Rubber texture imitating PVC hose and production method thereof

A PVC material and hose technology, applied in the direction of hoses, chemical instruments and methods, pipes, etc., can solve the problems of different appearance and texture of rubber hoses, and achieve the effects of dry hand feeling, good hygienic performance and good resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

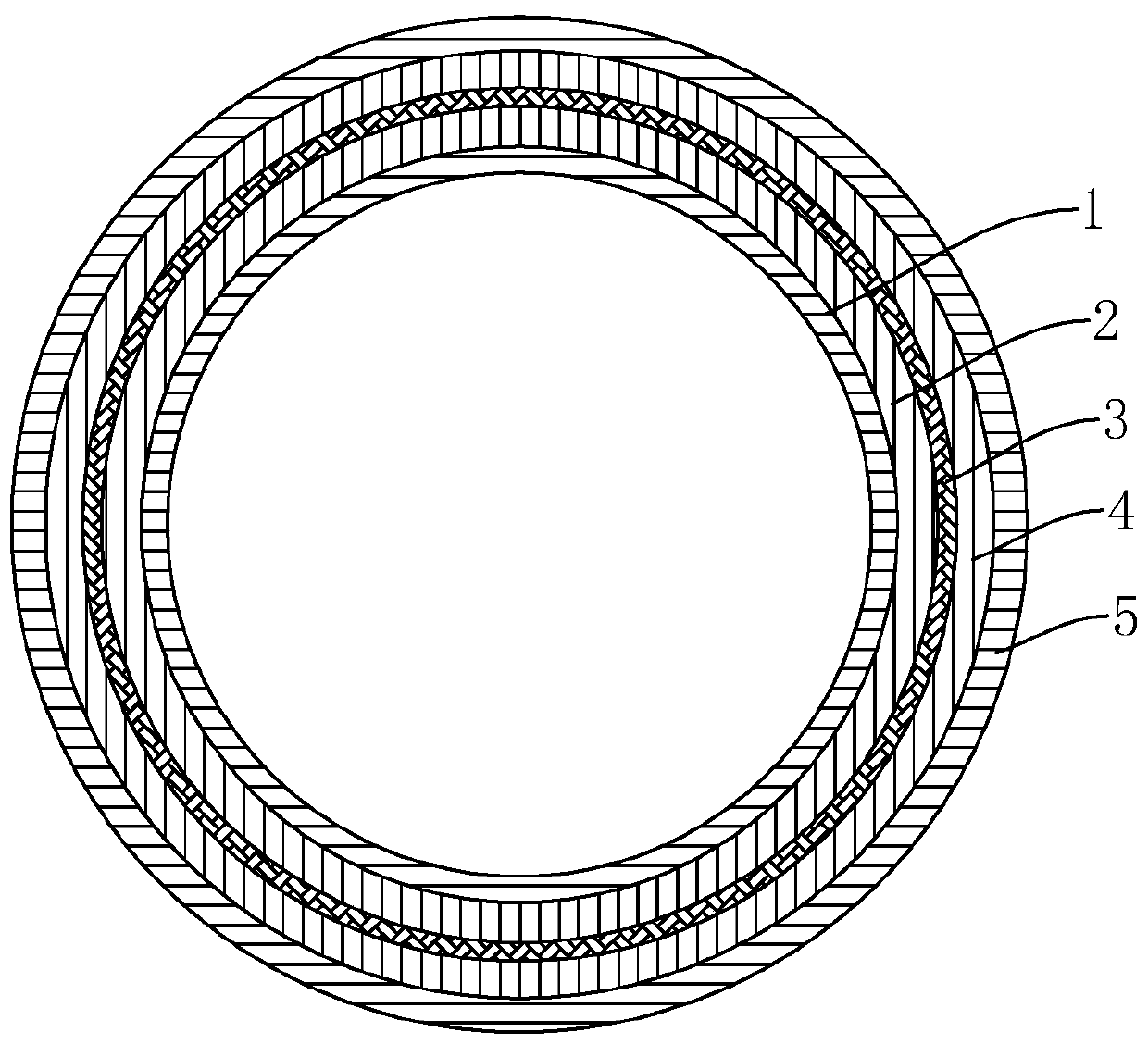

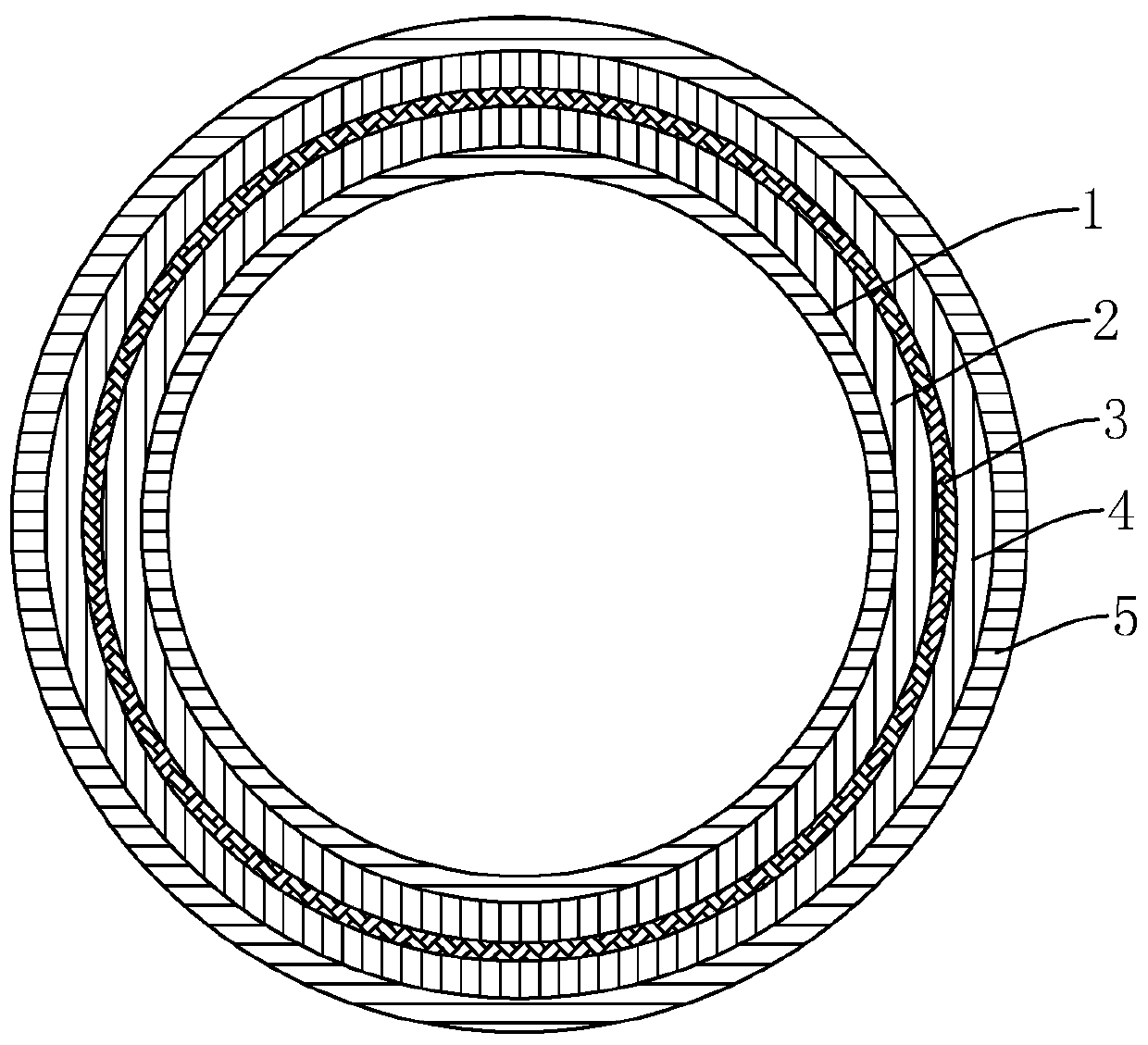

[0050] A rubber-like texture PVC hose, such as figure 1 As shown, it includes an antibacterial layer 1, an inner layer 2, a mesh layer 3, an outer layer 4 and a wear-resistant layer 5 from the inside to the outside. The inner layer 2, the outer layer 4 and the wear-resistant layer 5 are all made of the same PVC material, the only difference is that the filler calcium carbonate is added to the PVC material formula of the inner layer 2 and the outer layer 4, and the PVC material formula of the wear-resistant layer 5 is No filler calcium carbonate was added. The PVC material formula is specially designed. On the one hand, it has a matte surface and good resilience, which is close to the texture of rubber. On the other hand, it has good high and low temperature performance. Both the antibacterial layer 1 and the wear-resistant layer 5 are formed by a co-extrusion process, and the antibacterial layer 1 is made of PTEE material. Mesh layer 3 is wound from 1000D polyester.

Embodiment 2

[0052] The used PVC material of inner layer and outer layer among the embodiment one comprises the component of following parts by weight:

[0053] 50 parts of HPVC resin, grade DH-3000, purchased from Hangzhou Electrochemical New Material Co., Ltd.;

[0054] 50 parts of matting PVC resin, brand PX-3000, purchased from Hangzhou Denka New Material Co., Ltd.;

[0055] DINCH 60 parts, BASF environmental protection plasticizer, Chinese name cyclohexane 1,2-diisononyl dicarboxylate;

[0056] 4 parts of epoxidized soybean oil, brand CP Cizer B-22;

[0057] 2 parts of matting agent, matting agent is high-porosity silica, particle size 3μm, porosity 1.8ml / g;

[0058] 8 parts of low temperature resistant modifier, the low temperature resistant modifier is DOA modifier, namely dioctyl adipate;

[0059] 8 parts of tackifying resin, tackifying resin is gum rosin;

[0060] 1 part of stabilizer, the stabilizer is a calcium-zinc composite stabilizer;

[0061] 50 parts of calcium carbonate...

Embodiment 3

[0072] The used PVC material of inner layer and outer layer among the embodiment one comprises the component of following parts by weight:

[0073] 50 parts of HPVC resin, grade DH-3000, purchased from Hangzhou Electrochemical New Material Co., Ltd.;

[0074] 50 parts of matting PVC resin, brand PX-3000, purchased from Hangzhou Denka New Material Co., Ltd.;

[0075] DINCH 90 parts, BASF environmental protection plasticizer, Chinese name cyclohexane 1,2-diisononyl dicarboxylate;

[0076] 6 parts of epoxidized soybean oil, brand CP Cizer B-22;

[0077] 4 parts of matting agent, matting agent is high-porosity silica, particle size 3μm, porosity 1.8ml / g;

[0078] 14 parts of low temperature modifier, the low temperature modifier is DOA modifier, namely dioctyl adipate;

[0079] 14 parts of tackifying resin, tackifying resin is hydrogenated rosin;

[0080] 1.4 parts of stabilizer, the stabilizer is a calcium-zinc composite stabilizer;

[0081] 75 parts of calcium carbonate, pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com