Thin film master batch with low-precipitation and yellowing-resisting special functions and preparation method thereof

A kind of yellowing-resistant and special technology, which is applied in the field of polymer material processing and modification, can solve the problems of product deterioration, darkening, yellowing and other problems, and achieve good heat-sealing strength, improved efficiency, and good precipitation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

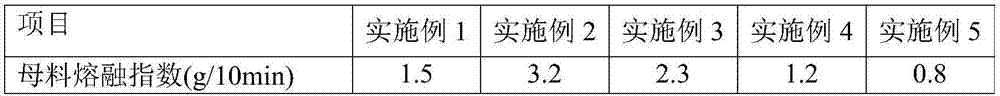

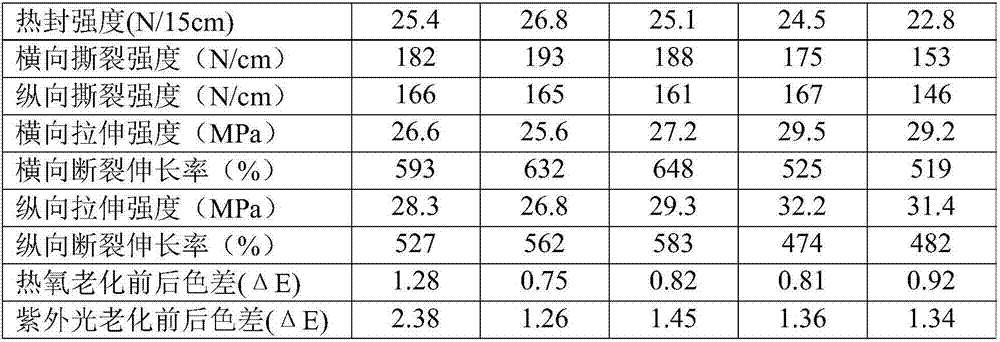

Examples

Embodiment 1

[0044] Weighing and batching according to the following formula: 20 parts of low density polyethylene, 5 parts of POP plastic elastomer, 65 parts of titanium dioxide, 3 parts of ethylene-glycidyl methacrylate, 0.5 parts of antioxidant 1790, 0.5 parts of antioxidant 626 1 part, 1 part of UV stabilizer 944, 5 parts of molecular sieve adsorbent.

[0045] The above-mentioned components are pre-mixed uniformly with a mixer, and then mixed with a double-rotor continuous mixing equipment, extruded and granulated to obtain a film masterbatch with special functions of low precipitation and yellowing resistance. The mixing temperature is 170°C and the rotor speed is 600rpm. , the temperature of the extruder is 180° C., and the rotational speed of the main engine is 400 rpm.

[0046] The prepared low-separation and anti-yellowing film masterbatch and linear low-density polyethylene (LLDPE7042) and low-density polyethylene (LDPE 1F7B) are blown at a ratio of 15:75:10, and the blown film t...

Embodiment 2

[0048]Weighing and ingredients according to the following formula: 15 parts of low-density polyethylene, 15 parts of POP plastic elastomer, 45 parts of titanium dioxide, 3 parts of phthalocyanine blue, 5 parts of ethylene-glycidyl methacrylate, 5 parts of antioxidant 1790 , 5 parts of antioxidant 626, 9442 parts of ultraviolet light stabilizer, 5 parts of molecular sieve adsorbent.

[0049] The above-mentioned components are pre-mixed uniformly with a mixer, and then banbury-mixed with a banbury mixer and extruded and granulated with a single-screw extruder to obtain a film masterbatch with special functions of low precipitation and yellowing resistance. The temperature of the extruder is set at 160 °C, 180°C, 180°C, 180°C, the host speed is 400rpm.

[0050] The prepared low-separation and anti-yellowing film masterbatch and linear low-density polyethylene (LLDPE7042) and low-density polyethylene (LDPE 1F7B) are blown at a ratio of 15:75:10, and the blown film temperature is 1...

Embodiment 3

[0052] Weighing and batching according to the following formula: 22 parts of linear low density polyethylene, 10 parts of POP plastic elastomer, 35 parts of titanium dioxide, 2.5 parts of carbon black, 3 parts of ethylene-glycidyl methacrylate, 1 part of antioxidant 1790 , 1 part of antioxidant 627, 2.5 parts of ultraviolet light stabilizer 944, 2.5 parts of external light stabilizer 622, 0.5 part of molecular sieve adsorbent, 10 parts of calcium carbonate, and 10 parts of barium sulfate.

[0053] The above-mentioned components are pre-mixed uniformly with a mixer, and then extruded and granulated with a twin-screw extruder to obtain a film masterbatch with special functions of low precipitation and yellowing resistance. The temperature of the extruder is set at 160°C, 180°C, 180°C, 180°C, host speed 400rpm.

[0054] The prepared low-separation and anti-yellowing film masterbatch and linear low-density polyethylene (LLDPE7042) and low-density polyethylene (LDPE 1F7B) are blown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com