Application of diquinoline phosphite in PVC barium-zinc composite heat stabilizer

A technology of bisquinoline phosphite and composite heat stabilizer, which is applied in the application field of bisquinoline phosphite in PVC barium zinc composite heat stabilizer, and can solve the problem of easy decomposition, limited aging resistance and limited application To improve the precipitation performance, reduce the color difference of the film, and improve the printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through specific implementation examples.

[0023] The raw materials used in the examples are conventional raw materials in the market.

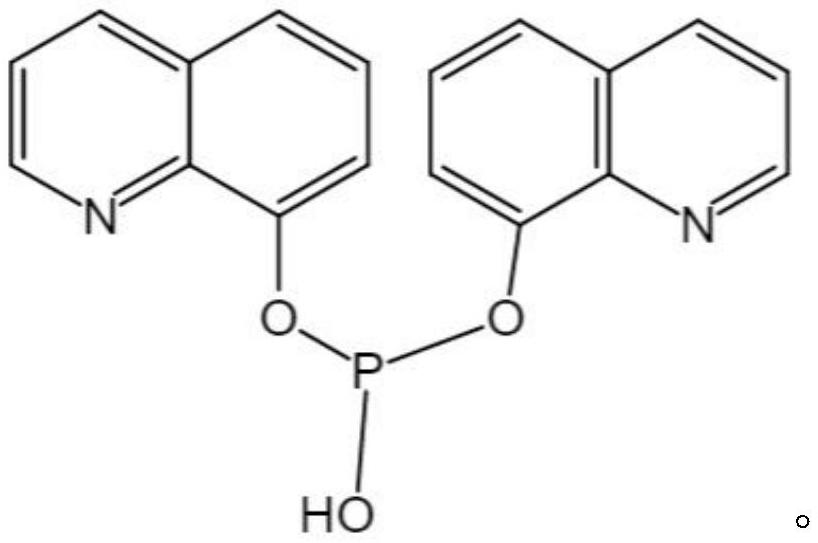

[0024] Preparation of bisquinoline phosphite:

[0025] Using 68.7g of phosphorus trichloride and 228.4g of 8-hydroxyquinoline as raw materials, add phosphorus trichloride dropwise to 8-hydroxyquinoline at a temperature of 70°C and a time of 120 minutes to obtain triquinoline phosphite Phosphorous acid ester: 20.5 g of phosphorous acid was dropped into the above product, and reacted for 60 minutes at 120° C. to obtain 168 g of diquinoline phosphite.

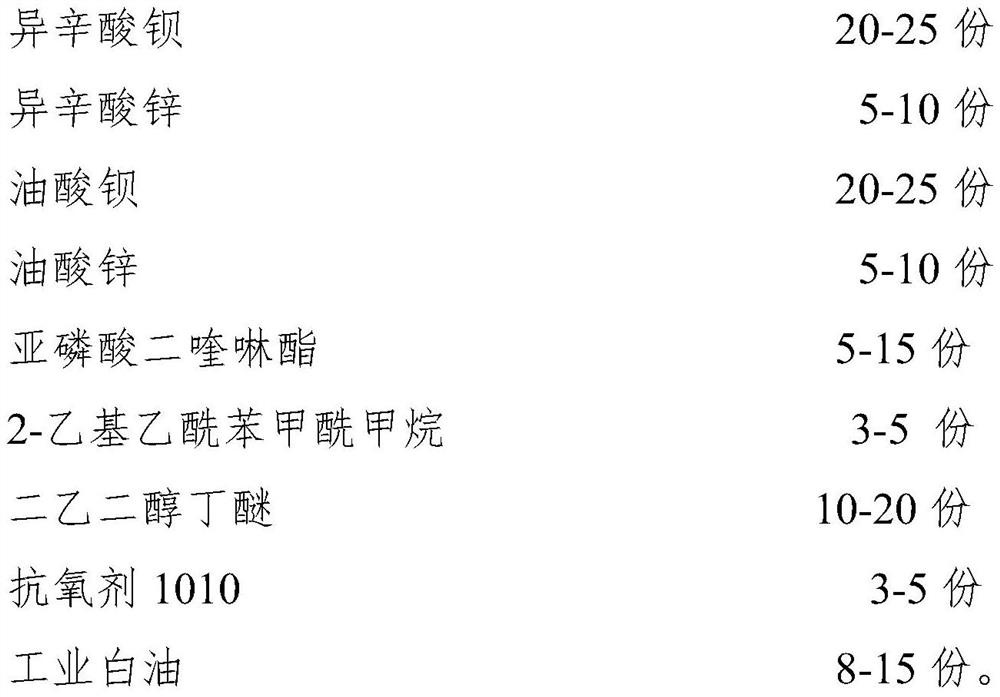

[0026] The formula composition of the liquid barium zinc stabilizer of embodiment 1-4 is as follows table:

[0027]

[0028]

[0029] The preparation method of the liquid barium zinc stabilizer of example 1-4 carries out according to the following steps:

[0030] (1) Add barium isooctano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com