Environment-friendly water-based polyurethane paint vehicle and water-based polyurethane finish paint for courts

A water-based polyurethane, environmentally friendly technology, applied in the field of topcoat, can solve the problems of hardness, wear resistance adhesion and poor high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

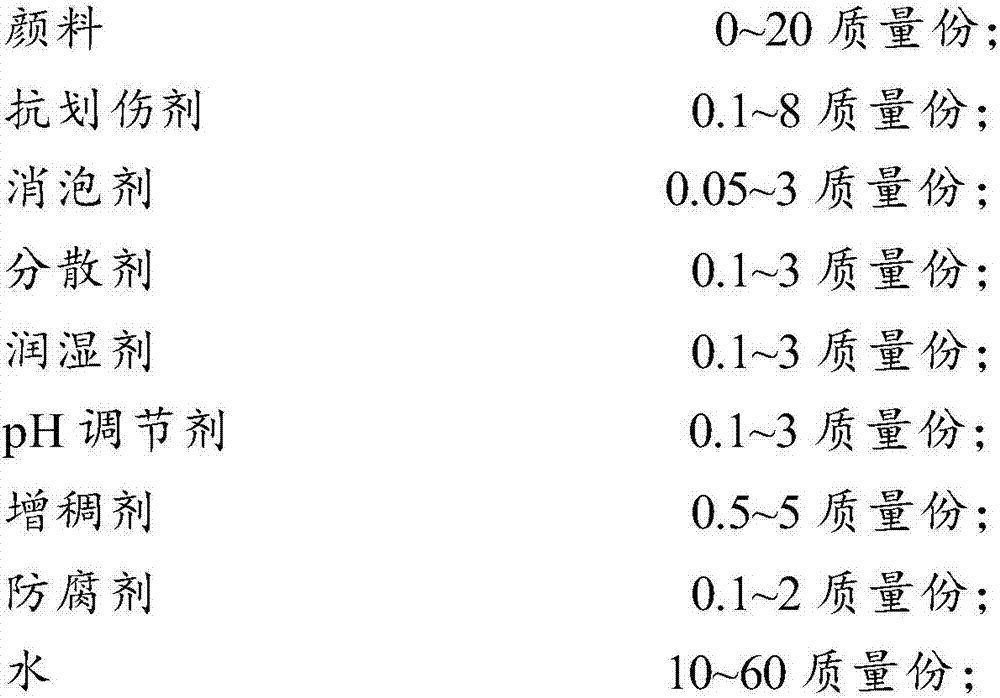

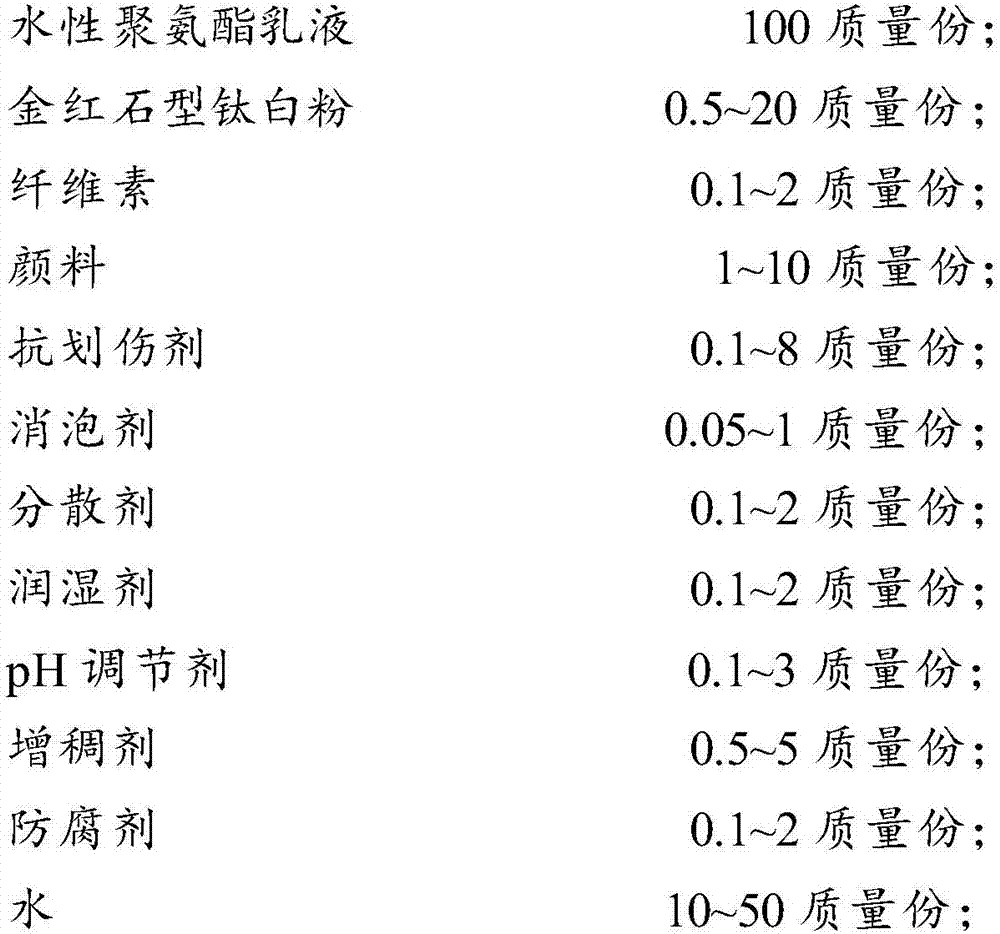

Method used

Image

Examples

Embodiment 1

[0061] a) Preparation of water-based polyurethane emulsion

[0062] Add 100 parts by mass of carbon dioxide copolymer polyol (Mn=3000, hydroxyl value 37±2), 3 parts by mass of ethylene glycol, and 8 parts by mass of dimethylol propionic acid under the condition of stirring at 500 RPM, and vacuumize and dehydrate at 100°C For 2 hours, cool down to 60°C, add 50 parts by mass of isophorone diisocyanate, stir for 0.5 hours, add 0.2 parts by mass of stannous octoate catalyst, heat up to 85°C for 3 hours, cool down to 60°C, add 6 parts by mass of three Ethylamine, stirred for 0.5 hour, 200 parts by mass of water was added under high-speed stirring condition of 1500 RPM, and stirred for 15 minutes to obtain an aqueous polyurethane emulsion.

[0063] Water-based polyurethane film sample preparation: The water-based polyurethane emulsion was formed into a film at room temperature for 24 hours, and then dried at 80°C for 12 hours to obtain a water-based polyurethane film.

[0064] b) P...

Embodiment 2

[0069] a) Preparation of water-based polyurethane emulsion

[0070] Add 100 parts by mass of carbon dioxide copolymer polyol (Mn=2000, hydroxyl value 56 ± 2), 6 parts by mass of ethylene glycol, 1 part by mass of trimethylolpropane, 12 parts by mass of dimethylolpropionic acid under stirring conditions Vacuum dehydration at 100°C for 2 hours, lower the temperature to 60°C, add 80 parts by mass of isophorone diisocyanate, stir for 0.5 hours, add 0.2 parts by mass of stannous octoate catalyst, heat up to 85°C for 3 hours, and cool to 50 degrees, add 9 parts by mass of triethylamine, stir for 0.5 hours, add 200 parts by mass of water under high-speed stirring condition of 1500 RPM, and stir for 15 minutes to obtain an aqueous polyurethane emulsion.

[0071] Water-based polyurethane film sample preparation: The water-based polyurethane emulsion was formed into a film at room temperature for 24 hours, and then dried at 80°C for 12 hours to obtain a water-based polyurethane film.

...

Embodiment 3

[0077] a) Preparation of water-based polyurethane emulsion

[0078] Add 100 parts by mass of carbon dioxide copolymer polyol (Mn=3000, hydroxyl value 37±2), 6 parts by mass of 1,6-hexanediol, and 5 parts by mass of dimethylol propionic acid under stirring conditions at 100°C Vacuumize and dehydrate for 2 hours, cool down to 60°C, add 45 parts by mass of isophorone diisocyanate, stir for 0.5 hours, add 0.2 parts by mass of stannous octoate catalyst, heat up to 80°C for 5 hours, cool to 45°C, add 9 Parts by mass of triethylamine were stirred for 0.2 hours, and 200 parts by mass of water were added under high-speed stirring conditions of 1500 RPM, and stirred for 15 minutes to obtain an aqueous polyurethane emulsion.

[0079] Water-based polyurethane film sample preparation: The water-based polyurethane emulsion was formed into a film at room temperature for 24 hours, and then dried at 80°C for 12 hours to obtain a water-based polyurethane film.

[0080] b) Preparation of waterbor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com