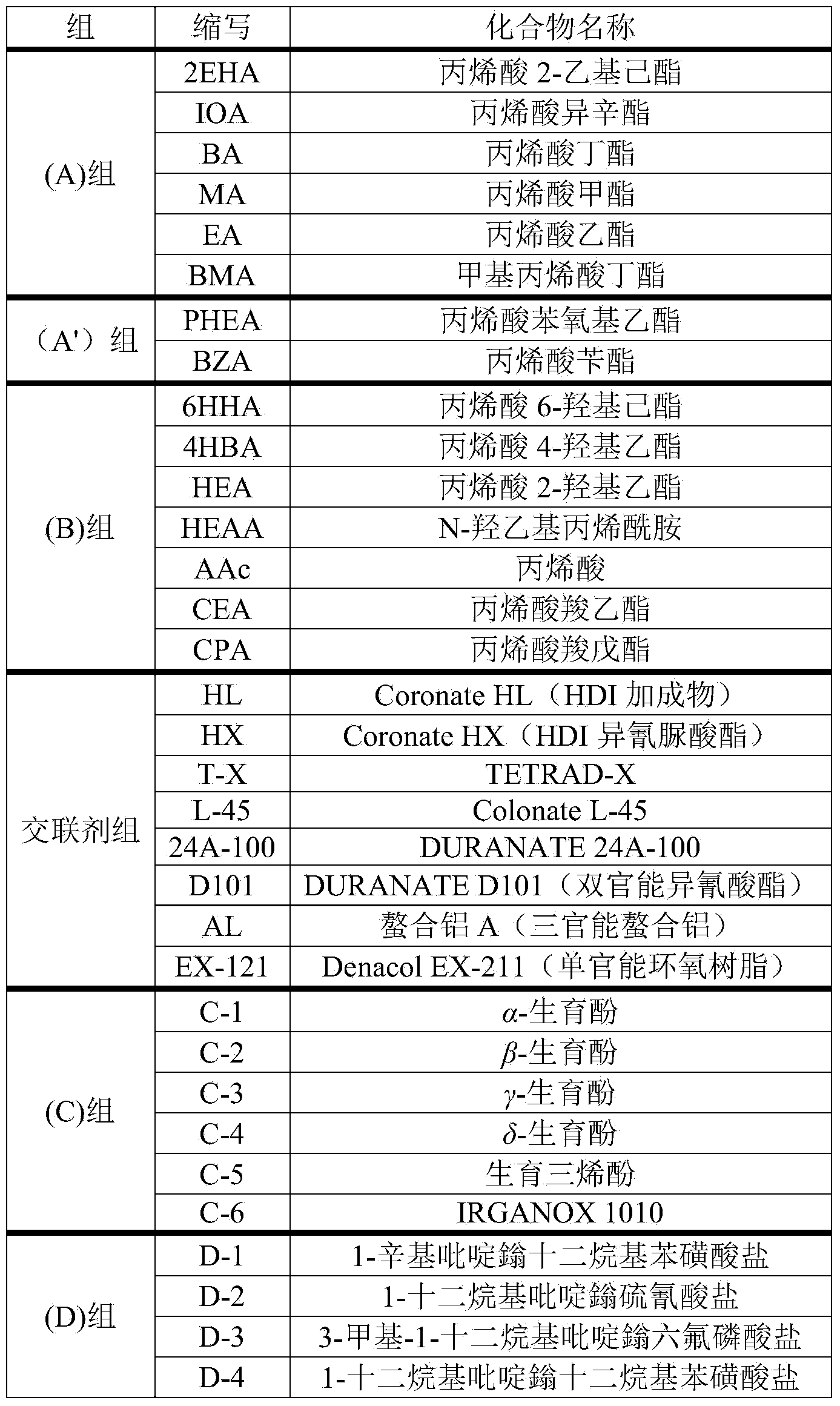

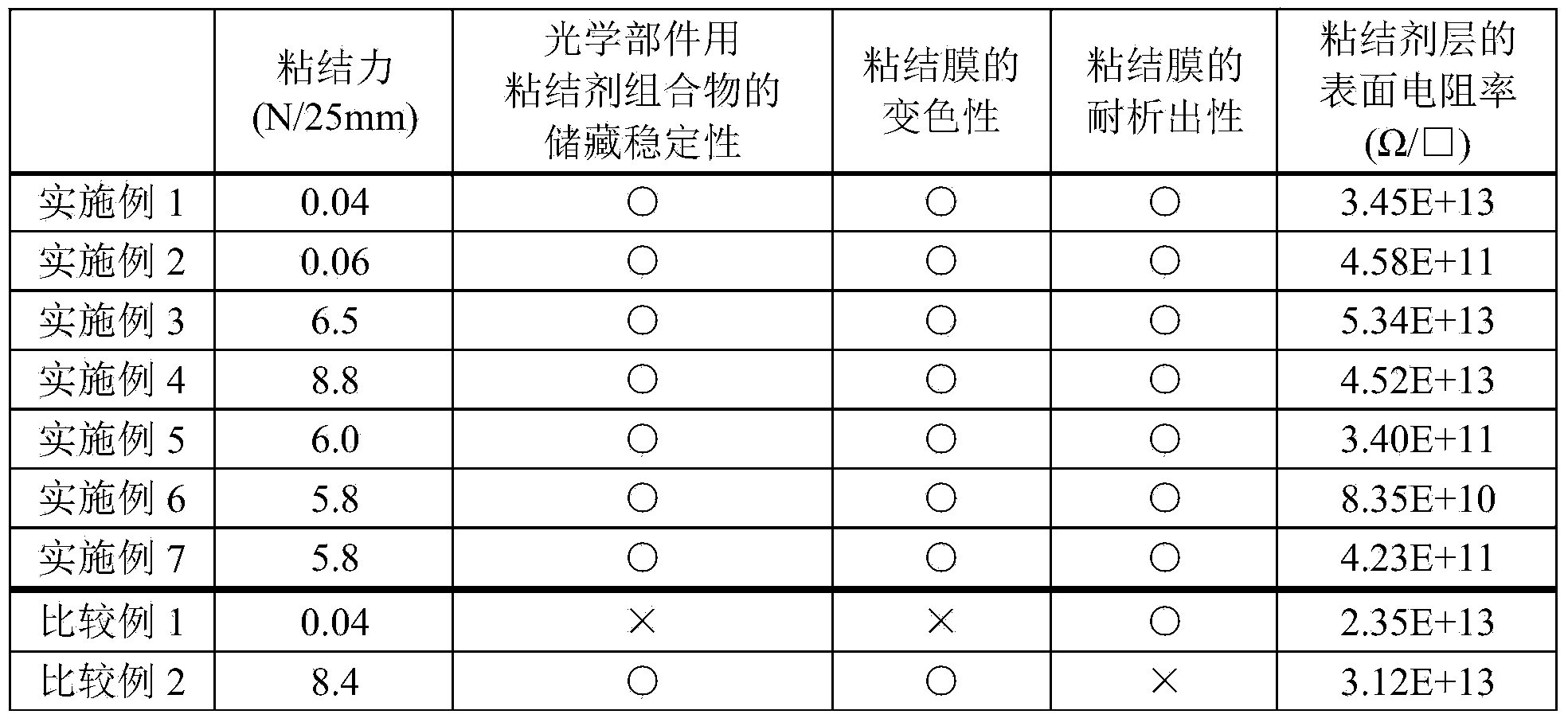

Adhesive composition for optical members, adhesive film for optical members, and surface-protective adhesive film

ActiveCN104073194ACost controlExcellent resistance to precipitationNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkAdhesive

The invention provides an adhesive composition for optical members, an adhesive film for optical members, and a surface-protective adhesive film, which can prevent the oxidation and color change of an adhesive for optical members, can control the cost even if the additive amount is large, and are good in precipitation resistance. Meanwhile, the surface resistivity of an adhesive layer is reduced, thereby enabling a surface-protective film to be easily peeled off. The adhesive composition contains an acrylic copolymer, a cross-linking agent, and an antioxidant, which all take (methyl) acrylic alkyl ester as the main component. Moreover, the antioxidant contains phenolic compounds, and ionic compounds.

Owner:FUJIMORI KOGYO CO LTD

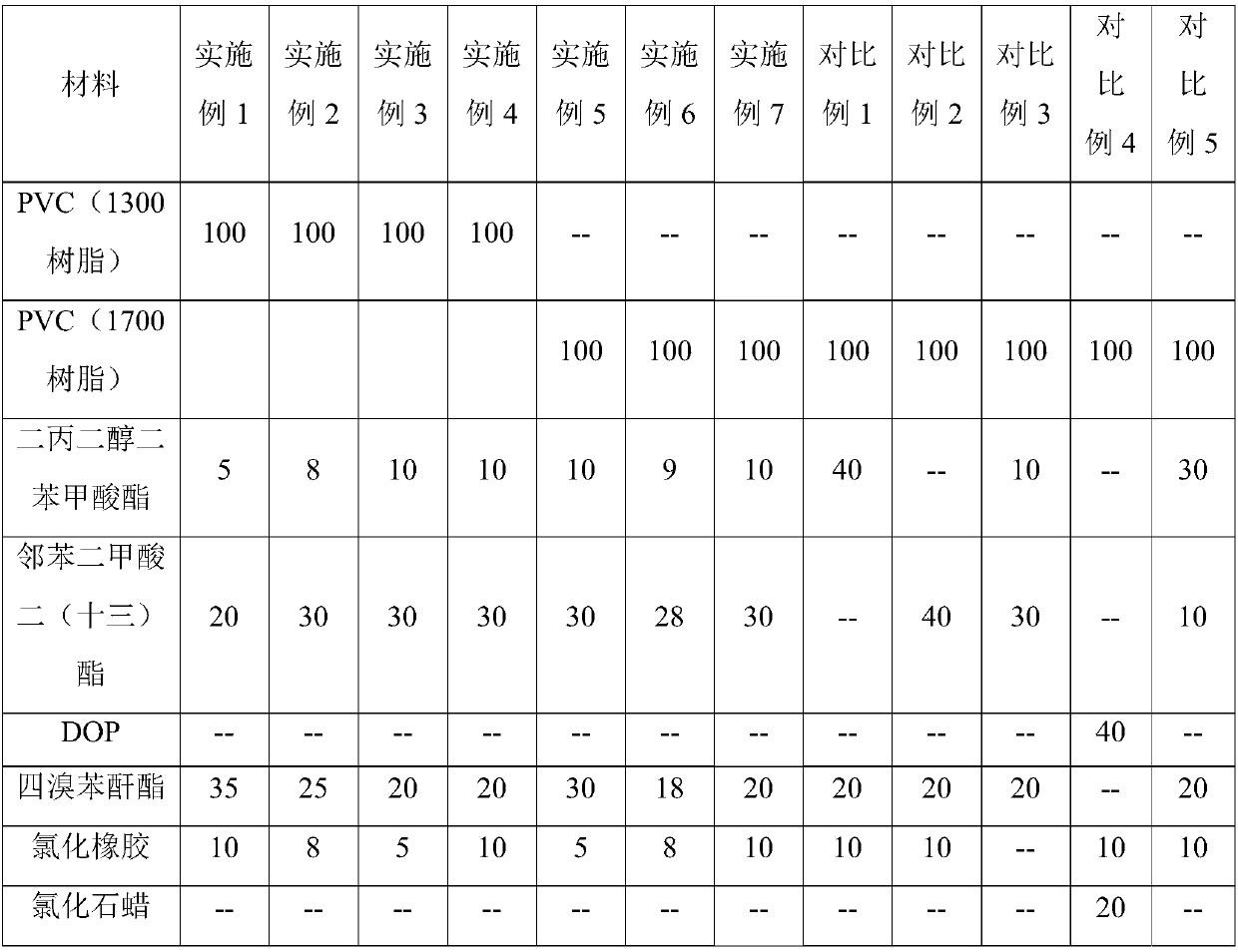

High-resistivity flame-retardant polyvinyl chloride composition for cable material

ActiveCN110760139AReduce leachingImprove flame retardant performancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl chloride

The invention relates to a high-resistivity flame-retardant polyvinyl chloride composition for a cable material, and belongs to the technical field of polyvinyl chloride modification. The high-resistivity flame-retardant PVC cable material composition provided by the invention includes the following raw materials in parts by weight: 100 parts of PVC resin, 30-50 parts of a special composite plasticizer, 15-35 parts of a flame-retardant plasticizer, 5-10 parts of powdered chlorinated rubber, 3-10 parts of a calcium zinc stabilizer, 0.5-1.2 parts of a composite antioxidant, 0.5-2 parts of a composite lubricant, and 0-5 parts of active calcium carbonate, wherein the special composite plasticizer is a mixture of dipropylene glycol dibenzoate and di(tridecyl)phthalate. The cable material prepared by using the high-resistivity flame-retardant polyvinyl chloride cable material composition provided by the invention has a high volume resistivity, and excellent flame retardancy, resistance to precipitation, and aging resistance.

Owner:CHINA PETROLEUM & CHEM CORP

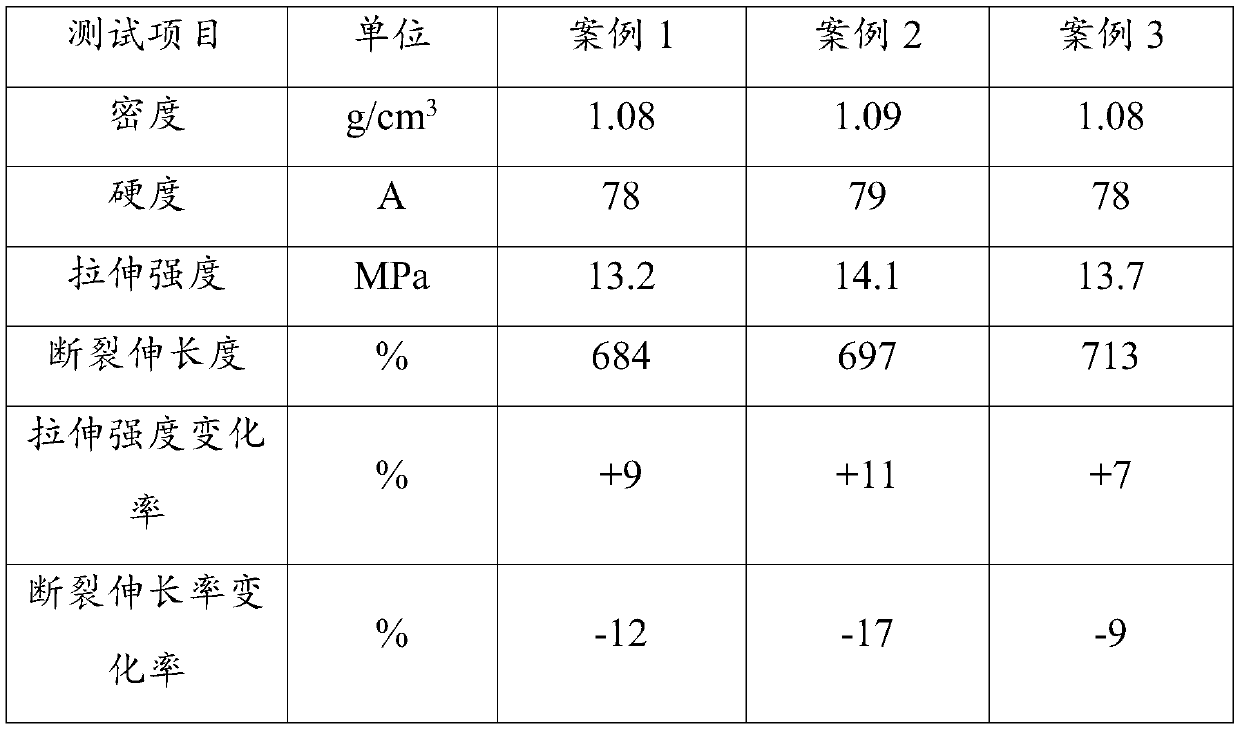

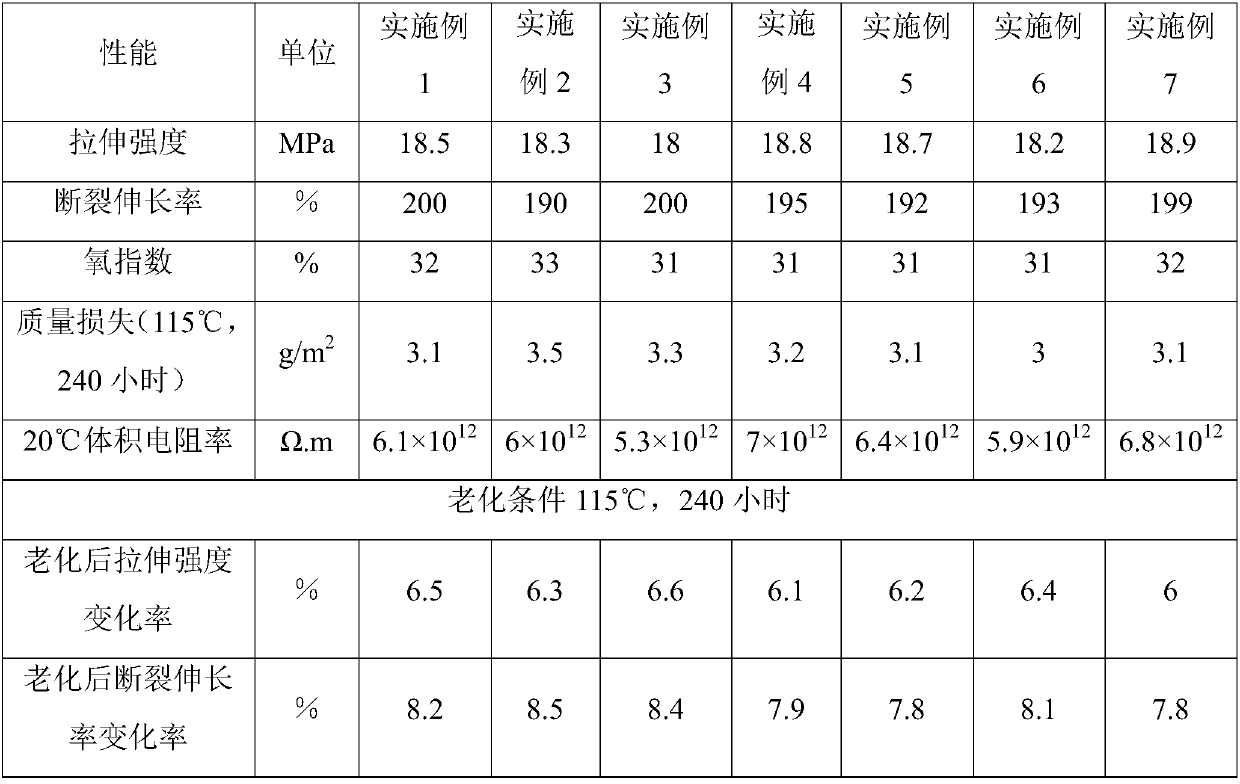

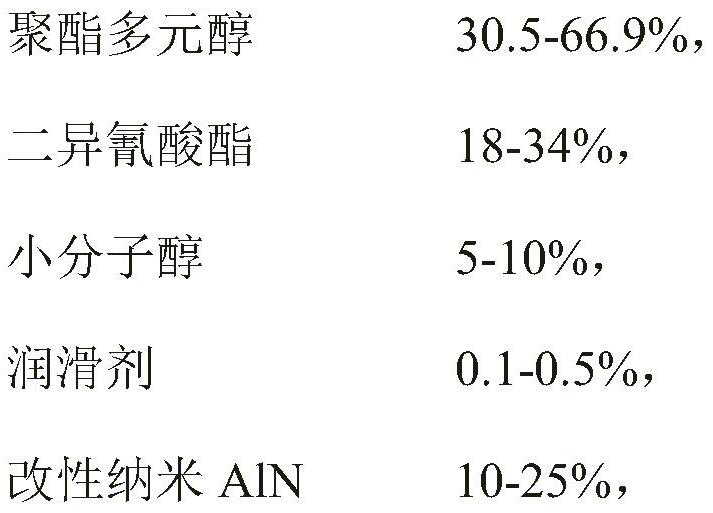

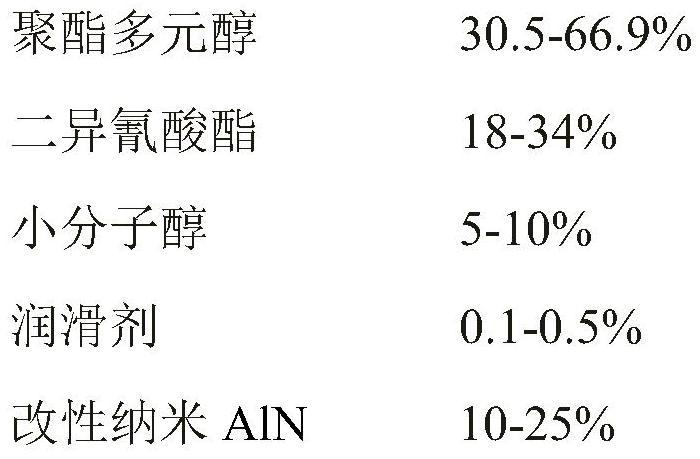

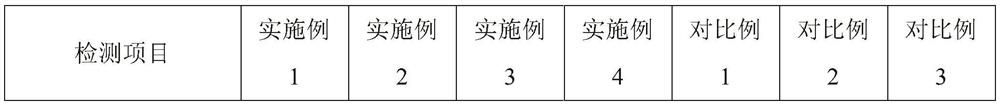

High-thermal-conductivity low-abrasion TPU material and preparation method thereof

The invention belongs to the technical field of thermoplastic polyurethane elastomers, and particularly relates to a high-thermal-conductivity low-abrasion TPU material and a preparation method thereof. The TPU material is prepared by adding a catalyst into the following raw materials in percentage by mass: 30.5-66.9% of polyester polyol, 18-34% of diisocyanate, 5-10% of small molecular alcohol, 0.1-0.5% of a lubricant and 10-25% of modified nano AlN, the use amount of the catalyst is 0.04-0.1% of the total mass of the raw materials, the modified nano AlN is copper chloride modified aluminum nitride, and the small molecular alcohol is composed of a chain extender and a cross-linking agent. The TPU material prepared by the invention has a micro-crosslinking structure, so that the thermal conductivity and the abrasion resistance of the TPU material are improved; and the preparation method adopts one-step synthesis, is simple and easy to operate, and is scientific and reasonable.

Owner:SHANDONG INOV POLYURETHANE

A kind of pvc environment-friendly calcium zinc stabilizer

The invention relates to the technical field of materials, and discloses a PVC environment-friendly calcium-zinc stabilizer. The PVC environmentally friendly calcium-zinc stabilizer comprises the following parts by weight: 10-30 parts of calcium salt main stabilizer, 10-30 parts of zinc salt main stabilizer, 15-25 parts of modified hydrotalcite, 10-20 parts of lubricant, 5-10 parts of modified halloysite nanotubes, 1-5 parts of antioxidant, 1-5 parts of auxiliary stabilizer and 1-5 parts of ultraviolet absorber. The PVC environment-friendly calcium-zinc stabilizer of the invention has high stability, strong initial tinting strength and good precipitation resistance, and overcomes the defect of easy precipitation in the traditional calcium-zinc processing process. The PVC environment-friendly calcium-zinc stabilizer of the present invention has a wide adjustment range of the degree of plasticization for different products, and overcomes the disadvantage that the plasticization of the traditional calcium-zinc stabilizer is early and fast. The PVC environment-friendly calcium-zinc stabilizer of the invention has high weather resistance, which is comparable to the weather resistance of the traditional lead salt system, and meets the requirements for outdoor use of PVC products.

Owner:杭州凌洲塑胶科技有限公司

A kind of halogen-free and phosphine-free Pbt reinforced composite material and preparation method thereof

ActiveCN104231575BExcellent resistance to precipitationImprove flame retardant performanceGlass fiberAntioxidant

The invention discloses a halogen-free and phosphorus-free PBT (polybutylece terephthalate) enhanced composite material and a preparation method thereof, and belongs to the technical field of composite flame-retardant enhanced materials. The halogen-free and phosphorus-free PBT enhanced composite material consists of the following components: 45-65 pats of PBT, 15-30 parts of glass fibers, 15-25 parts of a halogen-free flame retardant, 1-2 parts of a toughening agent, 0.1-0.2 part of a main antioxidant, 0.1-0.2 part of an auxiliary antioxidant, 0.1-1 part of a lubricating agent and 0.3-1.0 part of a nucleating agent. The preparation method comprises the steps of uniformly mixing PBT, the halogen-free flame retardant, the toughening agent, the main antioxidant, the auxiliary antioxidant, the lubricating agent and the nucleating agent according to the weight part to obtain a mixture, and performing melting, coblending and extruding granulation on the mixture and the glass fibers to obtain the halogen-free and phosphorus-free PBT enhanced composite material. The halogen-free and phosphorus-free PBT enhanced composite material prepared by the method is excellent in anti-separation performance, flame retardancy, mechanical property and creepage cracking resistance, does not release hydrogen phosphide poisonous gas and can totally meet a limiting requirement of Samsung on hydrogen phosphide emission concentration.

Owner:JINAN TAIXING FINE CHEM

Method for preparing PPS plastic particles for automotive trim

InactiveCN104987719AGood mechanical propertiesImprove heat aging performancePlasticultureManufactured material

The invention discloses a method for preparing PPS plastic particles for automotive trim. The method comprises the following steps that all components are weighed according to a weight part ratio and are added into a high-speed mixer to be stirred and mixed; then the evenly mixed materials are added into a double-screw extruder to be molten, plasticized, extruded and pelletized, and then the PPS plastic particles are obtained. The manufactured materials are excellent in mechanical property, heat aging property, photooxidation aging property, precipitation resistance and the like and can meet the requirement for 400h thermo-oxidative aging of polypropylene automotive trim materials; according to the method, the technique is simple.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

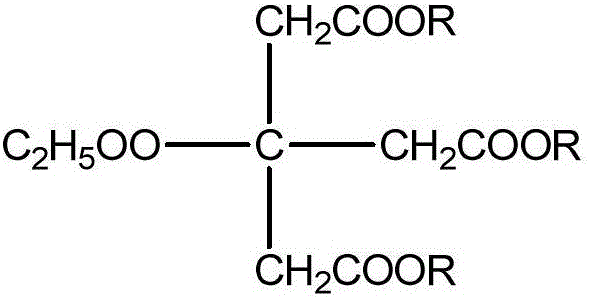

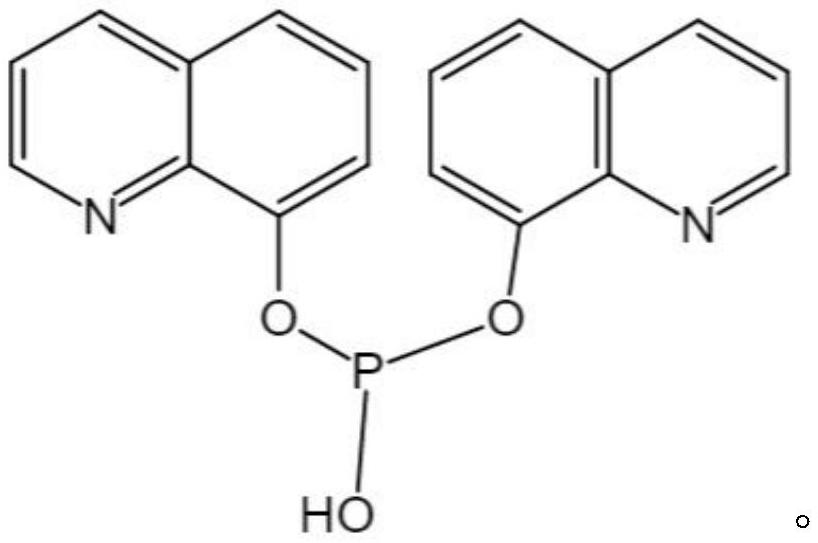

Application of diquinoline phosphite in PVC barium-zinc composite heat stabilizer

The invention relates to application of diquinoline phosphate in a PVC barium-zinc composite heat stabilizer, the structural formula of the diquinoline phosphate is shown in the specification, the diquinoline phosphate compound adopts a novel heterocyclic group to replace an aliphatic aromatic group, and the compound is added in the preparation of a liquid barium-zinc stabilizer, so that the precipitation resistance of the liquid barium-zinc stabilizer can be effectively improved, efficient heat aging resistance (static stability) is also achieved, and excellent processability in secondary printing of advertising films and the like can be realized.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

A low-separation flame-retardant polyamide composition and its preparation method

ActiveCN104231622BExcellent resistance to precipitationImprove flame retardant performanceAlkali freePolyamide

The invention relates to the technical field of a high polymer material and especially relates to a low-temperature flame-retarded polyamide composition, and the composition includes the raw materials based on the following mass percentage: 20-70% of nylon resin, 10-30% of main flame retardant, 0-15% of synergistic agent, 10-40% of alkali-free glass fiber, 0-1% of antioxidant, and 0-2% of lubricant, wherein the nylon resin is one of nylon 66 and nylon 6 or their mixture; the main flame retardant is a brominated flame retardant; the synergistic agent is selected from one of compounds of antimonous oxide master batch, zinc borate, silicon dioxide and metallic oxide or the mixture prepared by more than one compound; the lubricant is a lubricant with high molecular weight and dispersion and includes one of polyethylene wax, modified PE wax, OP wax and lignite wax. The polyamide composition isn't easily migrated or precipitated at high-temperature moisture conditions and low in material cost, the preparation method is simple and beneficial to popularization and application.

Owner:江苏晋伦塑料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com