Thermochromic thermoplastic elastomer (TPE) with V0 flame-retardant grade and preparation method thereof

A thermoplastic elastomer, temperature-sensitive color change technology, applied in the field of TPE materials, can solve problems such as hidden dangers, low temperature resistance, overheating and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

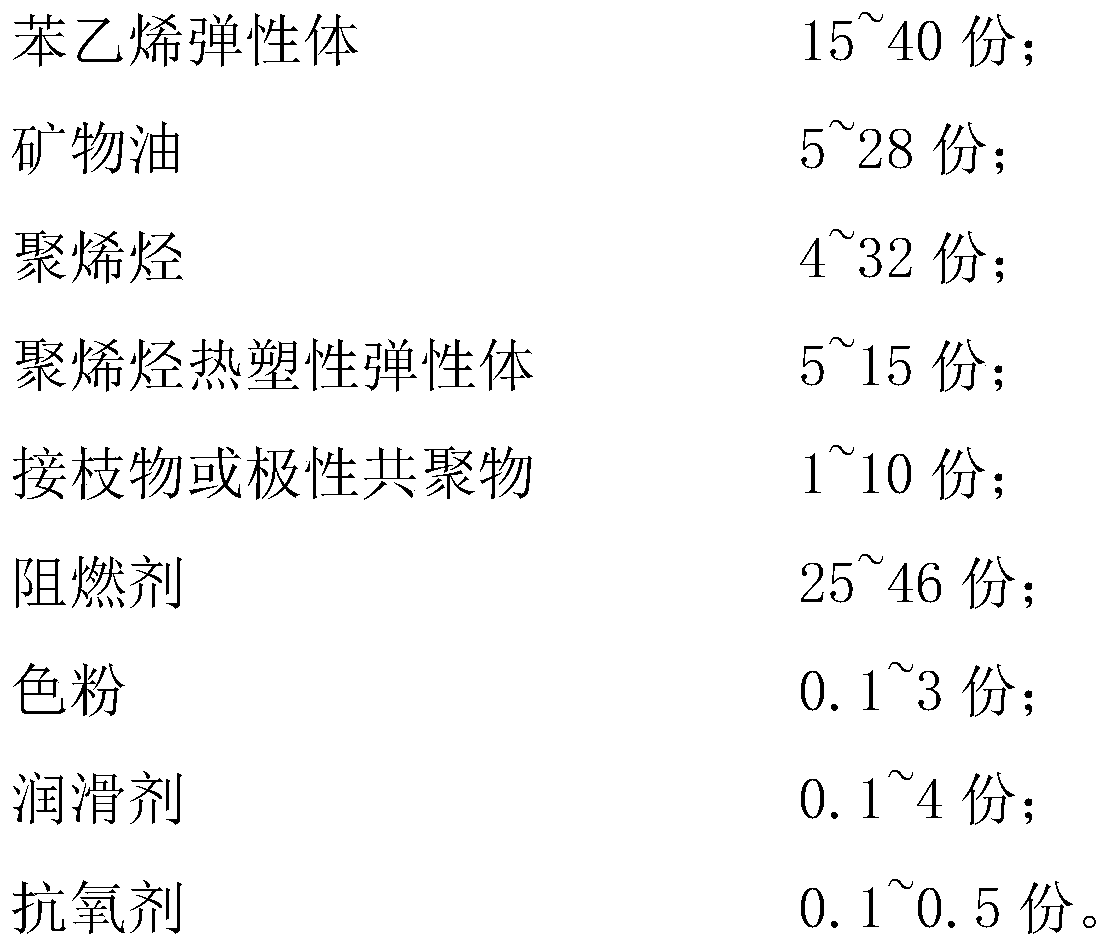

Method used

Image

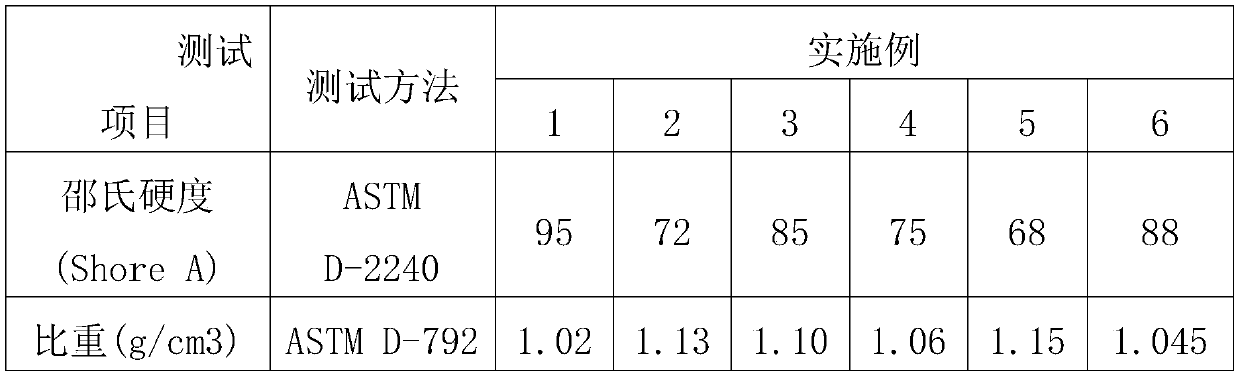

Examples

Embodiment 1

[0029] Put 15 parts by weight of SEBS 1654 into a high-speed mixer, uniformly add 5 parts by weight of mineral oil KDN4006, and stir at high speed for 3 minutes to obtain the first mixture, which is packaged and left to stand for 4 days.

[0030] Put 20 parts by weight of the required first mixture into a high-speed mixer, add 5 parts by weight of DOWTM 39001, 32 parts by weight of PP 1100NK, and 5 parts by weight of DOW GR216, and stir at high speed for 2 minutes to obtain the second mixture.

[0031] Add 25 parts by weight of Japan Adico FP2200S, 0.15 parts by weight of toner, 0.1 parts by weight of lubricant oleic acid amide, 0.1 parts by weight of antioxidant 1076, 0.1 parts by weight of antioxidant 168, and stir for 2.5 minutes in the second mixture , to obtain the premix.

[0032] Pour the premix into the hopper of a co-rotating twin-screw extruder, process and disperse through the co-rotating twin-screws, and pelletize to obtain a V0 flame-retardant grade thermochromic ...

Embodiment 2

[0034] Put 22 parts by weight of SEBS YH-511 and 10.6 parts by weight of SEBS G1645 into a high-speed mixer, evenly add 9.7 parts by weight of mineral oil KDN4006, and stir for 1.5 minutes to obtain the first mixture. After packing the mixture, place it for 2 days .

[0035] Put 42.3 parts by weight of the required first mixture into a high-speed mixer, add 4 parts by weight of PP 5090T, 6.9 parts by weight of Vistamaxx POE 6102, and 1 part by weight of graft FG 1901, and stir at high speed for 2 minutes to obtain the second mixture ;

[0036] Add 9.4 parts by weight of OP935, 5.2 parts by weight of MPP-A, 27.7 parts by weight of MCA-15, 0.3 parts by weight of toner, 4 parts by weight of silicone MB50-001, 0.2 parts by weight of antioxidant 1010, 0.3 parts by weight Antitrophic agent 1076, stirred for 3 minutes to obtain a premix.

[0037] Pour the premix into the hopper of a co-rotating twin-screw extruder, process and disperse through the co-rotating twin-screws, and pelleti...

Embodiment 3

[0039] Put 15 parts by weight of SEBS YH-503T and 6.8 parts by weight of SEBS DP6014 into a high-speed mixer, evenly add 13.2 parts by weight of mineral oil 150N, and stir for 2.5 minutes to obtain the first mixture. After packing the mixture, place it for 3 days .

[0040] First put 35 parts by weight of the required first mixture into a high-speed mixer, add 10 parts by weight of PP 1100NK, 5.1 parts by weight of Dow 8402, and 10 parts by weight of PP grafted maleic anhydride P353, and stir at a high speed for 2 minutes to obtain the first Two mixtures;

[0041] Add 34 parts by weight NP2536, 4.2 parts by weight HF600B, 1.5 parts by weight toner, 2.5 parts by weight of silicone MB50-002, 0.1 parts by weight of antioxidant 1010, 0.3 parts by weight of antioxidant 168, and stir for 2.5 minutes , to obtain the premix.

[0042] Pour the premix into the hopper of a co-rotating twin-screw extruder, process and disperse through the co-rotating twin-screws, and pelletize to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com