Patents

Literature

50results about How to "Feel dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

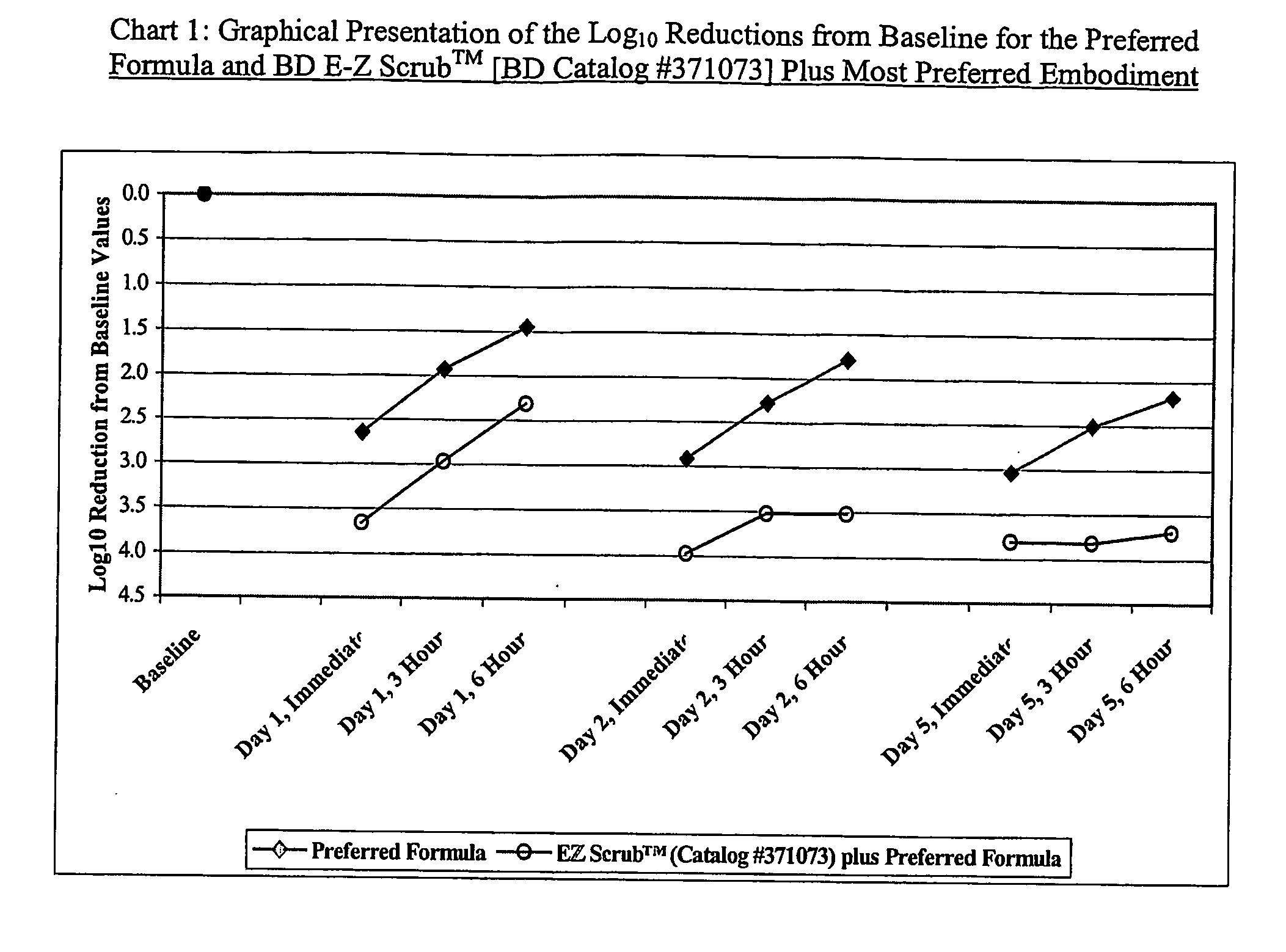

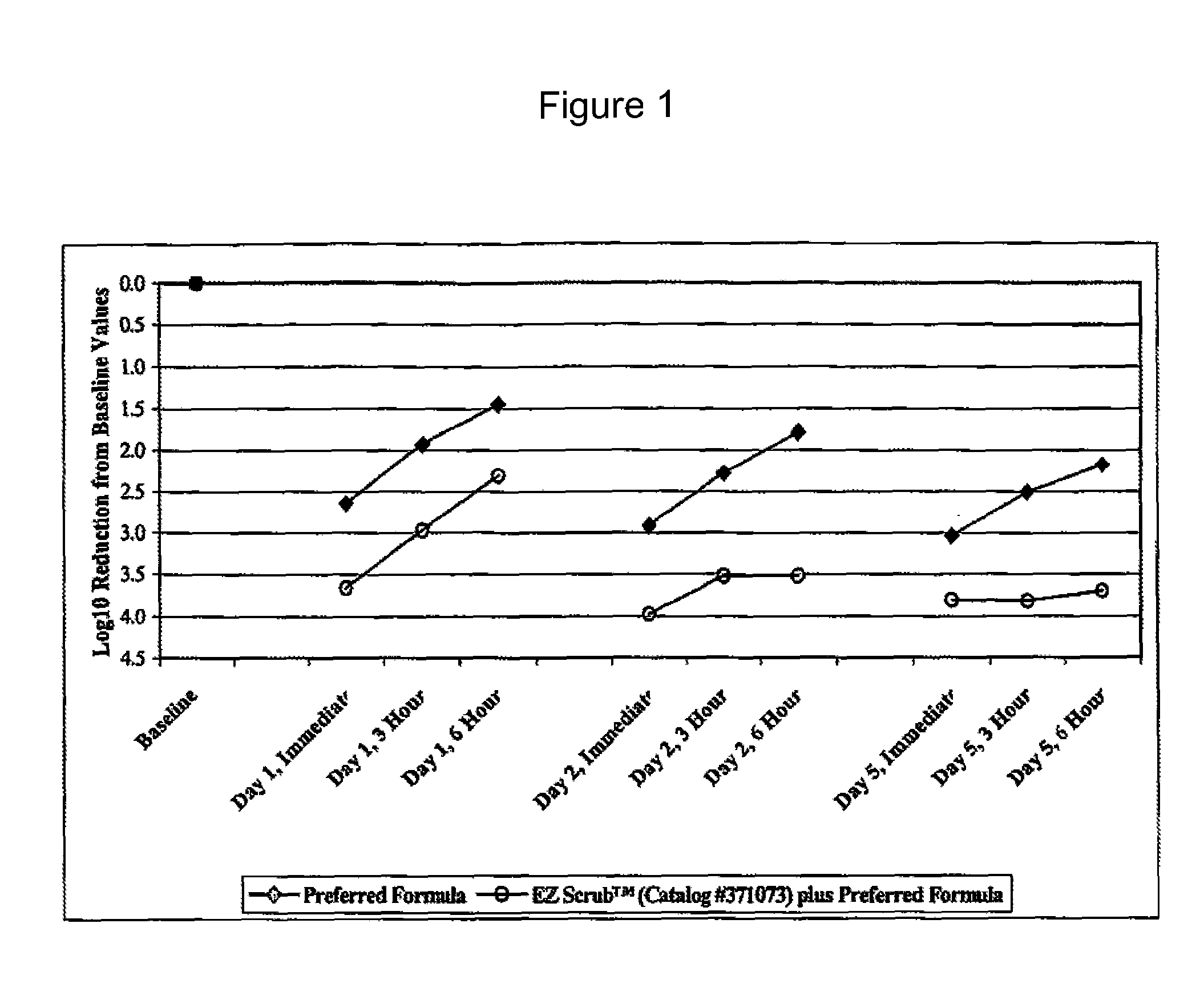

Invisible antimicrobial glove and hand antiseptic

An alcohol based hand surgical scrub, which includes cationic anti-microbial agent preservatives, cationic polymer film-forming agents and a skin emollient, and provides a long term residual, anti-microbial “invisible glove” on the skin. The composition provides an immediate reduction in bacterial microbes. The polymer system creates an invisible film on the skin following solvent evaporation. This invisible film provides a lasting anti-microbial barrier on the skin which acts to prevent microbial growth.

Owner:BECTON DICKINSON & CO

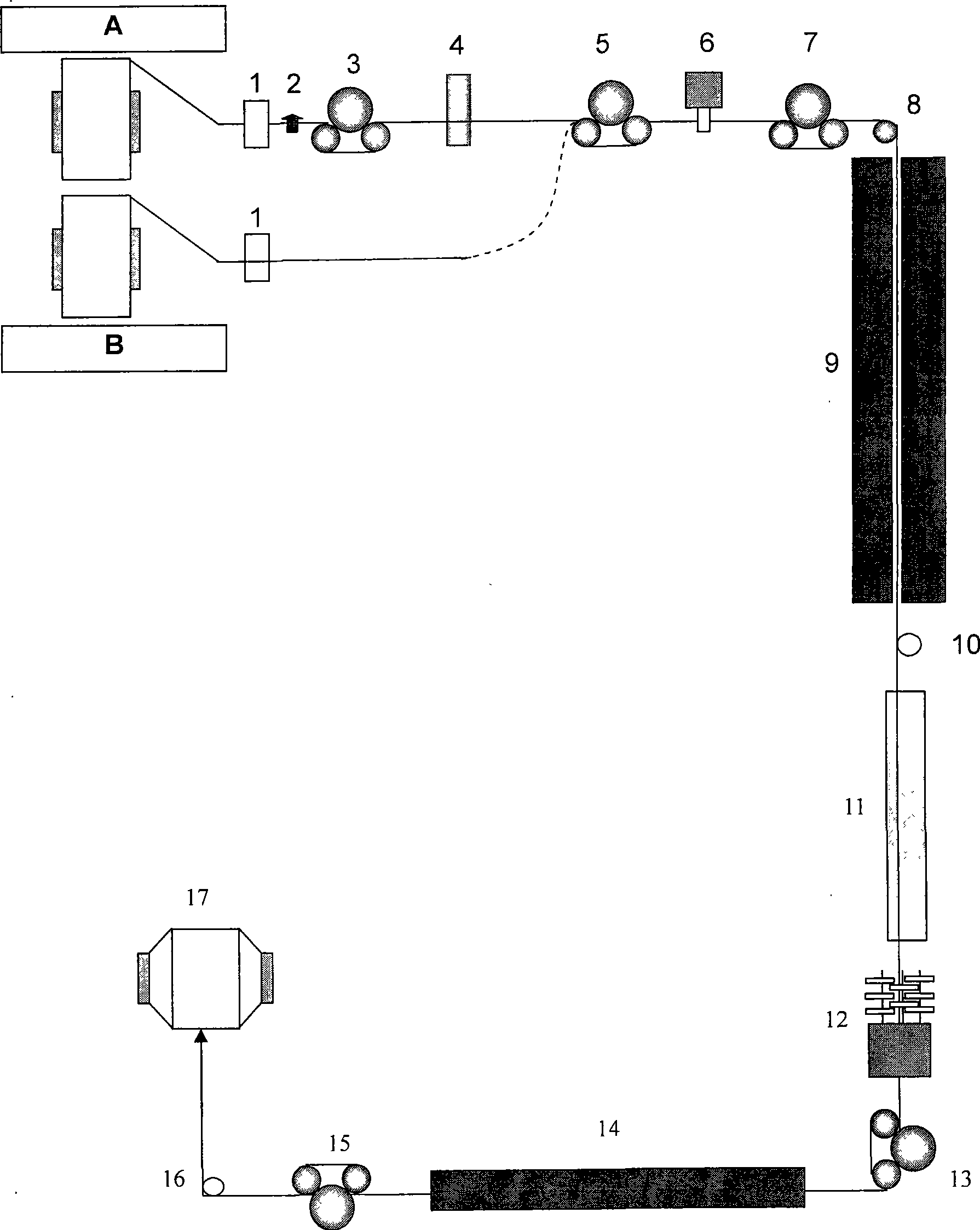

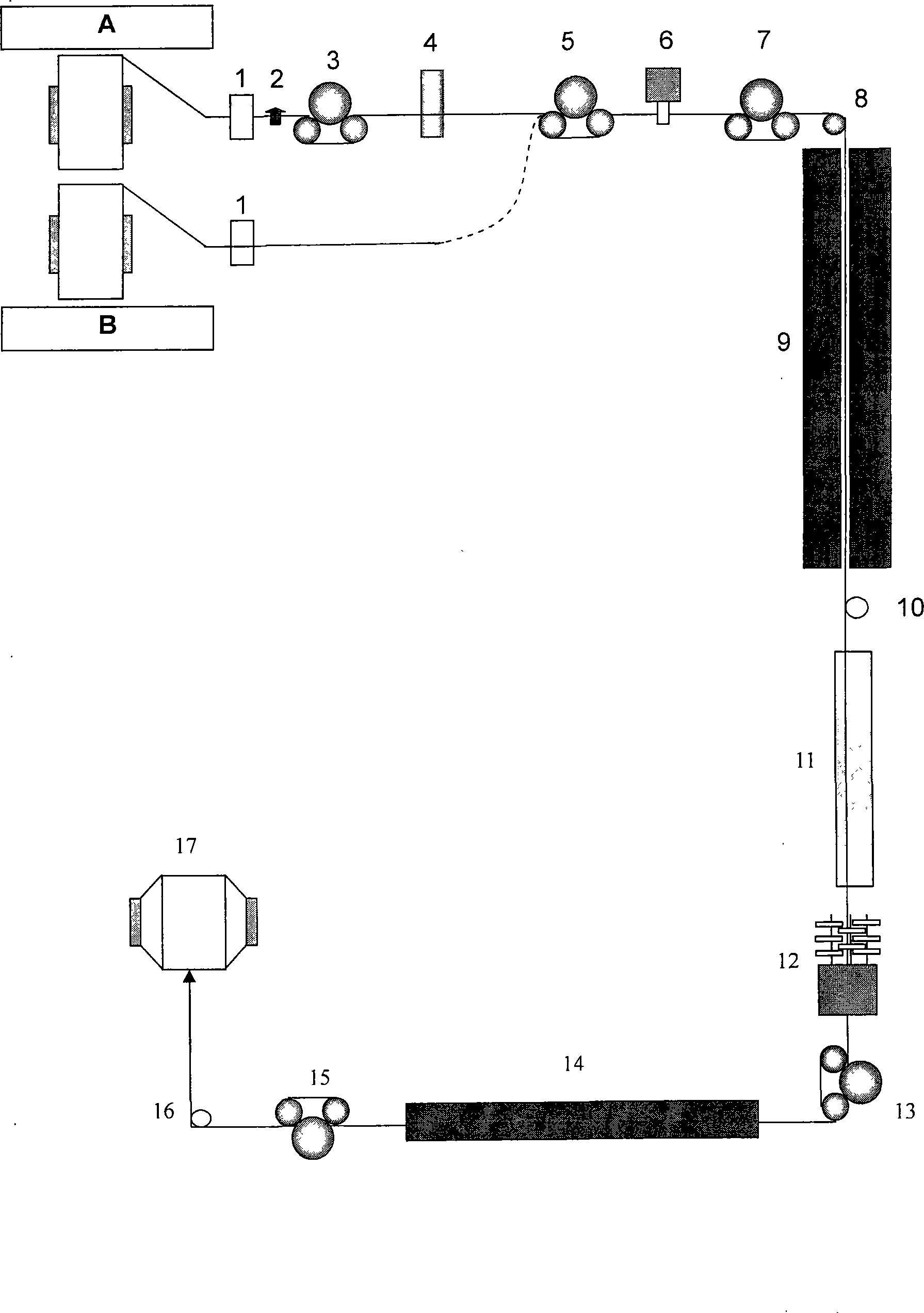

Imitation wool composite textured yam and method for producing the same

The invention discloses a wool-like composite textured yarn and a manufacturing method thereof. The composite textured yarn is provided with a core-sheath structure, and a core part and a sheath part of the composite textured yarn have different filament length differences and different extents. The manufacturing method is as follows: 2 POYs are taken as raw materials, wherein one POY raw material is heated to be stretched by a heater between a first yarn feeding roller and a second yarn feeding roller, and merged with the second POY raw material in front of the second yarn feeding roller, enters into a network nozzle between the second yarn feeding roller and a third yarn feeding roller by means of certain overfeeding, forms a network through air blowing and twisting, and is heated, stretched and textured to form the composite textured yarn. The prepared yarn has low manufacturing cost; and textile fabrics which are woven by the yarn after twisting have good wool-like effect, soft, dry and comfortable hand feeling and good rebound resilience and color emissivity after being subjected to alkali decrement, and are good fabrics of black formal dresses.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Invisible antimicrobial glove and hand antiseptic

ActiveUS7488757B2Prevent defatting effectFeel dryBiocideCosmetic preparationsAlcoholSolvent evaporation

An alcohol based hand surgical scrub, which includes cationic anti-microbial agent preservatives, cationic polymer film-forming agents and a skin emollient, and provides a long term residual, anti-microbial “invisible glove” on the skin. The composition provides an immediate reduction in bacterial microbes. The polymer system creates an invisible film on the skin following solvent evaporation. This invisible film provides a lasting anti-microbial barrier on the skin which acts to prevent microbial growth.

Owner:BECTON DICKINSON & CO

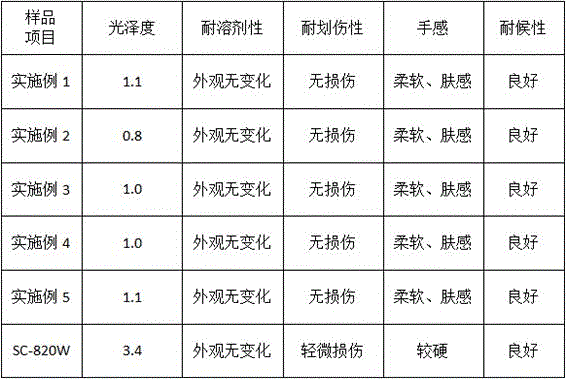

Waterborne polyurethane surface treating agent for synthetic leather and preparation method thereof

InactiveCN106634524AGood dispersionGood matte effectPolyurea/polyurethane coatingsTextiles and paperEmulsionWear resistant

The invention relates to a waterborne polyurethane surface treating agent for synthetic leather and a preparation method thereof. The waterborne polyurethane surface treating agent for the synthetic leather is formed by compounding, by weight, 40-50 parts of deionized water, 2-4 parts of silicon dioxide matting powder, 45-55 parts of waterborne polyurethane emulsion, 1.5-2.0 parts of highly-smooth organosilicon flatting agent, 2-4 parts of weak anion organosilicone wear-resistant agent, 3-5 parts of nonionic organosilicone feeling agent, 0.2-0.3 part of non-ionic waterborne defoamer and 1-2 parts of associative waterborne polyurethane thickening agent. The waterborne polyurethane surface treating agent has functional advantages of having skin touch and being matt and resistant to scratching and solvents.

Owner:LIAONING FIXED STAR FINE CHEM

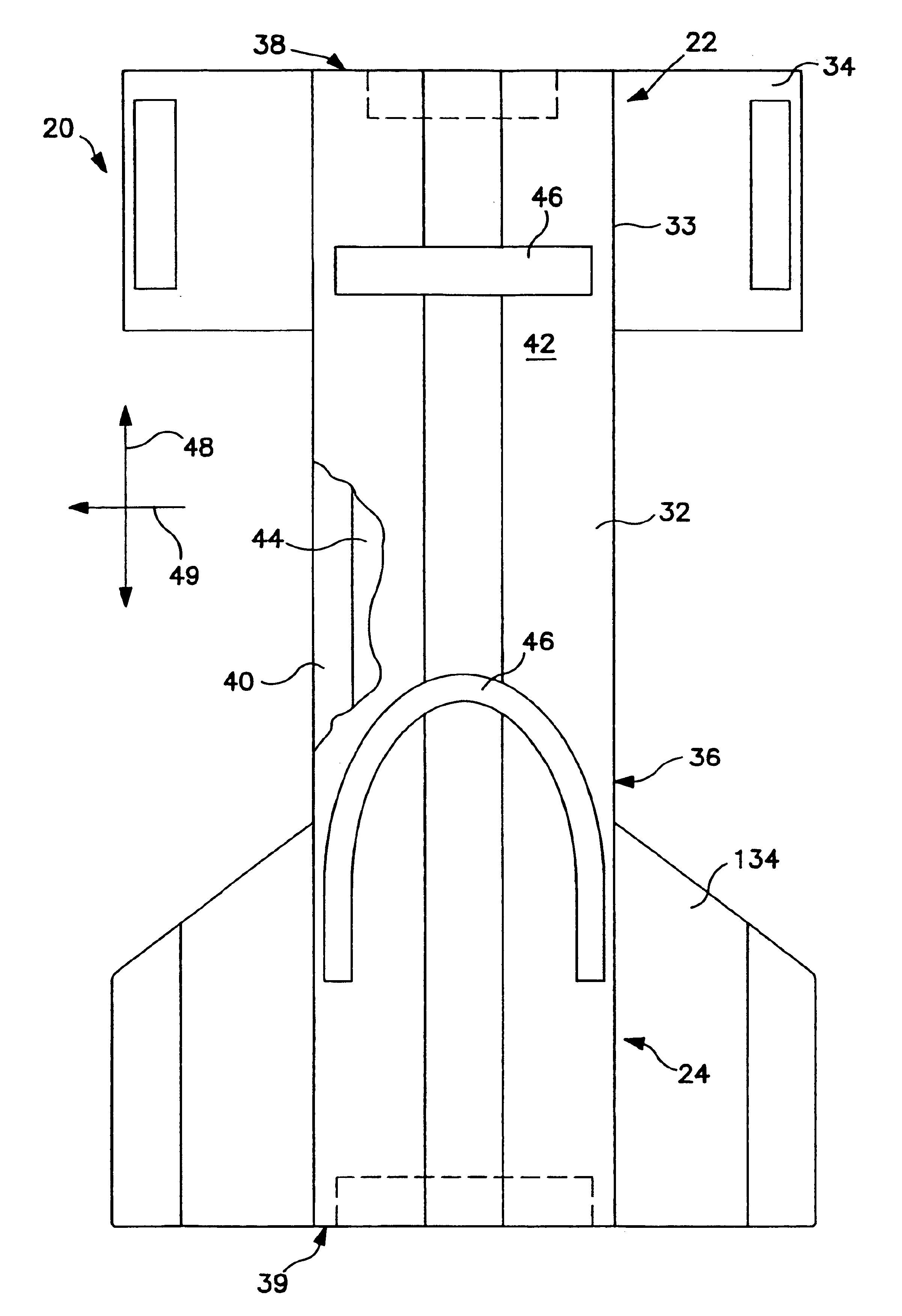

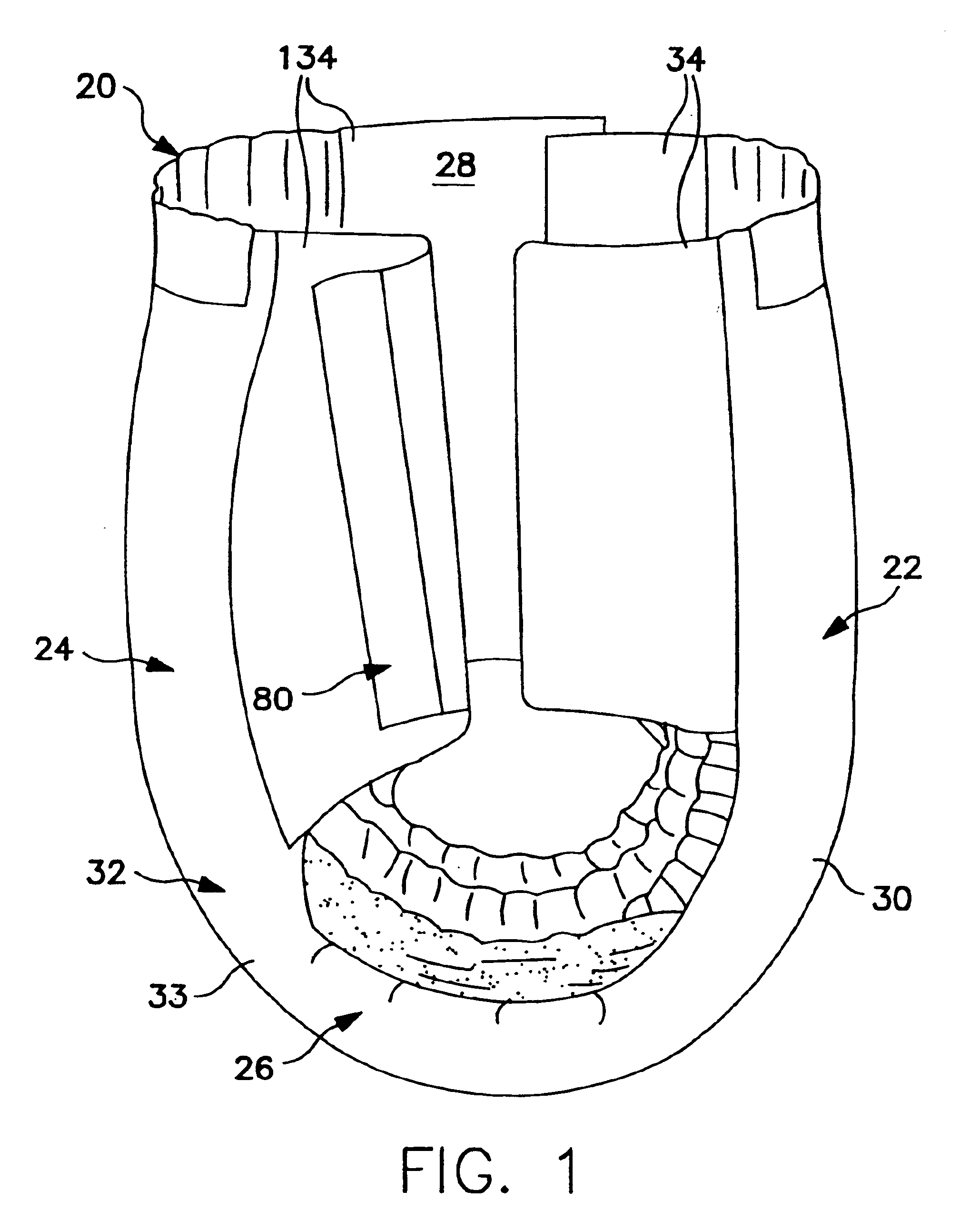

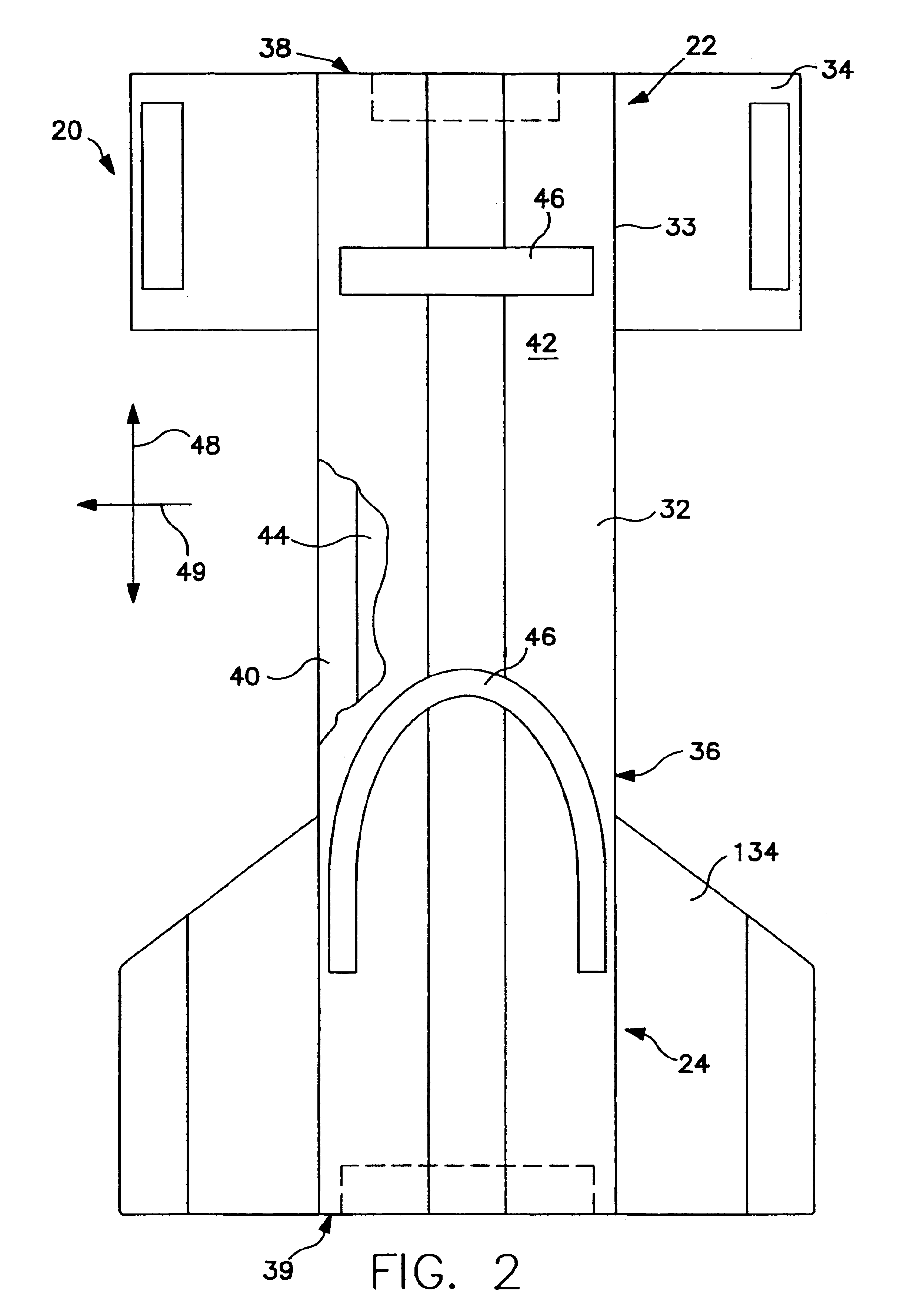

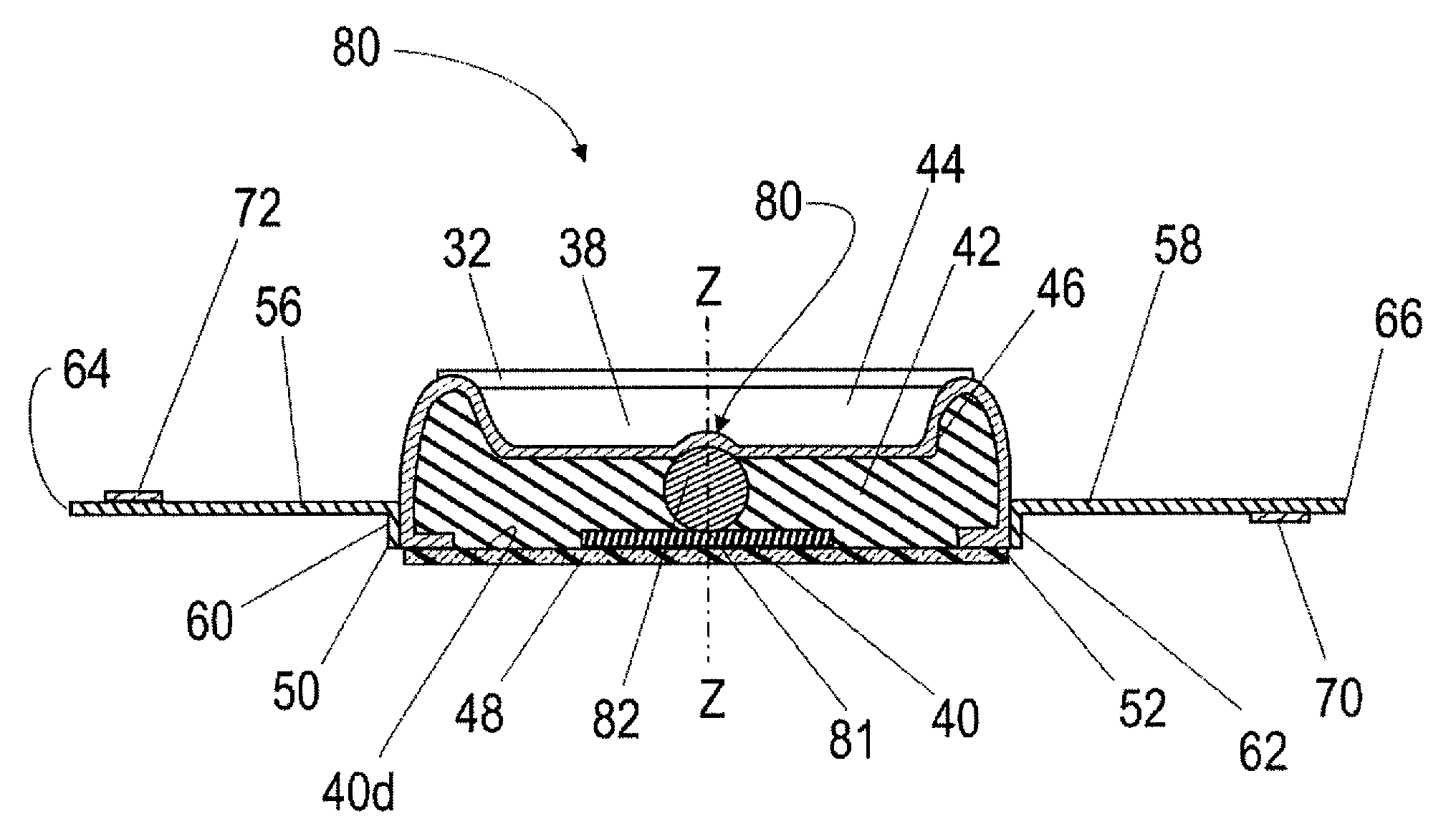

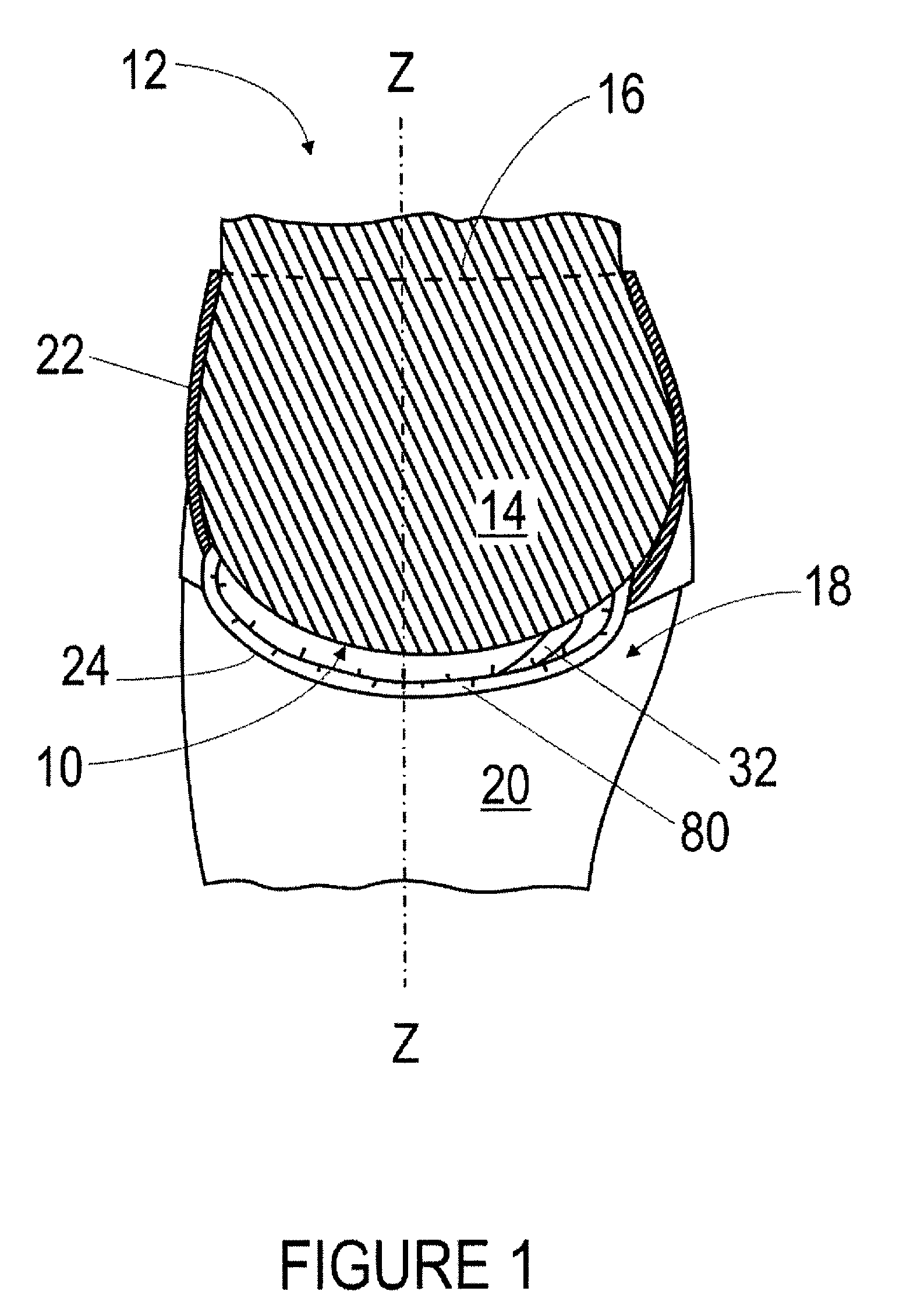

Swellable structure having a pleated cover material

InactiveUS6908458B1Soft drape characteristicGood fluid penetration propertySanitary towelsBaby linensPersonal careEngineering

A personal care absorbent article, such as an infant diaper, a training pant, an incontinence garment and the like, having at least one swellable structure attached thereto for use as a containment dam or support structure. The swellable structure having a swellable layer and a cover material adapted to expand upon swelling of the swellable layer. The pleated cover material allows the swellable layer to swell freely in a z-direction.

Owner:KIMBERLY-CLARK WORLDWIDE INC

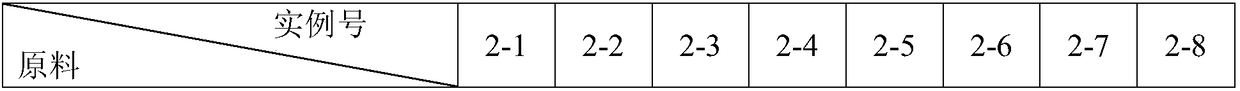

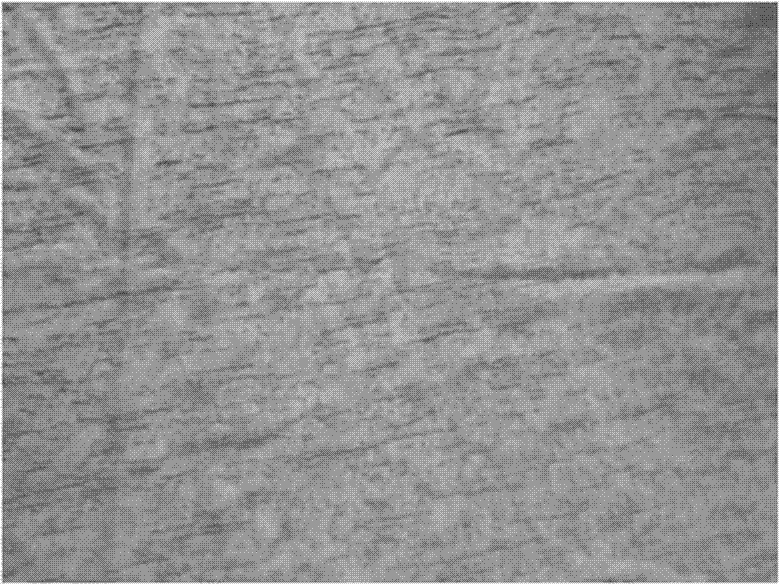

Preparation method of waterborne phosphorus-silicon flame-retardant polyurethane coating material

ActiveCN108059913AIncreased light transmittance of the coatingAddressing transparencyFireproof paintsHeat resistant fibresPolyesterCross-link

The invention discloses a preparation method of a waterborne phosphorus-silicon flame-retardant polyurethane coating material. The preparation method is characterized by comprising the following steps: adding 33-57 parts of anhydrous phosphorus-containing polyester polyol by mass, 10-29 parts of polydimethylsiloxane by mass and 5-15 parts of a solvent by mass into a reactor, uniformly stirring, adding 15-30 parts of diisocyanate by mass and 0.01-0.05 part of a catalyst by mass, heating to 60-90 DEG C, and reacting for 1-2h; adding 1-4 parts of a small molecular chain extender by mass, 2-8 parts of a hydrophilic chain extender by mass and 0.1-0.8 part of a cross-linking agent by mass, heating to 75-90 DEG C, reacting for 2-4h, cooling to room temperature, and adding a neutralizer to make pHto be 6-7; adding 1-4 parts of deionized water by mass, stirring into an emulsion, performing vacuum distillation to remove the solvent to obtain the waterborne phosphorus-silicon flame-retardant polyurethane coating material. The waterborne phosphorus-silicon flame-retardant polyurethane coating material is suitable to be used as a surface covering material for textiles, leather, wood and steelstructural buildings, and has high transparency and flexibility.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Blended yarn of acrylic fibers, linen fibers and milk protein fibers

The invention provides a blended yarn of acrylic fibers, linen fibers and milk protein fibers, which comprises the following components: 40-50 weight parts of acrylic fibers, 40-50 weight parts of linen fibers and 15-25 weight parts of milk protein fibers. The characteristics of the acrylic fibers, the linen fibers and the milk protein fibers are mutually complemented and the advantages of the three components are utilized by the blended yarn provided by the invention.

Owner:JIANGSU TONGHAI THREAD

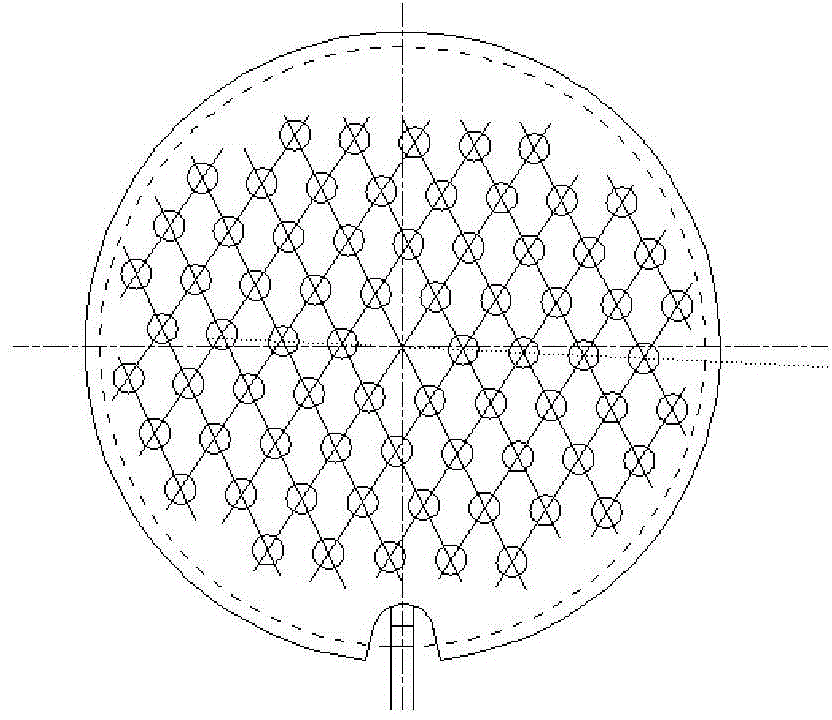

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

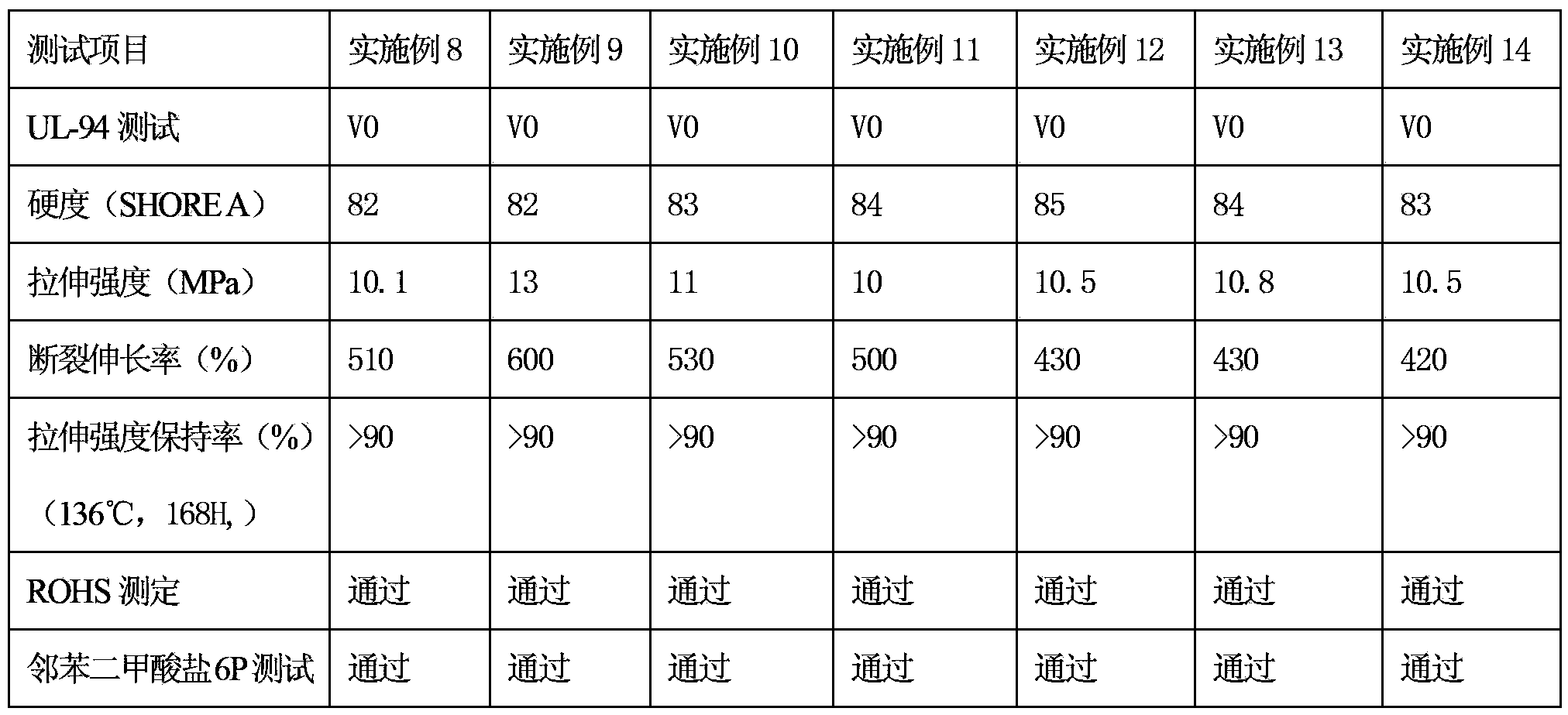

Weather-proof environment-friendly flame-retardant polymer material for flexible cable and preparation method thereof

InactiveCN104059321AWon't releaseEasy to processInsulated cablesInsulated conductorsTetrabromobisphenol AAntimony trioxide

The invention discloses a weather-proof environment-friendly flame-retardant polymer material for a flexible cable and a preparation method thereof. The polymer material comprises the following components by weight: 100 parts of a component A, 20 to 200 parts of a component B and 50 to 130 parts of a component C, wherein the component A is TPE, the component B is TPV, the component C is a fire retardant and comprises C1 and C2, C1 is one selected from the group consisting of decabromodiphenylethane, 1,2-bis(tribromophenoxy)ethane, tetrabromobisphenol A, tetrabromo-benzene anhydride, octabromo-ether, bis(tetrabromo-o-benzene-dimethyl ether imide)ethane and hexabromocyclododecane and has a particle size in a range of 10 to 30 mu m, and C2 is one selected from the group consisting of antimony trioxide, zinc borate and zinc oxide. The polymer material provided by the invention has improved processing performance and tensile strength, high usage temperature and excellent weatherability, environmental protection performance and flame resistance and is especially applicable to outdoor usage in a severe environment.

Owner:SINOTEX INVESTMENT & DEV CO LTD

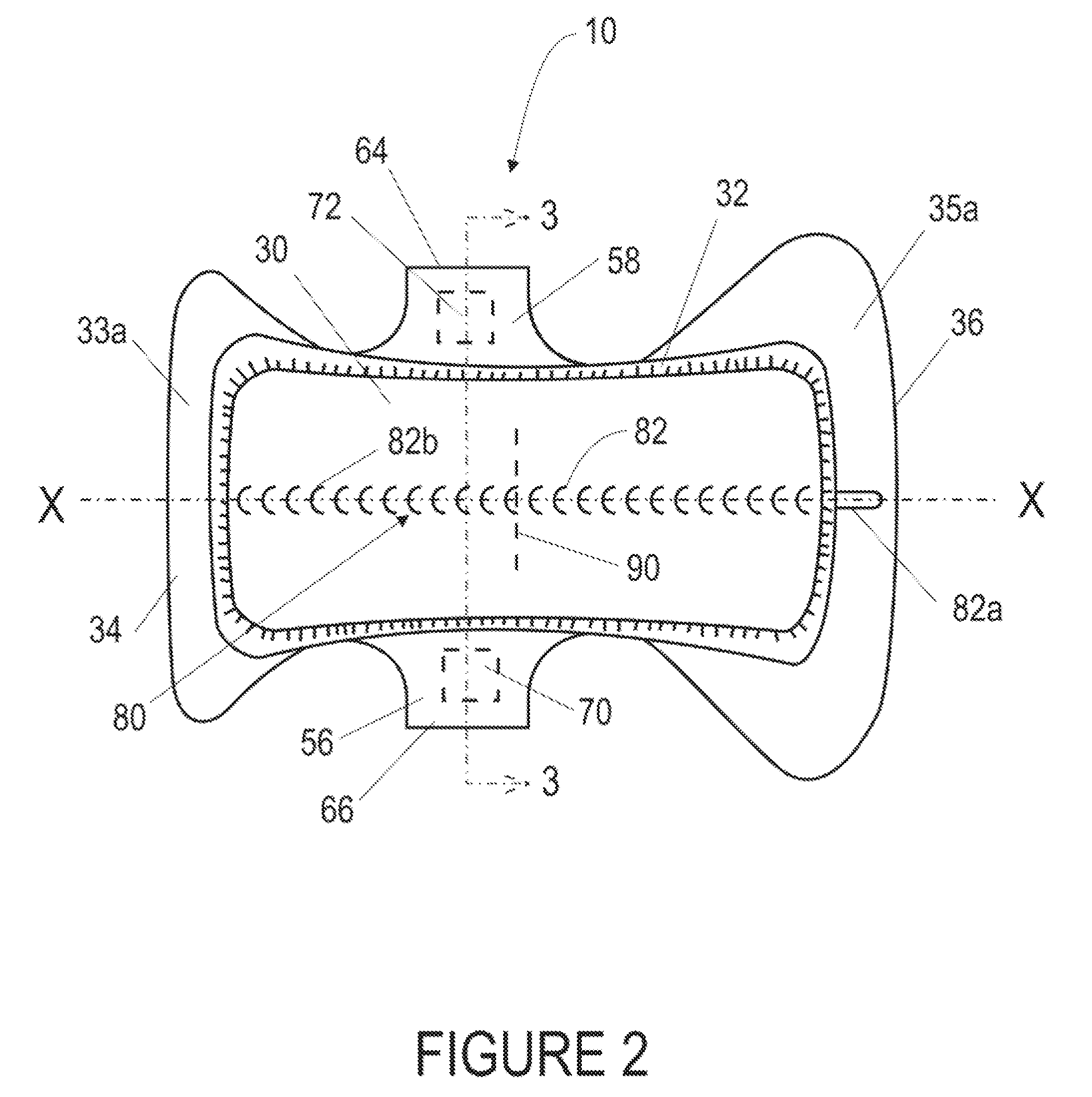

Combination pad and panty shield with raised channel

InactiveUS20100318056A1Comfortable to wearConveniently eliminate any leaksSanitary towelsBaby linensAbsorbent PadsEngineering

A combination absorbent pad and panty shield with raised channel designed to be secured to an undergarment having a crotch region with a pair of side edges includes a liquid permeable cover; a liquid-impermeable cover; a liquid-impermeable baffle having a center section and opposite end sections that form a front end and a back end of the panty shield; an absorbent disposed in the central section of the baffle and enclosed by the cover to form an absorbent pad; first and second flaps mounted to opposite sides of the baffle and sized to depend downwardly and inwardly around the crotch portion of the undergarment; and a raised projection which projects upward from the liquid permeable cover and forms a ridge that extends along a centerline x-x that extends along the length of the combination pad and panty shield and substantially bisects the width of the combination pad and panty shield.

Owner:TUCKER VALERIE +1

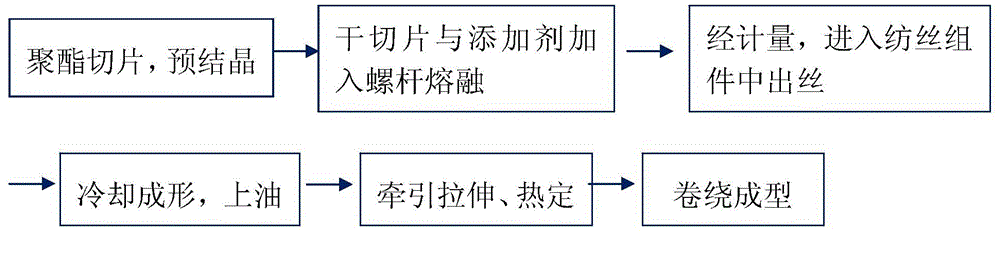

Production technology for orderly dacron bamboo node yarns of identical specification

The invention discloses a production technology for orderly dacron bamboo node yarns of identical specification. The production technology for the orderly dacron bamboo node yarns of identical specification is characterized in that the production technology comprises the following steps that (1) polyester raw materials are sliced and conveyed to a material wetting bin, and ventilation drying is carried out after pre-crystallization; (2) under the melting condition, slices enter a screw extrusion machine, and then enter a spinning box after filtration; (3) the slices enter a spinning assembly for filament production after being metered through a metering pump; (4) side air blasting cooling is carried out, and oil is applied; (5) traction, stretching and heat shaping are carried out; (6) winding and forming are carried out through a winding head, and products are formed. The identical-specification orderly dacron bamboo node yarns prepared through the production technology have super-linen-imitated and super-wool-imitated styles and effects of being moisture absorbable, breathable, dry and comfortable in hand feeling, full in touch sense and good in drapability and wearing comfortableness and the like, and have the advantages of having the super-linen-imitated and super-wool-imitated styles and effects and being good in function and performance, obvious in cost performance and the like.

Owner:ZHONGRUN SCI & TECH

Skin collagen production-promoting agent

InactiveUS20130225497A1Loss of elasticityGood effectCosmetic preparationsPeptide/protein ingredientsBULK ACTIVE INGREDIENTAcidic amino acids

A skin collagen production-promoting agent includes a milk protein fraction having following properties (a) to (c) as an active ingredient: (a) being derived from milk, (b) containing proteins having a molecular weight determined by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) of 6000 to 150,000 daltons, and (c) containing 12 to 14 wt % of basic amino acids with respect to the constituent amino acid composition, and having a basic amino acid / acidic amino acid ratio of 0.5 to 0.7.

Owner:SNOW BRAND MILK PROD CO LTD

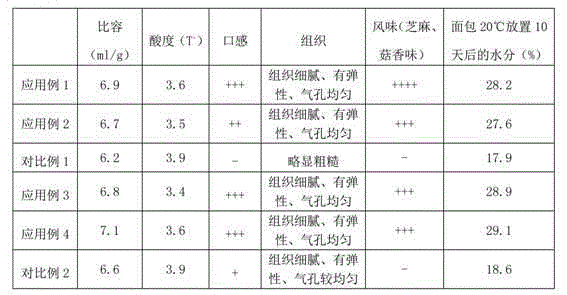

Flour improver and application thereof

The invention discloses a flour improver and application thereof in bread making. The flour improver comprises the components in percentage by weight of 70-73% of soybean isolate protein culture, 20-25% of wheat bran culture and the balance of konjak powder. The additive amount of the improver in the bread making is 1-2% of the weight of flour. The dough added with the improver in bread making has high tenacity and good air holding capacity and is fermentation-resistant, the well kneaded dough has dry hand feeling and large elasticity, and the machining performance of the dough is improved; the dough is largely expanded after entering an oven and is high in stiffness and fine in tissue, a made bread has large size, good flavor and soft mouth feeling, and the softness of the bread is obviously improved.

Owner:CHINA THREE GORGES UNIV

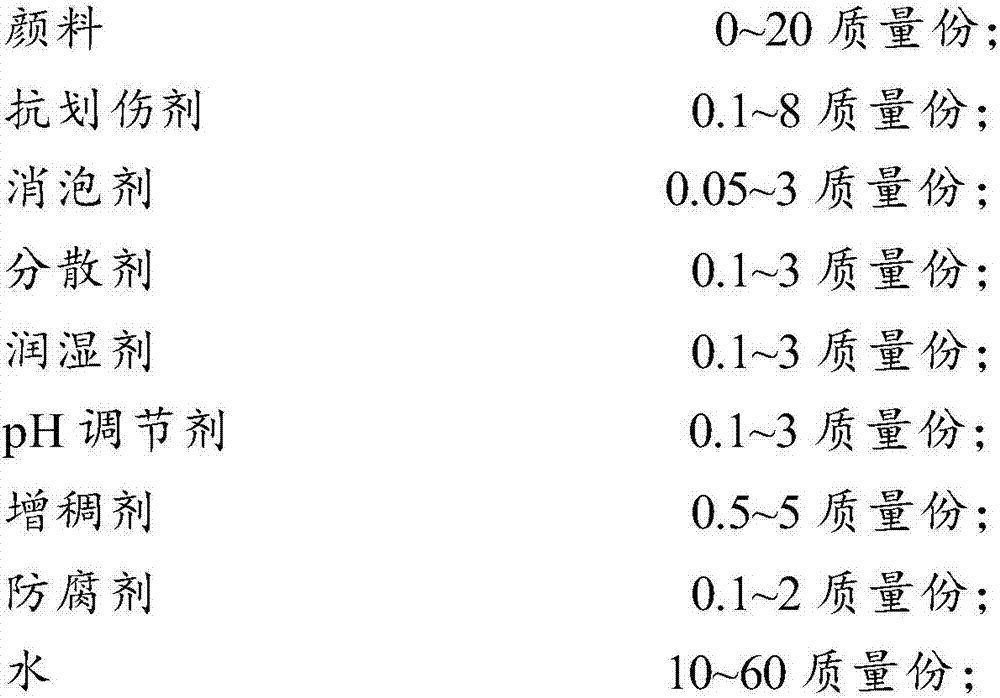

Environment-friendly water-based polyurethane paint vehicle and water-based polyurethane finish paint for courts

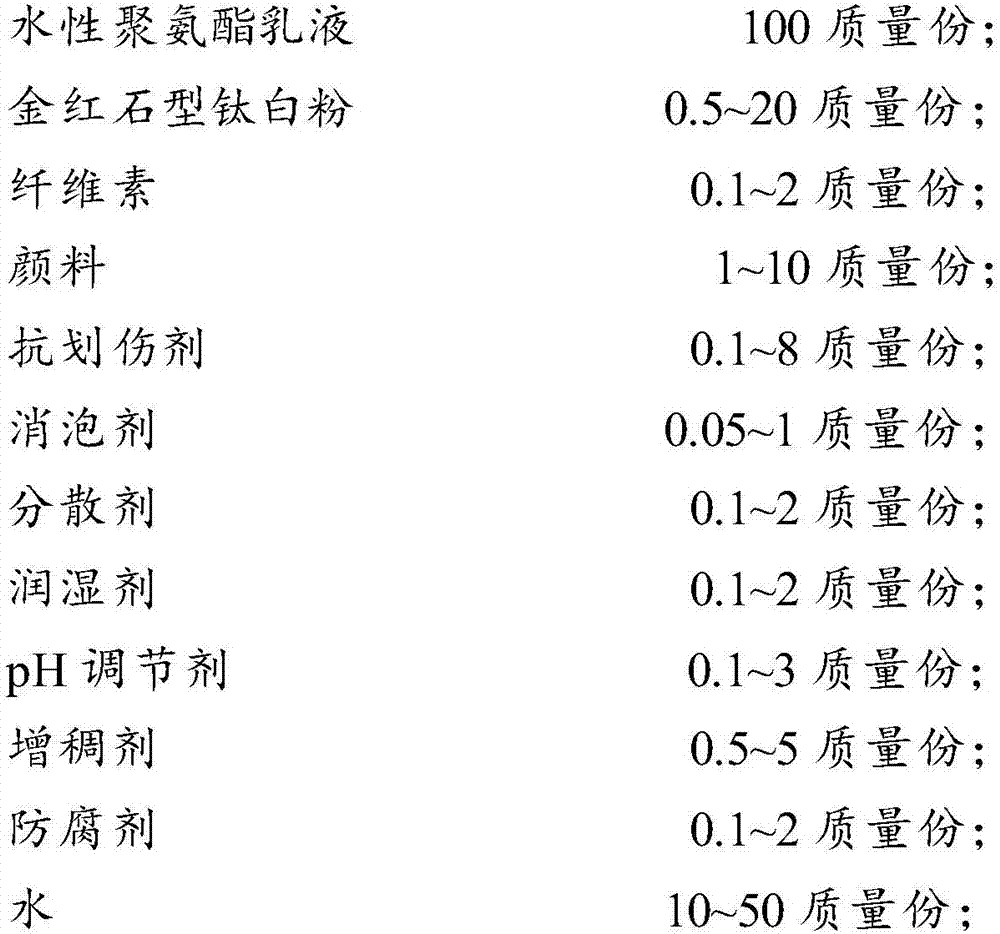

ActiveCN107216799AHigh hardnessImprove adhesionFireproof paintsPolyurea/polyurethane coatingsWater basedCellulose

The invention belongs to the field of finish paints, and particularly relates to an environment-friendly water-based polyurethane paint vehicle and a water-based polyurethane finish paint for courts. The finish paint provided by the invention is prepared from the following components: 100 parts of paint vehicle; and 2 to 20 parts of curing agent. The paint vehicle is prepared from the following components: 100 parts of water-based polyurethane emulsion; 0.5 to 40 parts of rutile titanium dioxide; 0.1 to 2 parts of cellulose; 0 to 20 parts of pigment; 0.1 to 8 part of scratch-resistant agent; 0.05 to 3 parts of defoamer; 0.1 to 3 parts of dispersant; 0.1 to 3 parts of wetting agent; 0.1 to 3 parts of pH regulator; 0.5 to 5 parts of thickening agent; 0.1 to 2 parts of preservative; and 10 to 60 parts of water. The invention provides the finish-optimizing composition and the content of each component, so the finish paint shows high hardness and adhesive force after being formed into a film, and also shows excellent high-temperature dryness and low-temperature flexibility and terrific abrasive resistance.

Owner:广州康狄夫环保科技有限公司

Preparation method of Janus type textile

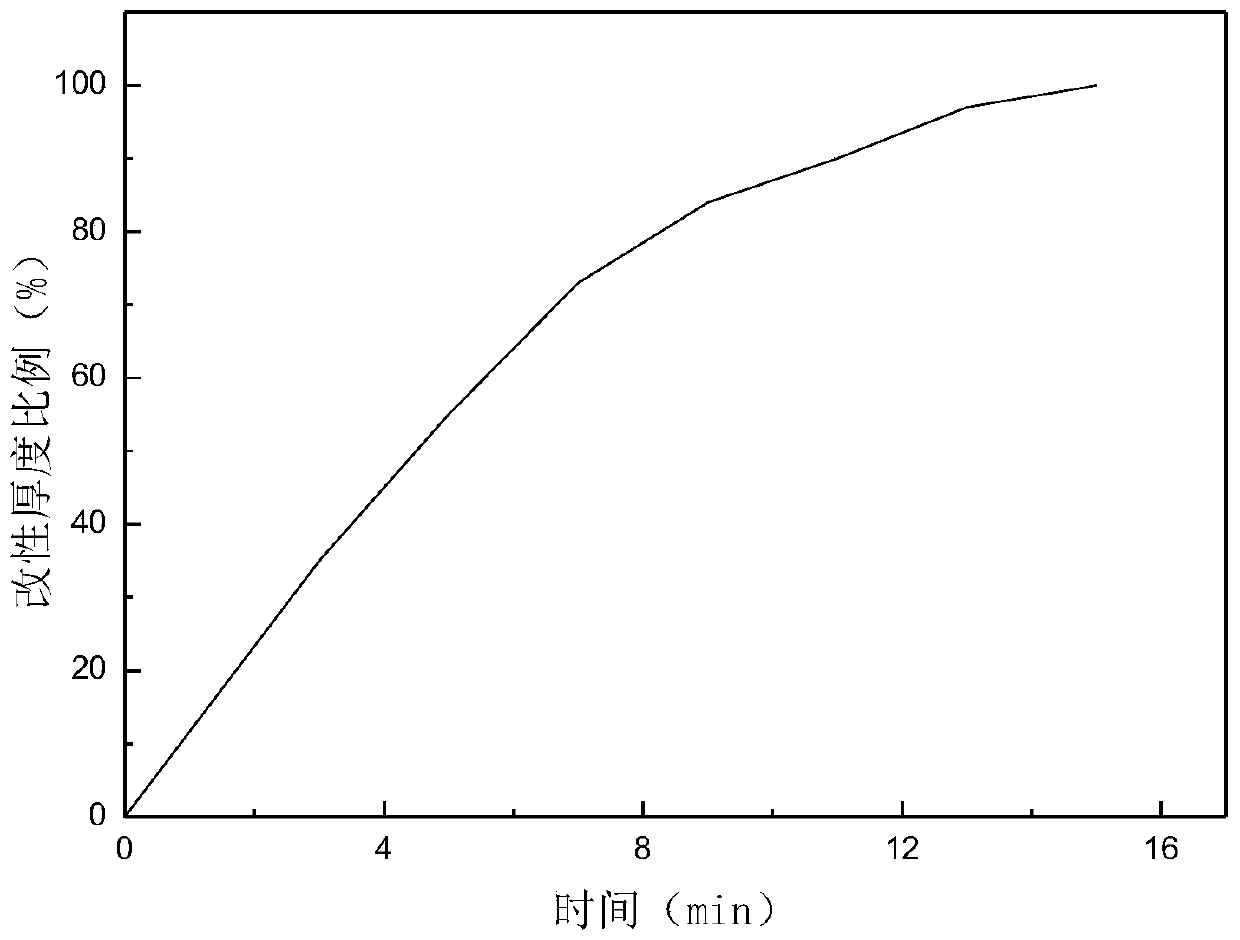

ActiveCN110983785APromote absorptionFeel dryLiquid repellent fibresTextile/flexible product manufacturePolymer scienceThiol Reagents

The invention discloses a preparation method of a Janus type textile. The preparation method of the Janus type textile comprises the following steps of dissolving 1-10 parts by mass of hydrophobic active substance, 0.2-3 parts by mass of thiol reagent, 0.01-0.2 part by mass of initiator and 0.05-2.5 parts by mass of auxiliary agent in 89.7-98.2 parts by mass of solvent to prepare a photosensitivesolution, treating the textile by using the photosensitive solution, performing ultraviolet irradiation on the textile treated by the photosensitive solution for 3-15 min, dissolving uncured photosensitive solution components on the textile treated by the photosensitive solution by using the solvent, and drying the obtained textile to obtain the Janus type textile. The invention provides a methodfor curing macromolecules on the surface of the textile by using sulfydryl / olefin click chemistry, which has the advantages of being non-selective to textile material, good in durability, controllablein modification depth, simple in preparation method, low in cost and suitable for industrial production.

Owner:INST OF ANALYSIS GUANGDONG ACAD OF SCI (CHINA NAT ANALYTICAL

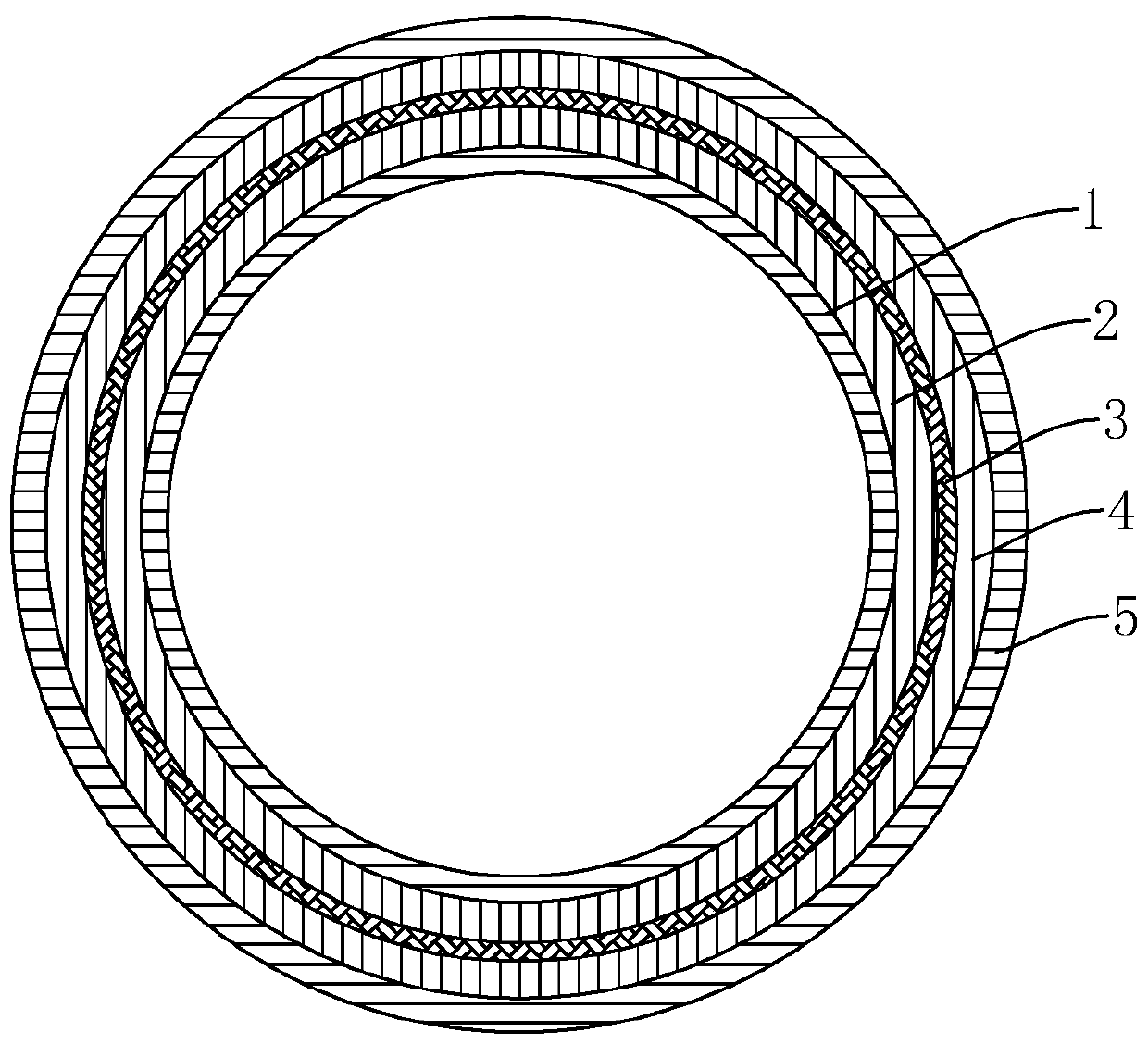

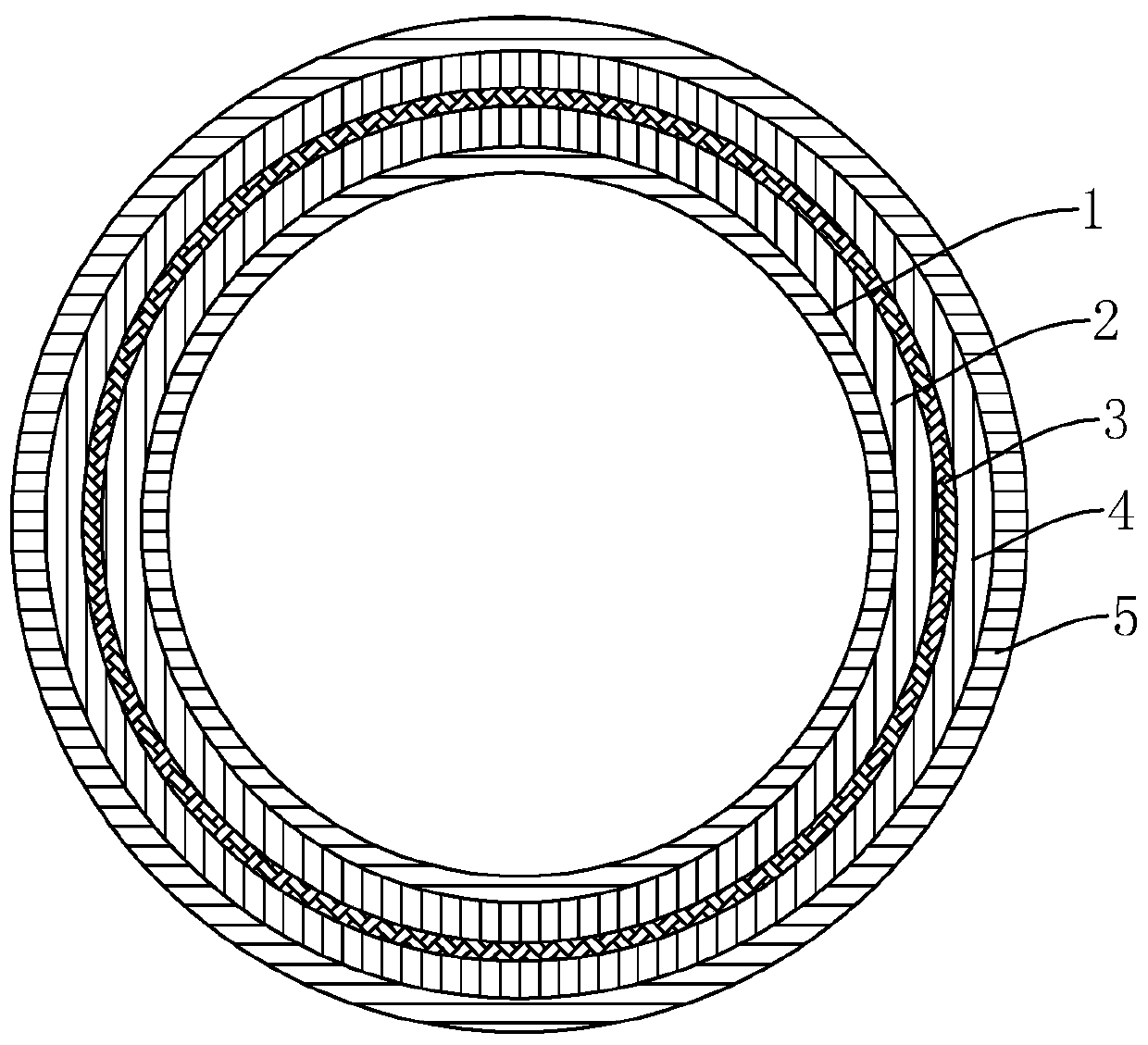

Rubber texture imitating PVC hose and production method thereof

ActiveCN111169121AFeel dryGood hygienic performanceSynthetic resin layered productsLaminationPolymer chemistrySoybean oil

The invention discloses a rubber texture imitating PVC hose and a production method thereof. The PVC hose sequentially comprises an inner layer, a net layer and an outer layer from inside to outside,wherein the inner layer and the outer layer are both made of a PVC material, and the PVC material comprises, in parts by weight, 50 parts of HPVC resin, 50 parts of matting PVC resin, 60 to 90 parts of DINCH, 4-6 parts of epoxidized soybean oil, 2-4 parts of a matting agent, 8-14 parts of a low temperature resistant modifier, 8 to 14 parts of tackifying resin, 1-1.4 parts of a stabilizer, 0-75 parts of calcium carbonate, and 0.5-1.5 parts of lubricant. Through reasonable design of the formula of the PVC material, on one hand, the prepared PVC hose meets the international standard in environmental protection property, is dry and comfortable in hand feeling, free of oil stain precipitation, tasteless and good in hygienic property, and can be used at the temperature of -20 DEG C to 80 DEG C;on the other hand, the hose is matte in appearance, good in resilience, close to a rubber hose in overall texture, easy to accept by old people and large in market space.

Owner:浙江新洁新材料科技有限公司

Skincare composition with whitening, spot-fading and anti-aging functions and cosmetic

InactiveCN106880567ASolve the slackAchieve firm and smooth effectCosmetic preparationsToilet preparationsCentella asiatica extractMedicine

The invention belongs to the technical field of daily chemical products, and particularly relates to a skincare composition with whitening, spot-fading and anti-aging functions and a cosmetic. The skincare composition is mainly prepared from the following raw materials in parts by weight: 1 to 4 parts of narcissus extract, 1 to 3 parts of algin, 0.5 to 2 parts of grape peel extract, 0.5 to 2 parts of herba centellae extract and 1 part of niacinamide. The comestic contains the skincare composition provided by the invention; the skincare composition accounts for 5 to 15 percent of the total weight of the cosmetic. The cosmetic has the obvious whitening, spot-fading and anti-aging functions, and moreover, is convenient to use; the appearance and the inner quality can be maintained to be stable for a long time.

Owner:国东启

Spandex, flax fiber and silkworm pupa protein fiber blended yarn

The invention provides a spandex, flax fiber and silkworm pupa protein fiber blended yarn. The spandex, flax fiber and silkworm pupa protein fiber blended yarn comprises, by weight, 75-85 parts of spandex, 10-20 parts of flax fibers and 5-10 parts of silkworm pupa protein fibers. The spandex, flax fiber and silkworm pupa protein fiber blended yarn has the advantages that characteristics of the spandex, the flax fibers and the silkworm pupa protein fibers are complementary to one another, and accordingly merits of the spandex, the flax fibers and the silkworm pupa protein fibers can be played.

Owner:南通市京山锦纶有限公司

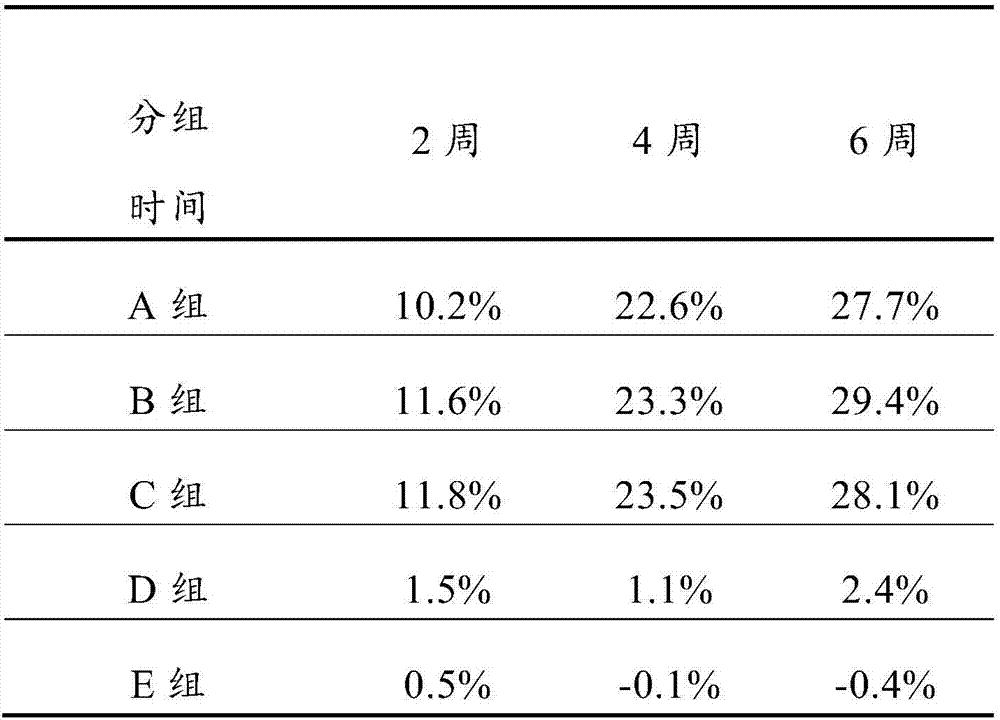

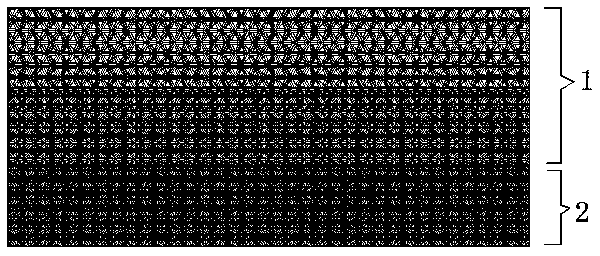

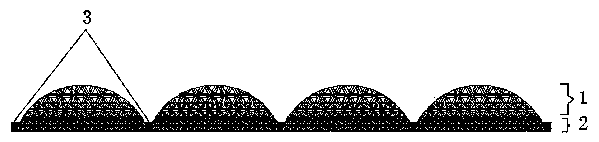

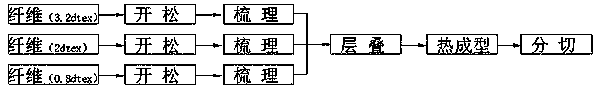

Multi-component integrally formed hot air non-woven fabric and manufacturing method thereof

A multi-component integrally formed hot air non-woven fabric comprises a plurality of layers of stacked fibers, specifically, the hot air non-woven fabric finally made of the stacked fibers is in a structure gradually becoming dense from loose from top to bottom, loose crude fibers face the skin, and dense fine fibers face a core body. Meanwhile, the invention further provides a manufacturing method of the multi-component integrally formed hot air non-woven fabric. The multi-component integrally formed hot air non-woven fabric provided by the invention has the characteristics of rapid absorption and diffusion, large absorbing area, and dry and clean contact surface.

Owner:宋志敏

Method for producing wrinkle resistant elastic whole-wool worsted face fabric

InactiveCN101104992AEasy to produceIncrease elasticityTextile treatment by pouringWrinkle skinWorsted

The invention relates to a production method of anti-crease elastic all-wool worsted fabrics. The production method comprises the following steps: weaving all-wool worsted grey fabric, wherein the weft is twisted yarn with a yarn count of 60-80Nm / 2, the single yarn of the twisted yarn is Z-twisted at a twist number of 700-800 twists, the twisted yarn is Z-twisted at a twist number of 750-850 twists, and the density of warp and weft is (240-250) is multiplied by(220-230) / 10cm; dyeing and singeing the grey fabric; soaking and washing for 2-5 min in an industrial washing machine at 95-100 DEG C; and dewatering and drying in an industrial roller drier at 90-100 DEG C. The invention has the advantages of simple production, less pollution, high elasticity and crease resistance, dry touch, and good conformality and drapability.

Owner:JIANGSU SUNSHINE +1

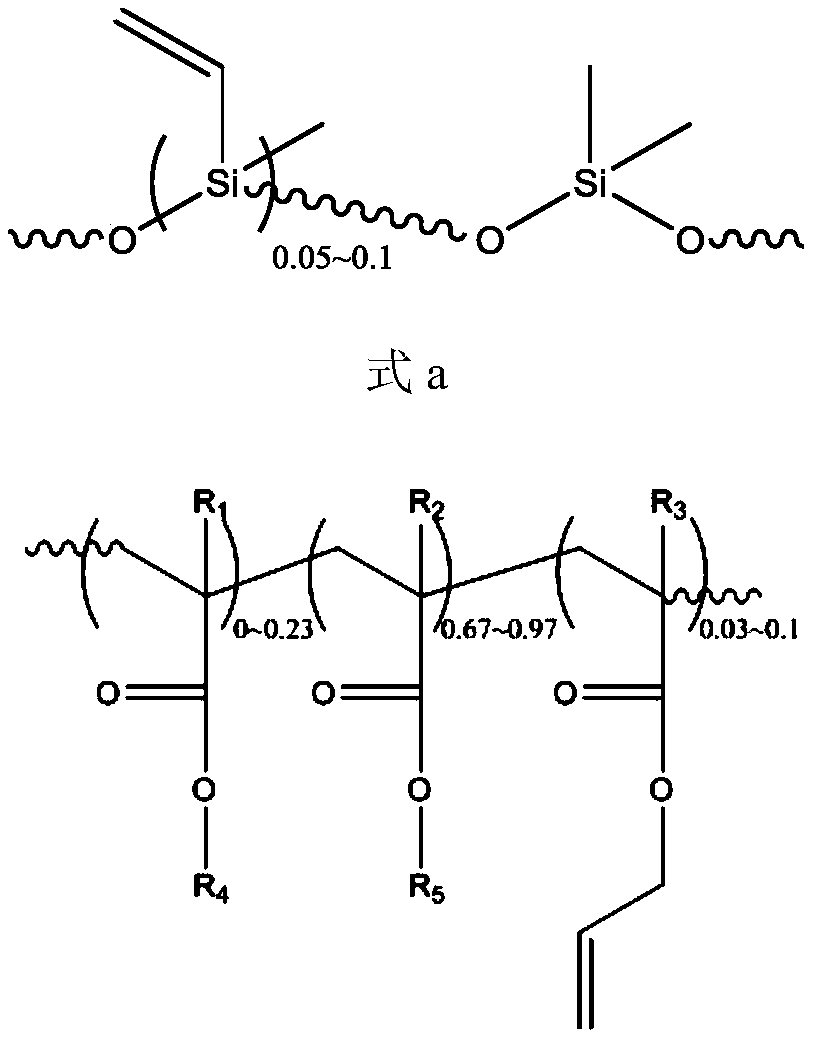

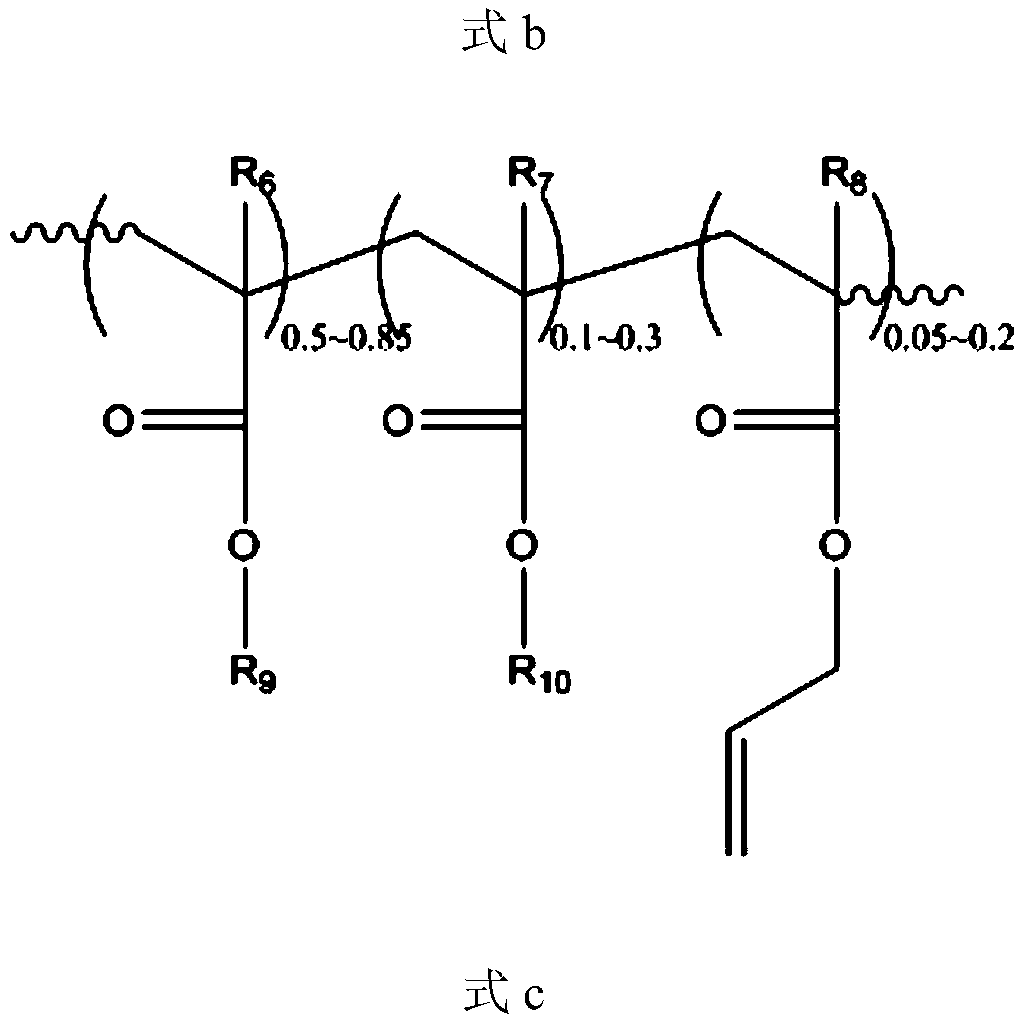

Indoor-temperature foaming flame-retarding liquid silicone rubber with controllable specific gravity and preparing method and application thereof

The invention provides an indoor-temperature foaming flame-retarding liquid silicone rubber with controllable specific gravity and a preparing method and application thereof. The indoor-temperature foaming flame-retarding liquid silicone rubber with controllable specific gravity is prepared from 107 indoor-temperature vulcanization methyl silicone rubber, hydrogen-containing polysiloxane and a foaming-promoting agent; the foaming-promoting agent comprises a non-ionic surfactant. According to the indoor-temperature foaming flame-retarding liquid silicone rubber and the preparing method and application thereof, foaming silicone rubber is prepared through hydrosilylation between hydroxyl in the 107 indoor-temperature vulcanization methyl silicone rubber and the hydrogen-containing polysiloxane, the liquid non-ionic surfactant is adopted as the foaming-promoting agent, and by adjusting the use amount of a filler, the hydrogen-containing polysiloxane and the like and the proportion of a catalyst and an inhibitor, the specific gravity control over the foaming silicone rubber is achieved; the prepared foaming silicone rubber has a smooth and integral surface, and is dry and comfortable inhandfeel, the specific gravity is within the range of 0.2-0.6 g / cm<3>, the mechanical property is good, and the flame-retarding level reaches the UL94 V-0 level.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Novel quick-drying cloth

InactiveCN103734955AGood moisture absorption and air permeabilityFeel dryProtective garmentSpecial outerwear garmentsFiberMoisture absorption

The invention discloses novel quick-drying cloth which comprises tencel fibers, cotton fibers and linen fibers. The novel quick-drying cloth is formed by blending the tencel fibers, the cotton fibers and the linen fibers, the tencel fibers account for 63%-65% of the novel quick-drying cloth by weight, the cotton fibers account for 21%-23% of the novel quick-drying cloth by weight, and the linen fibers account for 12%-14% of the novel quick-drying cloth by weight. Through the mode, the tencel fibers are specifically adopted in the novel quick-drying cloth to improve the moisture transfer performance and the straightness of fabric, and the obtained fabric is good in moisture absorption and air permeability, dry and comfortable in hand feeling, soft and elegant, not prone to wrinkling, and suitable for being made into various summer clothes.

Owner:WUJIANG BEISHENG TEXTILE

Cloth fast to dry

InactiveCN107752180AGood moisture absorption and air permeabilityFeel dryYarnProtective garmentEngineeringFiber

The invention discloses cloth fast to dry. The cloth fast to dry is formed by blending, by weight, 70% to 72% of inflaming retarding modacrylic fibers, 26% to 30% of cotton fibers and 18% to 20% of linen fibers. In this way, the cloth fast to dry is good in moisture absorption performance and breathability, dry and comfortable in hand feeling, soft and elegant, not likely to wrinkle, suitable forbeing made into various summer clothes and suitable for being worn when people do sports.

Owner:RUGAO QIRUN SPORTS ARTICLES

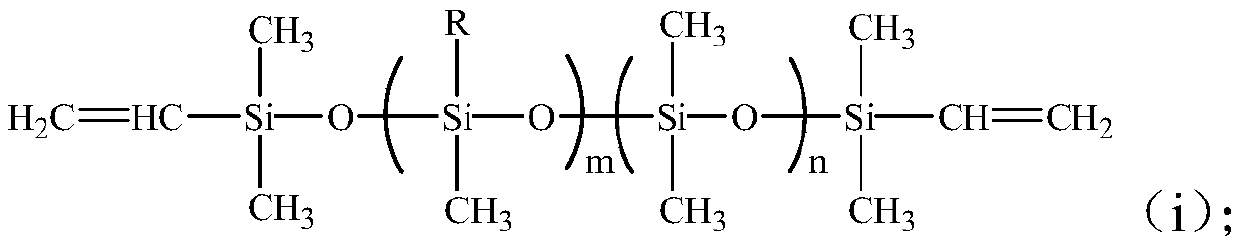

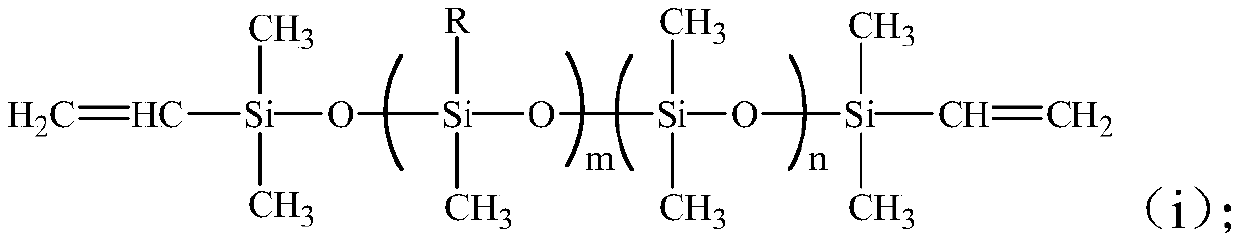

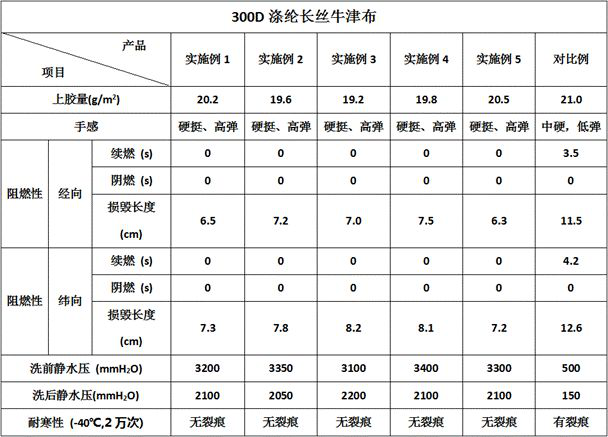

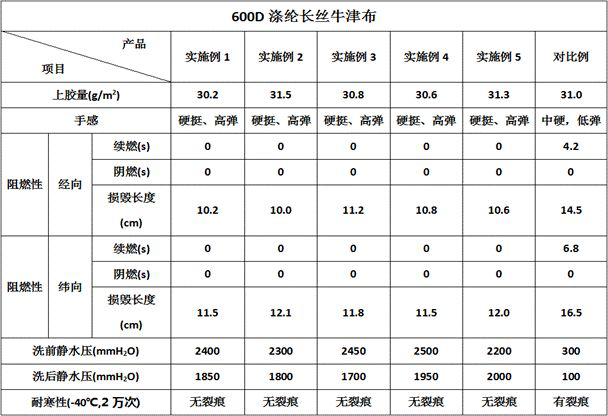

Preparation method of water-based flame-retardant water-pressure-resistant polyurethane emulsion for fabrics

The invention relates to a preparation method of a water-based flame-retardant water-pressure-resistant polyurethane emulsion, which is prepared from isophorone diisocyanate, hydrogenated phenylmethane diisocyanate, polyoxypropylene triol, tris(dipropylene glycol)phosphite, linear dihydroxyalkyl siloxane, melamine cyanurate, dimethylolpropionic acid, 2-methyl-1,3-propylene glycol, triethylamine, hydrazine hydrate and deionized water through a prepolymerization reaction, a neutralization reaction, an emulsification reaction and a chain extension reaction. The fabric is stiff and dry in hand feeling and is high in elasticity, high in fastness, cold-resistant, high in water pressure resistance, good in flame retardance, environmentally friendly and low in production cost.

Owner:LIAONING FIXED STAR FINE CHEM

Imitation silk fabric and production method thereof

The invention discloses imitation silk fabric and a production method thereof. The fabric is woven fabric formed by composite yarn, wherein the composite yarn at least comprises decorative yarn and core yarn, the decorative yarn is modified polyester pre-oriented yarn, the core yarn is modified polyester fully-drawn yarn and the composite yarn accounts for more than 50% of the fabric in weight. The surface friction coefficient of the fabric is over 0.4. The production method includes the specific steps that after delayed heat treatment is conducted on the decorative yarn, the decorative yarn and the core yarn are composited at an interweaving spray nozzle to form the composite yarn, and the obtained composite yarn is twisted; then pretreatment, dyeing and post processing are conducted to obtain a finished product; in the processing process, fabric which is dry and comfortable in hand feeling and excellent in resilience and scroop can be obtained without a special processing method.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Imitation wool composite textured yam and method for producing the same

ActiveCN101423990BGood wool-like effectSoft touchContinuous wound-up machinesOpen-end spinning machinesYarnPulp and paper industry

The invention discloses a wool-like composite textured yarn and a manufacturing method thereof. The composite textured yarn is provided with a core-sheath structure, and a core part and a sheath part of the composite textured yarn have different filament length differences and different extents. The manufacturing method is as follows: 2 POYs are taken as raw materials, wherein one POY raw material is heated to be stretched by a heater between a first yarn feeding roller and a second yarn feeding roller, and merged with the second POY raw material in front of the second yarn feeding roller, enters into a network nozzle between the second yarn feeding roller and a third yarn feeding roller by means of certain overfeeding, forms a network through air blowing and twisting, and is heated, stretched and textured to form the composite textured yarn. The prepared yarn has low manufacturing cost; and textile fabrics which are woven by the yarn after twisting have good wool-like effect, soft, dry and comfortable hand feeling and good rebound resilience and color emissivity after being subjected to alkali decrement, and are good fabrics of black formal dresses.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

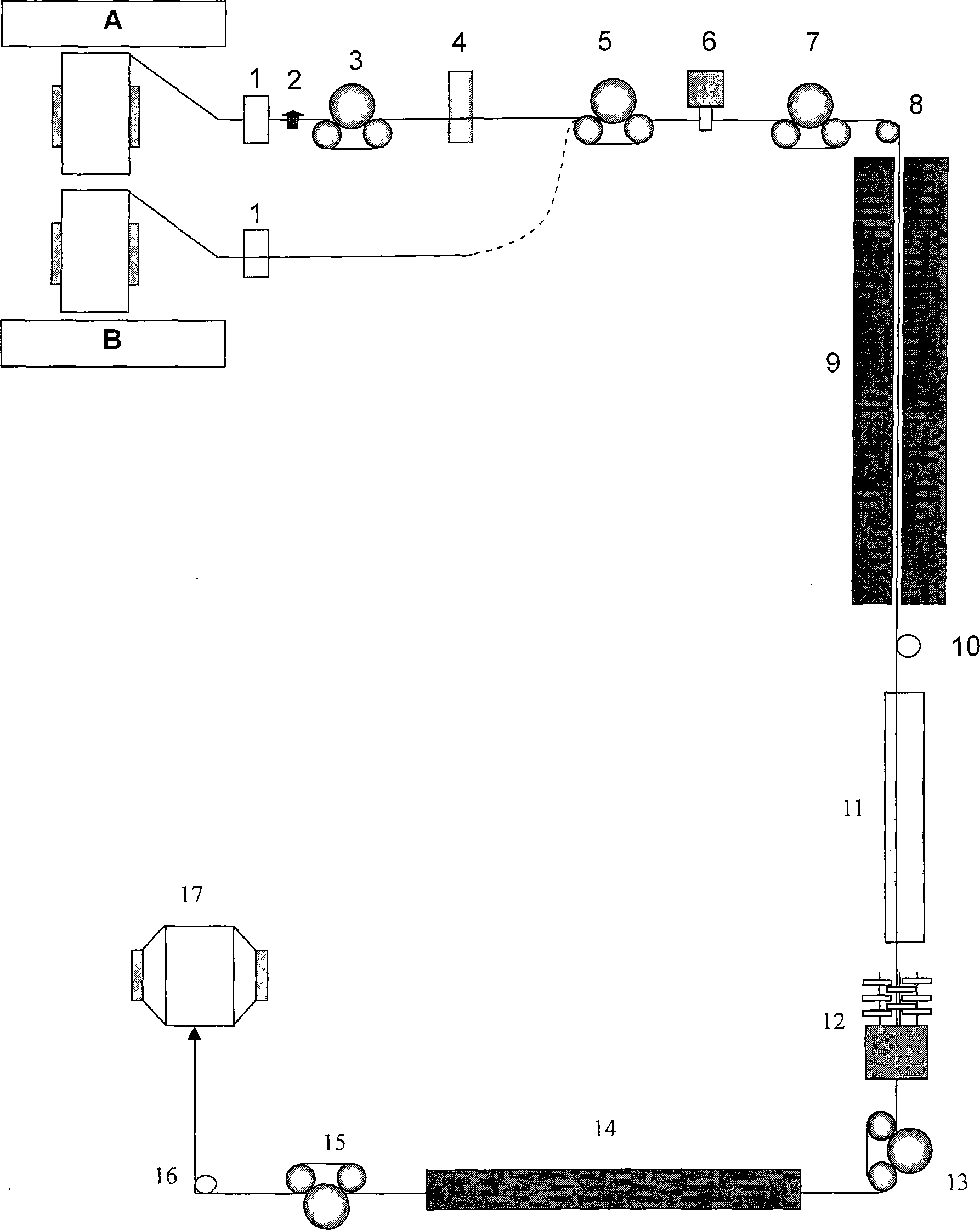

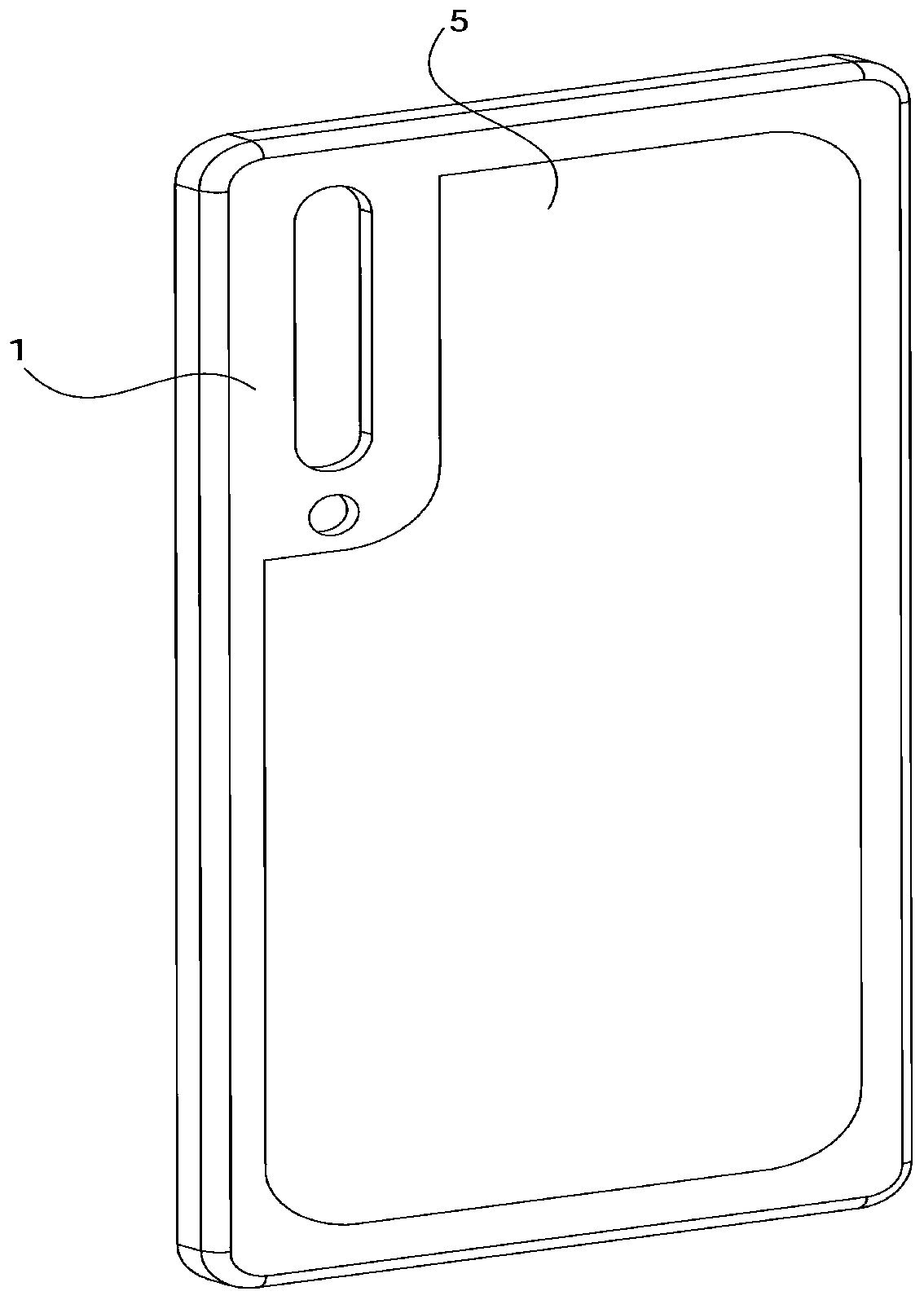

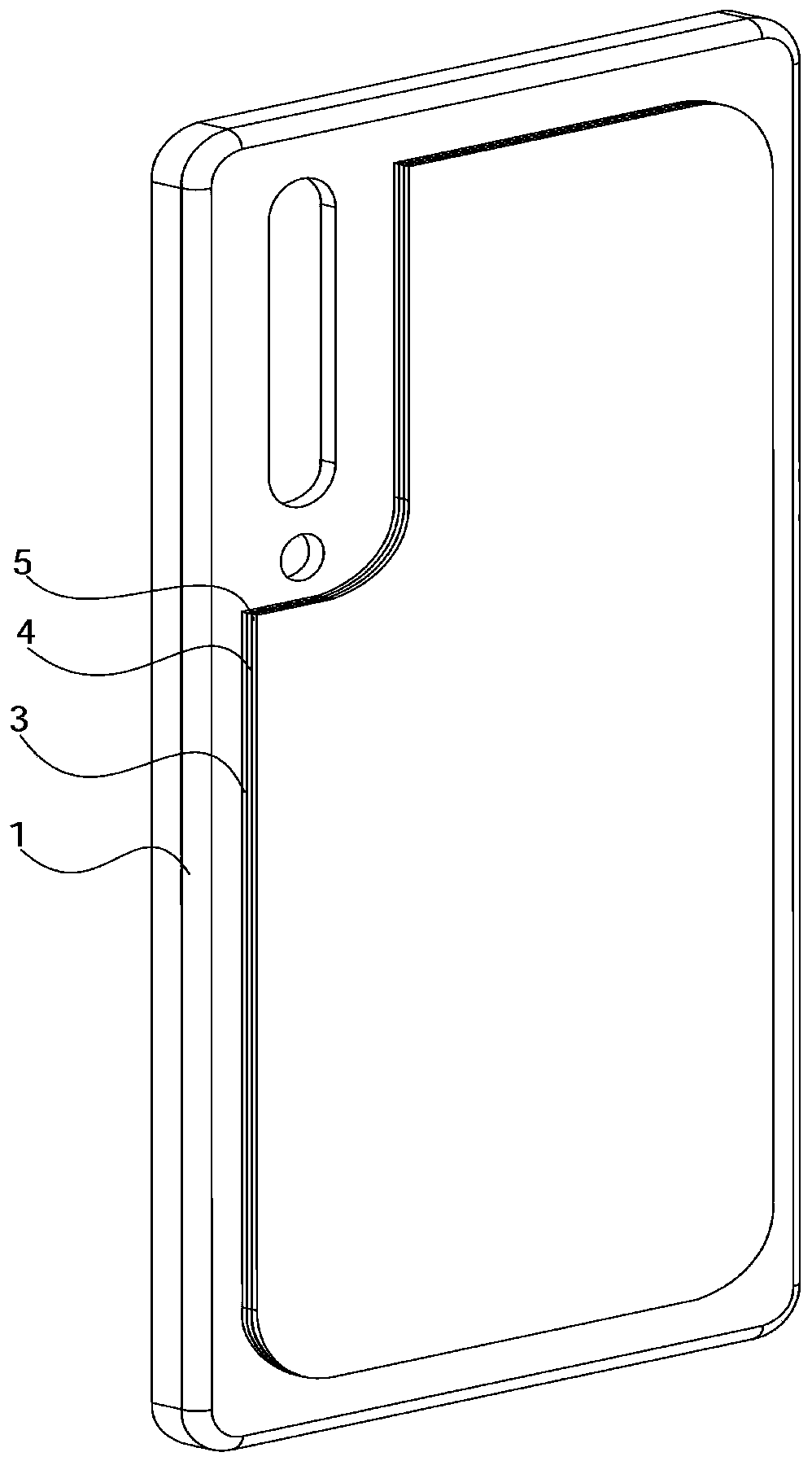

Mobile phone heat dissipating device

PendingCN110402072AImprove performanceFeel dryModifications using liquid coolingTelephone set constructionsAgricultural engineeringMobile phone

The embodiment of the invention discloses a mobile phone heat dissipating device. The mobile phone heat dissipating device comprises a mobile phone case, a water absorbing member, a water storage member and a water diffusing member, wherein the water absorbing member is attached to the side wall of the mobile phone case, and the water storage member is connected to the outer side of the water absorbing member, the water diffusing member is connected to an outer side of the water storage member. The mobile phone heat dissipating device can effectively cool the mobile phone and can prevent the temperature of the mobile phone from too high.

Owner:杜行

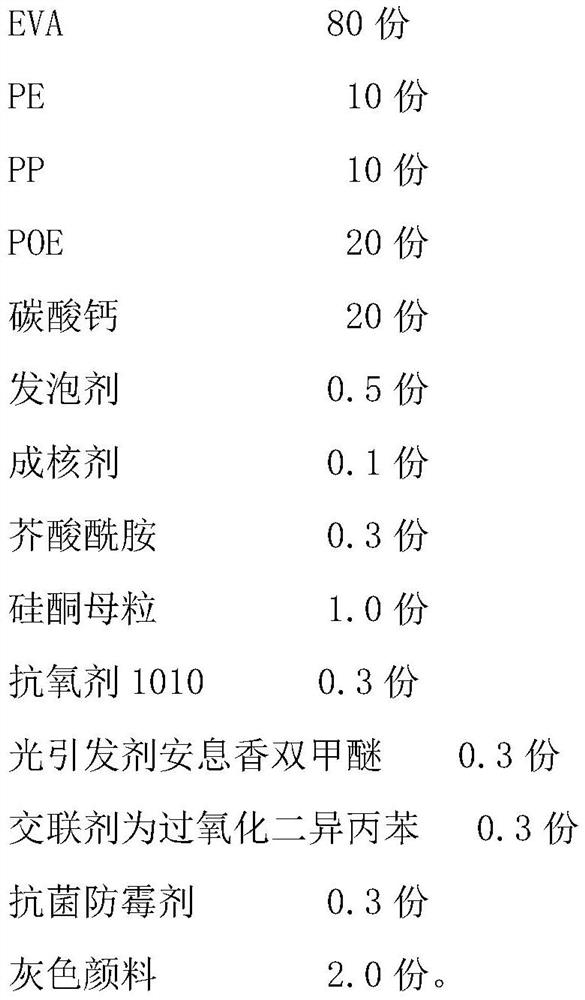

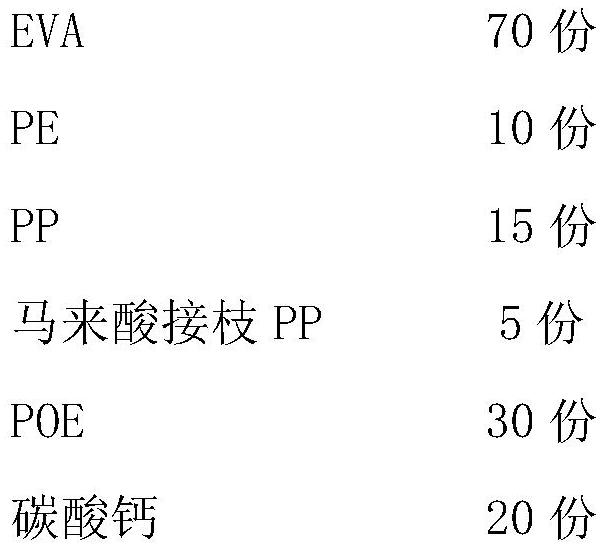

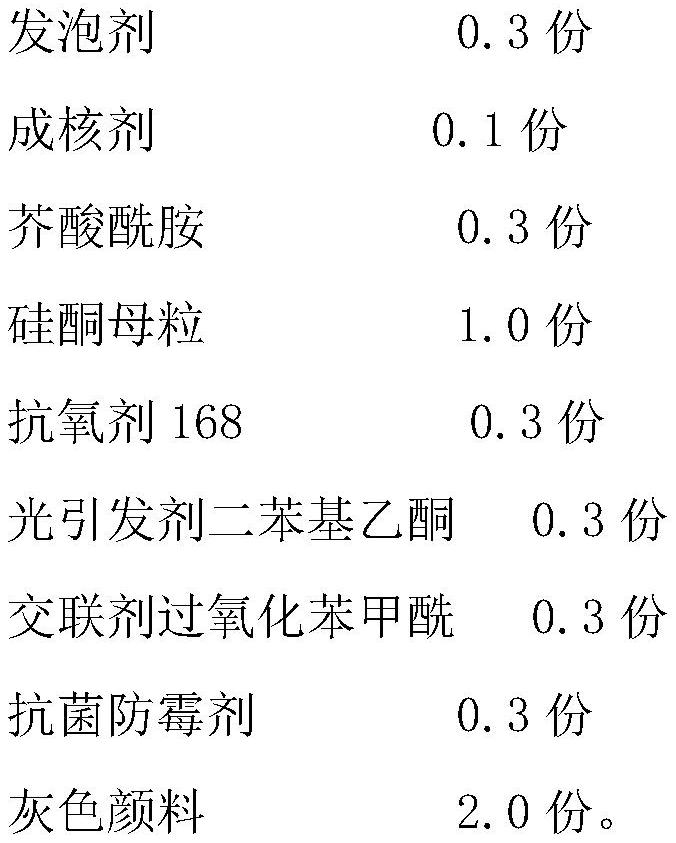

Ethylene-ethylene acetate copolymer (EVA) refrigerator door seal particle and preparation method thereof

The invention discloses an ethylene-ethylene-vinyl acetate copolymer (EVA) refrigerator door seal particle which is composed of an EVA, polyethylene (PE), modified polyethylene, polypropylene (PP), modified polypropylene, an ethylene-olefin copolymer (POE), a mineral filler, a foaming agent, a nucleating agent, a lubricant, an antioxidant, a photoinitiator, a cross-linking agent, an antibacterial and mildew-proof agent, a pigment and the like. The invention further discloses a preparation method of the micro-foaming type EVA refrigerator door seal particles capable of being directly extruded. The preparation method comprises the steps of weighing, grinding, pre-crosslinking, mixing, banburying and extruding granulation. The material is ground and pre-crosslinked, and the foaming agent and the nucleating agent are added, so that when the material is used for producing the refrigerator door sealing strip, direct extrusion molding can be realized, high-temperature vulcanization and mold pressurization are not needed, and the micro-foaming refrigerator door sealing material can be prepared. The product is smooth in surface, contains a large number of microbubbles in the middle, and is high in material tearing strength, large in weld fillet tension, good in rebound resilience, resistant to low temperature, resistant to aging, good in sealing performance and good in heat preservation effect.

Owner:上海新上化高分子材料有限公司

Polypropylene, flax fiber and soybean protein fiber blended yarn

InactiveCN103882590AImprove textureThe biggest advantage is the light textureYarnYarnPolymer science

The invention provides a polypropylene, flax fiber and soybean protein fiber blended yarn. The polypropylene, flax fiber and soybean protein fiber blended yarn comprises, by weight, 50-60 parts of polypropylene, 15-25 parts of flax fibers and 10-20 parts of soybean protein fibers. The polypropylene, flax fiber and soybean protein fiber blended yarn has the advantages that characteristics of the polypropylene, the flax fibers and the soybean protein fibers are complementary to one another, and accordingly merits of the polypropylene, the flax fibers and the soybean protein fibers can be played.

Owner:NANTONG MEIMING CHINLON

Method for producing wrinkle resistant elastic whole-wool worsted face fabric

InactiveCN100485111CEasy to produceIncrease elasticityTextile treatment by pouringWrinkle skinWorsted

The invention relates to a production method of anti-crease elastic all-wool worsted fabrics. The production method comprises the following steps: weaving all-wool worsted grey fabric, wherein the weft is twisted yarn with a yarn count of 60-80Nm / 2, the single yarn of the twisted yarn is Z-twisted at a twist number of 700-800 twists, the twisted yarn is Z-twisted at a twist number of 750-850 twists, and the density of warp and weft is (240-250) is multiplied by(220-230) / 10cm; dyeing and singeing the grey fabric; soaking and washing for 2-5 min in an industrial washing machine at 95-100 DEG C; and dewatering and drying in an industrial roller drier at 90-100 DEG C. The invention has the advantages of simple production, less pollution, high elasticity and crease resistance, dry touch, and good conformality and drapability.

Owner:JIANGSU SUNSHINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com