Graphene modified rubber material with high bending strength

A technology of graphene modification and bending strength, which is applied in the field of graphene modified rubber materials with high bending strength, can solve the problems of poor flame retardancy and mechanical properties of rubber, achieve good flame retardancy, high flame retardancy, and avoid secondary The effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

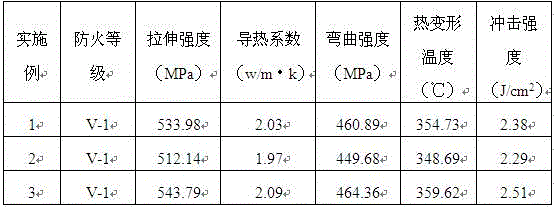

Examples

preparation example Construction

[0069] The preparation method of described high flexural strength graphene modified rubber material may further comprise the steps:

[0070] S1: Pulverize graphene and pass through a 300-500 mesh sieve to obtain powder. The obtained powder is under the conditions of magnetic field strength of 5830-6250GS, ultrasonic power of 350-480W, temperature of 42-53°C, and rotation speed of 200-300r / min , stirring for 22-36min to obtain graphene energy powder;

[0071] S2: adding a surfactant to the graphene energy powder prepared in step S1, and activating it for 0.9-1.4 hours at a temperature of 63-74° C. and a rotation speed of 120-150 r / min to obtain an activated graphene energy powder;

[0072] S3: Under nitrogen protection, add chlorohydrin rubber, neoprene rubber, tributoxyethyl phosphate, dibutyl phthalate, tris(2,4- Di-tert-butylphenyl) phosphite, acrylate stearate, maleic anhydride graft, magnesium hydroxide, kaolin, carbon black, calcium cetyl sulfonate, zinc diethyldithiocar...

Embodiment 1

[0084] A high bending strength graphene modified rubber material, in parts by weight, comprising the following raw materials: 76-104 parts of chlorohydrin rubber, 55 parts of neoprene rubber, 52 parts of graphene, 30 parts of tributoxyethyl phosphate , 20 parts of dibutyl phthalate, 22 parts of tris(2,4-di-tert-butylphenyl) phosphite, 14 parts of acrylate stearate, 20 parts of maleic anhydride graft, 5 parts of magnesium hydroxide 8 parts of kaolin, 7 parts of carbon black, 6 parts of calcium cetyl sulfonate, 8 parts of zinc diethyldithiocarbamate, 14 parts of chlorinated polyethylene, 14 parts of isoprene, 18 parts of amide wax 12 parts of polybutylene terephthalate fiber, 12 parts of simethicone, 10 parts of carbon fiber, 5 parts of polyamide fiber, 7 parts of carboxyethyl cellulose, 0.9 part of surfactant, 0.5 part of initiator , 0.7 parts of chain extender, 0.4 parts of crosslinking agent, 0.3 parts of degassing agent, 0.6 parts of leveling agent, 0.3 parts of catalyst, 0....

Embodiment 2

[0119] A high bending strength graphene modified rubber material, in parts by weight, comprising the following raw materials: 79 parts of chlorohydrin rubber, 50 parts of neoprene rubber, 43 parts of graphene, 24 parts of tributoxyethyl phosphate, ortho 16 parts of dibutyl phthalate, 15 parts of tris(2,4-di-tert-butylphenyl) phosphite, 12 parts of acrylate stearate, 16 parts of maleic anhydride graft, 4 parts of magnesium hydroxide, 7 parts of kaolin, 5 parts of carbon black, 4 parts of calcium cetyl sulfonate, 5 parts of zinc diethyldithiocarbamate, 12 parts of chlorinated polyethylene, 12 parts of isoprene, 14 parts of amide wax, 9 parts of polybutylene terephthalate fiber, 8 parts of dimethyl silicone oil, 7 parts of carbon fiber, 4 parts of polyamide fiber, 5 parts of carboxyethyl cellulose, 0.6 part of surfactant, 0.4 part of initiator, expansion 0.6 parts of chain agent, 0.3 parts of crosslinking agent, 0.3 parts of degassing agent, 0.4 parts of leveling agent, 0.2 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com