Fatty acid polyester PVC plasticizer and preparation method thereof

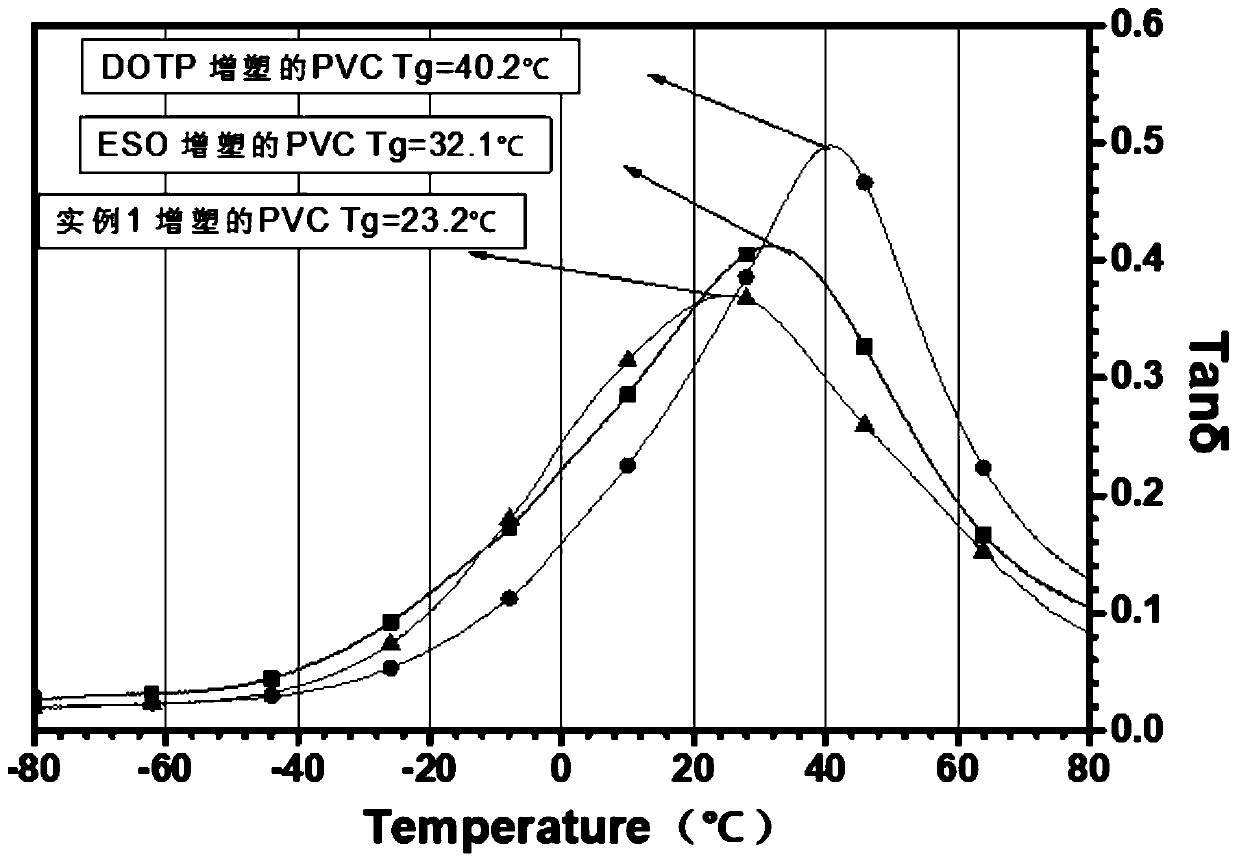

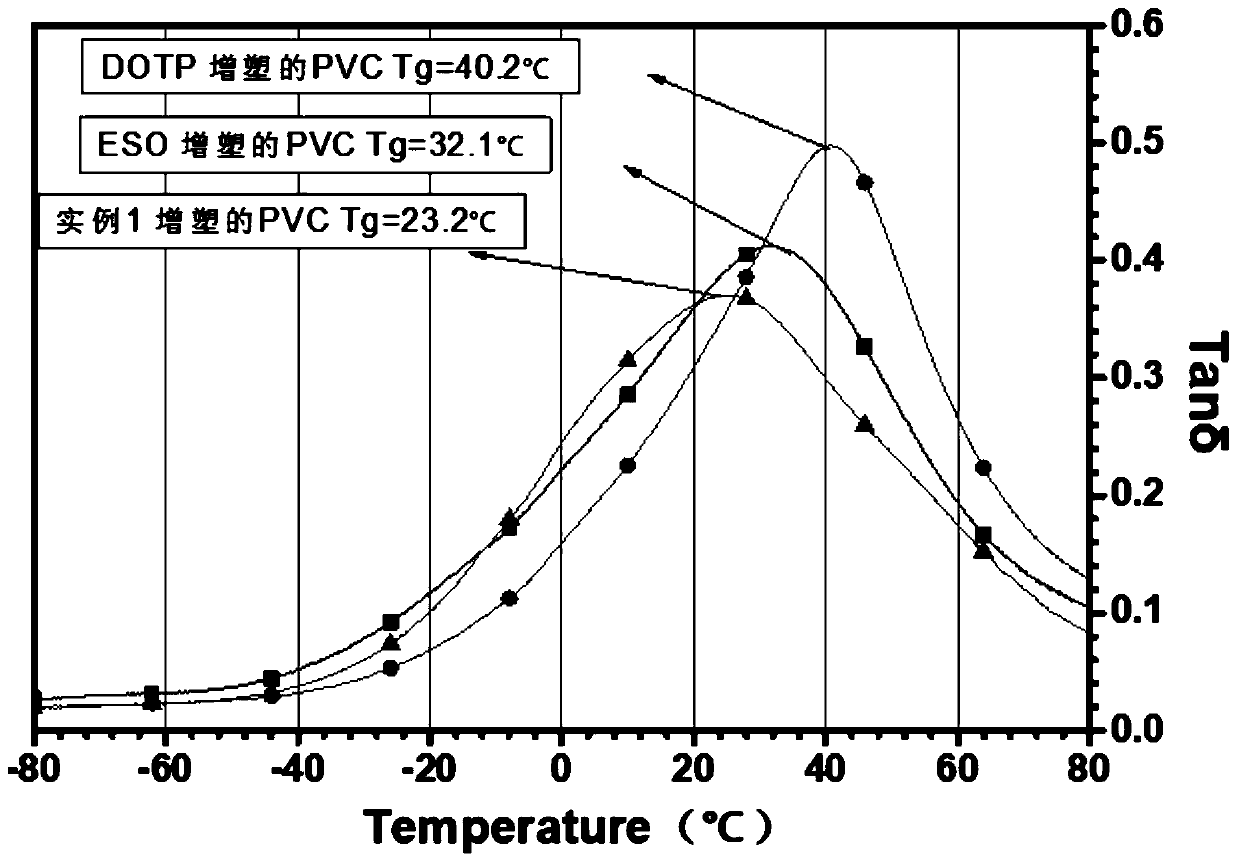

A technology of fatty acid esters and fatty acid monoesters, which is applied in the preparation of bio-based PVC plasticizer fatty acid polyesters, in the field of environmental protection, and can solve the problems of large differences in the purity of oil-based plasticizers, product performance differences, and easy precipitation. , to achieve the effects of less side reactions, shortened production time, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

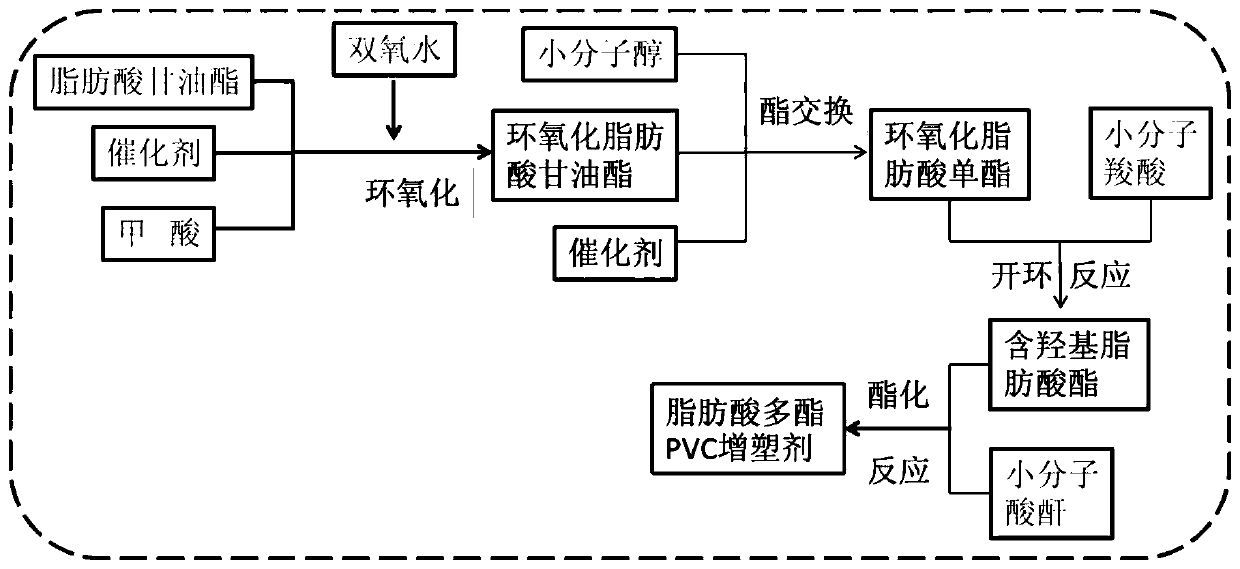

Method used

Image

Examples

Embodiment 1

[0027] The first step, the preparation of epoxidized fatty acid glyceride (epoxidized soybean oil ESO): get the hydrogen peroxide 45mL of 35wt.% concentration and add dropwise to 50g soybean oil (iodine value 122), 3mL formic acid and 0.1g concentrated sulfuric acid In the three-necked flask used as a catalyst, control the hydrogen peroxide to be added dropwise within 1.0h, and the temperature is not higher than 65°C, then keep the temperature at 65°C for 2h, neutralize with 4wt.% sodium carbonate solution after the reaction, wash with water until neutral , and then dried to obtain epoxidized soybean oil with an epoxy value of 6.2% pale yellow.

[0028] The second step, epoxidized fatty acid glyceride and small molecule alcohols transesterification reaction prepares epoxidized fatty acid ester: the epoxidized soybean oil 50g that last step makes, 20g methyl alcohol (water content is less than 0.2wt.%) React with 0.5g of sodium methoxide catalyst in a 250ml three-water flask at...

Embodiment 2

[0031] The first step, the preparation of epoxidized fatty acid glyceride (epoxidized rapeseed oil): get the hydrogen peroxide 50mL of 35wt. In the three-necked flask with sulfuric acid as the catalyst, control the hydrogen peroxide to be added dropwise within 1.0 h, and the temperature is not higher than 65 ° C, and then keep the temperature at 65 ° C for 2 h. After the reaction, neutralize with 4wt.% sodium carbonate solution and wash with water until properties, and then dried to obtain epoxy value of 5.8% pale yellow epoxidized rapeseed oil. The second step, epoxidized fatty acid glyceride and small molecule alcohols transesterification reaction prepare epoxidized fatty acid ester: the epoxidized rapeseed oil 50g that last step makes, 20g methyl alcohol (water content is less than 0.2wt.%) ) and 0.45g potassium methylate catalyst in the three-water flask of 250ml, 55 ℃ of conditions reacted 12min, then layered to remove the by-product glycerol, and the supernatant liquid w...

Embodiment 3

[0034] The first step, preparation of epoxidized fatty acid glyceride (epoxidized corn oil): get 50mL of hydrogen peroxide of 35wt.% concentration and add dropwise to 50g corn oil (iodine value 108), 4mL formic acid and 0.1g concentrated sulfuric acid to make In the three-necked flask of the catalyst, control the hydrogen peroxide to be added dropwise within 1.0 h, and the temperature is not higher than 65 ° C, and then keep the temperature of 65 ° C for 2 h. After the reaction, neutralize with 4wt.% sodium carbonate solution and wash with water until neutral. Then dry to obtain epoxidized corn oil with an epoxy value of 6.0% pale yellow.

[0035] Second step, epoxidized fatty acid glyceride and small molecule alcohols transesterification reaction prepares epoxidized fatty acid ester: the epoxidized corn oil 50g that last step makes, 35g ethanol (water content is less than 0.2wt.%) React with 0.6g of lithium hydroxide catalyst in a 250ml three-water flask at 55°C for 15min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Open flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com