Preparation method of waterborne phosphorus-silicon flame-retardant polyurethane coating material

A polyurethane coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, fire-resistant coatings, etc., can solve the problems of non-environmental protection, non-washing resistance, and hard hand feeling of fabrics, etc., and achieve dry hand feeling and good transparency Sex, the effect of reducing moisture absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

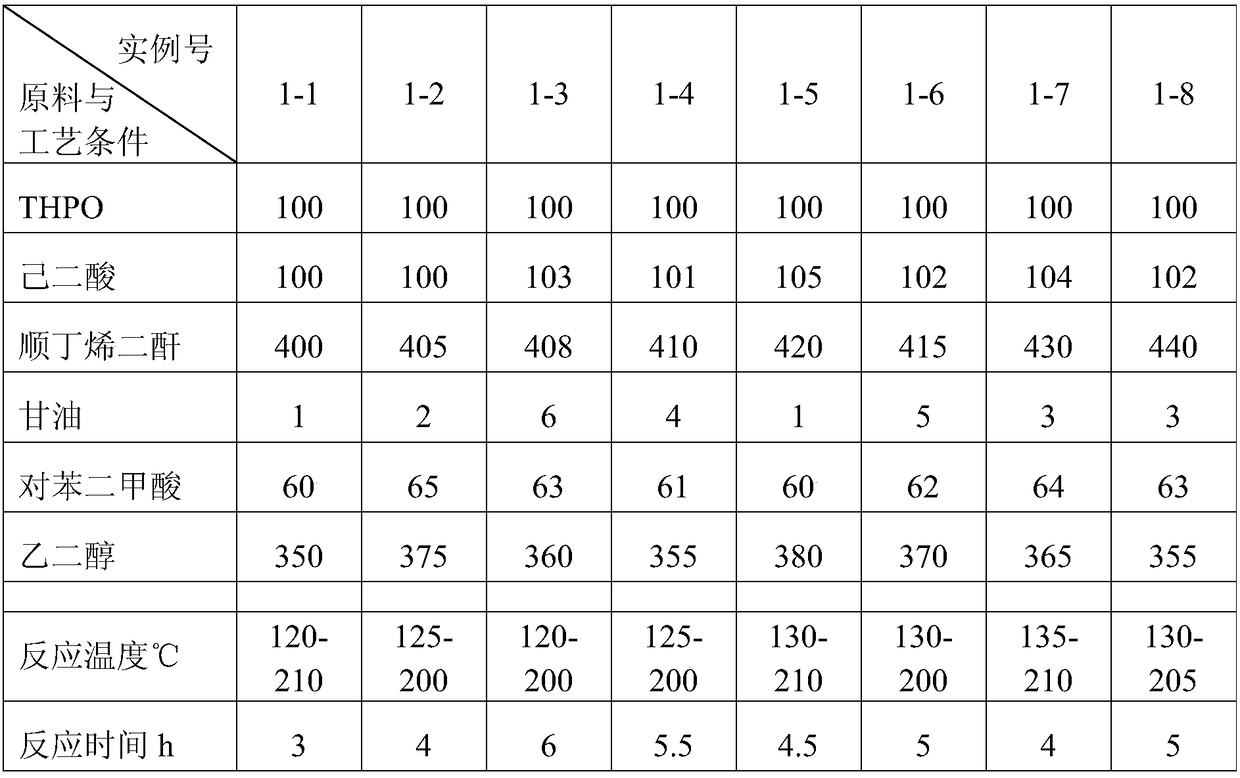

Examples

Embodiment 25

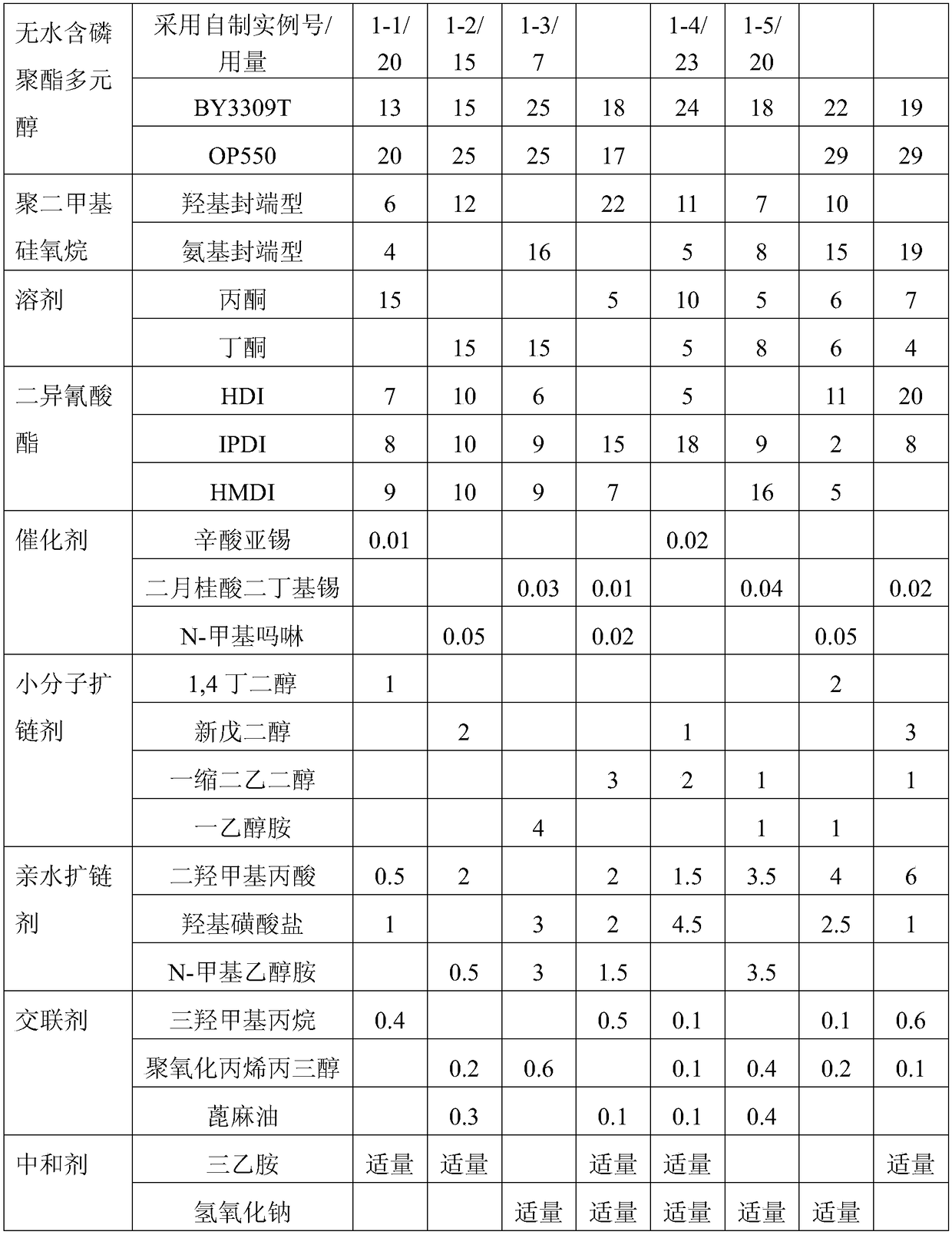

[0055] A method for preparing a water-based phosphorus-silicon flame-retardant polyurethane coating material, the steps are: in a reactor A at room temperature, add 33 parts by mass of anhydrous phosphorus-containing polyester polyol, 10 parts by mass of polydimethylsiloxane Alkanes and 5 parts by mass of solvent, stirred evenly, then (slowly) added 15 parts by mass of diisocyanate under stirring, then added 0.01 parts by mass of catalyst, heated to 60 ° C for 2 hours; then added 1 part by mass of small molecule chain extender, 2 Parts by mass of a hydrophilic chain extender and 0.1 part by mass of a cross-linking agent, heated up to 75°C for 4 hours, cooled to room temperature, and then added (appropriate amount) neutralizing agent for neutralization reaction, so that the pH (of the reaction material) = 6-7 , to obtain phosphorus-silicon flame-retardant polyurethane prepolymer; add 1 mass part of deionized water to the reactor under (high-speed) stirring, continue (high-speed)...

Embodiment 26

[0057] A method for preparing a water-based phosphorus-silicon flame-retardant polyurethane coating material, the steps are: in a reactor A at room temperature, add 57 parts by mass of anhydrous phosphorus-containing polyester polyol, 29 parts by mass of polydimethylsiloxane Alkanes and 15 parts by mass of solvent, stirred evenly, then (slowly) added 30 parts by mass of diisocyanate under stirring, then added 0.05 parts by mass of catalyst, heated to 90 ° C for 1 h; then added 4 parts by mass of small molecule chain extender, 8 Parts by mass of a hydrophilic chain extender and 0.8 parts by mass of a crosslinking agent, heated up to 90°C for 2 hours, cooled to room temperature, and then added (appropriate amount) neutralizing agent for neutralization reaction, so that the pH (of the reaction material) = 6-7 , to obtain phosphorus-silicon flame-retardant polyurethane prepolymer; add 4 parts by mass of deionized water to the reactor under (high speed) stirring, continue (high spee...

Embodiment 27

[0059] A method for preparing a water-based phosphorus-silicon flame-retardant polyurethane coating material, the steps are: in a reactor A at room temperature, add 45 parts by mass of anhydrous phosphorus-containing polyester polyol, 19 parts by mass of polydimethylsiloxane Alkanes and 10 parts by mass of solvent, stirred evenly, then (slowly) added 23 parts by mass of diisocyanate under stirring, then added 0.03 parts by mass of catalyst, heated to 75 ° C for 1.5 h; then added 2.5 parts by mass of small molecule chain extender, 5 parts by mass of a hydrophilic chain extender and 0.45 parts by mass of a crosslinking agent, heat up to 88°C for 3 hours, cool down to room temperature, and then add (appropriate amount) neutralizing agent to carry out neutralization reaction, so that the pH (of the reaction material) = 6~ 7. The phosphorus-silicon flame-retardant polyurethane prepolymer is obtained; add 2.5 parts by mass of deionized water to the reactor under (high-speed) stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com