Acetylated citric acid fatty acid ester plasticizer, preparation method thereof and application

A technology for acetylating citric acid and fatty acid ester, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as poor compatibility and precipitation, achieve mild conditions, reduce dependence, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

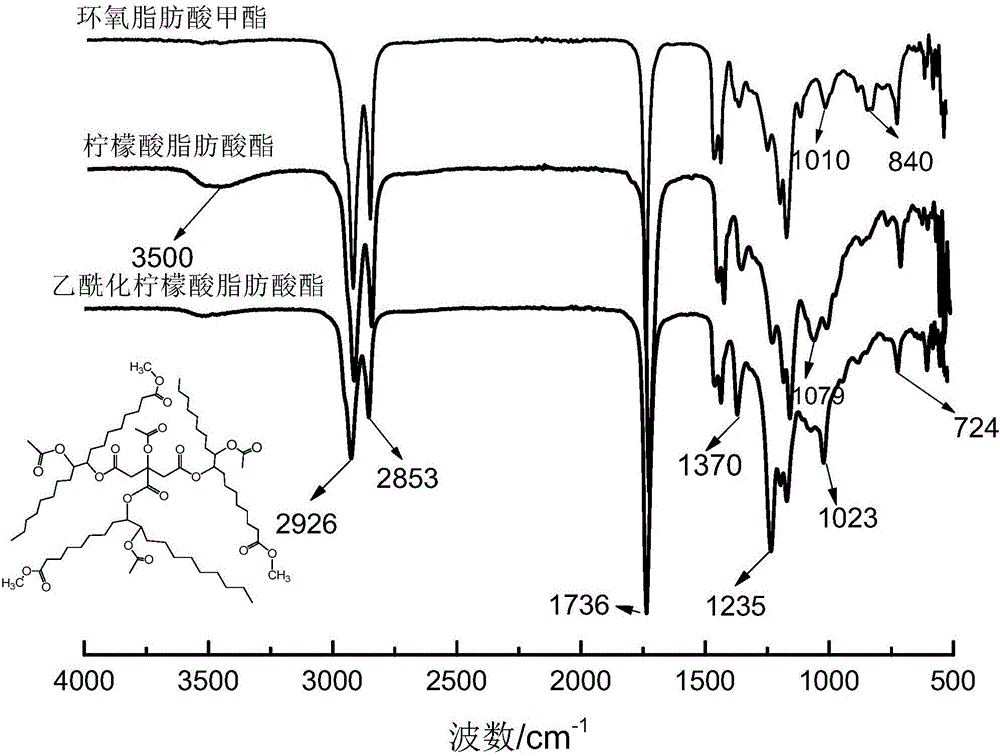

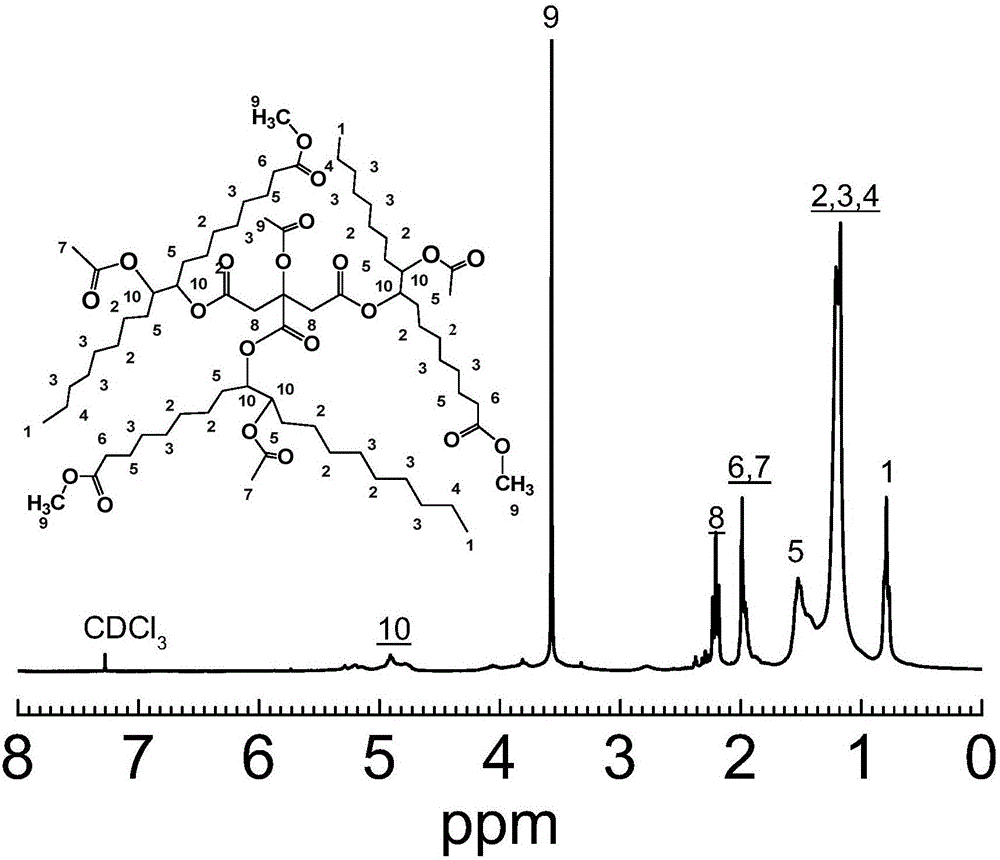

[0028] The first step, the preparation of epoxidized methyl oleate: get the hydrogen peroxide 45mL of 30wt.% concentration and add dropwise in the there-necked flask that has added 30g methyl oleate, 30mL acetic acid and 1.5g ion exchange resin catalyst, control hydrogen peroxide in After 1.5 hours of dropwise addition, the temperature should not be higher than 65°C, and then keep the temperature at 65°C for 3 hours. After the reaction, neutralize with 4wt.% sodium carbonate solution, wash with water until neutral, and then dry to obtain an epoxy value of 3.6%. Pale yellow epoxidized methyl oleate.

[0029] In the second step, citric acid and epoxidized fatty acid methyl ester ring-opening reaction prepare citric acid fatty acid ester, the epoxidized methyl oleate 100g obtained in the first step, citric acid 13g, antioxidant 1010 0.1g and catalyst Dimethylimidazole 0.4g, reacted at 140°C for 3 hours to obtain a crude product with an acid value of 0.82mg / g, then distilled out t...

Embodiment 2

[0032] The first step, the preparation of epoxidized fatty acid methyl ester: the hydrogen peroxide 50mL that gets 30wt.% concentration is added dropwise to the ethyl acetate that has added 30g methyl oleate, 20mL and 1.2g phosphotungstic heteropolyacid quaternary ammonium salt catalyst In the three-necked flask, control the dropwise addition of hydrogen peroxide in 2.0 hours, the temperature is not higher than 65°C, and then keep the temperature at 65°C for 3 hours. After the reaction is completed, neutralize with 4wt.% sodium carbonate solution, wash with water until neutral, and then dry to obtain epoxy Value 4.1% yellowish epoxidized methyl oleate.

[0033] Second step, citric acid and epoxidized fatty acid methyl ester ring-opening reaction prepare citric acid fatty acid ester, the epoxidized methyl oleate 100g that the first step obtains, citric acid 14g, antioxidant 168 0.1g and catalyst 0.3g of diethylenetriamine was reacted at 140°C for 4 hours to obtain a crude produ...

Embodiment 3

[0036] The first step, the preparation of epoxidized methyl ricinoleate: get the hydrogen peroxide 55mL of 30wt.% concentration and add dropwise to the ethyl acetate that has added 30g methyl ricinoleate, 20mL and 1.2g phosphotungstic heteropolyacid quaternary ammonium In the three-necked flask of the salt catalyst, control the dropwise addition of hydrogen peroxide in 2 hours, the reaction temperature is not higher than 65 ° C, and then maintain the temperature of 65 ° C for 3 hours, after the reaction is completed, neutralize with 4% sodium carbonate solution, wash with water until neutral, and then dry. The epoxidized ricinoleic acid methyl ester with an epoxy value of 3.8% was obtained as light yellow.

[0037] In the second step, citric acid and epoxidized ricinoleic acid methyl ester ring-opening reaction prepare citric acid fatty acid ester, and the epoxidized ricinoleic acid methyl ester 100g that the first step obtains, citric acid 14g, 50% of the second Phosphoric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Open flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com