Precipitation resistant, toughening and flame-retardant polypropylene composite material and preparation method thereof

A technology of flame retardant polypropylene and composite materials, applied in the field of flame retardant composite materials, can solve the problems of decreased mechanical properties and toughness of products, easy moisture absorption and hydrolysis of ammonium polyphosphate, and decreased flame retardant properties of products, etc. Excellent precipitation resistance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

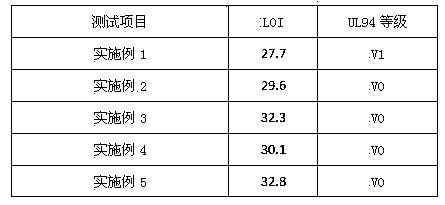

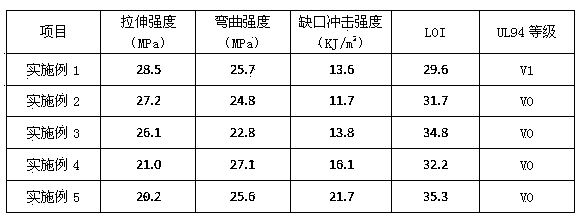

Embodiment 1

[0027] Prepare raw materials: 73 parts of polypropylene T30S, 3 parts of POE, 2 parts of POE-g-MAH, 14 parts of siloxane-coated ammonium polyphosphate, 7 parts of melamine cyanurate, 1 part of nano-zinc oxide, 0.3 parts of antioxidant 168 , 0.2 parts of antioxidant 1010.

[0028] The preparation method is:

[0029] 1) 14 parts of siloxane-coated ammonium polyphosphate, 7 parts of melamine cyanurate, 1 part of nano-zinc oxide, 0.3 part of antioxidant 168, and 0.2 part of antioxidant 1010. Add it into a high mixer, stir for 4 minutes and mix evenly, then add 73 parts of polypropylene, 3 parts of POE, and 2 parts of POE-g-MAH, and continue stirring for 5 minutes to obtain a mixed material.

[0030] 2) Put the mixed material obtained in step 1 into a twin-screw extruder for mixing and plasticizing. The plasticizing temperature is 190°C-240°C. The extruded material is water-cooled, air-dried, and pelletized to obtain precipitation-resistant toughened flame-retardant polypropylene ...

Embodiment 2

[0032] Prepare raw materials: 65.5 parts of polypropylene T30S, 6 parts of EVA, 3 parts of PP-g-MAH, 18 parts of siloxane-coated ammonium polyphosphate, 6 parts of melamine cyanurate, 0.5 parts of nano-zinc oxide, 0.3 parts of antioxidant 168 , 0.2 parts of antioxidant 1010.

[0033] The preparation method is:

[0034] 1) Mix 18 parts of siloxane-coated ammonium polyphosphate, 6 parts of melamine cyanurate, 1 part of nano-zinc oxide, 0.3 part of antioxidant 168, and 0.2 part of antioxidant 1010. Add it into a high mixer, stir for 4 minutes and mix evenly, then add 65.5 parts of polypropylene, 6 parts of EVA, and 3 parts of PP-g-MAH, and continue stirring for 5 minutes to obtain a mixed material.

[0035] 2) Put the mixed material obtained in step 1 into a twin-screw extruder for mixing and plasticizing. The plasticizing temperature is 190°C-240°C. The extruded material is water-cooled, air-dried, and pelletized to obtain precipitation-resistant toughened flame-retardant polyp...

Embodiment 3

[0037] Prepare raw materials: 59 parts of polypropylene T30S, 8 parts of EVA, 3 parts of PE-g-GMA, 22 parts of siloxane-coated ammonium polyphosphate, 7 parts of melamine cyanurate, 0.5 parts of nano-zinc oxide, 0.3 parts of antioxidant 168 , 0.2 parts of antioxidant 1010.

[0038] The preparation method is:

[0039] 1) 22 parts of siloxane-coated ammonium polyphosphate, 7 parts of melamine cyanurate, 0.5 parts of nano-zinc oxide, 0.3 parts of antioxidant 168, and 0.2 parts of antioxidant 1010. Add it into a high mixer, stir for 4 minutes and mix evenly, then add 59 parts of polypropylene, 8 parts of EVA, and 3 parts of PE-g-GMA, and continue stirring for 5 minutes to obtain a mixed material.

[0040] 2) Put the mixed material obtained in step 1 into a twin-screw extruder for mixing and plasticizing. The plasticizing temperature is 190°C-240°C. The extruded material is water-cooled, air-dried, and pelletized to obtain precipitation-resistant toughened flame-retardant polyprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com