Preparation method of transparent high impact-resistant MBS resin

A technology of high impact resistance and resin, which is applied in the field of preparation of transparent high impact MBS resin, can solve the problem that the transparency and impact resistance of MBS resin are difficult to have at the same time, and achieve the incompatibility of transparency and high impact resistance effects of tooling, high impact strength, excellent impact performance and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 A kind of preparation method of transparent high-impact MBS resin

[0020] A preparation method of transparent high-impact MBS resin comprises the following preparation steps in sequence: synthesizing styrene-butadiene latex, synthesizing polymer latex, synthesizing bimodal distribution latex, grafting and synthesizing MBS emulsion, demulsification, water washing, centrifugation and drying.

[0021] (1) The specific operation steps for synthesizing styrene-butadiene latex include: putting 20kg of soft water, 0.09kg of potassium chloride, 0.579kg of emulsifier, 0.36kg of divinylbenzene, 2.45kg of styrene, and 0.02kg of potassium persulfate into a 50L polymerization kettle in sequence , replace with high-purity nitrogen, add 9.8kg of butadiene after the oxygen content is qualified, stir for 10 minutes, then raise the temperature, and raise the temperature to 65°C within one hour, and react at a constant temperature at 65°C, and control the pressure below 1Mpa ...

experiment example 1

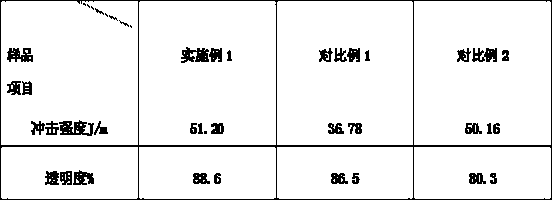

[0039] Experimental Example 1 Performance Test

[0040] Mix the MBS-1, MBS-2, MBS-3 prepared in Example 1, Comparative Example 1, and Comparative Example 2 with PVC to prepare samples, and measure the impact resistance according to GB / T 8814-2004.

[0041] The physical index experiment process is as follows:

[0042] 1. Impact strength test: Put the PVC (S-800) base material and MBS1-3 respectively on the open plastic refining machine, set the temperature at 185°C, the speed of the front roller is 15r / min, the speed of the rear roller is 18r / min, and start refining After 3 minutes, pull it into a sheet, and then place it in a flat vulcanizing machine as required. Set the temperature at 185°C, preheat for 3 minutes, and then mold it at 15MPm for 3 minutes, then pass water to cool down for 3 to 5 minutes, take out the obtained sheet, and cut it into standard sample. Tested with a pendulum impact testing machine (Shenzhen Wance Experimental Instrument Co., Ltd.).

[0043] 2. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com