Special TPU material for encapsulation, and preparation method thereof

A technology of encapsulation and raw materials, which is applied in the field of special TPU materials for encapsulation and its preparation, can solve the problems of poor bonding strength between encapsulation materials and substrates, loss of protective effect of encapsulation sheath, and surface precipitation affecting the appearance, etc., to achieve Good protection and modification, superior soft touch, excellent melt flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

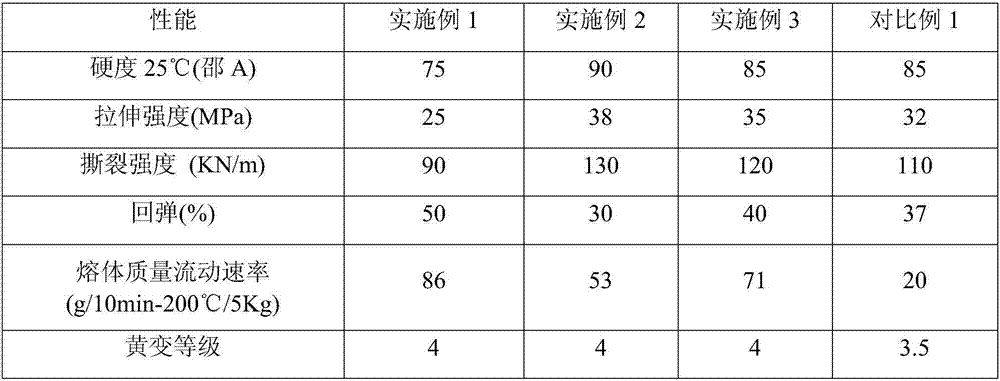

Examples

Embodiment 1

[0023] Polybutylene adipate (M=3500): 78.77g, MDI-100: 15.94g, BDO: 3.75g, antioxidant 1010 and DLTP each 0.25g, anti-yellowing agents UV-320 and 292 each 0.2 g, 0.3 g each of stearic acid amide and oleic acid amide. Add the metered polyester polyol, antioxidant, light stabilizer, and lubricant into the A reactor equipped with mechanical stirring and thermometer, and set the temperature at 100±5°C; place the diisocyanate MDI-100 in the B reaction kettle In the reactor, set the temperature at 70±5°C; place the chain extender BDO in the C reactor, set the temperature at 50±10°C; Infusion system, the raw material components in the A / B / C reactor are mixed and injected into the feed port of the twin-screw reactor through the high-speed rotating mixing head, and at the same time, the catalyst is added to the feed port of the twin-screw extruder through a micro injection pump. T-12: 0.04g, the mixed material is uniformly reacted and plasticized in the twin-screw barrel, and cut into...

Embodiment 2

[0025] Prepare according to the preparation method of Example 1.

[0026] Polyethylene adipate (M=1500): 49.2g, MDI-100: 38.29g, BDO: 10.9g, antioxidant 1010 and 168 each 0.35g, anti-yellowing agent UV-P and 292 each 0.25 g, 0.2 g each of oleic acid amide and butyl stearate, catalyst T-9: 0.01 g.

Embodiment 3

[0028] Prepare according to the preparation method of Example 1.

[0029] Polybutylene adipate (M=2500): 64.01g, MDI-100: 27g, BDO: 7.46g, 0.2g each of antioxidants 1076 and 168, 0.15g each of anti-yellowing agents UV-320 and 770 , stearic acid amide and stearic acid monoglyceride each 0.4, catalyst T-9: 0.03g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com