Preparation method of Janus type textile

A technology of textiles and weight parts, which is applied in the direction of textile/flexible product manufacturing, textile and paper making, final product manufacturing, etc. It can solve the problems of poor control of the modification depth of one-way liquid-conducting textiles and the lack of obvious improvement in textile performance. , to achieve the effect of controllable modification depth, low cost, and dry body feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Polyvinyl silicone oil (n vinyl / no Si =10%, 500cs) 1g, ethylene glycol-bis(3-mercaptopropionate) 0.25g, benzoin dimethyl ether 0.05g and MQ resin 0.5g are dissolved in 98.20g toluene to make a photosensitive solution, and the knitted cloth is impregnated In the photosensitive solution obtained above for 3 minutes, after the immersion is completed, the knitted fabric is taken out from the photosensitive solution, and the free liquid on the knitted fabric is removed with a rolling mill, and the excess rate is 90%. The uncured components on the knitted fabric are dissolved to obtain a one-way fluid-conducting knitted fabric, and the hydrophobic thickness of the one-way fluid-conducting knitted fabric accounts for 35% of the total thickness. After testing, the moisture transmission time of the knitted fabric is 80s.

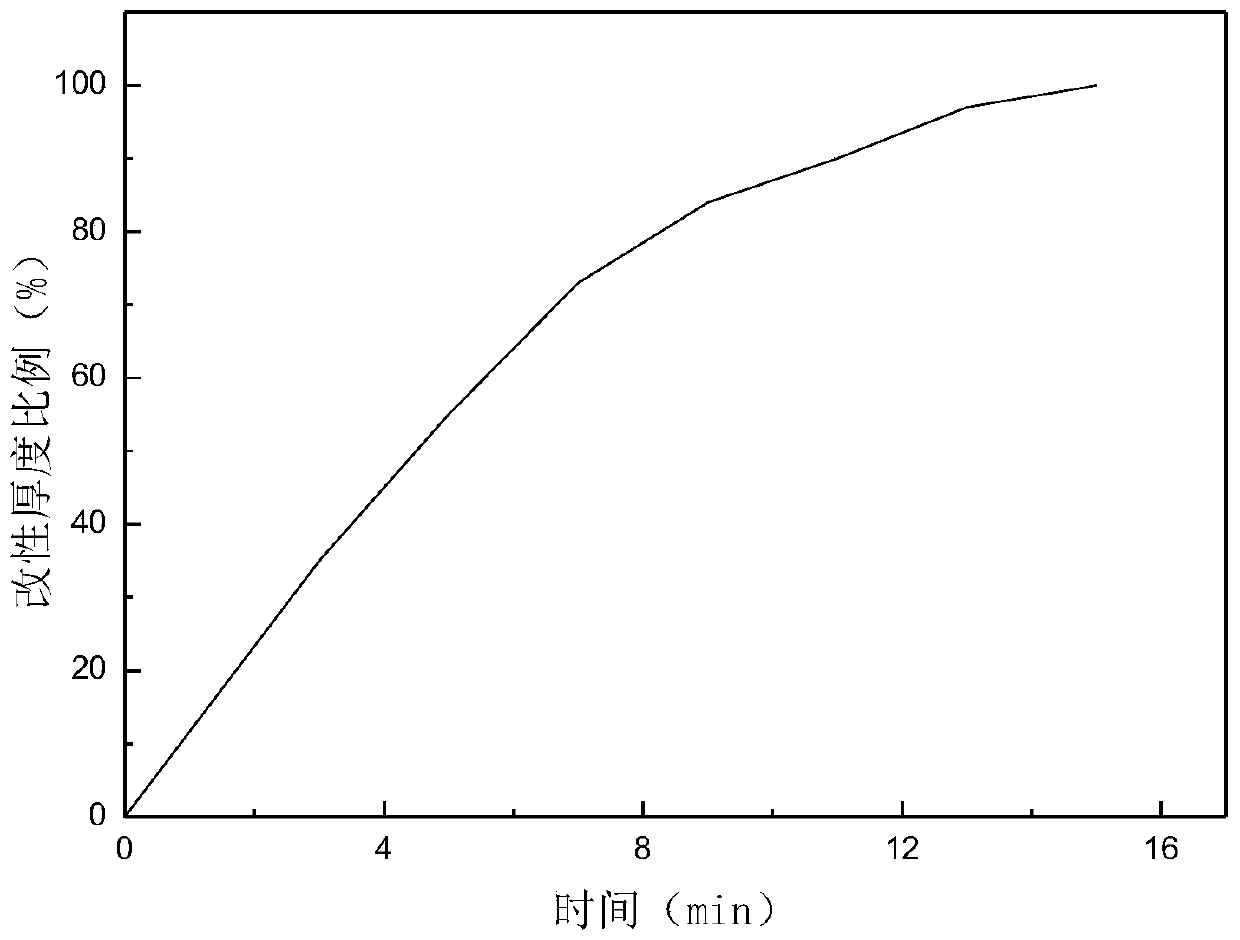

[0027] Under the same component conditions, only changing the time of ultraviolet light irradiation can obtain the one-to-one correspondence between the ti...

Embodiment 2

[0029] The terminal vinyl silicone oil (n vinyl / no Si =0.36%, 10000cs) 1g, trimethylolpropane three (3-mercaptopropionic acid) ester 0.84g, benzoin dimethyl ether 0.02g and vinyl POSS 0.5g are dissolved in 97.64g tetrahydrofuran to make photosensitive solution, will Immerse the woven fabric in the obtained photosensitive solution for 5 minutes. After the immersion, take the non-woven fabric out of the photosensitive solution, use a rolling mill to remove the free liquid on the non-woven fabric, the excess rate is 150%, and irradiate the non-woven fabric with ultraviolet light for 5 minutes. Finally, tetrahydrofuran was used to dissolve the uncured components on the non-woven fabric to obtain a unidirectional liquid-conducting non-woven fabric, and the hydrophobic thickness accounted for 50% of the total thickness. After testing, the moisture transmission time of the non-woven fabric is 2 minutes.

Embodiment 3

[0031] The terminal vinyl silicone oil (n vinyl / no Si =3%, 100000cs) 1g, tetrakis (3-mercaptopropionic acid) pentaerythritol ester 0.3g, benzoin ethyl ether 0.02g and vinyl fumed nano silicon dioxide 0.2g are dissolved in 97.64g ethyl acetate and make photosensitive solution, will Immerse the woven fabric in the obtained photosensitive solution for 10 minutes. After the impregnation is completed, take the nonwoven fabric out of the photosensitive solution, use a rolling mill to remove the free liquid on the nonwoven fabric, and the excess rate is 150%, and irradiate the nonwoven fabric with ultraviolet light for 15 minutes. Finally, ethyl acetate was used to dissolve the uncured components on the non-woven fabric to obtain a one-way liquid-guiding non-woven fabric, and the hydrophobic thickness accounted for 95% of the thickness of the textile. After testing, the moisture transmission time of the non-woven fabric is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com