Indoor-temperature foaming flame-retarding liquid silicone rubber with controllable specific gravity and preparing method and application thereof

A liquid silicone rubber, room temperature foaming technology, applied in the field of foamed silicone rubber, can solve the problems of difficult dispersion, the effect of raw material dispersion effect on the specific gravity of the silicone rubber sponge, etc., and achieve the effects of controllable specific gravity, dry hand feel, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

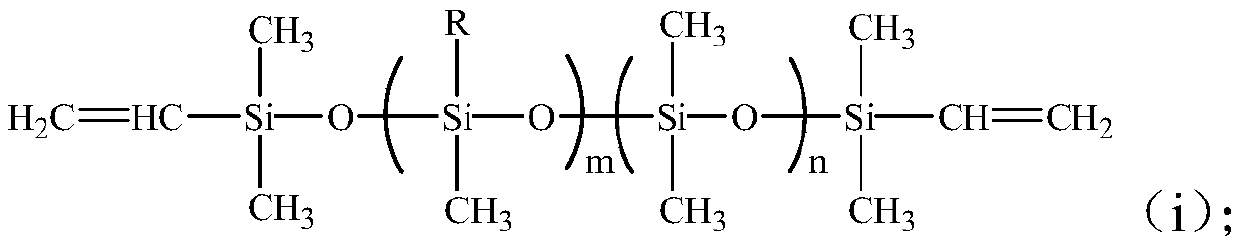

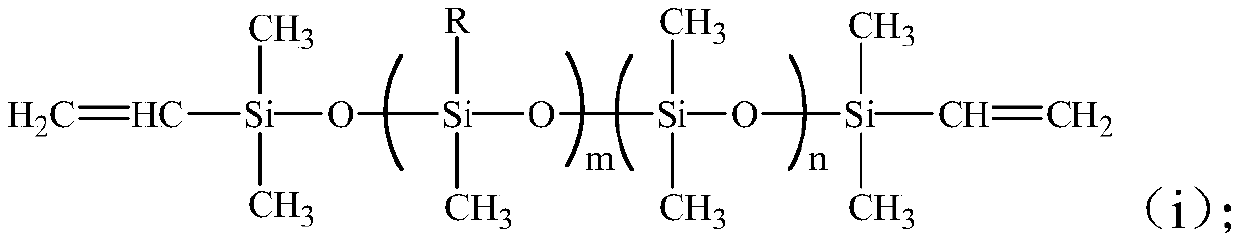

Image

Examples

preparation example Construction

[0080] Further, the present invention also provides the preparation method of the room temperature foamable flame retardant liquid silicone rubber with controllable specific gravity, comprising: including 107 room temperature vulcanized methyl silicone rubber, hydrogen-containing polysiloxane, and foaming aid The raw materials of the agent are mixed to obtain room temperature foaming flame retardant liquid silicone rubber with controllable specific gravity.

[0081] In some embodiments of the present invention, the preparation method of the room temperature foaming flame retardant liquid silicone rubber with controllable specific gravity comprises:

[0082] Mix the raw materials in component A to get component A; mix the raw materials in component B to get component B;

[0083] Then, the obtained components A and B are mixed and then foamed to obtain room temperature foaming flame-retardant liquid silicone rubber with controllable specific gravity;

[0084] As a preference, t...

Embodiment 1

[0098] Preparation of component A: Weigh 100g of 107 room temperature vulcanized methyl silicone rubber with a viscosity of 5000cp, 82g of vinyl-terminated polydimethylsiloxane of 5000cp, and polyvinyl polydimethylsiloxane of 20000cp with a vinyl content of 2%. Alkane 9g, using a high-speed disperser, after stirring evenly under the condition of 1500RPM, continue to add Al(OH) while stirring 3 Add 97g of filler within 10min, continue stirring for 10min, then add 4.11g of platinum(0)1,3-divinyltetramethyldisiloxane, stir at 1500RPM for 10min, mix well and then vacuumize for 10min to obtain A Component.

[0099] Preparation of component B: Weigh 157g of 107 room temperature vulcanized methyl silicone rubber with a viscosity of 5000cp, 27g of hydrogen-containing polysiloxane with a hydrogen content of 1.6%, use a high-speed disperser, stir at 1000RPM for 5min, and mix well while stirring While adding Al(OH) 3 Add 95g of filler within 10min, then continue stirring at 1500RPM for...

Embodiment 2

[0103] Preparation of reinforcing base glue: Add 100 parts by mass of 10000 cp vinyl polydimethylsiloxane, 2.5 parts by mass of distilled water, 12.5 parts by mass of hexamethyldisilazane into a kneader, stir at room temperature for 5 minutes, add white The total amount of carbon black added is 50 parts by mass. After adding all the carbon black, treat it at room temperature for 2 hours, then raise the temperature to 150°C, and treat it under vacuum -0.1MPa for 3 hours. After cooling, the reinforcing base rubber is obtained.

[0104] Preparation of component A: Weigh 100g of 107 room temperature vulcanized methyl silicone rubber with a viscosity of 5000cp, 78g of vinyl-terminated polydimethylsiloxane of 5000cp, and polyvinyl polydimethylsiloxane of 20000cp with a vinyl content of 2%. 8.5g of alkane, 24g of reinforcing base glue, using a high-speed disperser, stirring evenly under the condition of 1500RPM, continue to add Al(OH) while stirring 3 Filler 61g, add within 10min, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com