Multi-component integrally formed hot air non-woven fabric and manufacturing method thereof

A hot air non-woven, multi-component technology, applied in the field of personal hygiene products, can solve the problems of difficult rapid liquid diffusion, reduced contact area, complicated manufacturing process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

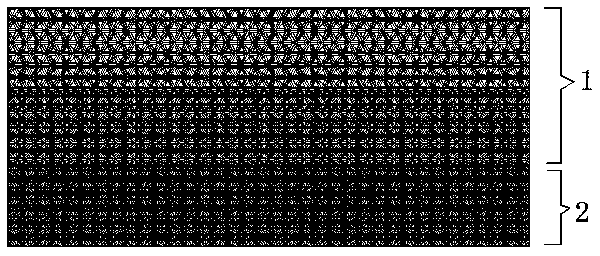

[0031] Such as figure 1 As shown, a multi-component one-time molding air-through non-woven fabric is composed of several layers of fiber lamination. Specifically, the air-through non-woven fabric finally formed by fiber lamination has a structure that gradually changes from loose to dense from top to bottom. The coarse fiber layer faces the skin and the dense fine fiber layer faces the core.

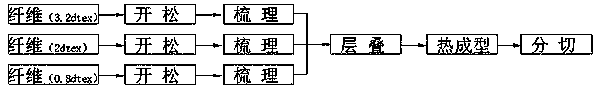

[0032] Its production process is as image 3 As shown, first select 15 grams per square meter of fibers with deniers of 0.8 tex, 2 tex, and 3.2 tex respectively, and open them on the opener respectively, then card them separately, and then loosen them according to the above. Three kinds of fiber layers are laminated in the order of coarse fiber and dense fine fiber. It is then sent to an oven for drying and shaping, and finally forms a structure that gradually changes from the upper loose layer 1 to the lower dense layer 2. Finally, the air-through non-woven fabric prepared by thermof...

Embodiment 2

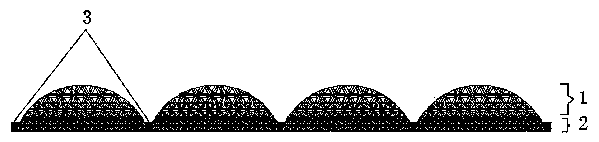

[0034] Such as figure 2 As shown, repeating Example 1, only further, in order to make the liquid quickly diffuse to the bottom of the surface layer, and at the same time lock the liquid, there are hot-rolled pits 3 on the multi-component once-molded hot-air non-woven fabric, The liquid can be concentrated at the pit 3 . Its hot rolling process is in such as image 3 The thermoforming step shown is completed. After the laminated fiber layers are sent to an oven for drying and shaping, the multi-component laminated fiber layers are hot-rolled to form the pits 3 .

[0035] When the multi-component one-time forming air-through non-woven fabric described in any of the above embodiments is used, the side of the loose thick fiber faces the skin, and the side of the dense fine fiber faces the core. When the liquid encounters the surface layer, due to capillary action, The liquid will quickly spread from the upper loose layer 1 to the lower dense layer 2 of the surface layer, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com