Flame-retardant TPE sheath material, and preparation method and application thereof

A sheath material and flame retardant technology, applied in the field of flame retardant TPE sheath material and its preparation, can solve the problems of low mechanical properties, reduced comprehensive performance, poor resilience, etc., and achieve good mechanical properties and high flame retardant properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention also discloses a preparation method of the flame-retardant TPE sheath material, which specifically comprises the following steps:

[0042] (1) After stirring SEBS and filling oil at low speed for 1 to 3 minutes according to the formula ratio, let it stand for use;

[0043] (2) Add raw material POE, polypropylene, organic flame retardant, flame retardant synergist, anti-scratch agent, antioxidant and processing aid to the silo, and set the program according to the proportion of raw material components, and automatically After batching and mixing, melt extrusion and granulation, and finally the flame retardant TPE sheath material is obtained.

[0044] In order to further realize the technical effect of the present invention, the melt extrusion granulation process in step (2) is specifically as follows: the raw materials are added to the twin-screw extruder through an automatic weight loss weighing scale for melting and mixing, and then extruded through a sin...

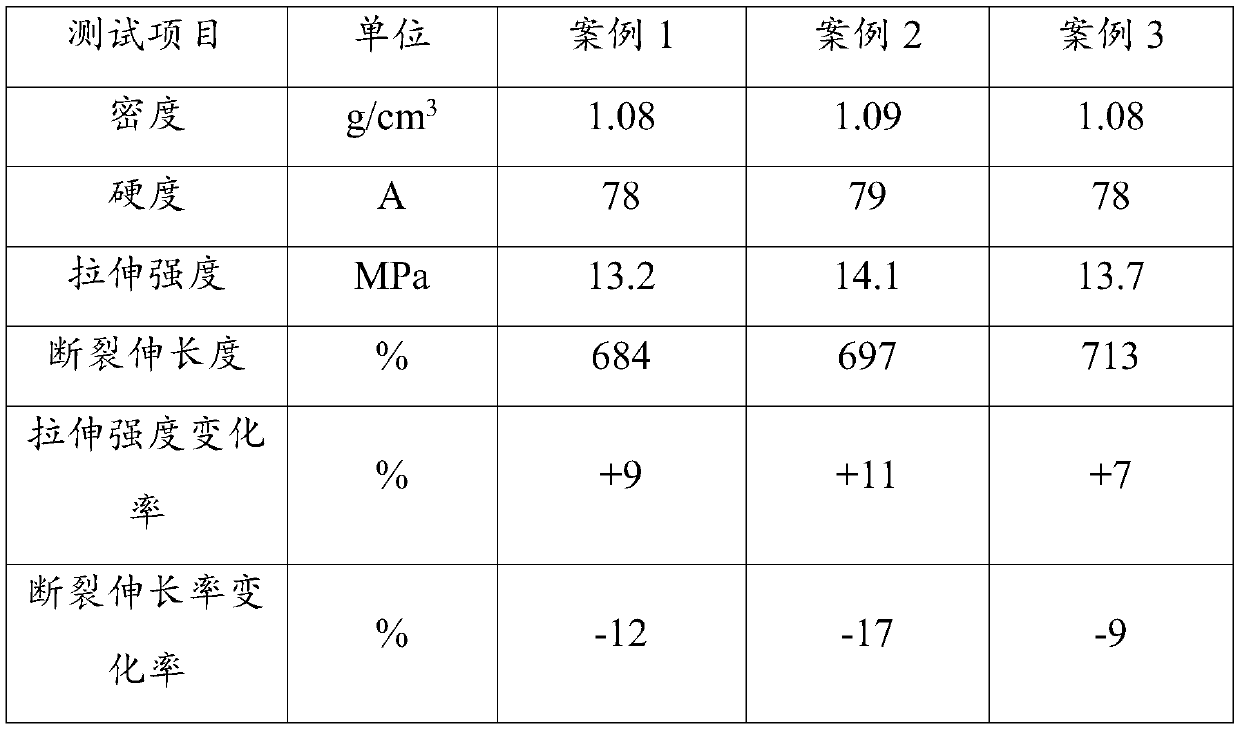

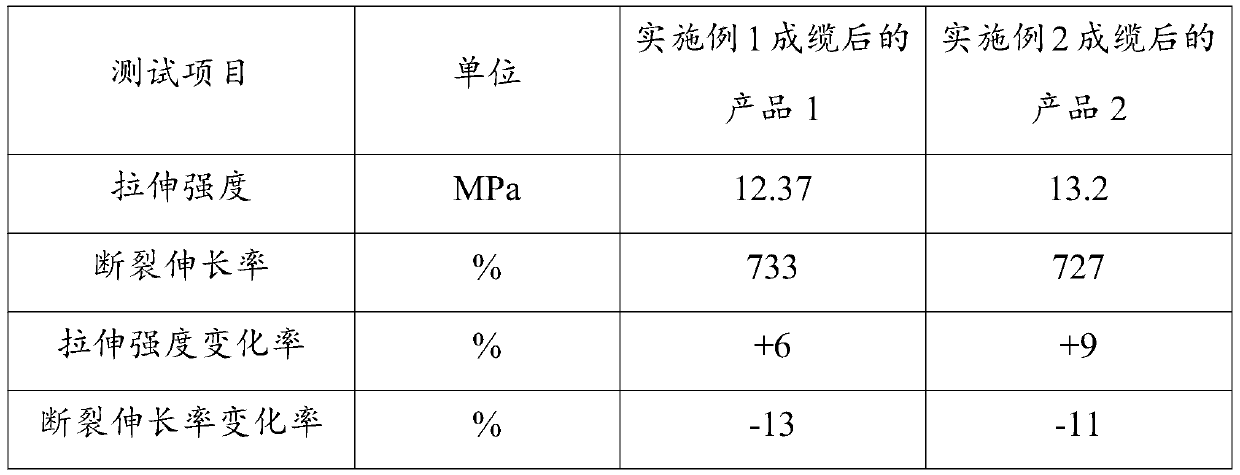

Embodiment 1

[0048] A flame retardant TPE sheathing material, calculated in parts by weight, is prepared from the following raw materials: 30 parts of SEBS, 10 parts of POE, 10 parts of polypropylene, 30 parts of aluminum hypophosphite, 5 parts of melamine cyanurate, 5 parts of nano silica, 5 parts of anti-scratch agent, 0.3 part of antioxidant, 10 parts of filler oil, 0.5 part of EBS, balance of deionized water.

Embodiment 2

[0050] A flame retardant TPE sheathing material, calculated in parts by weight, is prepared from the following raw materials: 30 parts of SEBS, 10 parts of POE, 10 parts of polypropylene, 20 parts of aluminum hypophosphite, and 10 parts of aluminum diethylphosphinate. parts, 7 parts of melamine cyanurate, 3 parts of nano calcium carbonate, 5 parts of anti-scratch agent, 0.3 parts of antioxidant, 10 parts of filler oil, 2 parts of silicone, and the balance of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com