Weather-proof environment-friendly flame-retardant polymer material for flexible cable and preparation method thereof

A polymer material and flexible cable technology, applied in the direction of cables, insulated cables, conductors, etc., can solve the problems of low inkjet firmness, strong surface greasy feeling, low use temperature, etc., and achieve good miscibility and high use temperature , Improve the effect of processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

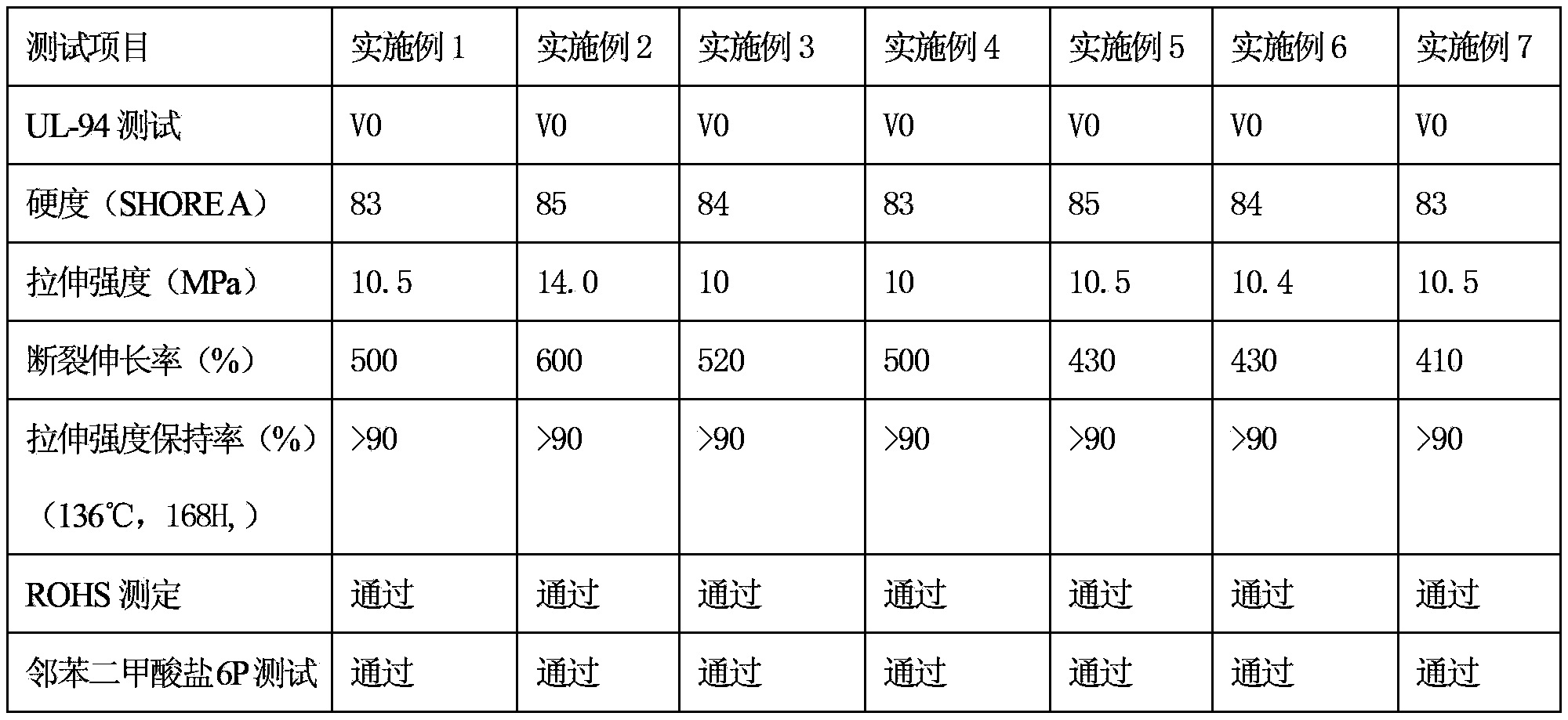

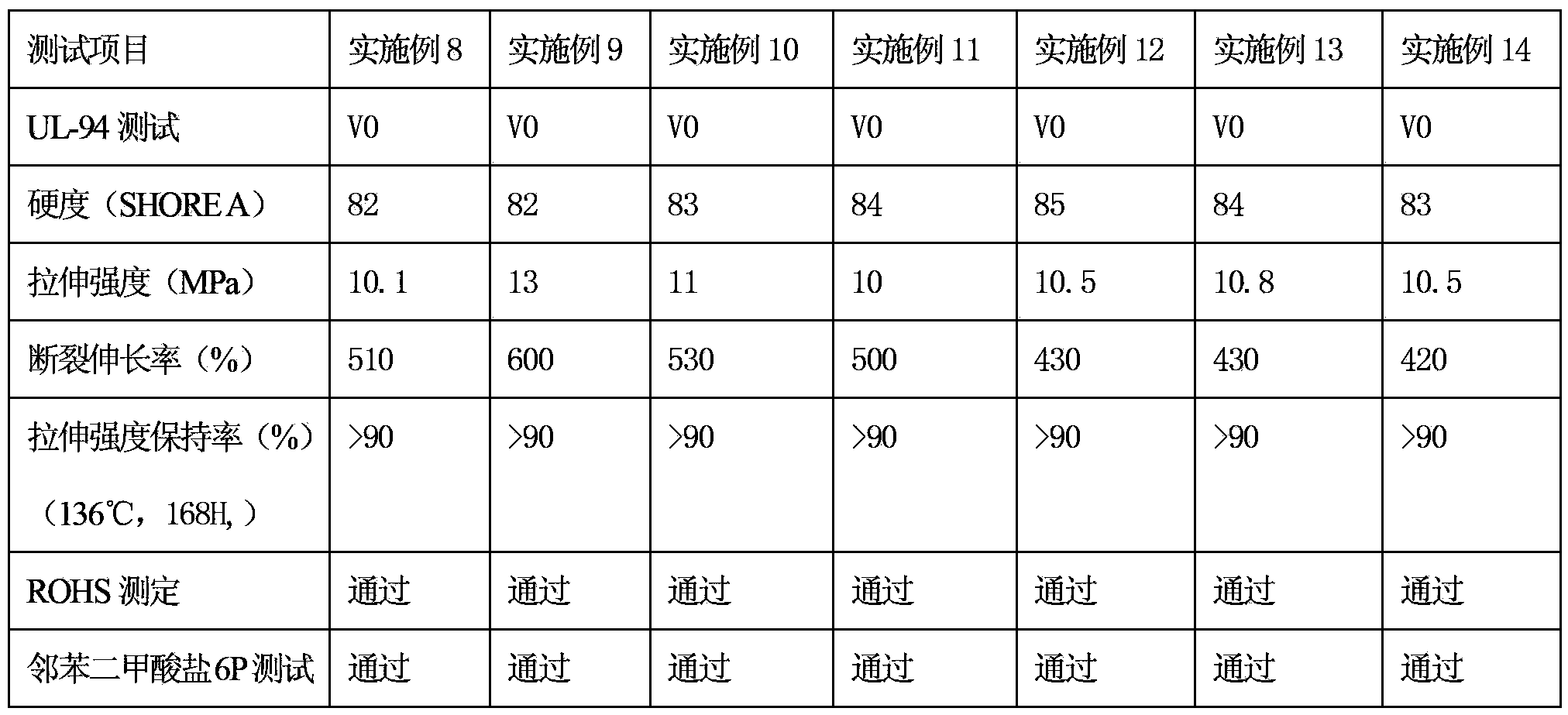

Examples

Embodiment Construction

[0109] The present invention will be further described below in conjunction with embodiment.

[0110] The various raw materials in the embodiments can be purchased from related products of multiple manufacturers, all of which are commercially available and easy to purchase.

[0111] 1. Raw material ratio

[0112] Components (number of servings)

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

110

110

110

110

110

110

110

50

SEBS

100

100

100

100

100

100

100

150

150

150

150

150

150

150

EPDM

100

100

100

100

100

100

100

Phenolic Resin

4

4

4

4

4

4

4

Decabromodiphenylethane

180

180

180

180

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com