Flame-retardant photodiffusion polypropylene composite material for LED and workpiece thereof

A technology of composite materials and polypropylene, which is applied in the field of flame-retardant light-diffusing polypropylene composite materials and its parts for LEDs. It can solve the problems of not having light-diffusing effect and not solving the problem of flame retardancy, and achieves excellent light transmittance. , excellent coating, fine crystal nucleus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

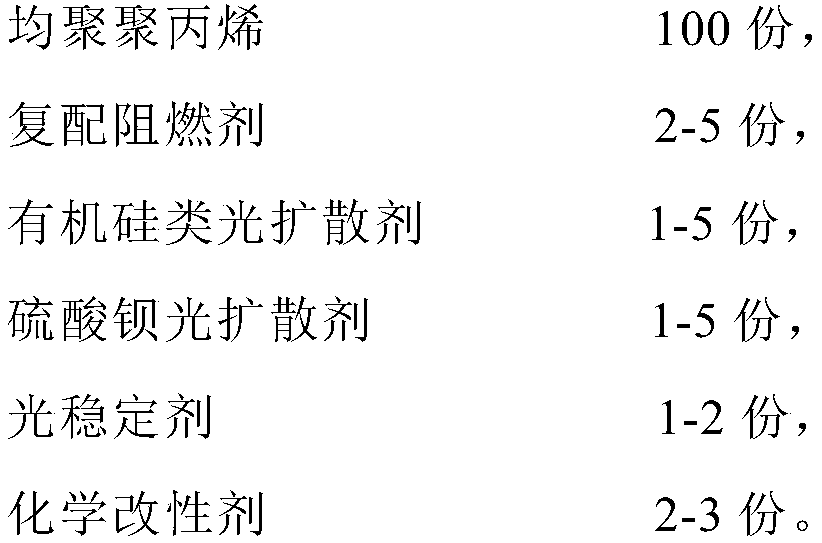

[0033] This embodiment relates to a flame-retardant light-diffusing polypropylene composite material for LEDs, which is prepared according to the following components and parts by weight:

[0034]

[0035] All the raw materials are put into a high mixer and mixed for 2-5 minutes, and then discharged; then the mixed material is put into a twin-screw extruder to extrude and granulate to prepare a flame-retardant light-diffusing polypropylene composite material for LED. Wherein, the process temperature is 200° C., and the screw speed is 400 rpm.

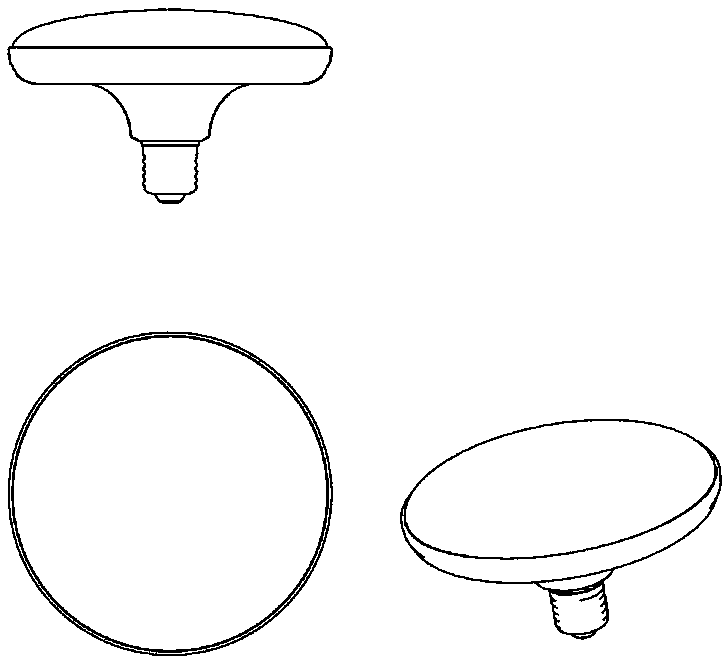

[0036] The LED lamp parts made of the flame-retardant light-diffusing polypropylene composite material for LEDs of this embodiment are as follows: figure 1 shown.

Embodiment 2

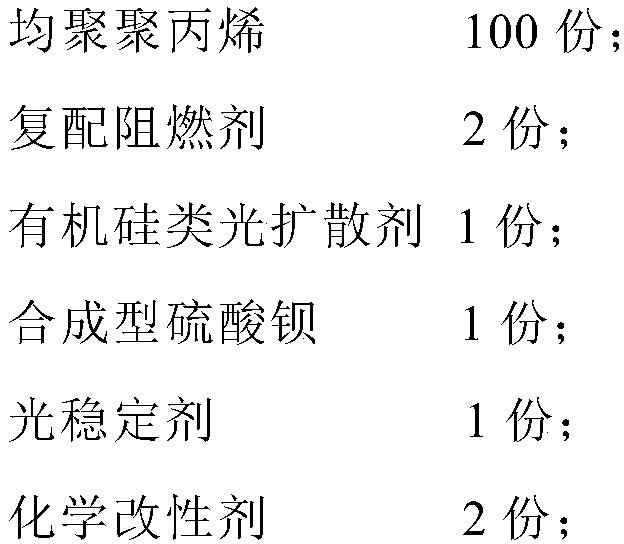

[0038] This embodiment relates to a flame-retardant light-diffusing polypropylene composite material for LEDs, which is prepared according to the following components and weight percentages:

[0039]

[0040] All the raw materials are put into a high mixer and mixed for 2-5 minutes, and then discharged; then the mixed material is put into a twin-screw extruder to extrude and granulate to prepare a flame-retardant light-diffusing polypropylene composite material for LED. Wherein, the process temperature is 190° C., and the screw speed is 300 rpm.

Embodiment 3

[0042] This embodiment relates to a flame-retardant light-diffusing polypropylene composite material for LEDs, which is prepared according to the following components and weight percentages:

[0043]

[0044] All the raw materials are put into a high mixer and mixed for 2-5 minutes, and then discharged; then the mixed material is put into a twin-screw extruder to extrude and granulate to prepare a flame-retardant light-diffusing polypropylene composite material for LED. Wherein, the process temperature is 180° C., and the screw speed is 350 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com